Overview

The article delves into the methods, benefits, and challenges associated with supplement encapsulation, a crucial technique that enhances the bioavailability and stability of nutraceutical products. Encapsulation not only safeguards sensitive ingredients and boosts their absorption but also introduces challenges, including elevated production costs and intricate manufacturing processes. Manufacturers must adeptly navigate these hurdles to maintain competitiveness in the expanding market. Understanding these dynamics is essential for industry stakeholders aiming to optimize product efficacy and market presence.

Introduction

Supplement encapsulation is at the forefront of the nutraceutical industry, revolutionizing the delivery and absorption of dietary supplements. This innovative process not only enhances the bioavailability of active ingredients but also protects sensitive compounds from environmental factors, ensuring consumers receive maximum health benefits.

As the demand for encapsulated products surges, manufacturers encounter a myriad of challenges, including high production costs and complex regulatory landscapes.

How can they navigate these hurdles while continuing to meet consumer expectations for quality and efficacy? The answer lies in strategic innovation and adherence to industry standards.

Define Supplement Encapsulation and Its Importance

Supplement encapsulation is the process of containing powders, liquids, or oils within capsules, a technique that plays a crucial role in the nutraceutical industry. This approach significantly enhances the bioavailability of active components, ensuring that users derive maximum health benefits from their supplements. By protecting delicate compounds from environmental factors such as moisture and light, the process not only preserves the integrity of these ingredients but also improves the overall user experience by simplifying ingestion.

For manufacturers, understanding the complexities of packaging is essential for creating products that align with consumer demands for efficient and convenient delivery methods. This understanding leads to enhanced product performance and marketability, as supplement encapsulation typically demonstrates superior stability and shelf life. Recent advancements in coating technology, particularly supplement encapsulation, have further enhanced the ability to control the release of bioactive compounds, ensuring they are delivered at the optimal time and location within the body.

Real-world examples illustrate the effectiveness of this technique in boosting bioavailability. For instance, probiotics, which are vulnerable to harsh gastrointestinal conditions, benefit from microencapsulation technology that safeguards them during processing and digestion, thereby enhancing their viability and efficacy as functional foods. As the market for encapsulated products continues to grow, projected to reach USD 20.4 billion by 2035—driven by increasing health awareness and demand for functional foods—manufacturers are compelled to leverage these technologies to remain competitive in the evolving nutraceutical landscape. As noted by Kasipathy Kailasapathy, 'Preservation of bioactivity and controlled release of components at the appropriate location and moment is a crucial capability that can be offered by supplement encapsulation technologies.

Explore Methods of Supplement Encapsulation

Several methods of supplement encapsulation exist, each offering unique benefits that cater to diverse needs in the industry:

-

Gelatin Capsules: These traditional capsules are widely utilized due to their suitability for various formulations. They dissolve rapidly in the stomach, ensuring a swift release of active components. The gelatin capsule market is projected to reach USD 8.08 billion by 2030, driven by their versatility and ease of manufacturing.

-

Vegetarian Capsules: Crafted from plant-derived materials, these capsules address the needs of vegan and vegetarian consumers. While they provide similar advantages to gelatin capsules, their dissolution rates may differ. The vegetarian capsules market is expected to experience significant growth, increasing from $1.57 billion in 2024 to $1.76 billion in 2025, reflecting a compound annual growth rate (CAGR) of 12.3%.

-

Supplement encapsulation: This advanced technique involves enclosing active substances within a protective coating, thereby enhancing stability and enabling controlled release. It is particularly advantageous for sensitive compounds that require protection from heat, moisture, or light.

-

Nanoencapsulation: By utilizing nanotechnology, this method enhances the solubility and bioavailability of poorly soluble compounds, making it ideal for improving the effectiveness of dietary supplements.

-

Spray Drying: As a common method for producing microencapsulated powders, spray drying converts liquid solutions into dry powders, which improves ingredient stability and handling.

Each encapsulation method has specific applications and factors that allow manufacturers to tailor their packaging strategies to meet product requirements and customer preferences. As the market evolves, the choice between gelatin and vegetarian capsules will increasingly reflect consumer demand for health-conscious and ethical options.

Identify Benefits of Supplement Encapsulation

Supplement encapsulation offers a multitude of benefits that significantly enhance product quality and consumer experience:

-

Improved Bioavailability: Encapsulation enhances the absorption of active ingredients, ensuring that consumers receive the full health benefits intended. Studies indicate that encapsulated compounds can achieve higher plasma concentrations, with the oral bioavailability of resveratrol calculated at 26.5% when encapsulated in casein nanoparticles, which is ten times higher than when administered as an oral solution.

