Overview

This article examines the pivotal role of contract pharma in nutraceutical manufacturing, emphasizing its significant benefits, including:

- Cost savings

- Access to cutting-edge technologies

- Enhanced production flexibility

By outsourcing production, nutraceutical firms can not only improve operational efficiency but also ensure compliance with regulatory standards and swiftly adapt to market demands. This strategic positioning allows them to maintain a competitive edge in a rapidly growing industry.

Introduction

The landscape of nutraceutical manufacturing is rapidly evolving, propelled by a surge in consumer demand for health-focused products and the complexities of regulatory compliance. Contract pharma has emerged as a pivotal strategy for companies aiming to enhance operational efficiency and innovate their offerings. As the industry anticipates substantial growth, the pressing question is: how can nutraceutical firms effectively navigate the challenges of outsourcing production while ensuring quality and compliance? This article delves into the multifaceted role of contract pharma in the nutraceutical sector, exploring its benefits and services, alongside the critical considerations that manufacturers must address to thrive in this competitive market.

Define Contract Pharma: An Overview

Pharmaceutical outsourcing, commonly referred to as contract pharma, involves delegating production processes to specialized firms that provide a comprehensive array of services, including formulation, production, packaging, and quality control. This strategic approach allows nutraceutical firms to concentrate on their core competencies while leveraging the expertise of their manufacturing partners. By utilizing pharmaceutical services, companies can significantly enhance operational efficiency, reduce costs, and expedite their time-to-market for new products.

The market for pharmaceutical manufacturing in nutraceuticals is poised for substantial growth, driven by increasing demand for complex formulations and the imperative to comply with stringent regulatory standards. A prime example is the decade-long partnership between Johnson & Johnson and Catalent, which illustrates how strategic collaborations can foster improved efficiency and provide access to cutting-edge technologies, ultimately leading to cost savings and enhanced product development capabilities.

Moreover, outsourcing production to third-party manufacturers not only mitigates financial risks but also grants nutraceutical firms access to specialized expertise and state-of-the-art facilities without necessitating significant capital investment. However, it is crucial to weigh potential drawbacks, such as quality control challenges and regulatory complexities that may emerge in contract pharma outsourcing manufacturing. As the industry evolves, the role of manufacturers will become increasingly vital in meeting the growing global healthcare demands, with the market size for pharmaceutical production in nutraceuticals expected to reach impressive figures by 2025.

