Overview

Product serialization in supply chains entails the assignment of unique identifiers to individual items, significantly enhancing visibility, traceability, and compliance with regulations. This systematic approach not only combats counterfeit products but also improves inventory management, fostering consumer trust through the verification of product authenticity. Such measures underscore its critical role in modern supply chain practices, ultimately ensuring reliability and integrity in the logistics sector.

Introduction

Product serialization has emerged as a pivotal element in modern supply chains, fundamentally transforming the tracking and management of goods. By assigning unique identifiers to individual products, businesses can significantly enhance visibility and traceability, ensuring compliance with stringent regulations and bolstering consumer trust.

However, as the demand for transparency grows, companies face the challenge of effectively navigating the complexities of implementing serialization while reaping its numerous benefits. This article delves into the intricacies of product serialization, exploring its significance, evolution, and the strategic approaches necessary for successful integration within supply chain practices.

Define Product Serialization and Its Role in Supply Chains

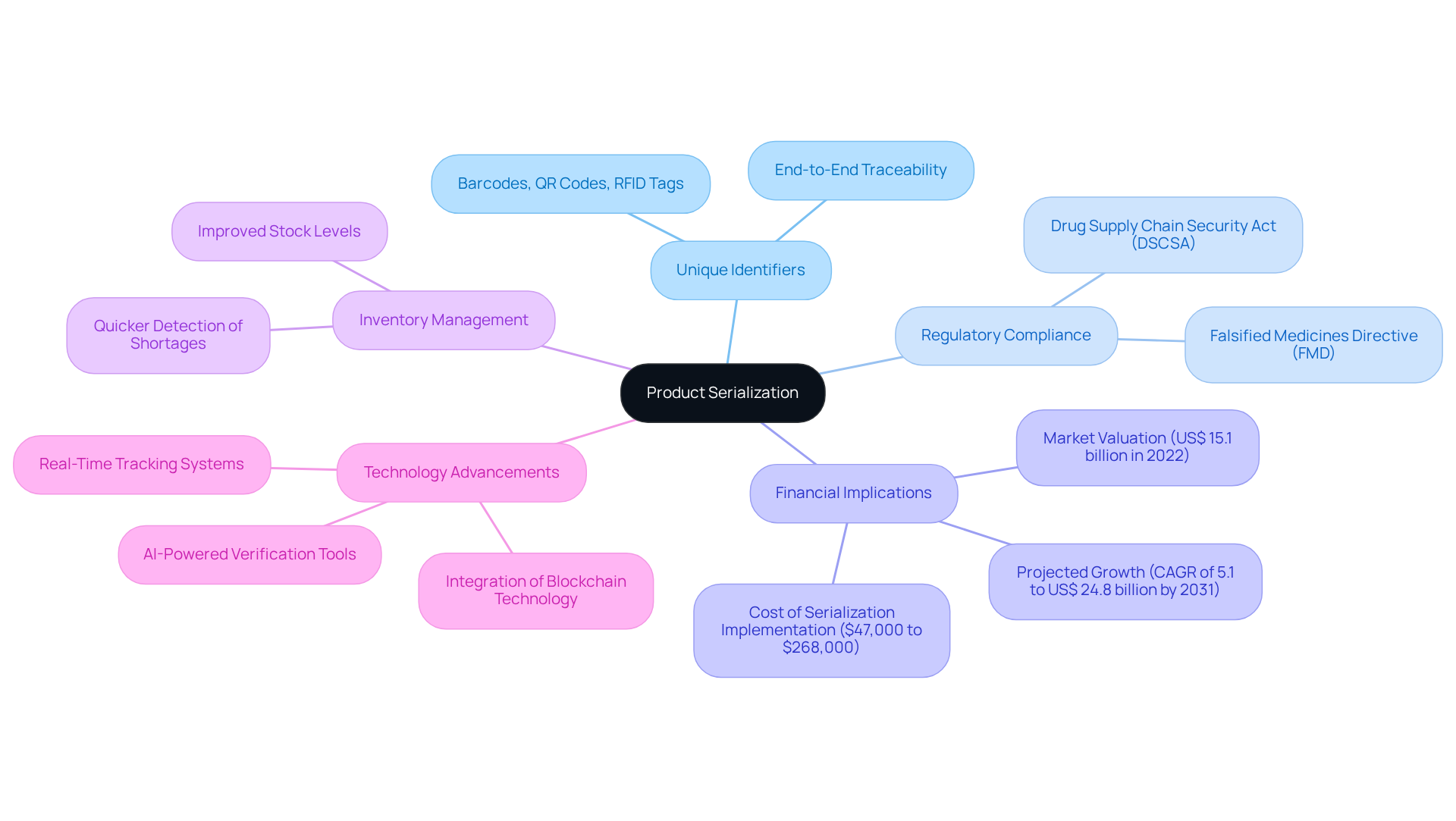

Product serialization involves assigning a unique identifier to each individual saleable unit, typically represented by barcodes, QR codes, or RFID tags. This process of product serialization is essential for enhancing item visibility and traceability within supply chains, which is crucial for maintaining item integrity and adhering to regulatory standards. By adopting a systematic approach, companies can efficiently monitor the movement of products from manufacturing through distribution, ensuring accountability at every stage of the product's journey.