-

Protection of Sensitive Ingredients: Supplement encapsulation effectively shields sensitive compounds from environmental factors such as moisture, heat, and light. This protective barrier is vital for preserving component potency and prolonging shelf life, as demonstrated by studies indicating that encapsulated curcumin has enhanced resistance to digestive enzymes in comparison to its unencapsulated version.

-

Controlled Release: The supplement encapsulation process enables the creation of time-release formulations, allowing for a gradual discharge of components. This controlled delivery can enhance effectiveness while minimizing potential side effects, making products more user-friendly.

-

Concealing Unpleasant Flavors and Scents: Encapsulated supplements can effectively conceal the taste and aroma of certain components, enhancing palatability. This is especially advantageous for individuals who may be sensitive to the flavors of certain nutraceuticals.

-

Enhanced Stability: Supplement encapsulation significantly improves the stability of active ingredients, reducing the risk of degradation during storage and transportation. For instance, encapsulated curcumin has been shown to resist digestive enzymes better than its unencapsulated counterpart, ensuring that more of the active compound reaches the target site in the body.

These benefits not only enhance the quality of dietary products but also promote greater customer satisfaction and loyalty, ultimately aiding manufacturers and distributors in the nutraceutical sector.

Address Challenges in the Encapsulation Process

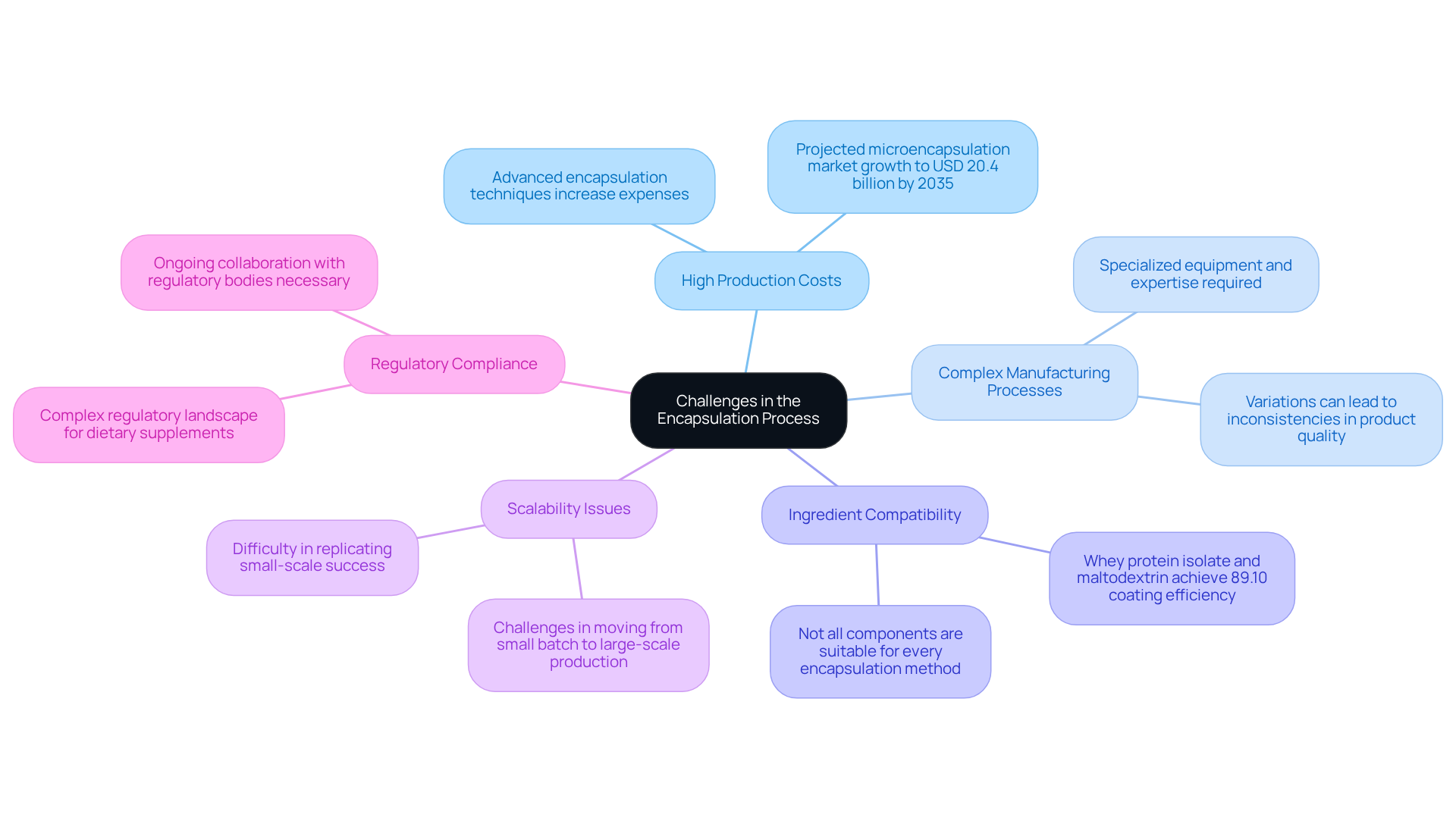

While supplement encapsulation offers numerous advantages, it also presents several challenges that manufacturers must navigate:

