Overview

Reducing the cost of a product's packaging can significantly enhance profits by lowering production expenses and improving profit margins. This article presents various strategies to achieve this, such as:

- Utilizing economical materials

- Optimizing designs

These approaches not only reduce costs but also enhance supply chain efficiency and attract cost-conscious consumers. Ultimately, this benefits both companies and their customers, reinforcing the importance of adopting effective packaging solutions.

Introduction

The packaging of products represents a significant portion of a company's expenses, particularly in competitive sectors such as retail and nutraceuticals. By strategically reducing these costs, businesses can enhance their profit margins and create opportunities for more competitive pricing. However, the challenge lies in balancing cost reductions with the maintenance of product quality and appeal.

How can companies navigate this delicate landscape to maximize profits while still attracting and retaining cost-conscious consumers?

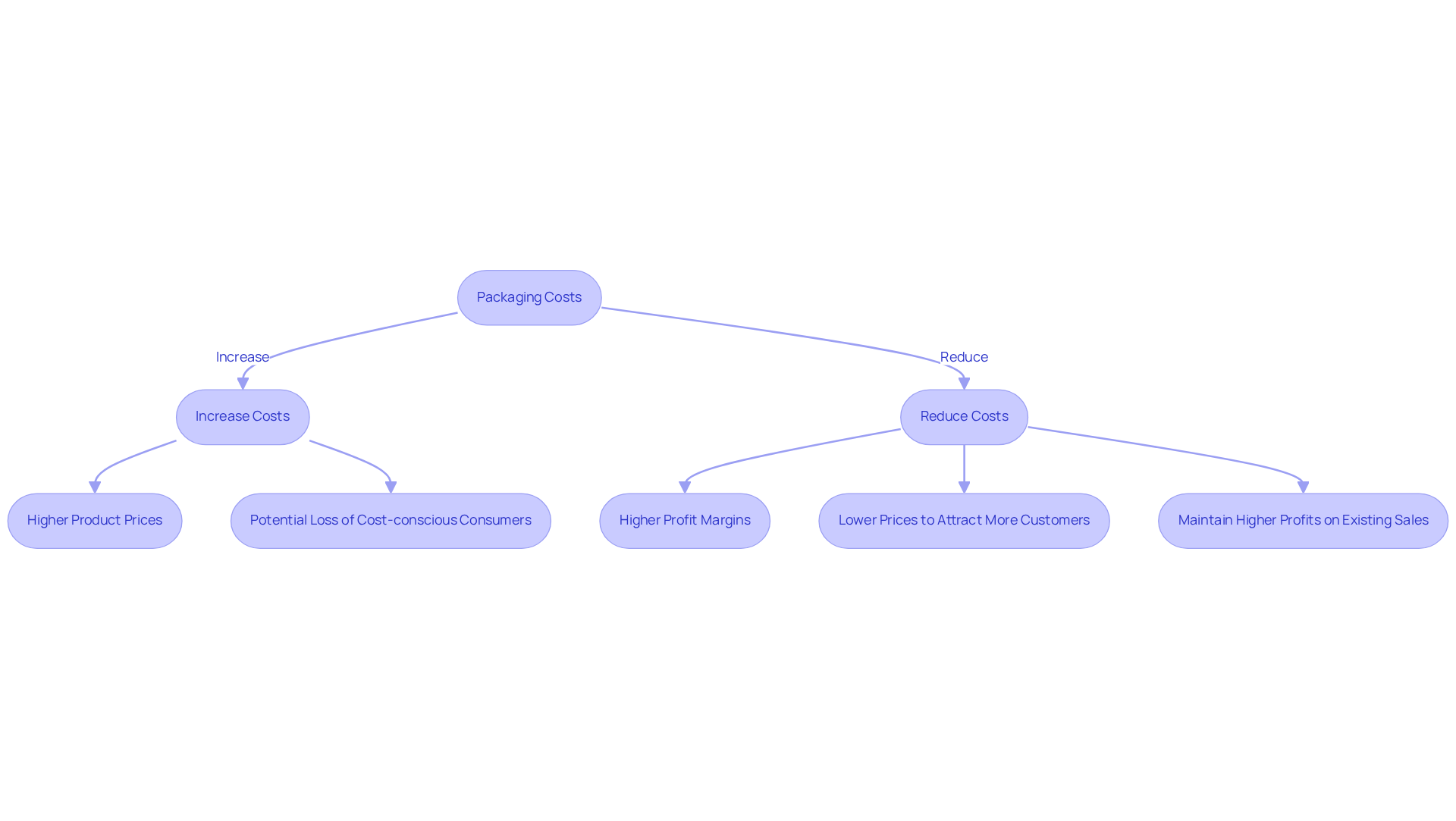

Explore the Link Between Packaging Costs and Profit Margins

Packaging expenses represent a substantial portion of total expenditures for companies, particularly within the nutraceutical and retail sectors. A significant investment in packaging can lead to increased product prices, potentially deterring cost-conscious consumers. On the other hand, reducing the cost of a product's packaging can lead to higher profits and markedly improve profit margins. This can be achieved by selecting more economical materials without sacrificing product quality or appeal. For example, transitioning from premium to economical containers can directly enhance profit margins, allowing companies to either lower prices to attract a broader customer base or maintain higher profits on existing sales.

The relationship between container-related costs and profit margins is crucial for firms aiming to improve financial performance while implementing competitive pricing strategies. Recent trends indicate that companies are increasingly reevaluating their packaging components to mitigate rising expenses. For instance, Abacus Brands Inc. has opted for thinner paper in its project books to prevent retail price increases due to tariffs, illustrating how minor adjustments can collectively counteract financial impacts. Similarly, businesses are restructuring products to ship as individual parts, thereby reducing shipping costs and enhancing overall efficiency. In fact, some companies are even encouraging consumers to assemble more items at home, further decreasing shipping expenses.

As the industry faces pressures from rising costs in ingredients, labor, and transportation, the phenomenon of shrinkflation—reducing product size or weight without lowering prices—may resurface. Steve Rad, President of a leading firm, noted that "three or four cents here, seven or six cents there, two more pennies over there, all of a sudden, you’ve made up the difference." This trend underscores the importance of understanding that reducing the cost of a product's packaging can lead to higher profits, ultimately benefiting both companies and consumers.

In conclusion, by strategically managing material expenses, organizations can not only enhance their profit margins but also remain competitive in a challenging market landscape.

