Overview

The article delineates the fundamental differences between primary and secondary packaging, emphasizing their distinct functions and purposes. Primary packaging is designed to directly protect the product and engage consumers, whereas secondary packaging primarily addresses logistics, storage, and branding. This distinction is further underscored by the article's comprehensive analysis of the roles, materials, advantages, and challenges inherent to each type of packaging. Such insights highlight their critical importance in maintaining product integrity and shaping effective marketing strategies.

Introduction

In today's competitive market, understanding the nuances of packaging is essential; the first impression can indeed make or break a sale.

- Primary packaging, which directly interacts with products, plays a pivotal role in both protection and consumer engagement.

- Meanwhile, secondary packaging streamlines logistics and enhances branding.

As businesses strive for efficiency and sustainability, a critical question arises: how can manufacturers effectively balance the advantages and challenges of both packaging types to meet the evolving expectations of consumers?

This inquiry not only highlights the complexity of packaging solutions but also underscores the necessity for strategic approaches in this dynamic field.

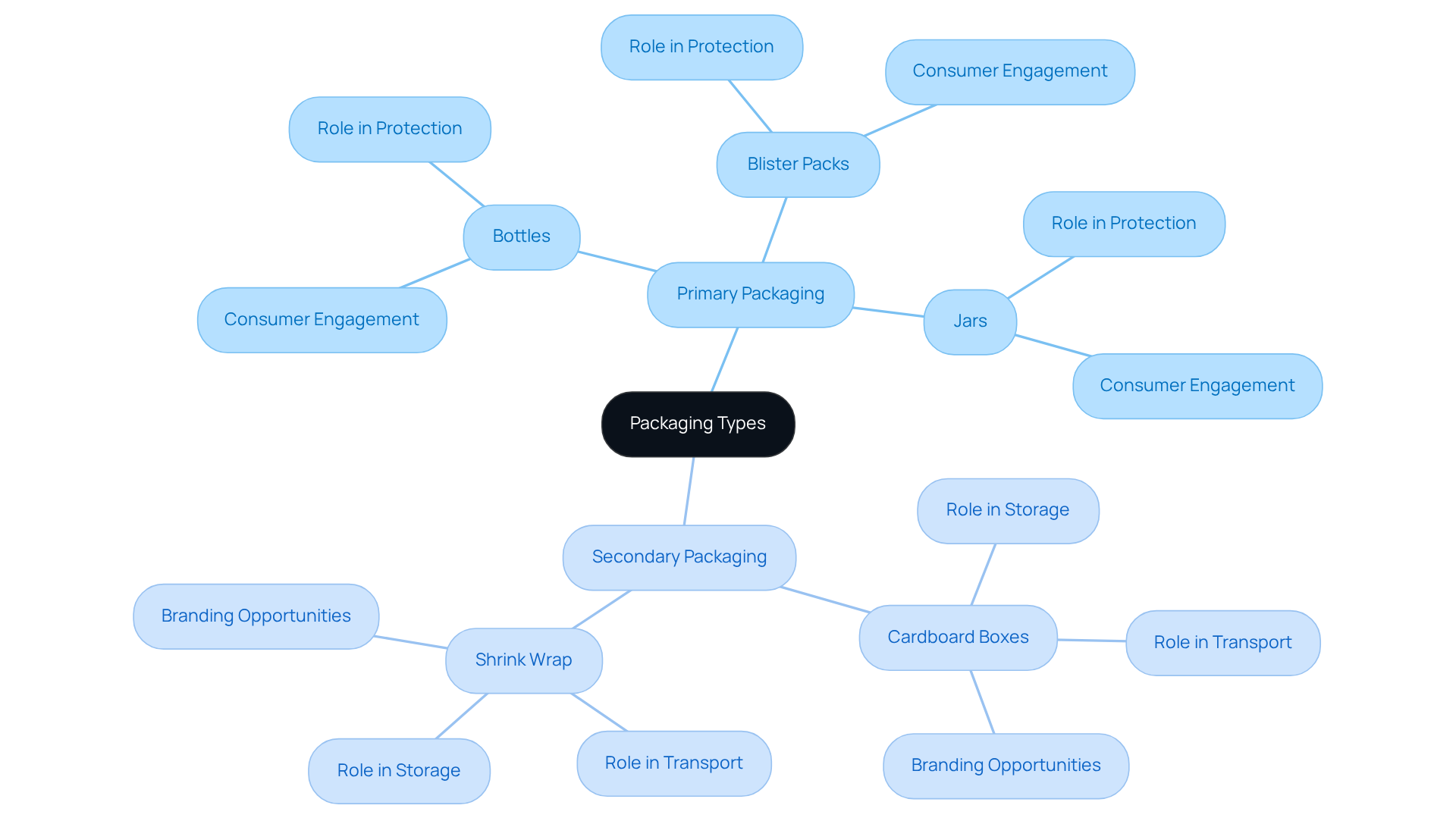

Define Primary and Secondary Packaging

Primary covering represents the initial layer of wrapping that directly interacts with the item, ensuring its protection from external elements. This form of wrapping is essential for preserving item integrity and often serves as the first point of contact for consumers. Examples of primary containers include:

- bottles

- blister packs

- jars

All designed to be user-friendly and effective in maintaining product quality.

Conversely, the outer layer functions to group multiple primary containers together. Its primary roles encompass facilitating storage, transport, and display, while also providing additional protection and branding opportunities. Typical examples of additional wrapping include:

- cardboard boxes

- shrink wrap

Which encase primary packages for shipping and retail presentation.

The secondary container market is witnessing significant growth, with a valuation of approximately USD 259.48 billion in 2023, projected to register a compound annual growth rate (CAGR) exceeding 5% from 2024 to 2032. This expansion is driven by the increasing demand for efficient logistics and sustainable wrapping solutions.

Industry leaders emphasize the importance of both types of containers. For instance, primary containers are frequently highlighted for their role in branding and consumer engagement, while secondary wrappers are acknowledged for their utility in logistics and marketing. Understanding the distinctions between primary packaging vs secondary packaging is crucial for manufacturers aiming to enhance their strategies and boost item appeal.

At Western Packaging, we concentrate on customized flexible solutions that not only protect your item but also elevate its shelf attractiveness and brand visibility. Furthermore, we develop compelling graphic assets, such as labels and brochures, ensuring a cohesive and captivating brand identity that stands out in a competitive market.

