Overview

This article delves into the realm of pack manufacturing, elucidating its core concepts, historical evolution, key characteristics, and the myriad challenges it encounters, particularly concerning regulatory compliance and quality control. It underscores the critical role of material selection, design, and sustainability in the manufacturing process. Effective packaging not only safeguards products but also elevates branding and responds to consumer demands for eco-friendly solutions. By understanding these elements, stakeholders can navigate the complexities of the industry and implement strategies that ensure both compliance and quality.

Introduction

The intricate world of pack manufacturing plays a pivotal role in safeguarding products while enhancing their market appeal. As businesses increasingly recognize the significance of effective packaging, understanding the core concepts and challenges of this industry becomes essential. However, with evolving consumer demands and stringent regulatory standards, manufacturers face the pressing question: how can they navigate the complexities of material selection, design, and quality control to ensure both compliance and brand integrity?

This article delves into the fundamental aspects of pack manufacturing, exploring its historical evolution, key characteristics, and the challenges that shape its future.

Defining Pack Manufacturing: Core Concepts and Relevance

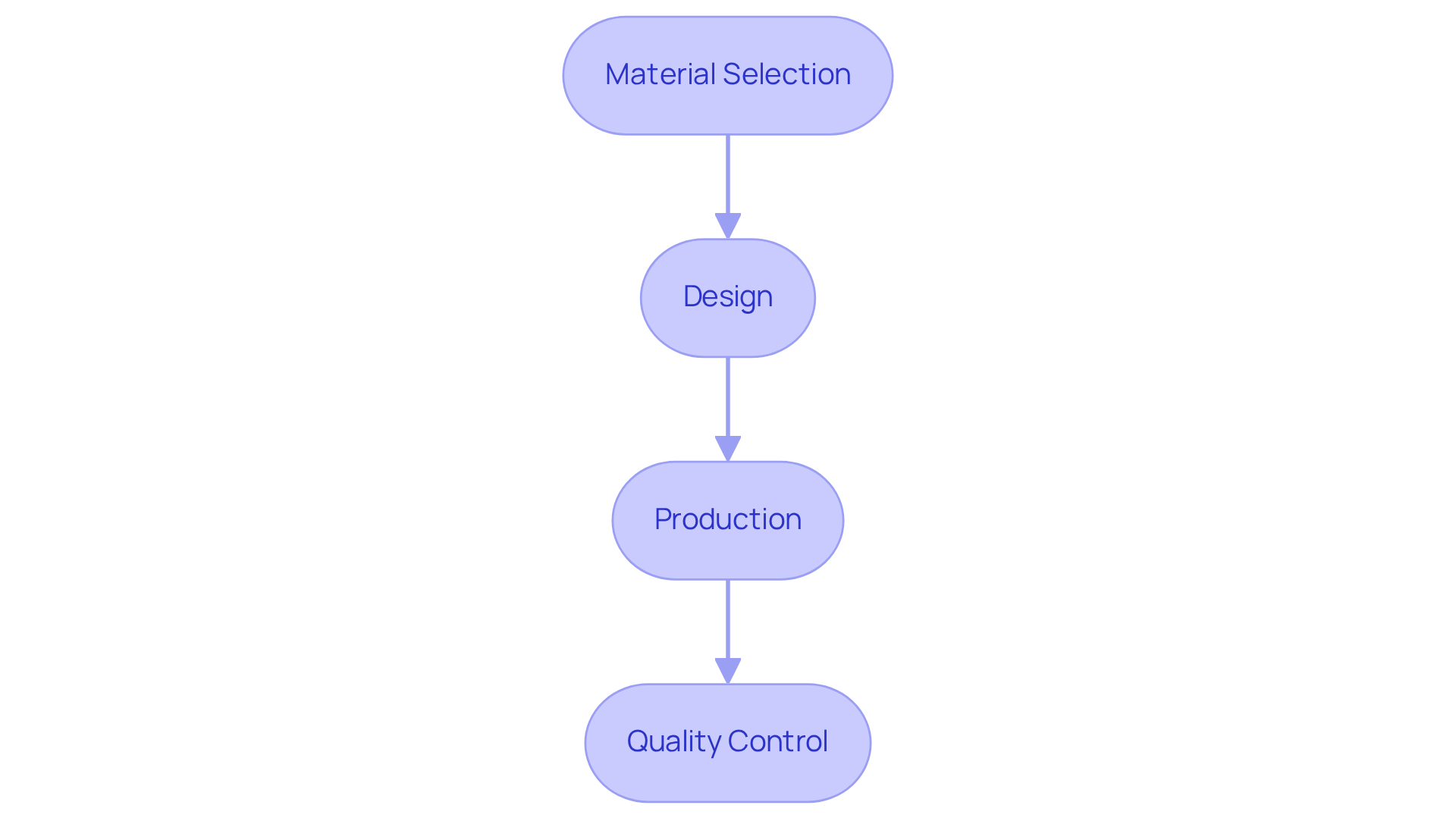

The essential process of pack manufacturing involves creating, producing, and assembling packaging components and containers that safeguard and promote items. This involves a comprehensive array of activities, including:

- Material selection

- Design

- Production

- Quality control

The significance of pack manufacturing goes beyond mere item protection; it is essential for branding, consumer perception, and supply chain efficiency. Effective packaging not only enhances product visibility on shelves but also communicates brand values and ensures compliance with regulatory standards. This makes pack manufacturing an indispensable element of contemporary manufacturing strategies.

