Overview

Assembly warehouses serve a vital function in supply chain management, seamlessly integrating processes such as:

- Receiving

- Assembling

- Packaging

- Inventory management

This integration significantly enhances operational efficiency and reduces lead times. By enabling businesses to respond swiftly to market demands and optimize costs, these warehouses address critical challenges, including:

- Labor shortages

- The complexities of inventory management

The expertise they provide is essential for companies looking to streamline operations and maintain a competitive edge in the market.

Introduction

Assembly warehouses signify a pivotal evolution in the realm of supply chain management, effectively merging various operational stages to enhance both efficiency and responsiveness. By integrating critical functions such as assembly, packaging, and inventory management, these facilities streamline workflows and adeptly adapt to the swift pace of market demands.

However, as businesses increasingly depend on these hubs, challenges including labor shortages and inventory inaccuracies arise, necessitating a comprehensive exploration of their role and impact within the logistics framework.

What are the authentic benefits and potential pitfalls of adopting assembly warehouses in today’s dynamic supply chain environment?

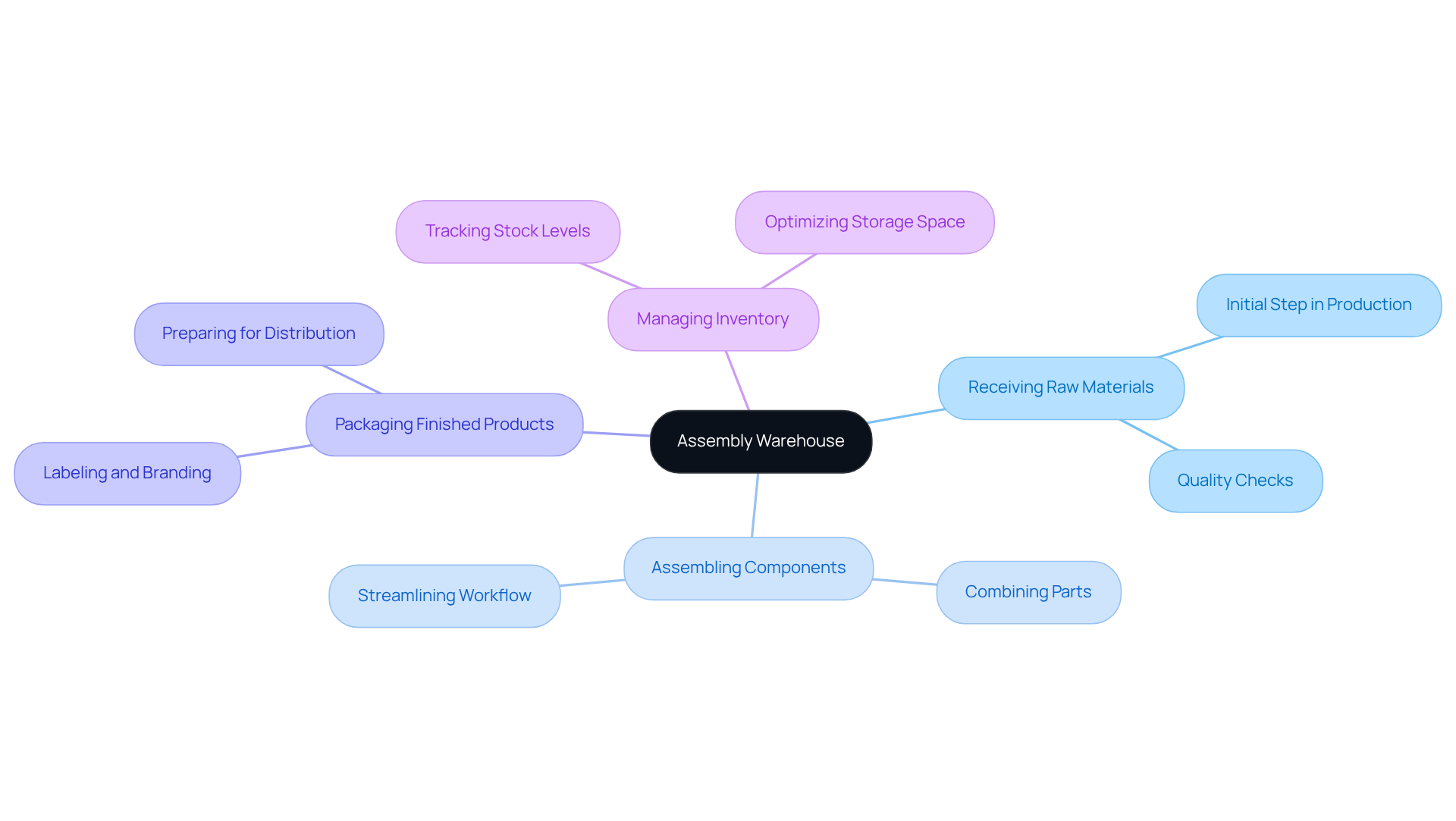

Define Assembly Warehouse: Key Concepts and Functions

A production center serves as a specialized facility that streamlines the construction of products prior to their distribution to retailers or final consumers. Unlike conventional storage facilities, which primarily focus on retaining items, integration centers encompass essential processes such as packaging, labeling, and quality assurance. This unification of various stages within the supply chain enhances operational efficiency and significantly reduces lead times, making storage facilities indispensable in modern supply chain management.

Key functions of an assembly warehouse include:

- Receiving raw materials

- Assembling components

- Packaging finished products

- Managing inventory

This integrated approach not only optimizes workflow but also meets the increasing demand for rapid fulfillment in today’s market. Western Packaging’s filling process amplifies these functions by delivering comprehensive services that streamline production from powders to gummies, soft-gels, and kitting. This integration facilitates quicker assembly and distribution, ultimately enhancing product delivery and customer satisfaction. Furthermore, the growing importance of effective storage solutions is underscored by the projected expansion of the management system (WMS) market, anticipated to grow at a CAGR of 16.1% from 2022 to 2030.

