Overview

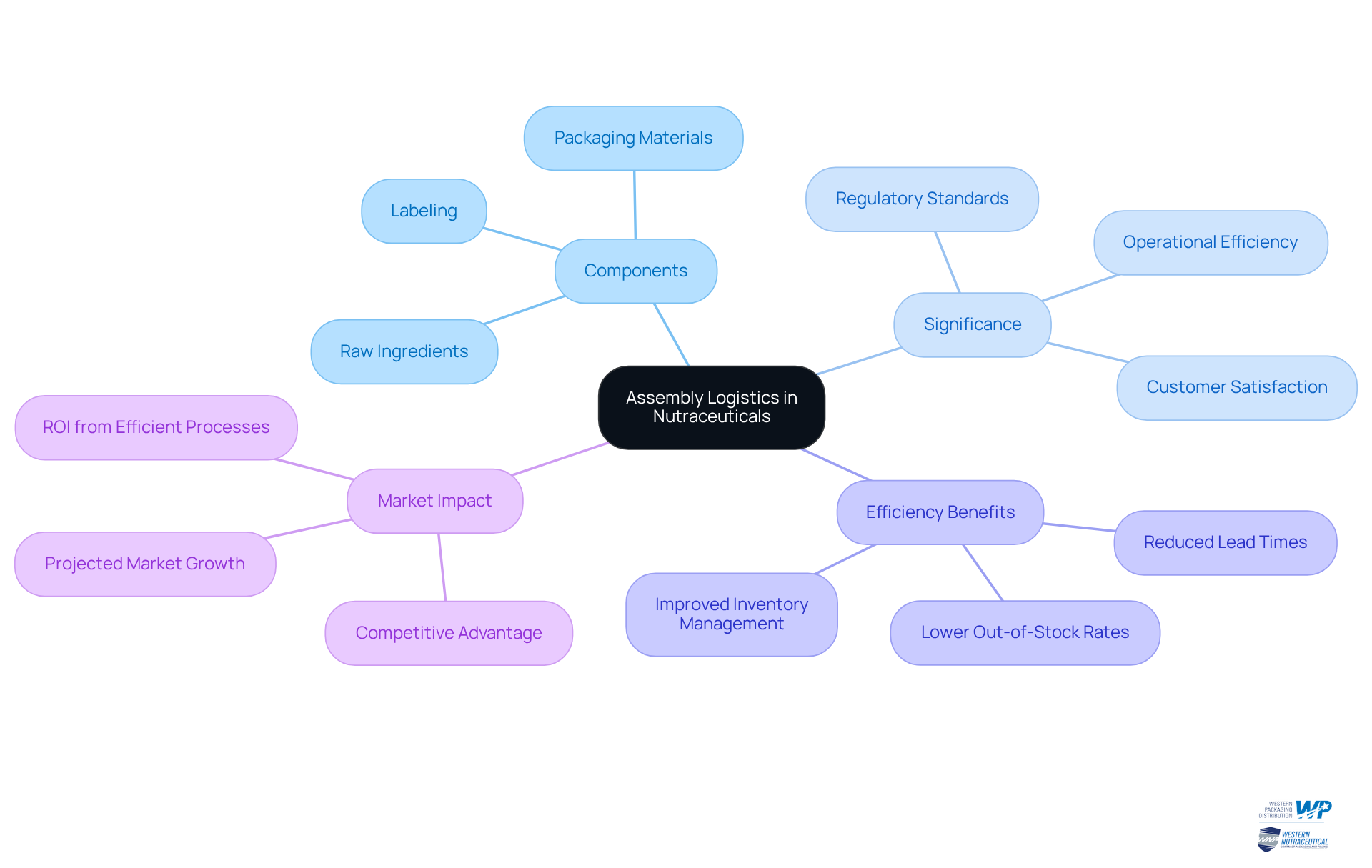

This article underscores the critical role of assembly logistics within the nutraceutical industry, highlighting its essential contribution to operational efficiency, regulatory compliance, and market responsiveness. Effective assembly logistics are pivotal; they not only reduce lead times but also enhance inventory management and improve customer satisfaction. These factors are crucial for maintaining a competitive edge in a rapidly evolving market. By prioritizing assembly logistics, businesses can ensure they are well-positioned to meet the demands of both consumers and regulatory bodies, ultimately fostering a robust operational framework.