Contextualize Contract Pharma in Nutraceutical Manufacturing

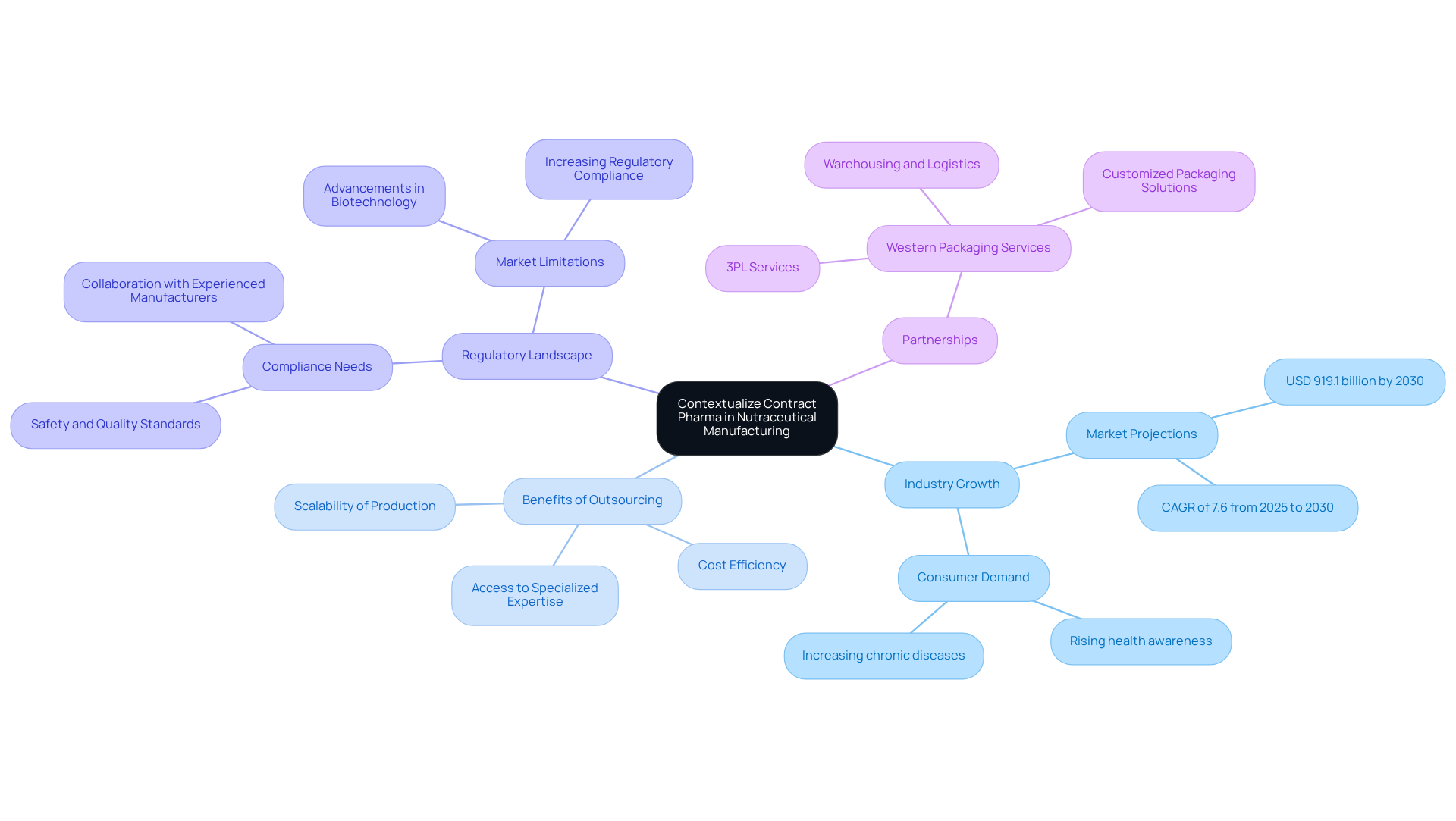

The nutraceutical industry has witnessed significant growth in recent years, fueled by an increasing consumer interest in health and wellness products. This escalating trend has prompted numerous companies to leverage pharmaceutical services to meet the burgeoning demand for dietary supplements and functional foods. Outsourcing has emerged as a strategic choice, driven by the necessity for cost efficiency, access to specialized expertise, and the ability to scale production swiftly.

The intricate regulatory landscape within the nutraceutical sector underscores the importance of collaborating with experienced manufacturers to ensure compliance with safety and quality standards. With projections indicating that the industry will reach USD 919.1 billion by 2030, the role of contract pharma in optimizing production processes and enhancing product offerings has become more critical than ever. Companies that embrace outsourcing can streamline their operations, enabling them to focus on innovation and responsiveness to market demands, thereby positioning themselves effectively in a competitive landscape.

Collaborating with Western Packaging for comprehensive 3PL services offers customized solutions that directly address the challenges faced by nutraceutical producers. Their extensive services, encompassing warehousing, inventory management, and logistics, empower producers to concentrate on their core strengths while ensuring a robust and agile supply chain.