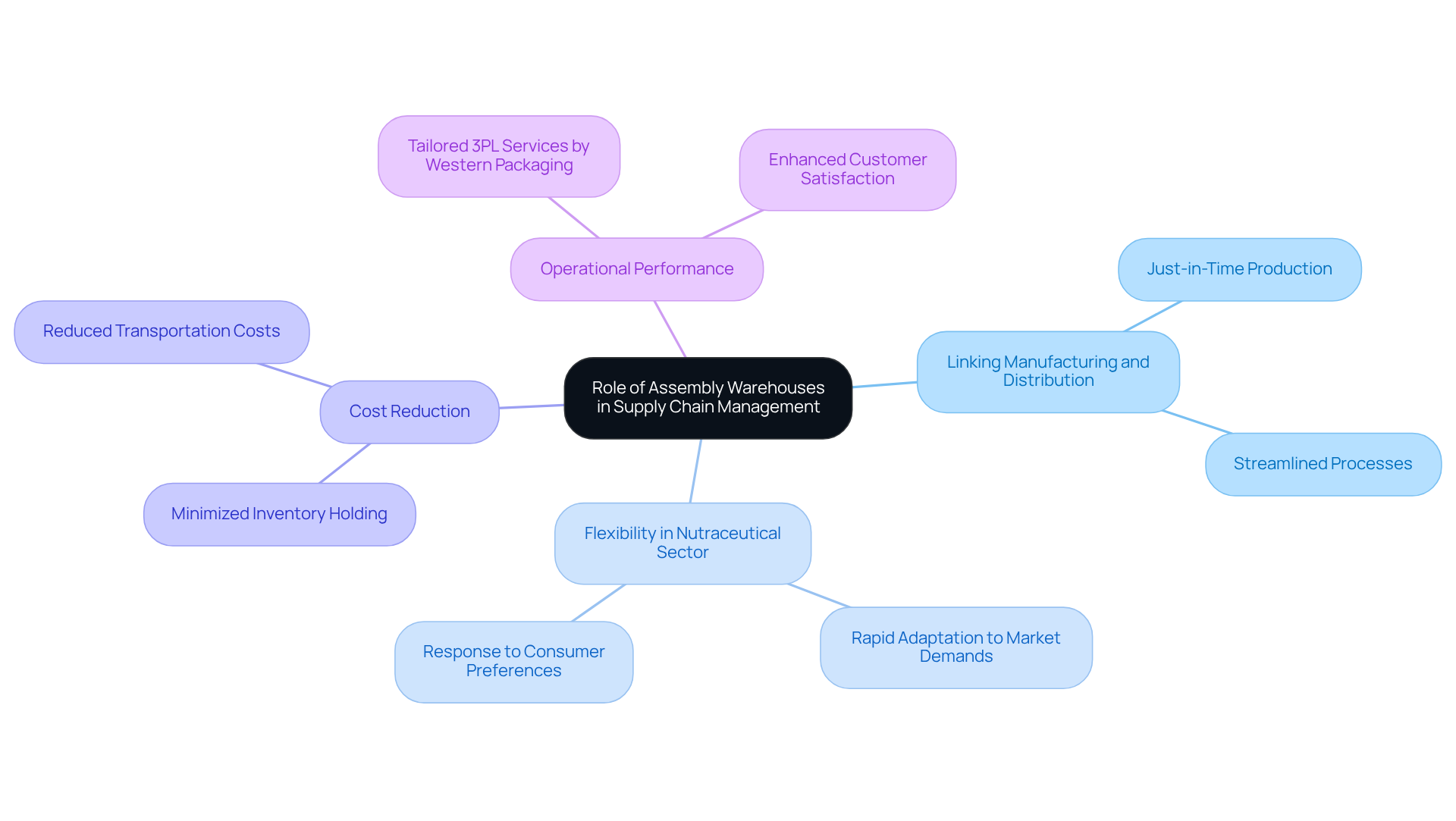

Contextualize the Role of Assembly Warehouses in Supply Chain Management

Assembly warehouses are pivotal in supply chain management, effectively linking manufacturing and distribution. They empower businesses to swiftly adapt to market demands through just-in-time production and packaging. In the nutraceutical sector, characterized by rapid shifts in product variations and consumer preferences, these warehouses provide the essential flexibility needed for effective responses.

By centralizing operations in an assembly warehouse, companies can significantly reduce transportation costs and minimize inventory holding, thereby enhancing their responsiveness to customer needs.

Western Packaging's extensive 3PL services amplify this process, delivering tailored solutions that enhance operational performance and elevate customer satisfaction. This strategic positioning not only streamlines processes but also cultivates a more agile supply chain, enabling companies to meet consumer demands promptly and efficiently.