Introduction

Assembly logistics is crucial in the nutraceutical industry, where the seamless integration of raw ingredients, packaging, and labeling is essential for delivering high-quality products to consumers. As the market for nutraceuticals continues to expand, a deep understanding of assembly logistics can provide manufacturers with a competitive edge, significantly enhancing operational efficiency and responsiveness to consumer demands.

However, with increasing regulatory pressures and the necessity for adaptability in a rapidly evolving market, companies must effectively navigate these challenges. How can they optimize their assembly processes to ensure product excellence?

Define Assembly Logistics and Its Importance in Nutraceuticals

Assembly logistics involves the systematic coordination of materials and processes that are vital for the assembly of items prior to distribution. In the nutraceutical sector, this involves the integration of various components, including raw ingredients, packaging materials, and labeling, into a cohesive final product.

The significance of organizational processes in nutraceuticals is profound; it not only ensures adherence to regulatory standards but also enhances operational efficiency and market responsiveness. Efficient assembly logistics management can lead to shortened lead times, with businesses achieving up to a 30% reduction in out-of-stock rates through advanced inventory systems, as highlighted in recent industry findings. This efficiency translates into improved inventory management and heightened customer satisfaction, which are crucial in a competitive landscape where consumer preferences are rapidly evolving.

Case studies illustrate that companies employing Just-In-Time (JIT) systems and robust supply chain planning have effectively reduced waste and optimized stock levels through assembly logistics, ensuring they meet customer demand without incurring extra costs. Furthermore, strategic warehouse positioning has proven capable of decreasing shipping durations by 15-40%, directly impacting product delivery and overall operational performance, as demonstrated by Commonwealth Inc.'s successful warehouse location strategy.

As the global nutraceuticals market is projected to reach USD 919.1 billion by 2030, rising from an estimated USD 591.1 billion in 2024, the importance of coordinating operations to maintain a competitive advantage cannot be overstated. Notably, firms such as Nutrition Formulators have achieved an impressive 250% ROI through enhanced warehouse systems, showcasing the tangible benefits of efficient production processes.