At Western Packaging, our integrated filling services and comprehensive 3PL solutions streamline production and improve supply chain management. This enables nutraceutical manufacturers to focus on elevating their brand visibility and shelf appeal through customized flexible containers.

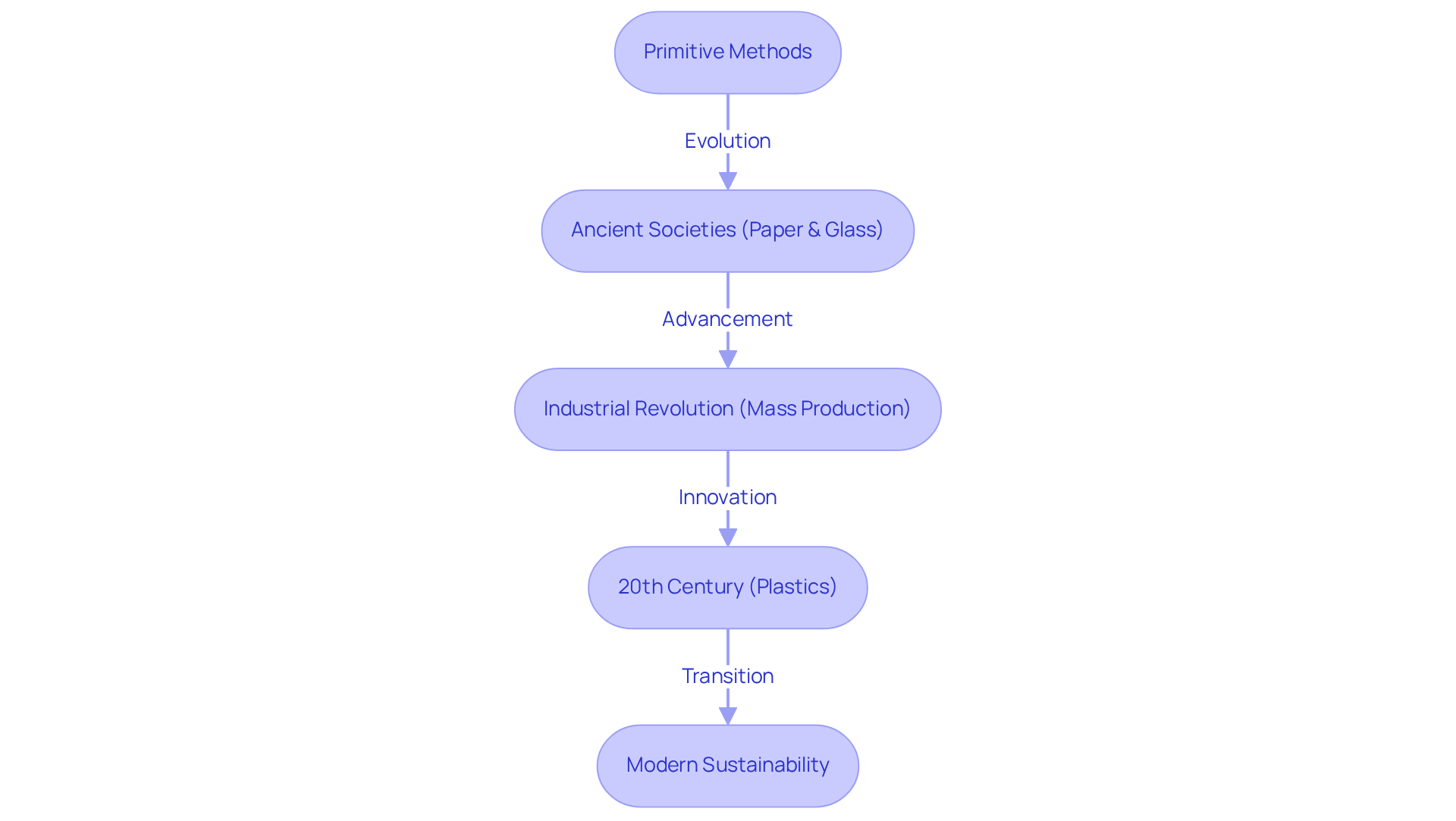

Historical Context: The Evolution of Pack Manufacturing

The history of pack manufacturing spans thousands of years, starting with primitive methods created to safeguard and transport goods. Ancient societies pioneered materials such as paper and glass, laying the groundwork for modern wrapping solutions. The Industrial Revolution marked a pivotal shift, introducing mass production techniques that enabled the creation of standardized containers. This era saw the emergence of innovative materials, particularly plastics in the 20th century, which transformed pack manufacturing by providing lightweight, durable, and versatile options.