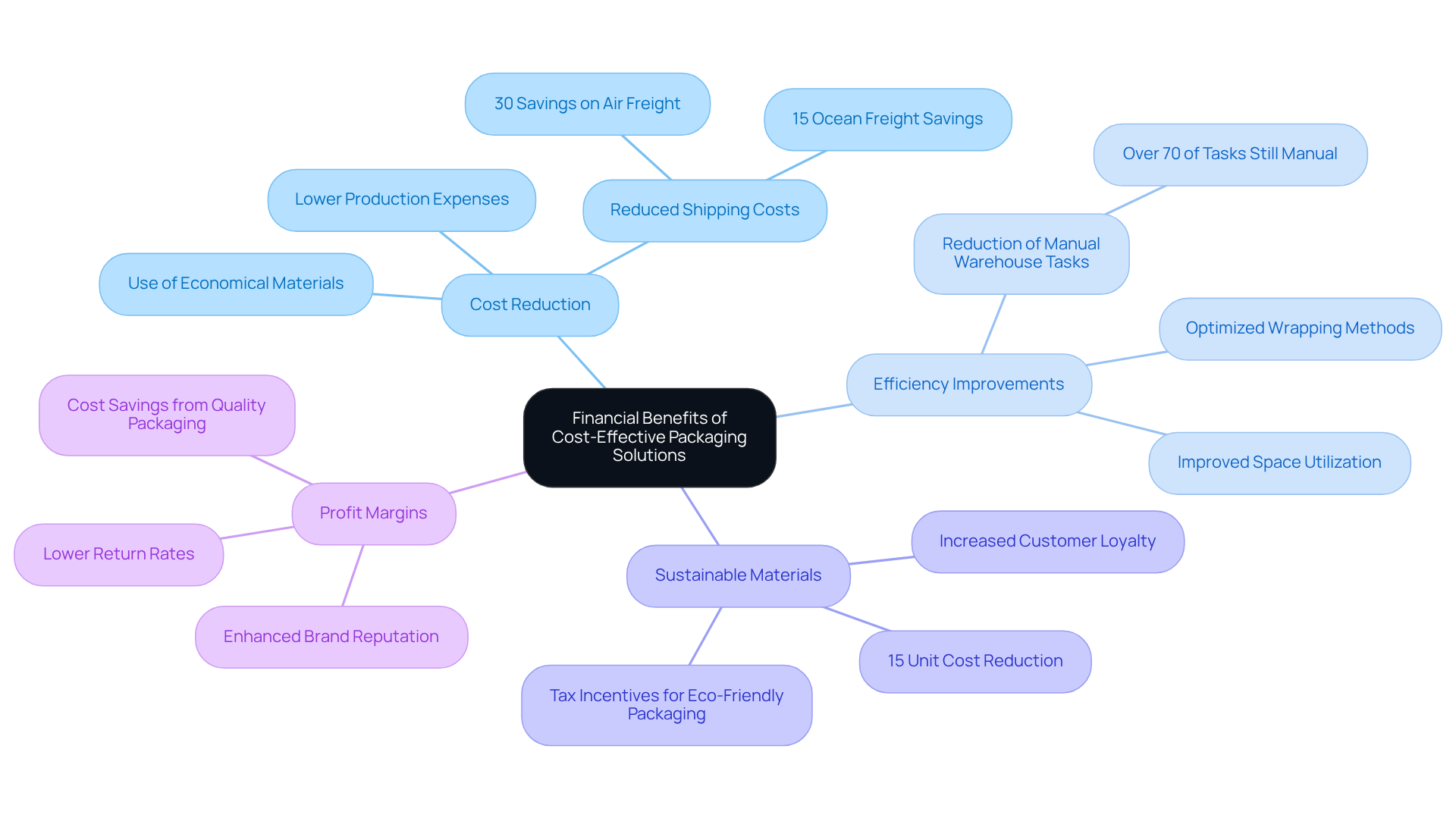

Identify Financial Benefits of Cost-Effective Packaging Solutions

Cost-effective wrapping solutions demonstrate that reducing the cost of a product's packaging can lead to higher profits for businesses. By enhancing container design and materials, companies can effectively lower production expenses and reduce waste, which is crucial since reducing the cost of a product's packaging can lead to higher profits.

For instance, employing lightweight materials significantly decreases shipping costs, while optimized wrapping methods can reduce labor expenditures. Notably, over 70% of warehouse activities are still conducted manually, presenting a considerable opportunity for efficiency improvements.

Furthermore, companies that embrace sustainable materials may benefit from tax incentives and increased customer loyalty, as environmentally conscious shoppers are often willing to pay a premium for eco-friendly products. Studies demonstrate that organizations adopting eco-friendly wrapping solutions can achieve unit expense reductions of up to 15%, and reducing the cost of a product's packaging can lead to higher profits by saving 30% on air freight costs due to improved space utilization.

These financial advantages not only enhance profit margins but also position companies favorably in a competitive market, as reducing the cost of a product's packaging can lead to higher profits. By investing in quality containers that ensure products reach customers in optimal condition, businesses can avoid the hidden costs associated with damaged goods and high return rates, ultimately fostering a positive brand reputation and enhancing customer satisfaction.