Trace the Evolution of Assembly Logistics in Supply Chain Management

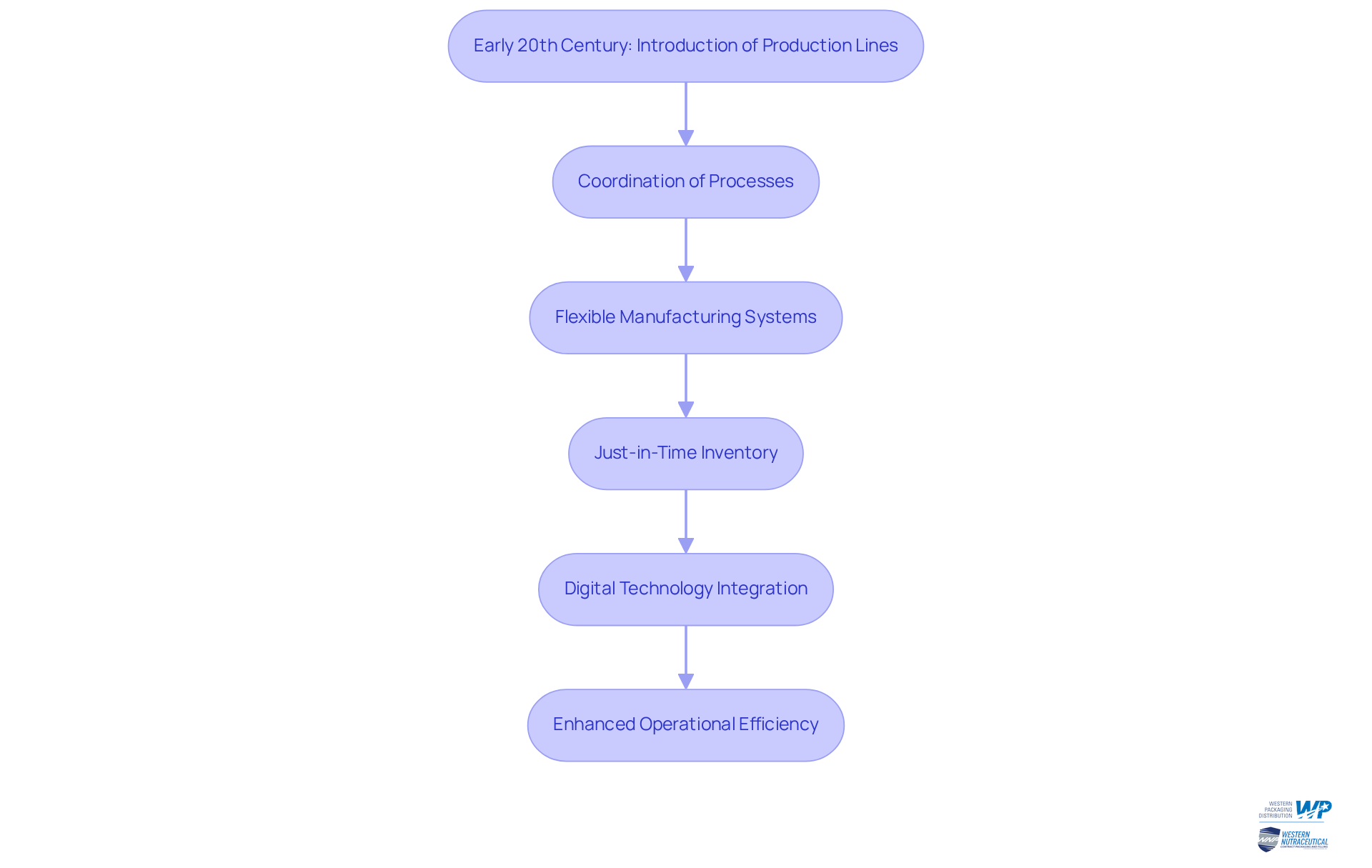

The development of manufacturing processes can be traced back to the early 20th century, characterized by the introduction of production lines—a concept popularized by innovators like Henry Ford. Originally intended for large-scale manufacturing, the coordination of processes has evolved to incorporate assembly logistics to address the complex needs of modern supply chains, particularly within the nutraceutical industry.

As consumer preferences increasingly lean towards personalized nutrition and health-focused items, operational processes have adjusted by incorporating flexible manufacturing systems and just-in-time inventory practices. Today, these processes encompass not only the physical construction of items but also assembly logistics, strategic planning, real-time monitoring, and the integration of digital technologies—all designed to improve efficiency and responsiveness throughout the supply chain.

Understanding these historical milestones is essential for manufacturers seeking to enhance their production processes. By utilizing integrated filling services and customized flexible packaging solutions from Western Packaging, health supplement manufacturers can increase product attractiveness, optimize their supply chain management, and improve assembly logistics, ultimately resulting in enhanced operational efficiency.