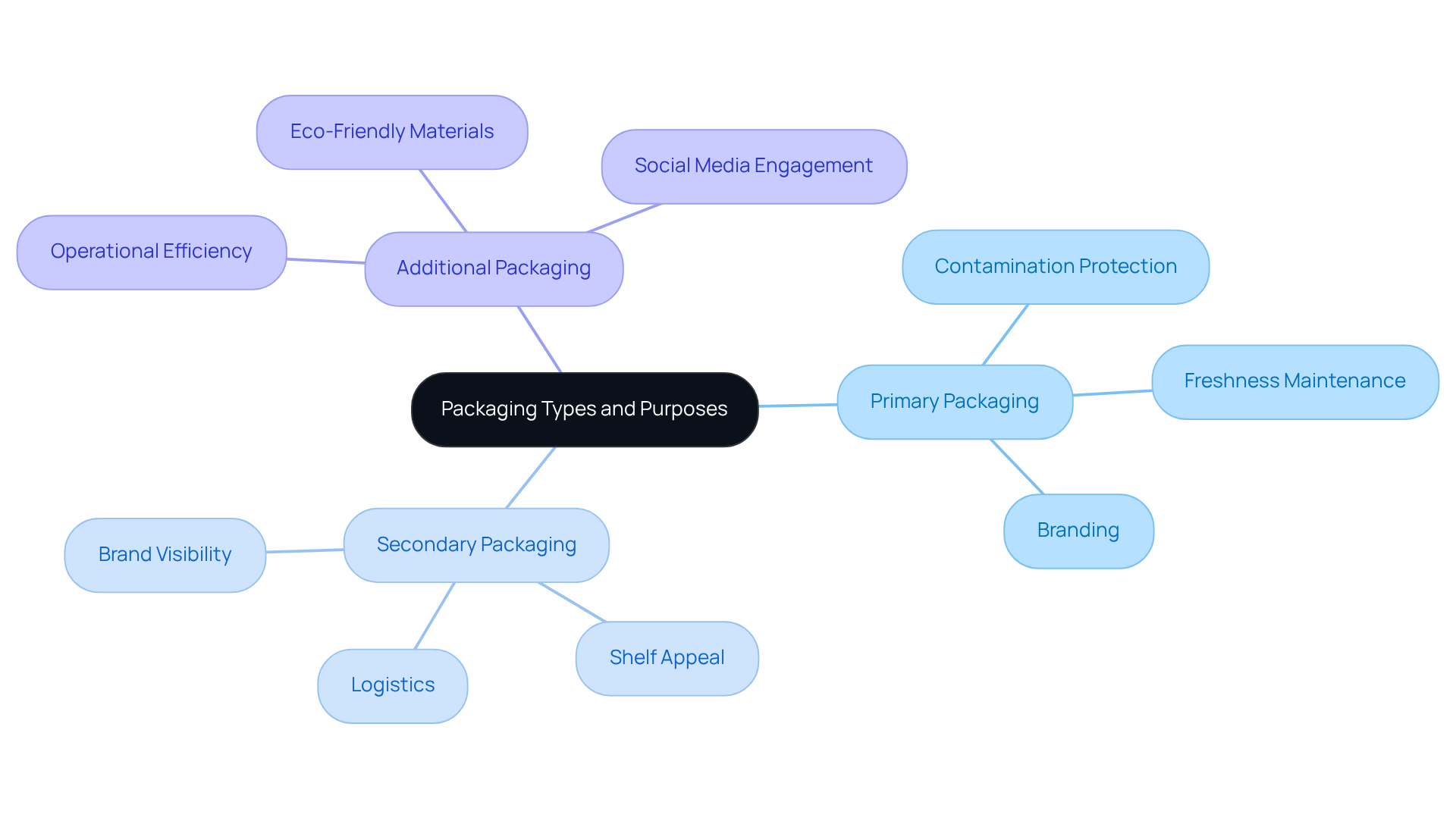

Examine Functions and Purposes of Each Packaging Type

Primary containers play a vital role in safeguarding items from contamination, maintaining freshness, and conveying essential details to consumers, such as ingredients and usage guidelines. They serve as a critical branding tool, representing the first interaction individuals have with a product. Research indicates that 72% of American consumers believe product design significantly influences their purchasing decisions, underscoring the importance of effective primary packaging in shaping consumer perceptions.

Conversely, the distinction between primary packaging vs secondary packaging primarily addresses logistical and marketing requirements. It ensures the safe transportation of various primary packages, enhances shelf appeal, and can be visually designed to attract consumer attention through engaging graphics and branding. Secondary containers, including cardboard boxes, pouches, and bubble mailers, secure primary packages during shipping while contributing to a cohesive brand presentation. This dual function is crucial, ensuring products arrive intact while boosting brand visibility and consumer engagement.

Moreover, additional packaging enhances operational efficiency by organizing and securing individual product units, facilitating safe delivery to retailers or end users. This strategic approach not only protects primary packaging vs secondary packaging but also reinforces brand identity, making it essential to the overall strategy of manufacturers, especially in the nutraceutical sector. Furthermore, with 40% of consumers inclined to share images of distinctive or branded packaging on social media, extra wrapping amplifies brand awareness and interaction. As sustainability becomes increasingly important, incorporating eco-friendly materials into secondary containers aligns better with consumer values and fosters brand loyalty. At Western Packaging, we specialize in crafting compelling graphic assets, from labels to brochures, ensuring a captivating brand identity that resonates with consumers.

Analyze Common Materials Used in Packaging

Common materials for primary packaging vs secondary packaging include glass, plastic, metal, and paper. Glass is widely utilized for its impermeability and aesthetic appeal, while plastic is preferred for its lightweight and versatile nature. Metal containers, such as aluminum cans, are favored for beverages due to their durability and recyclability. Conversely, when comparing primary packaging vs secondary packaging, secondary containers typically employ materials like cardboard, paperboard, and plastic. Cardboard is extensively used for its strength and printability for branding purposes, whereas plastic films are often utilized for shrink wrapping and bundling products. The selection of materials can significantly influence the environmental impact of products, with a growing emphasis on sustainable options in recent years.

The sustainable container market was estimated at approximately 274.15 billion USD in 2020 and is projected to expand at a CAGR of 6.1% from 2020 to 2028, reflecting the increasing demand from buyers for eco-friendly container solutions. Experts assert that employing recyclable, biodegradable, or compostable materials can substantially mitigate the environmental impact of containers. Moreover, half of buyers are willing to invest more in eco-friendly containers, highlighting the financial incentive for businesses to adopt these practices. As sustainability becomes increasingly paramount, companies are exploring innovative alternative materials that not only protect products but also resonate with environmentally conscious consumer preferences.