The importance of organizing data is underscored by the Drug Supply Chain Security Act (DSCSA) in the U.S. and the Falsified Medicines Directive (FMD) in the EU, both of which mandate product serialization through unique identifiers for each medicine package. These regulations not only facilitate compliance but also empower companies to utilize product serialization to combat counterfeit drugs—an issue that costs the global pharmaceutical industry billions annually. Notably, the worldwide pharmaceutical tracking market was valued at US$ 15.1 billion in 2022 and is projected to exceed US$ 24.8 billion by 2031, highlighting the growing significance of tracking in the industry.

A case study on enhancing demand management illustrates how product serialization provides brand owners with timely tracking history, which enables quicker identification of shortages and more effective inventory management. This results in improved stock levels and fewer instances of bare shelves, ultimately boosting customer satisfaction. The cost of converting cartoning lines to the item level can range from $47,000 to $268,000, underscoring the financial implications of implementing this process.

Experts in the field emphasize that efficient product serialization enhances logistics visibility, allowing for real-time tracking and improved decision-making. As Rohit Bhamburkar notes, "Ongoing innovation and advancements in track and trace technology will continue to transform business automation and logistics processes." Embracing structured data formats can serve as a transformative differentiator in supply chain management, unveiling numerous advantages that remain untapped for many companies.