Explore Benefits of Contract Pharma for Nutraceutical Manufacturers

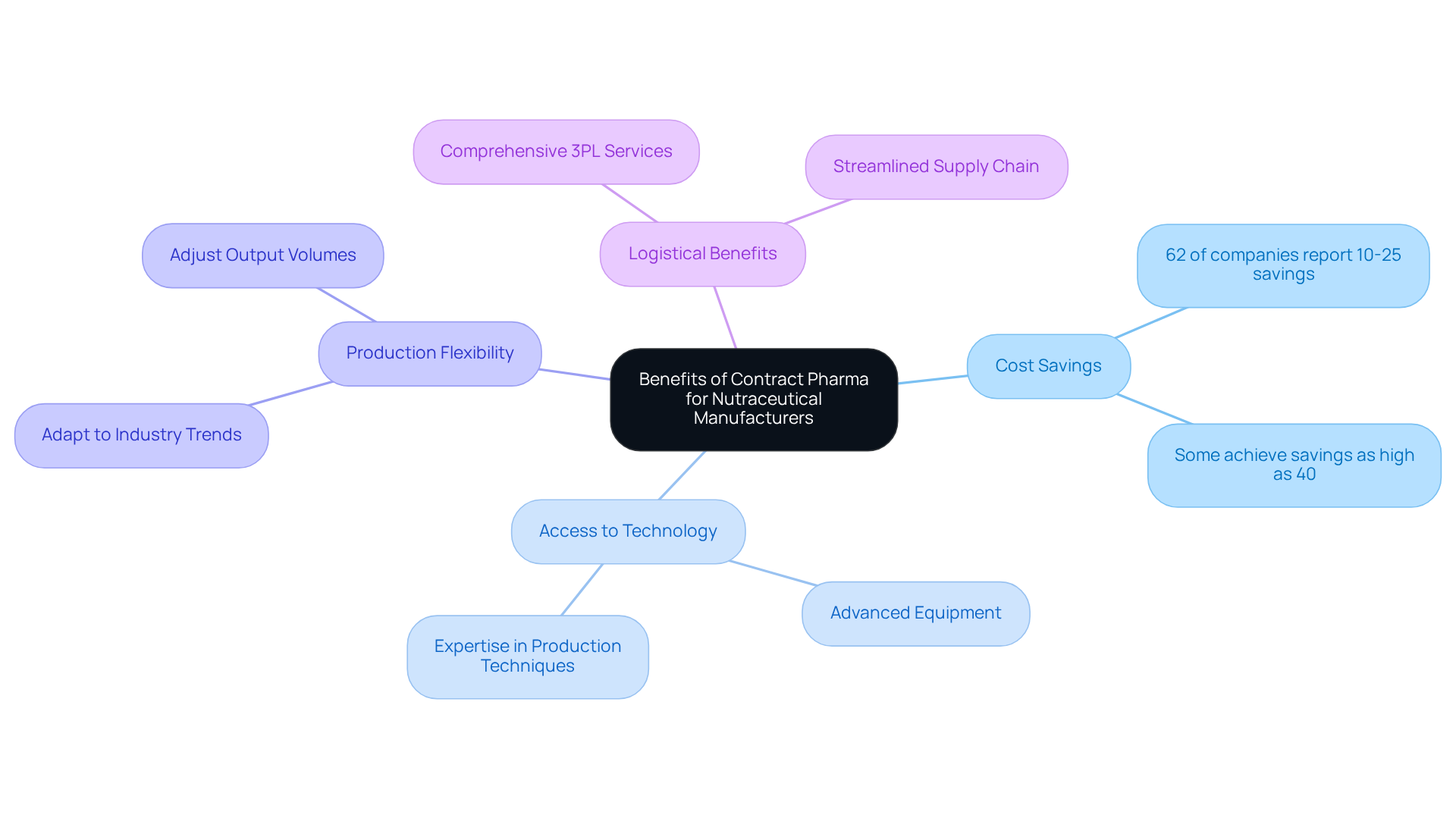

Contract pharma manufacturing offers substantial advantages for nutraceutical producers, including significant cost savings, access to advanced technology, and increased production flexibility. By outsourcing production to Western Packaging, companies can lower overhead costs associated with manufacturing facilities and specialized personnel. Studies reveal that 62% of businesses report savings ranging from 10% to 25% due to outsourcing, with some achieving savings as high as 40%.

Furthermore, Western Packaging delivers comprehensive third-party logistics (3PL) services, encompassing warehousing and inventory management, which streamline the supply chain and bolster operational efficiency. Contract manufacturers typically employ state-of-the-art equipment and possess expertise in the latest production techniques, expediting product development and enhancing overall efficiency. This technological edge is vital, as the nutraceutical sector is projected to grow at a compound annual growth rate (CAGR) of 8.7% from 2025 to 2033, underscoring the need for producers to stay competitive.