Integrating sustainable materials into secondary containers not only fulfills regulatory requirements but also bolsters brand reputation. As consumers grow more aware of the ecological ramifications of packaging, they increasingly favor brands that prioritize sustainability. This trend is evident, as 63% of individuals prefer brands that publicly commit to sustainability objectives. Nonetheless, companies encounter challenges in reaching these sustainability goals, including inadequate collaboration and a lack of incentives. By selecting materials that minimize waste and promote recycling, businesses can foster a circular economy while appealing to eco-conscious consumers.

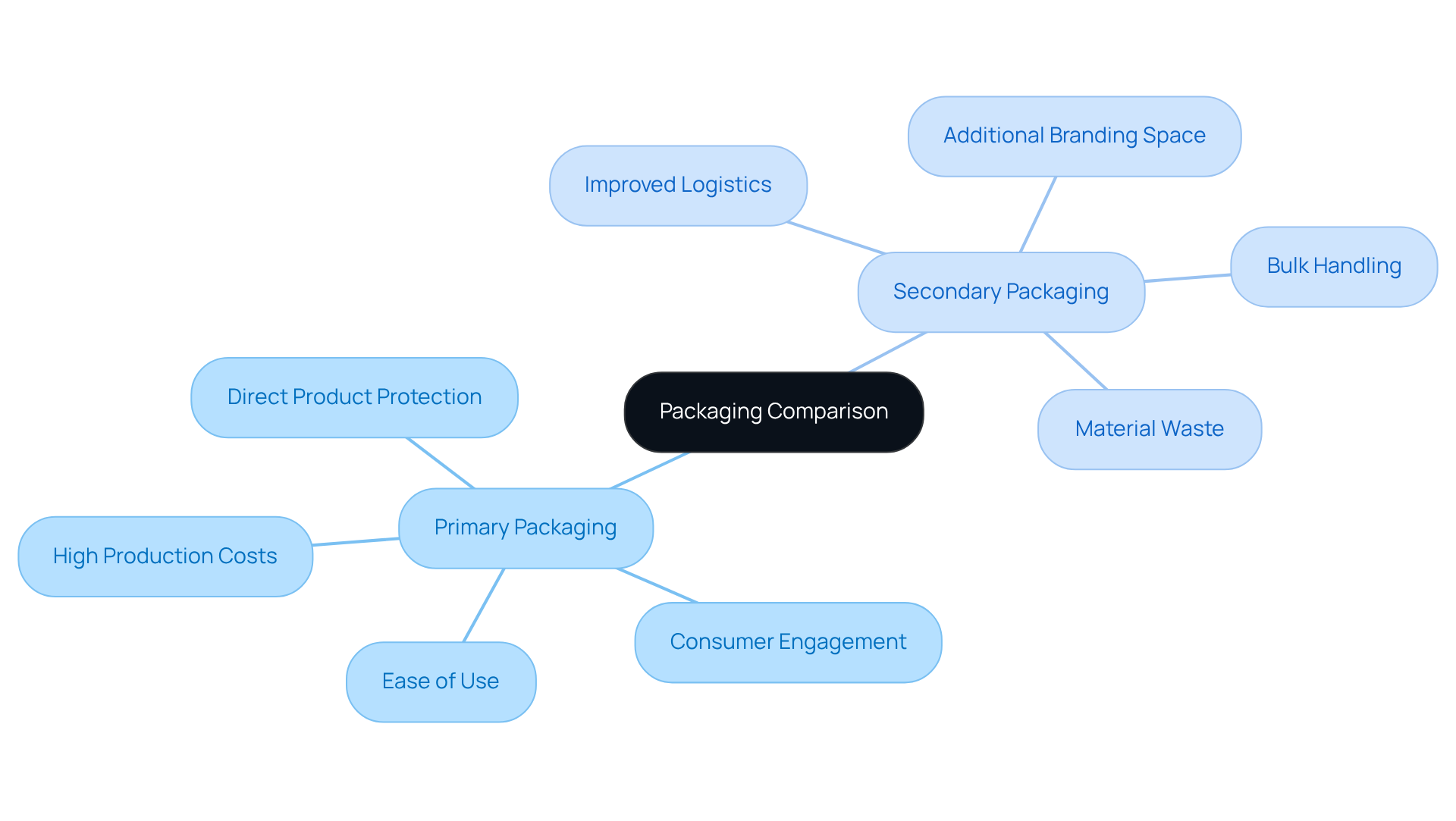

Compare Advantages and Disadvantages of Each Type

The benefits of primary packaging vs secondary packaging are substantial, as primary packaging offers direct product protection, enhances consumer engagement through effective branding, and ensures ease of use for end-users. However, it is essential to acknowledge that production costs can be high, particularly when premium materials are involved.