Examine Key Characteristics and Processes of Assembly Logistics

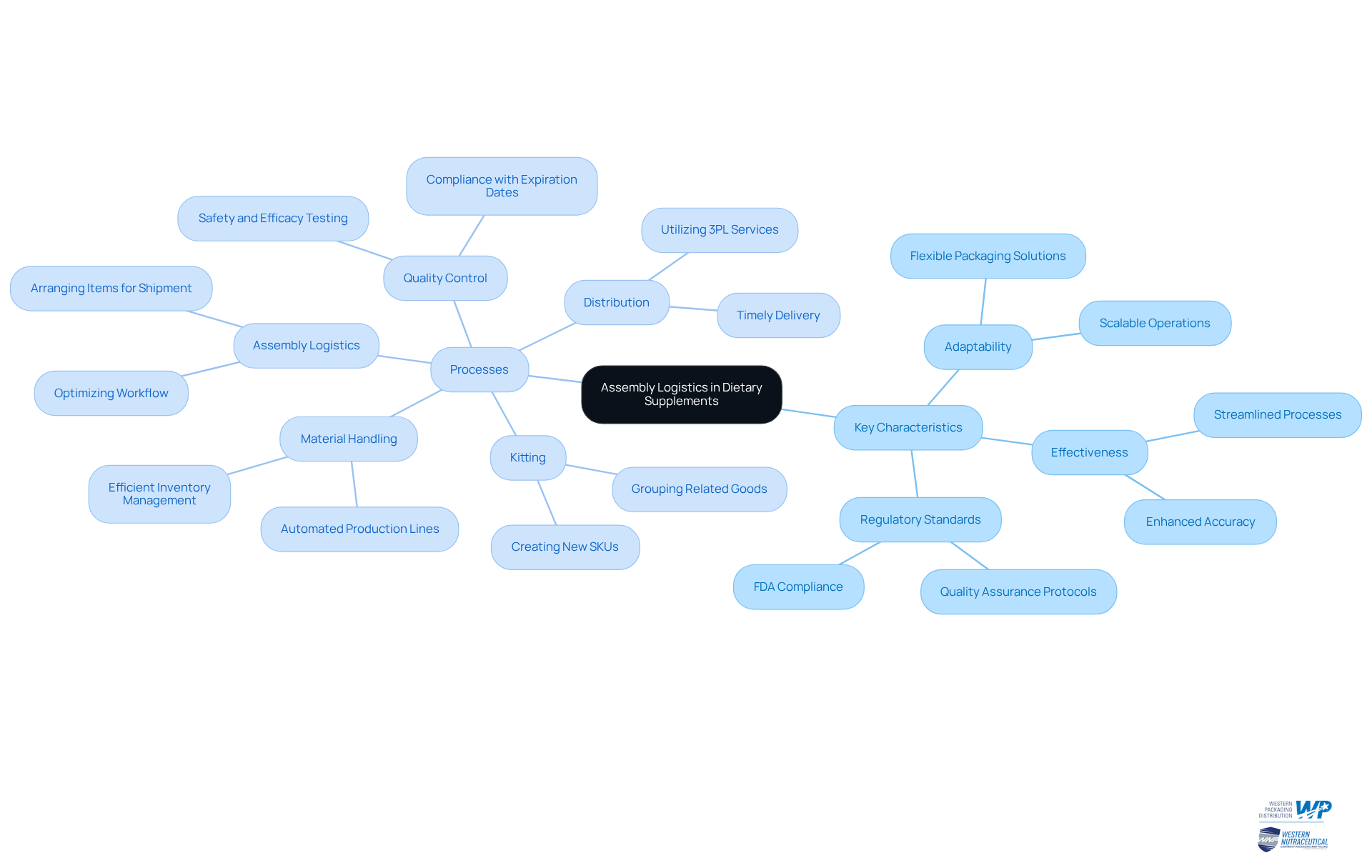

Essential traits of logistics in the dietary supplement sector include:

- Adaptability

- Effectiveness

- Strict adherence to regulatory standards

The processes involved typically encompass:

- Material handling

- Kitting

- Assembly logistics

- Quality control

- Distribution

For example, kitting involves gathering various components into a single package, particularly beneficial for nutraceuticals requiring multiple ingredients or formats. Quality control procedures guarantee that each item meets safety and efficacy standards, a crucial aspect in the nutraceutical sector.

Furthermore, Western Packaging's integrated filling services streamline production by accommodating a diverse range of products, from powders to gummies and soft-gels, enhancing product appeal through tailored flexible packaging solutions. The integration of technology, including automated production lines and inventory management systems, has revolutionized these processes, enabling enhanced accuracy and speed in production.