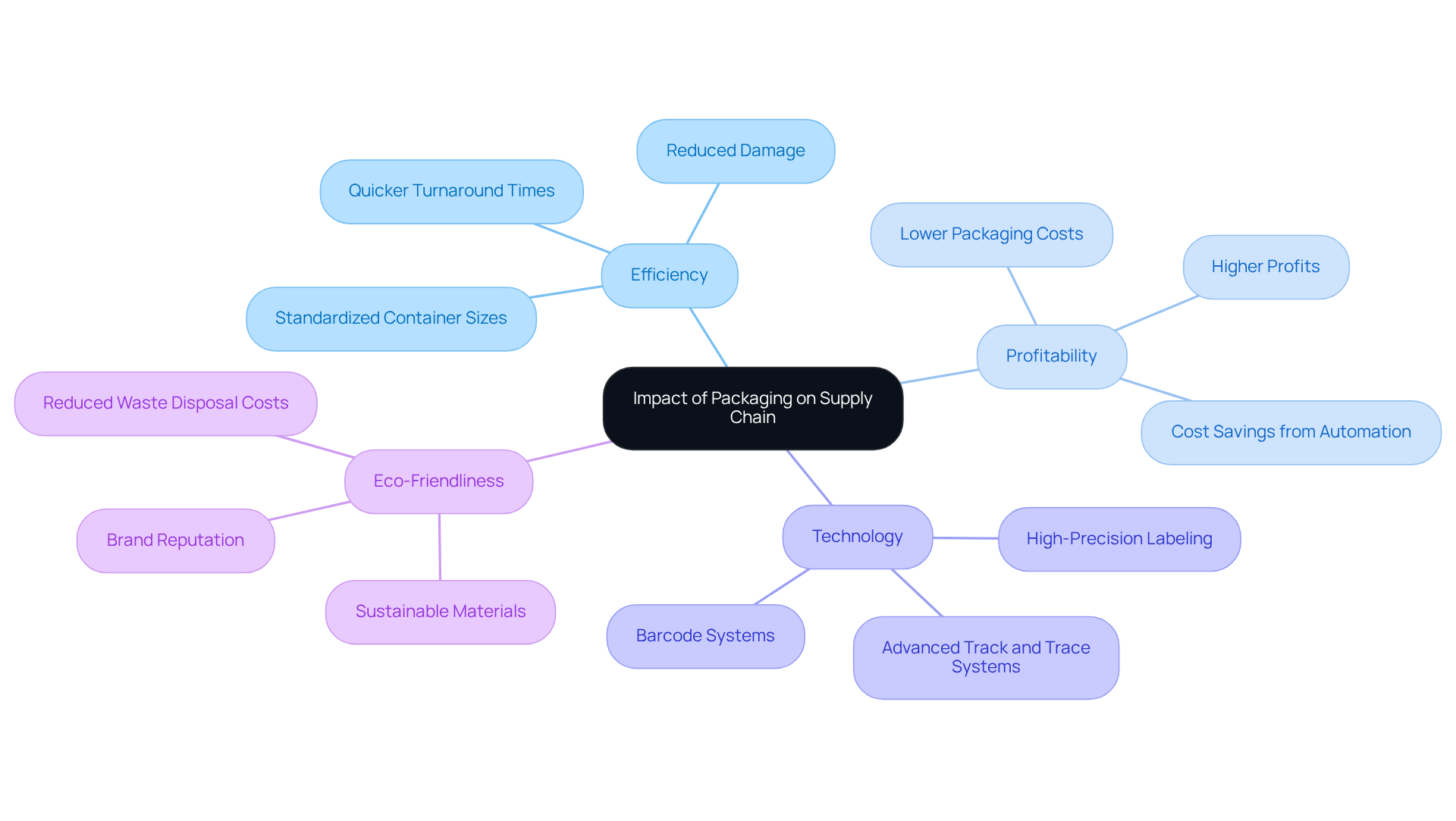

Analyze the Impact of Packaging on Supply Chain Efficiency and Profitability

Effective wrapping is pivotal in enhancing supply chain efficiency, and reducing the cost of a product's packaging can lead to higher profits. Well-crafted containers facilitate simpler handling, storage, and transportation, significantly decreasing the likelihood of damage during transit and lowering returns.

For instance, utilizing standardized container sizes optimizes warehouse space and enhances inventory management. Notably, firms such as Suzano have accessed approximately R$76 million in new prospects through supply chain enhancement, exemplifying the financial advantages of efficient material strategies.