Today, the focus has shifted towards sustainability in pack manufacturing, with manufacturers increasingly adopting eco-friendly materials and advanced technologies for containers. This evolution is propelled by consumer demand for sustainable practices, as highlighted by the anticipated growth of the eco-friendly materials market, projected to expand significantly, reflecting a robust transition towards sustainable practices in material usage across various sectors.

Moreover, case studies illustrate the impact of eco-friendly solutions, such as the use of post-consumer recycled content, which diverts waste from landfills and reduces reliance on new resources. As the industry continues to evolve, the integration of innovative methods and materials in pack manufacturing remains crucial to addressing the complexities of contemporary packaging needs.

Key Characteristics of Pack Manufacturing: Processes and Components

Key characteristics of pack manufacturing include component selection, design, production processes, and quality assurance. Central to this is material selection, which involves choosing substrates that meet specific product requirements, including barrier properties and durability. The rising demand for eco-friendly materials has catalyzed a significant shift towards recyclable and biodegradable substances, with 61.5% of buyers expressing a willingness to pay more for sustainable options. Furthermore, the average corrugated box comprises 52% recycled content, underscoring the industry's commitment to sustainability.

The design phase extends beyond mere functionality; it emphasizes the creation of visually appealing materials that incorporate branding elements to attract consumers. Innovative techniques, such as digital printing—anticipated to grow at a CAGR of 8.30%—and intelligent wrapping are revolutionizing this aspect, facilitating rapid adjustments and enhancing aesthetics.

Production processes exhibit considerable variation, spanning traditional methods like die-cutting and printing to advanced techniques such as 3D printing and automation. The prevalence of automation is on the rise, with AI and machine learning technologies bolstering efficiency and personalization in production processes. This evolution is crucial, as the U.S. market for containers is projected to grow from USD 208.98 billion in 2025 to USD 254.01 billion by 2030, driven by innovations and sustainability trends.

Quality assurance remains a fundamental component, ensuring that containers adhere to safety standards and function effectively throughout the supply chain. This is particularly significant given that approximately 71.1% of buyers report receiving items with damaged wrapping, highlighting the critical need for robust quality control protocols. By focusing on these essential characteristics, firms can enhance their container solutions through pack manufacturing, ultimately improving safety and customer satisfaction.

Challenges in Pack Manufacturing: Regulatory Compliance and Quality Control

Pack manufacturing faces significant challenges, especially regarding regulatory compliance and quality control. Producers are required to adhere to stringent regulations governing container materials, labeling, and safety standards, which can vary by region and product type. This complexity demands a comprehensive understanding of legal requirements and continuous monitoring to ensure adherence. Furthermore, maintaining high-quality standards is essential to prevent defects that could compromise product integrity and user safety. Implementing robust quality control measures, including regular inspections and testing, is crucial for minimizing risks and ensuring that pack manufacturing meets industry standards and consumer expectations.

Conclusion

The intricate world of pack manufacturing stands as a cornerstone of modern industry, embodying the essential processes of creating and assembling packaging that not only protects but also promotes products. This discipline is crucial for enhancing brand visibility, ensuring compliance with regulations, and optimizing supply chain efficiency, thereby underscoring its critical role in today’s manufacturing landscape.

Key insights reveal that the evolution of pack manufacturing has been shaped by historical advancements, particularly in material innovation and sustainability practices. From the early use of paper and glass to the contemporary shift towards eco-friendly materials, the industry has continually adapted to meet consumer demands. Moreover, the integration of advanced technologies, such as automation and digital printing, has revolutionized production processes, enabling manufacturers to enhance quality and efficiency while addressing the growing need for sustainable solutions.

Reflecting on the significance of pack manufacturing, it is evident that the challenges of regulatory compliance and quality control remain paramount. As the industry progresses, stakeholders must prioritize robust quality assurance practices and stay informed about evolving regulations to ensure product integrity and consumer safety. Embracing innovation and sustainability will not only address current challenges but also pave the way for a more resilient and responsible packaging future. Engaging with these trends and adopting best practices can empower manufacturers to thrive in an increasingly competitive marketplace.

Frequently Asked Questions

What is pack manufacturing?

Pack manufacturing is the process of creating, producing, and assembling packaging components and containers that protect and promote items.

What activities are involved in pack manufacturing?

The activities involved in pack manufacturing include material selection, design, production, and quality control.

Why is pack manufacturing significant?

Pack manufacturing is significant because it goes beyond item protection; it is essential for branding, consumer perception, and supply chain efficiency.

How does effective packaging impact products?

Effective packaging enhances product visibility on shelves, communicates brand values, and ensures compliance with regulatory standards.

What role does Western Packaging play in pack manufacturing?

Western Packaging provides integrated filling services and comprehensive 3PL solutions that streamline production and improve supply chain management for nutraceutical manufacturers.