On the other hand, when considering primary packaging vs secondary packaging, the latter provides significant advantages, including:

- Improved logistics

- Bulk handling capabilities

- Additional branding space

This type of wrapping can also minimize damage during transportation. Yet, one must consider the potential downsides; secondary containers may lead to material waste and may lack visual appeal if not thoughtfully designed. Both types of containers must navigate the delicate balance between cost, functionality, and sustainability, especially as consumers increasingly gravitate towards eco-friendly options.

Data indicates that a staggering 77% of shoppers will stop purchasing from brands they perceive as engaging in 'greenwashing.' This statistic underscores the critical need for genuine eco-friendly practices in packaging design. Examples of the advantages of additional wrapping in logistics for retail products include:

- Cases designed to hold multiple bottles of wine

- Cardboard containers utilized for various online purchases

These not only protect the items but also serve as promotional tools, enhancing brand visibility.

Logistics professionals consistently emphasize the necessity of balancing cost with both functionality and sustainability. Effective additional wrapping can streamline processes and elevate product visibility, yet it must align with consumer preferences for eco-friendly solutions. Ultimately, both primary packaging vs secondary packaging must adeptly navigate the complexities of cost, functionality, and sustainability, particularly as consumer demand for eco-friendly alternatives continues to surge.

Conclusion

Understanding the differences between primary and secondary packaging is crucial for manufacturers aiming to enhance product appeal and ensure effective logistics. Primary packaging serves as the first layer that directly interacts with the product, safeguarding its integrity and providing essential information to consumers. In contrast, secondary packaging groups multiple primary containers, facilitating transport, storage, and branding opportunities. Both types of packaging play vital roles in the overall success of a product in the market.

The distinct functions and materials associated with each packaging type are paramount. Primary packaging is instrumental in consumer engagement and product protection, while secondary packaging enhances logistical efficiency and brand visibility. The growing emphasis on sustainability further complicates the landscape, as consumers increasingly prefer eco-friendly options. As the market evolves, the importance of selecting appropriate materials and designs that resonate with consumer values cannot be overstated.

In light of these insights, businesses are encouraged to adopt a strategic approach to both primary and secondary packaging. By investing in sustainable practices and innovative designs, companies can not only meet consumer expectations but also strengthen their brand identity in a competitive marketplace. Embracing these principles is essential for fostering long-term success and aligning with the shifting preferences of environmentally conscious consumers.

Frequently Asked Questions

What is primary packaging?

Primary packaging refers to the initial layer of wrapping that directly interacts with the item, ensuring its protection from external elements and preserving item integrity. Examples include bottles, blister packs, and jars.

What is secondary packaging?

Secondary packaging is the outer layer that groups multiple primary containers together. Its main roles include facilitating storage, transport, and display, while also providing additional protection and branding opportunities. Examples include cardboard boxes and shrink wrap.

What is the current market valuation for secondary packaging?

The secondary container market is valued at approximately USD 259.48 billion in 2023, with a projected compound annual growth rate (CAGR) exceeding 5% from 2024 to 2032.

What factors are driving the growth of the secondary packaging market?

The growth of the secondary packaging market is driven by the increasing demand for efficient logistics and sustainable wrapping solutions.

Why are primary containers important for manufacturers?

Primary containers are important for manufacturers as they play a crucial role in branding and consumer engagement.

What are the benefits of secondary wrappers?

Secondary wrappers are acknowledged for their utility in logistics and marketing, providing additional protection and enhancing product presentation.

How does Western Packaging approach packaging solutions?

Western Packaging focuses on customized flexible solutions that protect items while elevating shelf attractiveness and brand visibility. They also develop graphic assets, such as labels and brochures, to ensure a cohesive brand identity.