Trace the Evolution of Product Serialization in Supply Chain Practices

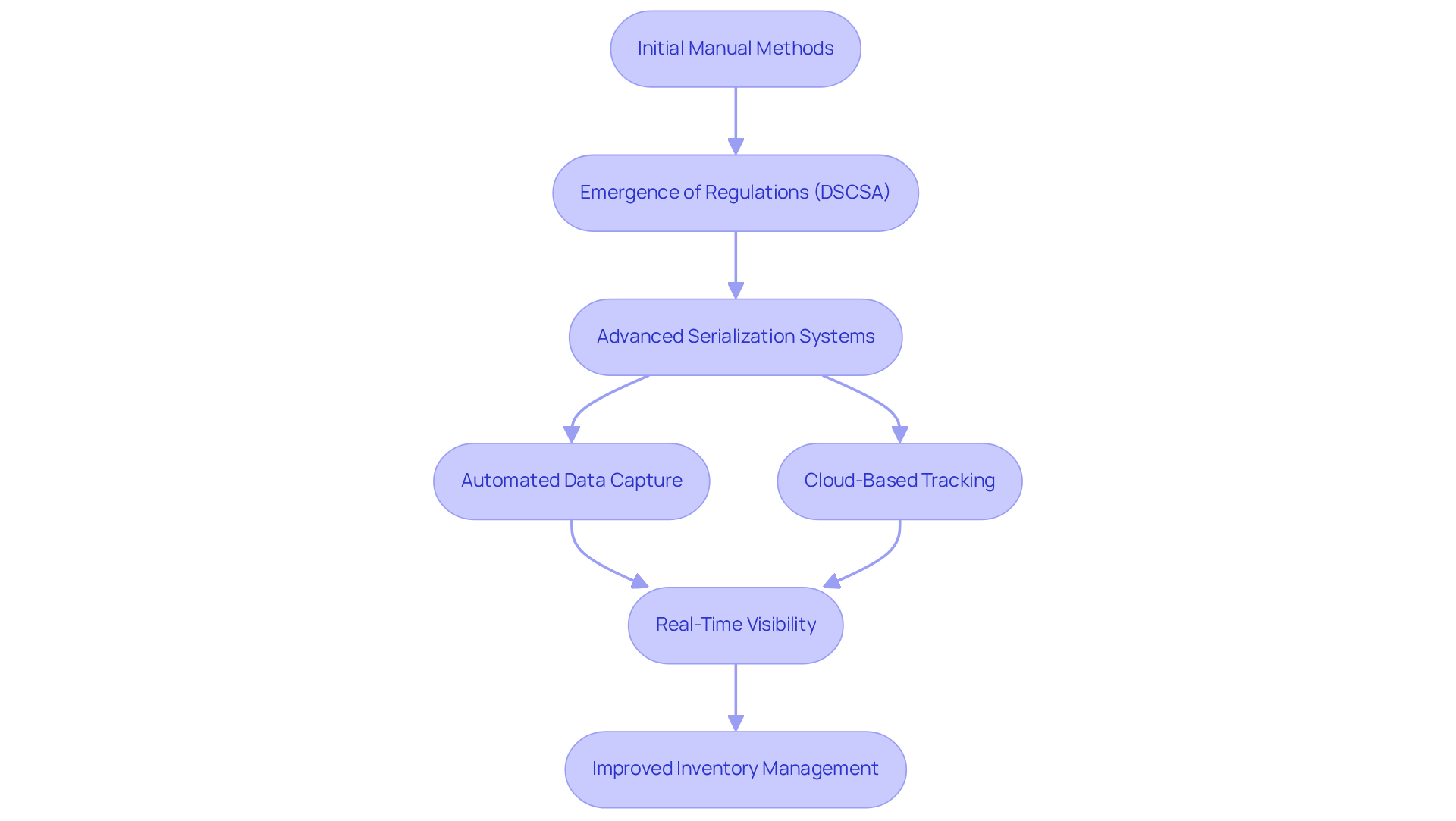

The development of product serialization has been marked by significant advancements aimed at enhancing traceability and compliance, particularly within the pharmaceutical sector. Initially, organizing data relied heavily on manual methods and basic labeling techniques. However, the emergence of stringent regulations, such as the Drug Supply Chain Security Act (DSCSA) in the United States, has prompted the creation of sophisticated product serialization systems.

Today, these systems utilize advanced technologies, including automated data capture and cloud-based tracking, which enable real-time visibility and improved inventory management. Product serialization not only enhances item visibility but also facilitates better handling of returns by tracking each item’s journey throughout the logistics network.

This transition underscores a growing focus on digitization and data-driven decision-making in supply chain management, highlighting the industry's commitment to combating counterfeit products and significantly mitigating the risk of such items entering the market. Furthermore, the implementation of data encoding provides a competitive advantage by demonstrating a commitment to quality and safety, thereby enhancing brand reputation.

As a result, the global pharmaceutical tracking market is projected to reach USD 29.35 billion by 2030, growing at a compound annual growth rate (CAGR) of 12.28% from 2025 to 2030, driven by increasing regulatory demands and technological innovations.