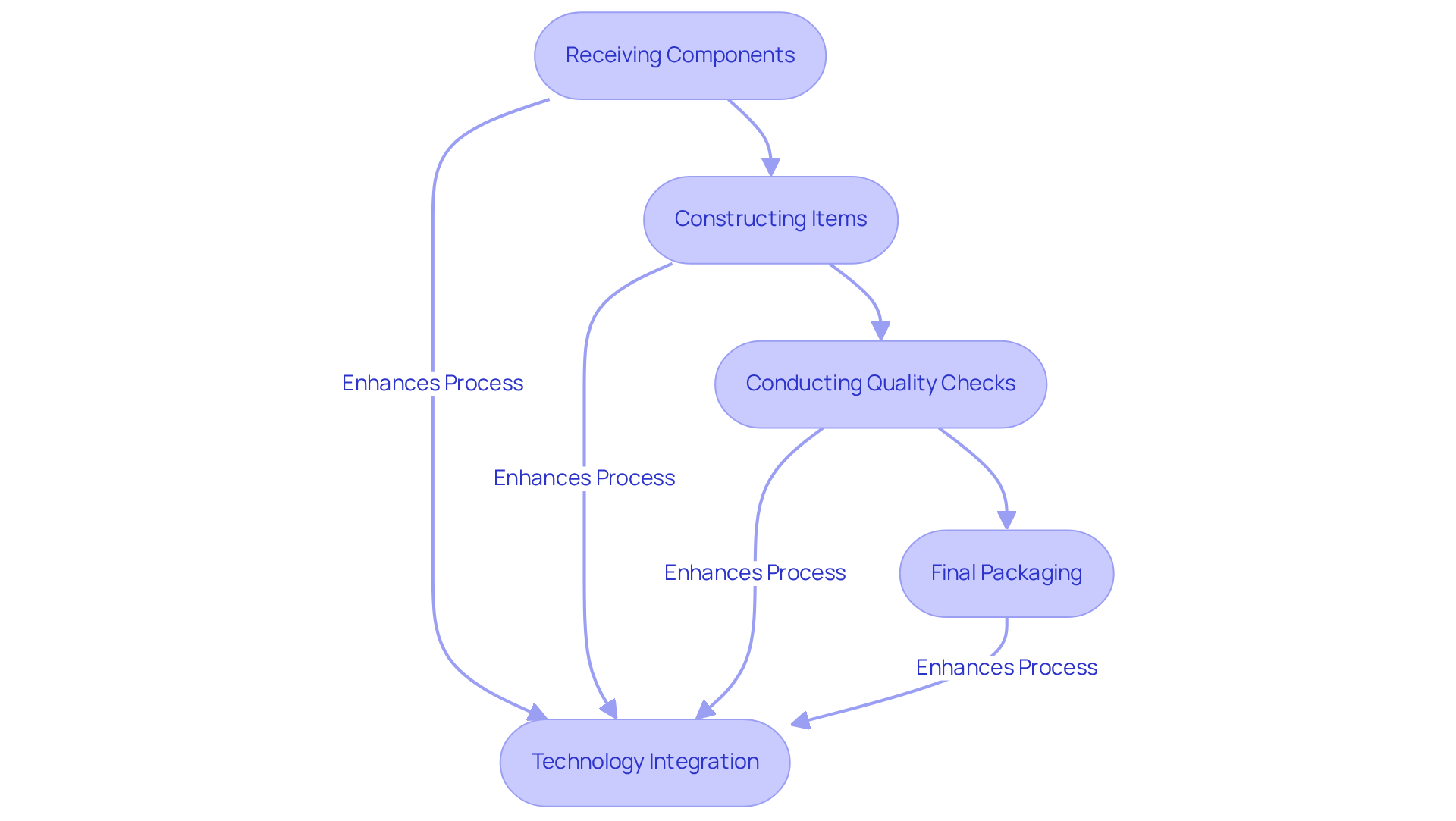

Examine Characteristics and Operations of Assembly Warehouses

Assembly warehouses exemplify the principles of flexibility, efficiency, and the seamless integration of diverse processes. By leveraging advanced technology, such as automated packing lines and sophisticated inventory management systems, these facilities significantly enhance production tasks. Typical activities within a manufacturing facility encompass several essential steps:

- Receiving components

- Constructing items to meet precise specifications

- Conducting quality checks

- Final packaging

For instance, a nutraceutical producer may utilize a blending facility to amalgamate various supplement components—powders, gummies, and soft-gels—into a cohesive product, ensuring compliance with regulatory standards before distribution. This operational framework not only elevates productivity but also facilitates real-time adjustments in the assembly warehouse based on inventory levels and customer demands.

The introduction of ergonomic workstations has been shown to enhance task cycle times by 18%, further amplifying productivity in these environments. As industry leaders increasingly recognize the importance of automation, a striking 90% of employees report that such technologies have positively impacted their productivity, underscoring the critical role of technology in modern manufacturing operations.

Furthermore, with 76% of today's supply chain operations grappling with labor shortages, Western Packaging's integrated filling services and comprehensive 3PL solutions provide essential support, enabling businesses to focus on their core competencies while optimizing overall operational performance.