Moreover, efficient wrapping contributes to quicker turnaround times, and reducing the cost of a product's packaging can lead to higher profits, enabling companies to respond swiftly to market demands. By integrating advanced technologies, such as high-precision labeling and barcode systems, businesses can significantly enhance accuracy in logistics and inventory management.

Additionally, implementing eco-friendly wrapping methods not only supports the idea that reducing the cost of a product's packaging can lead to higher profits, but it also bolsters brand reputation, appealing to environmentally-conscious consumers.

By streamlining the supply chain through thoughtful container solutions and collaborating with converters for innovative designs, businesses can effectively reduce operational costs, and by reducing the cost of a product's packaging, this can lead to higher profits, positioning containers as a strategic consideration in supply chain management.

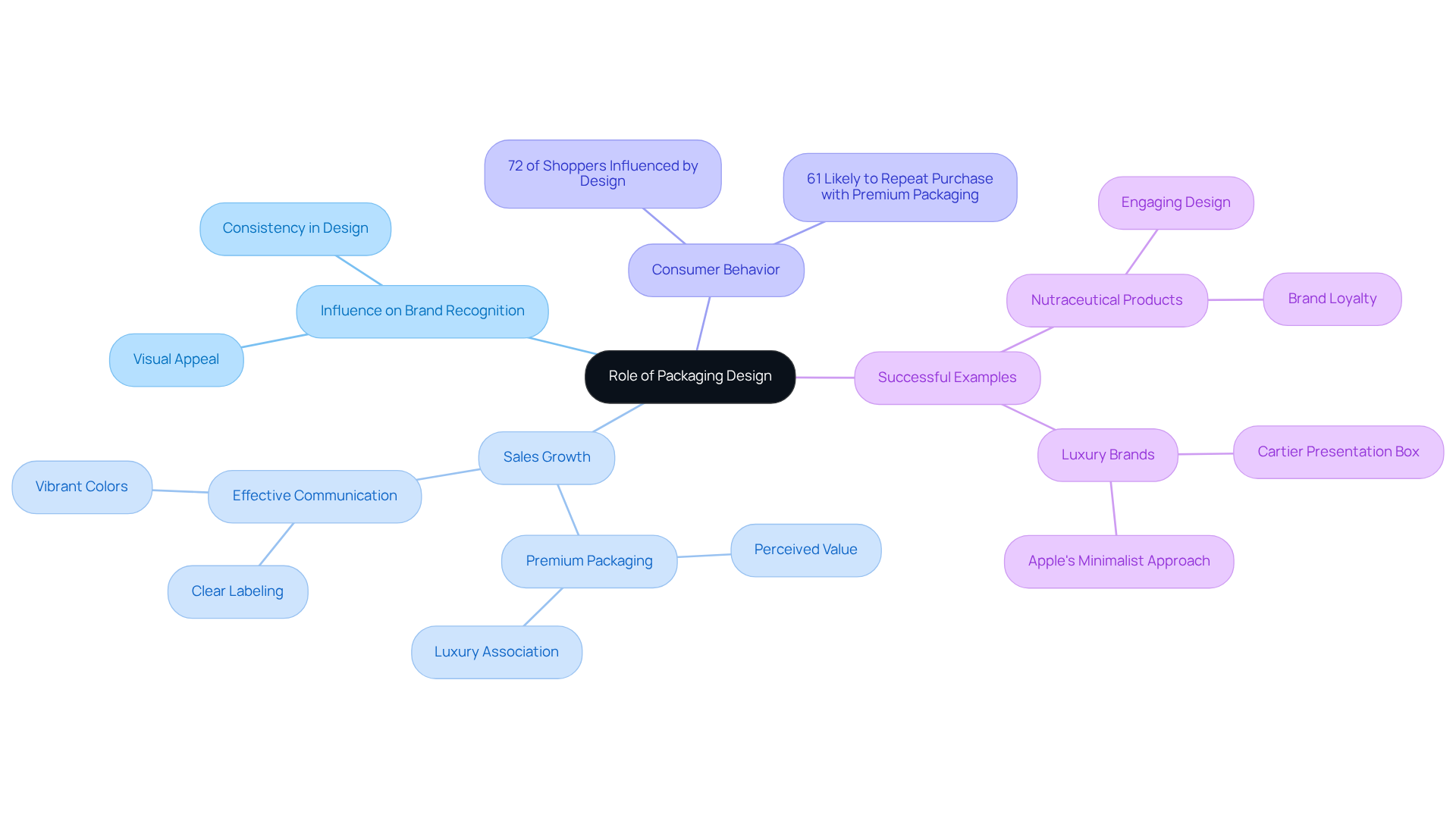

Evaluate the Role of Packaging Design in Brand Recognition and Sales Growth

Packaging design transcends mere aesthetics; it serves as a vital marketing instrument capable of profoundly influencing brand recognition and sales growth. An engaging design not only captures shopper attention in competitive retail settings but also fosters consistent branding across containers, enhancing brand memory.

For instance, nutraceutical products that utilize vibrant colors and clear labeling effectively convey their advantages, thereby fostering public interest and boosting sales. Furthermore, premium wrapping creates an impression of worth, encouraging buyers to prefer one brand over another.

This relationship between product presentation and buyer choice is underscored by studies indicating that 72% of shoppers are influenced by design in their purchasing decisions. Consequently, investing in innovative packaging strategies, as reducing the cost of a product's packaging can lead to higher profits, not only boosts market share but also enhances profitability, solidifying packaging as an essential element of a successful marketing approach.

Successful examples in the nutraceutical sector illustrate how thoughtful design can elevate product appeal, ultimately leading to increased consumer loyalty and repeat purchases.

Conclusion

Reducing the cost of a product's packaging emerges as a pivotal strategy for enhancing profit margins across various industries. By carefully selecting materials and optimizing design, companies can significantly lower packaging expenses, which in turn allows them to either offer competitive pricing or maintain higher profit levels. This dual benefit is crucial in today's market, where consumers are increasingly price-sensitive and demand value without compromising quality.