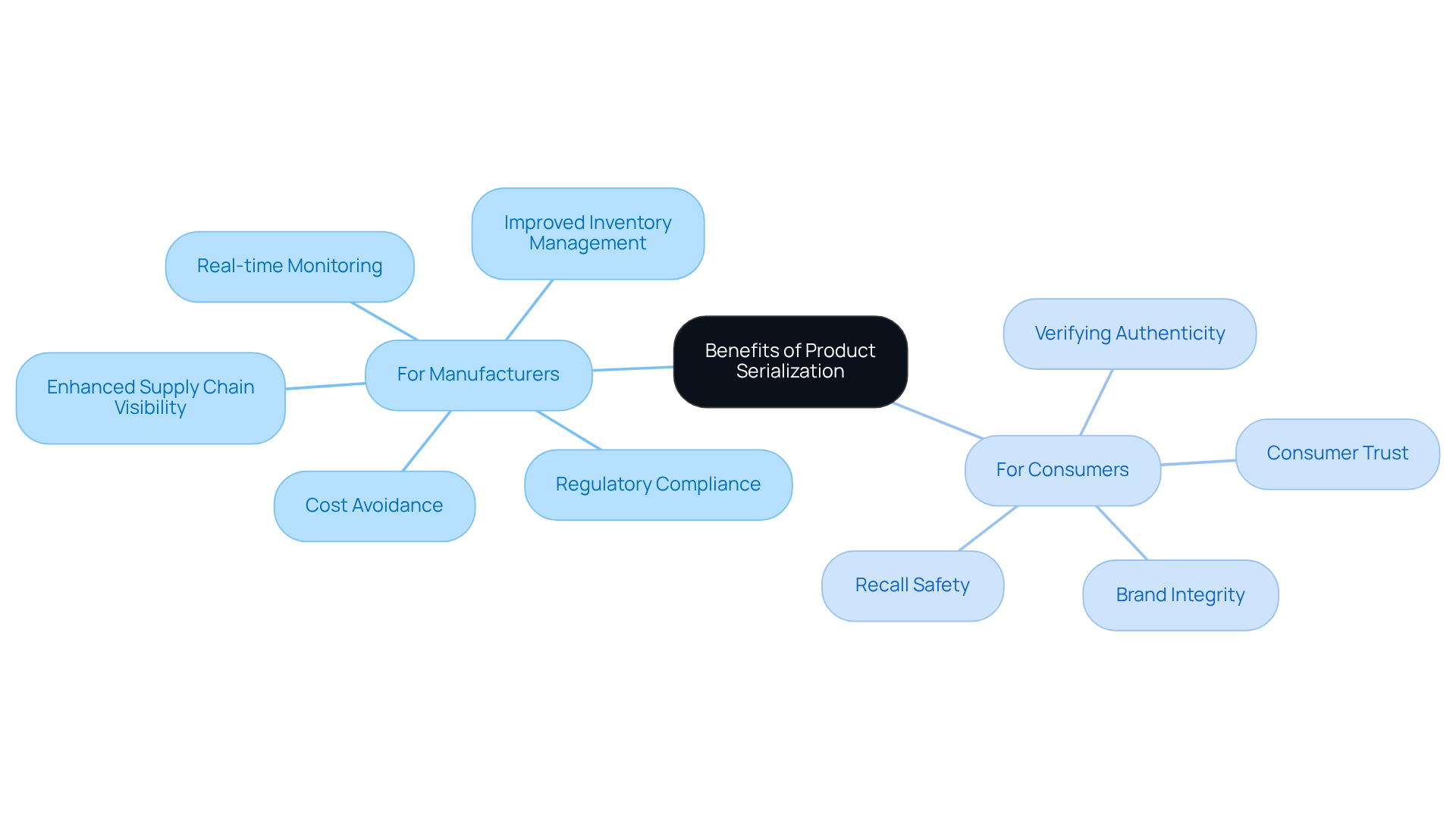

Examine the Benefits of Product Serialization for Manufacturers and Consumers

Product serialization provides significant advantages for both producers and buyers. For manufacturers, it enhances supply chain visibility, facilitating improved inventory management and minimizing the risks associated with stockouts and overstock situations. Businesses that implement item tracking can monitor inventory levels in real-time, which is crucial for accurate demand forecasting and operational efficiency. Furthermore, the data organization process aids in regulatory compliance, as mandated by laws such as the Drug Supply Chain Security Act (DSCSA) in the United States, helping companies avoid costly fines related to non-compliance.

From the consumer's perspective, product serialization serves as a vital tool for verifying authenticity, greatly enhancing trust in the brand. Product serialization empowers consumers to confirm the legitimacy of their purchases, fostering a sense of safety and assurance. Additionally, the ability to quickly identify and remove affected items during recall processes enhances consumer safety, ensuring that only safe products reach the market. Product serialization not only strengthens brand integrity and anti-counterfeiting measures but also further solidifies consumer trust.