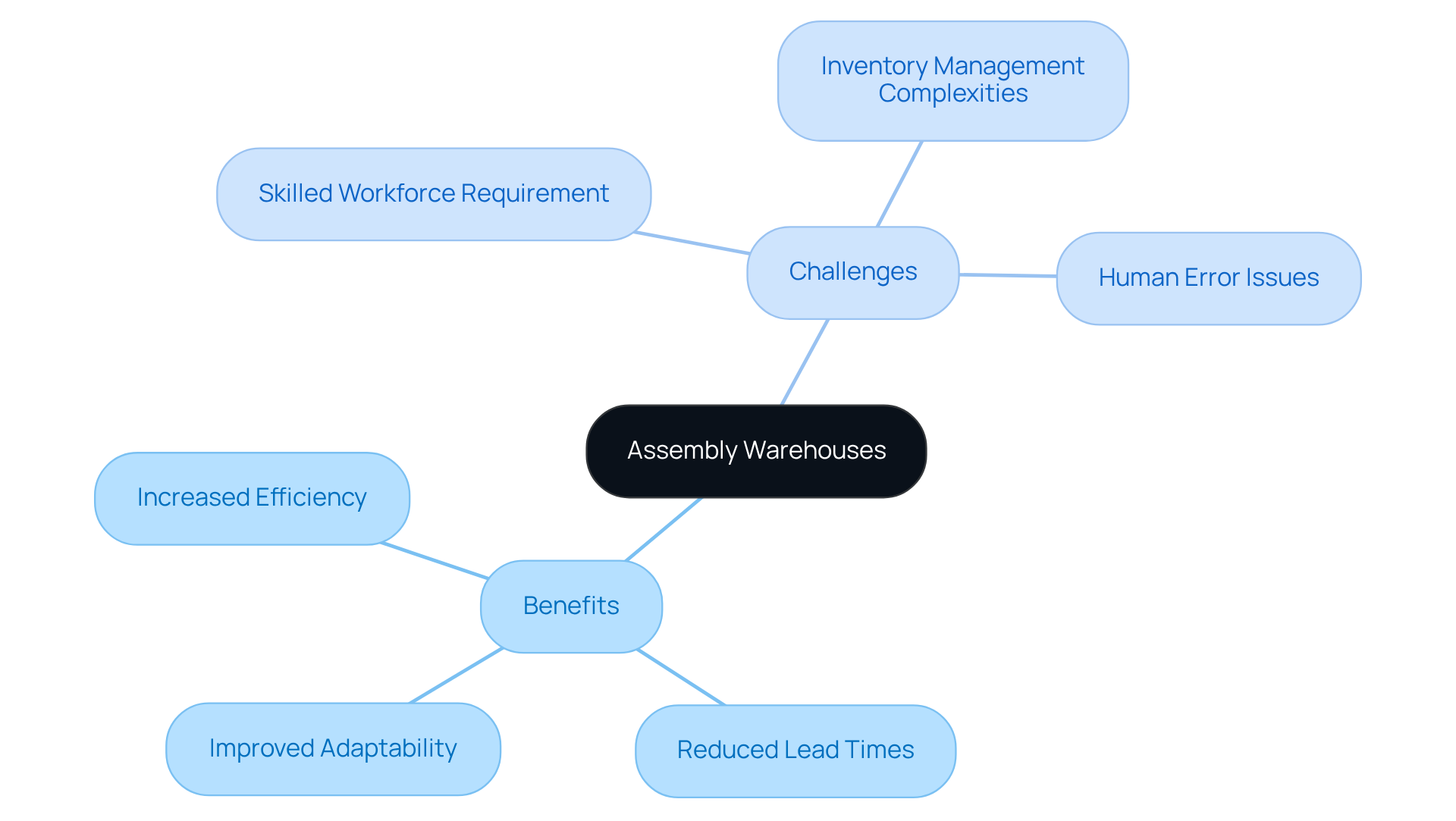

Analyze Benefits and Challenges of Using Assembly Warehouses

Utilizing storage facilities offers significant advantages, including increased efficiency, reduced lead times, and improved adaptability to market demands. By integrating production and packaging processes, businesses can streamline operations and minimize costs associated with multiple handling points.

Nonetheless, challenges persist, particularly in the nutraceutical sector, where reliance on production facilities necessitates a skilled workforce capable of managing diverse tasks. As industry analysts note, the intricacies of inventory management can pose considerable challenges for manufacturing facilities, especially when addressing the complex requirements of nutraceutical products.

Notably, human error accounts for 80% of inaccuracies in traditional storage systems, underscoring the critical need for robust inventory management systems to effectively track various product variations. Striking a balance between these benefits and the inherent challenges is vital for companies aiming to enhance their supply chain efficiency through distribution centers.

Furthermore, 33% of third-party logistics providers report profitability growth exceeding 25%, highlighting the financial benefits of utilizing assembly warehouses.

Conclusion

Assembly warehouses are pivotal in enhancing supply chain efficiency, integrating processes from receiving raw materials to packaging finished products. This streamlined approach fosters operational efficiency and meets the increasing demand for rapid fulfillment in today's competitive market. By centralizing these functions, businesses can swiftly respond to market changes, ultimately improving customer satisfaction and reducing costs.

Insights from the article reveal how assembly warehouses optimize workflow through advanced technology, enabling real-time adjustments based on inventory levels and customer needs. The integration of automation and ergonomic workstations significantly boosts productivity and addresses labor shortages within the industry. Nevertheless, challenges such as complex inventory management and the need for a skilled workforce remain critical considerations for companies aiming to leverage these facilities effectively.