The flexibility provided by outsourced manufacturing allows nutraceutical firms to swiftly adapt to evolving industry trends and consumer preferences. This adaptability is crucial in an environment where consumer demand for innovative dietary aids is on the rise, particularly for products offering significant benefits, such as probiotics and herbal supplements. By leveraging contract pharma manufacturing and integrated 3PL services, companies can enhance their responsiveness to industry dynamics, ultimately improving their competitiveness and market presence.

Break Down Components of Contract Pharma Services

Contract pharma services are essential to the nutraceutical industry, encompassing:

- Formulation development

- Manufacturing

- Packaging

- Quality assurance

Formulation development is pivotal for creating effective and compliant formulations that meet market demands. This process ensures that dietary supplements are not only effective but also adhere to regulatory standards. Manufacturing services facilitate large-scale production while strictly following Good Manufacturing Practices (GMP), which are crucial for maintaining product integrity and safety.

Packaging plays a vital role in enhancing product visibility and shelf life, focusing on creating appealing and functional designs that attract consumers. As the market evolves, current trends in packaging for nutraceuticals emphasize sustainability and innovation, aligning with consumer preferences for eco-friendly solutions.

Quality assurance is indispensable in this sector, involving rigorous testing and compliance checks to ensure safety and efficacy. This comprehensive approach to quality management aids nutraceutical producers in mitigating risks and upholding high standards. By integrating these components, contract pharma services provide a robust framework for optimizing production processes, ultimately supporting manufacturers in delivering high-quality products to the market.

Conclusion

Pharmaceutical outsourcing, commonly referred to as contract pharma, serves as a cornerstone in the nutraceutical manufacturing landscape, empowering companies to concentrate on their core competencies while accessing specialized expertise. This strategic maneuver not only bolsters operational efficiency but also equips firms to swiftly adapt to market demands, ultimately fostering innovation and growth within this rapidly evolving industry.

The article underscores several pivotal benefits of contract pharma, such as significant cost savings, access to cutting-edge technologies, and enhanced production flexibility. By outsourcing manufacturing processes, nutraceutical companies can alleviate financial risks and streamline their operations, thereby maintaining a competitive edge. Moreover, the critical importance of quality assurance and adherence to regulatory standards cannot be overstated, as these elements are vital for preserving consumer trust and ensuring product integrity.

As the nutraceutical market continues to flourish, embracing contract pharma services will be imperative for companies striving to excel in this dynamic environment. By capitalizing on the advantages of outsourcing, firms can augment their operational capabilities, adapt to emerging trends, and ultimately deliver high-quality products that satisfy the escalating health and wellness demands of consumers. The future of nutraceutical manufacturing is promising, and those who acknowledge the significance of strategic partnerships will be well-equipped to thrive.

Frequently Asked Questions

What is contract pharma?

Contract pharma, or pharmaceutical outsourcing, involves delegating production processes to specialized firms that offer services such as formulation, production, packaging, and quality control.

What are the benefits of using contract pharma services?

Utilizing contract pharma services allows nutraceutical firms to focus on their core competencies, enhance operational efficiency, reduce costs, and expedite the time-to-market for new products.

Why is the market for pharmaceutical manufacturing in nutraceuticals growing?

The market is growing due to increasing demand for complex formulations and the need to comply with stringent regulatory standards.

Can you provide an example of a successful partnership in contract pharma?

A notable example is the decade-long partnership between Johnson & Johnson and Catalent, which demonstrates how strategic collaborations can improve efficiency and provide access to advanced technologies.

What are the financial advantages of outsourcing production?

Outsourcing mitigates financial risks and allows nutraceutical firms to access specialized expertise and state-of-the-art facilities without significant capital investment.

What challenges should companies consider when outsourcing to contract pharma?

Companies should be aware of potential challenges such as quality control issues and regulatory complexities that may arise in contract pharma outsourcing.

What is the expected future of the pharmaceutical production market in nutraceuticals?

The market size for pharmaceutical production in nutraceuticals is expected to reach impressive figures by 2025, reflecting the growing global healthcare demands.