Case studies underscore the effectiveness of data organization in cultivating consumer trust. For example, companies that have adopted product serialization report increased customer satisfaction due to the transparency it provides. A notable case study on 'Enhanced Consumer Trust and Satisfaction' illustrates how enabling consumers to verify authenticity through simple scans bolsters brand reputation and nurtures loyalty.

In summary, product tracking not only streamlines inventory management for manufacturers but also cultivates a more transparent and trustworthy relationship with consumers, benefiting all parties involved in the logistics.

Outline the Key Components and Implementation Strategies for Product Serialization

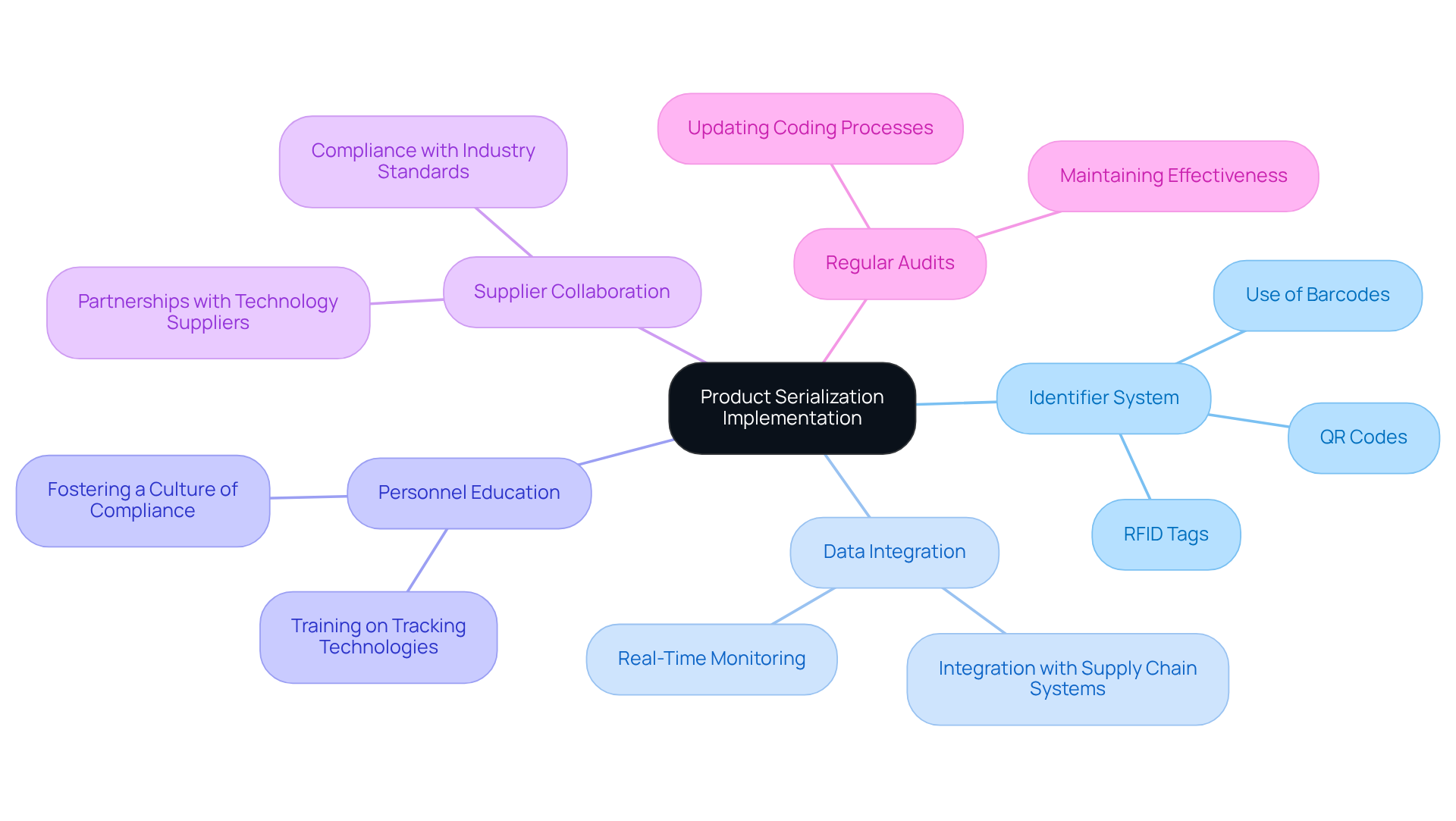

Implementing item tracking necessitates a strategic approach encompassing several crucial elements. Firstly, establishing a distinct identifier system is essential; this may involve the use of barcodes, QR codes, or RFID tags, enabling precise tracking and verification throughout the logistics network. Additionally, integrating data encoding with current supply chain management systems is vital for ensuring seamless information exchange and real-time monitoring of products. Educating personnel on the significance of item tracking and the operation of related technologies is also critical, as it fosters a culture of adherence and efficiency.