-

High Production Costs: Advanced encapsulation techniques can significantly increase production expenses. For instance, the microencapsulation market is projected to reach USD 20.4 billion by 2035, reflecting a compound annual growth rate (CAGR) of 9.4% from 2024 to 2029. These elevated costs can limit market access for many consumers, necessitating a balance between maintaining quality and ensuring cost-effectiveness.

-

Complex Manufacturing Processes: The enclosing procedure is intricate, often requiring specialized equipment and expertise. Ensuring consistency and quality control is crucial, as variations in the manufacturing process can lead to inconsistencies in product quality. The complexity of customizing packaging parameters creates barriers for standardized large-scale solutions, making it essential for manufacturers to invest in training and technology.

-

Ingredient Compatibility: Not all components are suitable for every method of encapsulating. Manufacturers must carefully select materials to avoid interactions that could compromise product quality. For instance, the coating of fat-soluble vitamins necessitates particular methods to maintain their stability and bioavailability, with whey protein isolate and maltodextrin attaining a coating efficiency of 89.10 ± 1.03%. This highlights the need for thorough research and testing.

-

Scalability Issues: Moving from small batch production to large-scale packaging can present considerable challenges, especially in preserving quality and efficiency. Manufacturers often face difficulties in replicating the success of small-scale processes on a larger scale, which can hinder growth and market expansion.

-

Regulatory Compliance: Navigating the regulatory landscape for dietary supplements can be complex. Producers must ensure that their packaging techniques adhere to industry standards, which can differ by region. This regulatory scrutiny adds another layer of complexity to the containment process, necessitating ongoing collaboration with regulatory bodies to ensure compliance.

By understanding these challenges, manufacturers can implement strategies to mitigate risks and enhance the effectiveness of their supplement encapsulation processes, ultimately leading to improved product quality and market competitiveness.

Conclusion

Supplement encapsulation is a pivotal technique in the nutraceutical industry, significantly enhancing the efficacy and user experience of dietary supplements. By effectively containing active ingredients within protective capsules, this method not only boosts bioavailability but also safeguards sensitive compounds from environmental damage. The importance of mastering encapsulation techniques cannot be overstated, as they directly influence product performance and marketability.

In this article, various encapsulation methods have been explored, including:

- Gelatin capsules

- Vegetarian capsules

- Nanoencapsulation

- Spray drying

Each technique offers distinct advantages tailored to meet specific consumer needs. The benefits of encapsulation—such as improved absorption, ingredient protection, controlled release, and enhanced stability—further solidify its importance in supplement formulation. However, the challenges associated with encapsulation, from high production costs to regulatory compliance, highlight the complexities manufacturers must navigate to achieve optimal results.

In conclusion, mastering supplement encapsulation is not merely a technical endeavor; it is a crucial element that shapes the future of the nutraceutical sector. As consumer awareness and demand for high-quality, effective supplements continue to rise, manufacturers are urged to embrace innovative encapsulation technologies. By doing so, they can enhance product offerings, improve customer satisfaction, and ultimately thrive in an increasingly competitive marketplace. The journey toward better health through effective supplementation begins with understanding and implementing these advanced encapsulation methods.

Frequently Asked Questions

What is supplement encapsulation?

Supplement encapsulation is the process of containing powders, liquids, or oils within capsules, which enhances the bioavailability of active components in supplements.

Why is supplement encapsulation important?

It is important because it protects delicate compounds from environmental factors like moisture and light, preserves their integrity, and improves user experience by simplifying ingestion.

How does encapsulation benefit manufacturers?

Understanding encapsulation allows manufacturers to create products that meet consumer demands for efficient delivery methods, resulting in enhanced product performance, marketability, and superior stability and shelf life.

What advancements have been made in supplement encapsulation technology?

Recent advancements in coating technology have improved the ability to control the release of bioactive compounds, ensuring they are delivered at the optimal time and location within the body.

Can you provide an example of how encapsulation enhances bioavailability?

Probiotics benefit from microencapsulation technology, which protects them from harsh gastrointestinal conditions, thereby enhancing their viability and efficacy as functional foods.

What is the projected market growth for encapsulated products?

The market for encapsulated products is projected to reach USD 20.4 billion by 2035, driven by increasing health awareness and demand for functional foods.

What is a key capability of supplement encapsulation technologies?

A key capability is the preservation of bioactivity and controlled release of components at the appropriate location and moment within the body.