Moreover, enhancing your supply chain with extensive 3PL services, including storage and transportation, allows nutraceutical producers to focus on their core strengths while ensuring effective assembly logistics for distribution.

Identify Challenges in Assembly Logistics for Nutraceutical Manufacturers

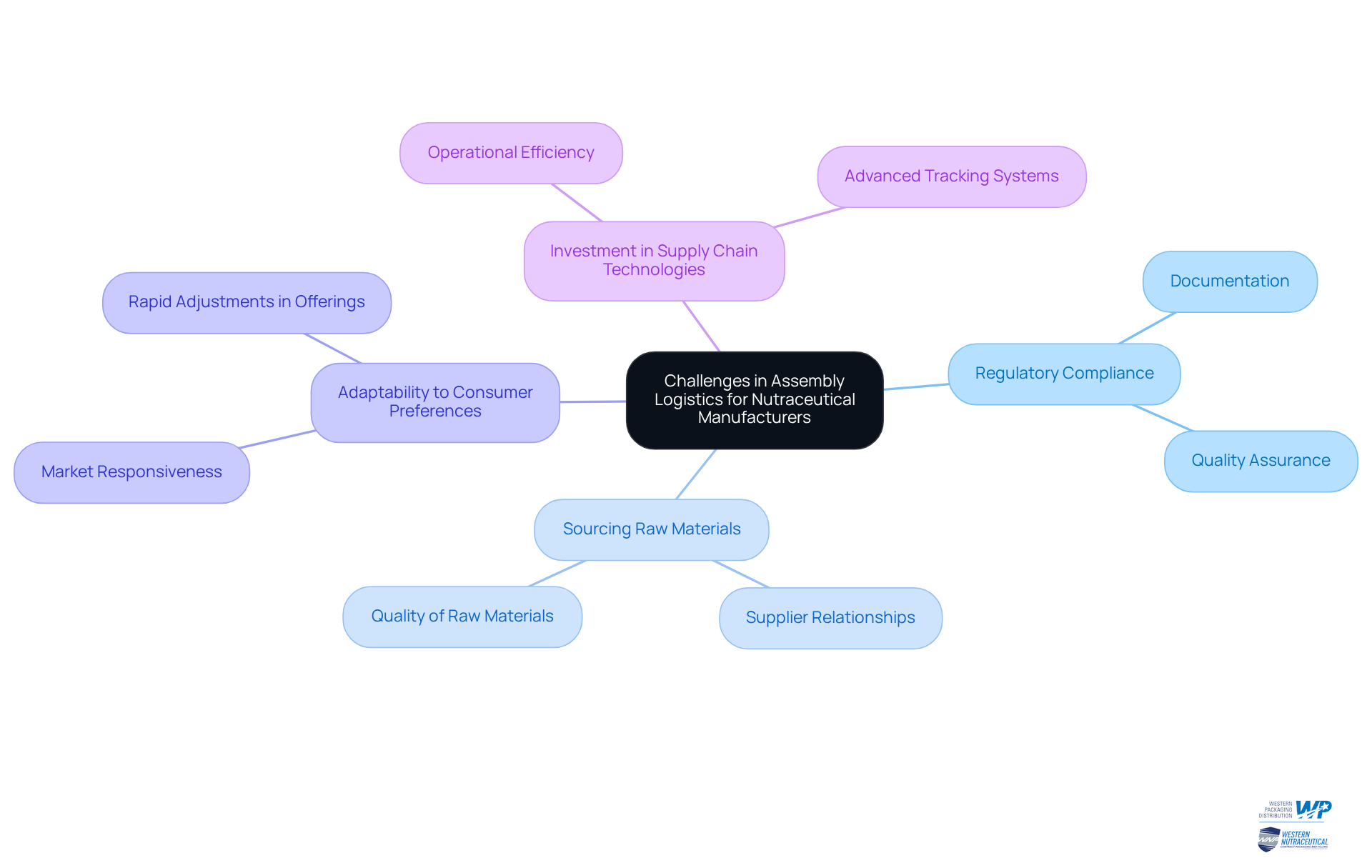

Nutraceutical producers face significant challenges in logistics, primarily driven by stringent regulatory compliance requirements. These regulations necessitate meticulous documentation and rigorous quality assurance procedures, which can impede the speed of production operations. A case study on compliance management demonstrates how expert handling of supplement regulations allows brands to navigate these complexities, thereby preserving their market position.