Moreover, collaborating with technology suppliers specializing in tracking solutions can enhance compliance with industry standards and regulations. Regular audits and updates to the coding process are necessary to maintain its effectiveness and adapt to evolving regulatory landscapes. For instance, a case study highlighted that companies employing robust tracking systems experienced improved supply chain visibility and operational efficiency, ultimately reducing the risks associated with counterfeit products.

The pharmaceutical tracking market is projected to grow significantly, reaching USD 24.8 billion by 2031, driven by stringent regulations such as the Drug Supply Chain Security Act (DSCSA) and the Falsified Medicines Directive (FMD). The average cost per pack for tracking is estimated at 4.1 cents, with high-volume locations facing annual expenses of up to €4.5 million. Furthermore, the implementation of data integration has been shown to negatively impact Overall Equipment Effectiveness (OEE), creating operational challenges that organizations must navigate.

By adhering to these strategies, organizations can successfully implement serialization, leading to enhanced product integrity, compliance with regulatory requirements, and substantial operational benefits.

Conclusion

Product serialization stands as a critical pillar in modern supply chain management, providing unique identifiers to individual saleable units. This practice not only enhances visibility and traceability but also ensures compliance with stringent regulations, thereby safeguarding product integrity across the supply chain. By implementing effective serialization systems, companies can significantly improve their operational efficiency and bolster consumer trust.

Throughout this discussion, several key insights have been highlighted, including:

- The evolution of serialization practices driven by regulatory demands

- The tangible benefits for both manufacturers and consumers

- The strategic approaches required for successful implementation

Serialization mitigates risks associated with counterfeit products, enhances inventory management, and fosters transparency, ultimately leading to increased customer satisfaction.

As the landscape of product serialization continues to evolve, it is imperative for organizations to embrace these advancements. The ongoing integration of technology and data-driven decision-making not only strengthens compliance but also positions businesses to capitalize on the growing demand for secure and reliable supply chains. By prioritizing product serialization, companies can enhance their operational frameworks and build lasting relationships with consumers, ensuring a safer and more transparent marketplace.

Frequently Asked Questions

What is product serialization?

Product serialization involves assigning a unique identifier to each individual saleable unit, typically represented by barcodes, QR codes, or RFID tags.

Why is product serialization important in supply chains?

Product serialization enhances item visibility and traceability within supply chains, which is crucial for maintaining item integrity and adhering to regulatory standards.

What regulations mandate product serialization?

The Drug Supply Chain Security Act (DSCSA) in the U.S. and the Falsified Medicines Directive (FMD) in the EU mandate product serialization through unique identifiers for each medicine package.

How does product serialization help combat counterfeit drugs?

By utilizing unique identifiers, product serialization enables companies to track and verify the authenticity of medicines, addressing the issue of counterfeit drugs that costs the global pharmaceutical industry billions annually.

What is the projected growth of the pharmaceutical tracking market?

The worldwide pharmaceutical tracking market was valued at US$ 15.1 billion in 2022 and is projected to exceed US$ 24.8 billion by 2031.

How does product serialization improve inventory management?

Product serialization provides brand owners with timely tracking history, enabling quicker identification of shortages and more effective inventory management, which results in improved stock levels and customer satisfaction.

What are the financial implications of implementing product serialization?

The cost of converting cartoning lines to the item level can range from $47,000 to $268,000.

How does product serialization enhance logistics visibility?

Efficient product serialization allows for real-time tracking and improved decision-making within logistics processes.

What role does innovation play in product serialization?

Ongoing innovation and advancements in track and trace technology are expected to continue transforming business automation and logistics processes.