The article illustrates several key insights:

- The importance of reevaluating packaging strategies to mitigate rising costs

- The financial advantages of adopting lightweight and sustainable materials

- The role of effective packaging in streamlining supply chain operations

Notable examples, such as Abacus Brands Inc. and the practices adopted by firms like Suzano, highlight how even minor adjustments can lead to substantial financial benefits. Additionally, the influence of packaging design on brand recognition and sales growth underscores the multifaceted impact of packaging beyond mere cost considerations.

Ultimately, embracing cost-effective packaging solutions is not just about cutting expenses; it represents a strategic approach to enhancing overall business performance. Companies are encouraged to innovate in their packaging practices, as doing so can lead to improved efficiency, increased customer loyalty, and greater market share. By recognizing the integral role of packaging in both cost management and brand positioning, businesses can navigate the complexities of the marketplace while driving profitability and sustainability.

Frequently Asked Questions

Why are packaging costs significant for companies, especially in the nutraceutical and retail sectors?

Packaging expenses represent a substantial portion of total expenditures for these companies, impacting product pricing and profit margins.

How can reducing packaging costs affect profit margins?

Reducing packaging costs can lead to higher profits and improved profit margins, allowing companies to lower prices to attract more customers or maintain higher profits on existing sales.

What strategies can companies use to reduce packaging costs without sacrificing quality?

Companies can select more economical materials or transition from premium to economical containers to enhance profit margins while maintaining product quality and appeal.

What recent trends are companies following to mitigate rising packaging expenses?

Companies are reevaluating their packaging components, such as using thinner materials or restructuring products to ship as individual parts to reduce shipping costs.

What is shrinkflation, and how does it relate to packaging costs?

Shrinkflation refers to reducing product size or weight without lowering prices, which can occur as companies face rising costs in ingredients, labor, and transportation.

How can strategic management of packaging expenses benefit companies and consumers?

By managing material expenses effectively, organizations can enhance profit margins, remain competitive, and potentially offer better prices to consumers.