Furthermore, sourcing high-quality raw materials introduces an additional layer of unpredictability, frequently resulting in production delays. Manufacturers must remain agile, swiftly adapting to evolving consumer preferences that demand rapid adjustments in assembly processes and product offerings. This adaptability is crucial, as the health product market is characterized by shifting trends and consumer needs.

To effectively tackle these challenges, manufacturers are increasingly investing in advanced supply chain technologies that bolster operational efficiency. Moreover, cultivating strong relationships with suppliers is vital to ensure a consistent and reliable flow of materials. By proactively addressing regulatory compliance issues and leveraging technology, nutraceutical manufacturers can enhance their responsiveness to market dynamics by streamlining their assembly logistics.

Conclusion

Assembly logistics is fundamental to the nutraceutical industry, acting as the backbone for the efficient assembly and distribution of health-focused products. By integrating various components such as raw ingredients, packaging, and labeling, assembly logistics ensures not only regulatory compliance but also enhances operational efficiency and responsiveness to market demands. This systematic coordination is essential for nutraceutical companies striving to maintain a competitive edge in a rapidly evolving marketplace.

The evolution of assembly logistics from traditional manufacturing practices to modern, technology-driven processes is noteworthy. The adoption of Just-In-Time systems, strategic warehouse positioning, and advanced inventory management has proven beneficial in reducing waste and optimizing stock levels. Furthermore, challenges faced by nutraceutical manufacturers, such as stringent compliance requirements and sourcing high-quality materials, underscore the need for agility and innovation in assembly logistics.

The significance of effective assembly logistics cannot be overstated. As the nutraceutical market continues to grow, manufacturers must prioritize optimizing their logistical processes to meet consumer demands and regulatory standards. Embracing advanced technologies and fostering strong supplier relationships will enhance operational efficiency and position companies for success in this dynamic industry. Investing in assembly logistics allows nutraceutical producers to ensure the delivery of high-quality products that align with consumer preferences and market trends.

Frequently Asked Questions

What is assembly logistics in the context of nutraceuticals?

Assembly logistics refers to the systematic coordination of materials and processes essential for assembling items before distribution in the nutraceutical sector. This includes integrating raw ingredients, packaging materials, and labeling into a final product.

Why is assembly logistics important in the nutraceutical industry?

Assembly logistics is crucial because it ensures compliance with regulatory standards, enhances operational efficiency, and improves market responsiveness. Effective management can lead to reduced lead times and lower out-of-stock rates, which are vital for customer satisfaction.

How can assembly logistics improve inventory management in nutraceuticals?

Efficient assembly logistics management can result in improved inventory management by utilizing advanced inventory systems, leading to up to a 30% reduction in out-of-stock rates and ensuring that businesses can meet customer demands effectively.

What strategies have companies used to optimize assembly logistics?

Companies have employed Just-In-Time (JIT) systems and robust supply chain planning to reduce waste and optimize stock levels. These strategies help meet customer demand without incurring additional costs.

How does warehouse positioning affect shipping times in assembly logistics?

Strategic warehouse positioning can decrease shipping durations by 15-40%, positively impacting product delivery and overall operational performance, as evidenced by successful strategies implemented by companies like Commonwealth Inc.

What is the projected growth of the global nutraceuticals market?

The global nutraceuticals market is projected to reach USD 919.1 billion by 2030, increasing from an estimated USD 591.1 billion in 2024.

Can efficient assembly logistics lead to financial benefits for companies?

Yes, companies that enhance their production processes through efficient assembly logistics can achieve significant financial benefits, such as an impressive 250% return on investment (ROI), as demonstrated by firms like Nutrition Formulators.