In light of these insights, it is clear that assembly warehouses serve not merely as storage solutions but as essential components of modern supply chains. As businesses adapt to evolving market demands, embracing the advantages of assembly warehouses while confronting their challenges is vital for maintaining a competitive edge. Companies should invest in robust inventory management systems and automation technologies, ensuring they can navigate the complexities of logistics while maximizing efficiency and customer satisfaction.

Frequently Asked Questions

What is an assembly warehouse?

An assembly warehouse is a specialized facility that streamlines the construction of products before they are distributed to retailers or final consumers, incorporating processes like packaging, labeling, and quality assurance.

How does an assembly warehouse differ from a conventional storage facility?

Unlike conventional storage facilities that primarily focus on retaining items, assembly warehouses integrate various stages of the supply chain, enhancing operational efficiency and reducing lead times.

What are the key functions of an assembly warehouse?

The key functions of an assembly warehouse include receiving raw materials, assembling components, packaging finished products, and managing inventory.

How does the integrated approach of assembly warehouses benefit workflow?

The integrated approach optimizes workflow by combining multiple processes, which helps meet the increasing demand for rapid fulfillment in the market.

What specific services does Western Packaging provide in relation to assembly warehouses?

Western Packaging offers a filling process that delivers comprehensive services, streamlining production from powders to gummies, soft-gels, and kitting, facilitating quicker assembly and distribution.

Why is effective storage solution important in today's market?

Effective storage solutions are crucial due to the growing demand for rapid fulfillment, which is highlighted by the projected growth of the warehouse management system (WMS) market, expected to grow at a CAGR of 16.1% from 2022 to 2030.