Overview

Roll packaging plays a pivotal role in the nutraceutical sector, ensuring product safety, extending shelf life, and enhancing market visibility through appealing designs. This assertion is supported by an exploration of various roll packaging materials—plastic, paper, foil, and laminated stocks—each tailored to meet specific product requirements. Furthermore, these materials comply with regulatory standards, which is essential for maintaining consumer trust and upholding product integrity. By prioritizing quality in roll packaging, businesses can effectively safeguard their products and strengthen their market presence.

Introduction

Roll packaging has emerged as a cornerstone in the nutraceutical industry, revolutionizing the presentation and preservation of dietary supplements. This innovative packaging solution not only enhances product safety and shelf life but also addresses the growing consumer demand for visually appealing and eco-friendly options.

However, as the market expands and regulations tighten, manufacturers encounter the challenge of balancing efficiency, compliance, and sustainability. What are the key types of roll packaging available, and how can they be leveraged to meet both consumer expectations and industry standards?

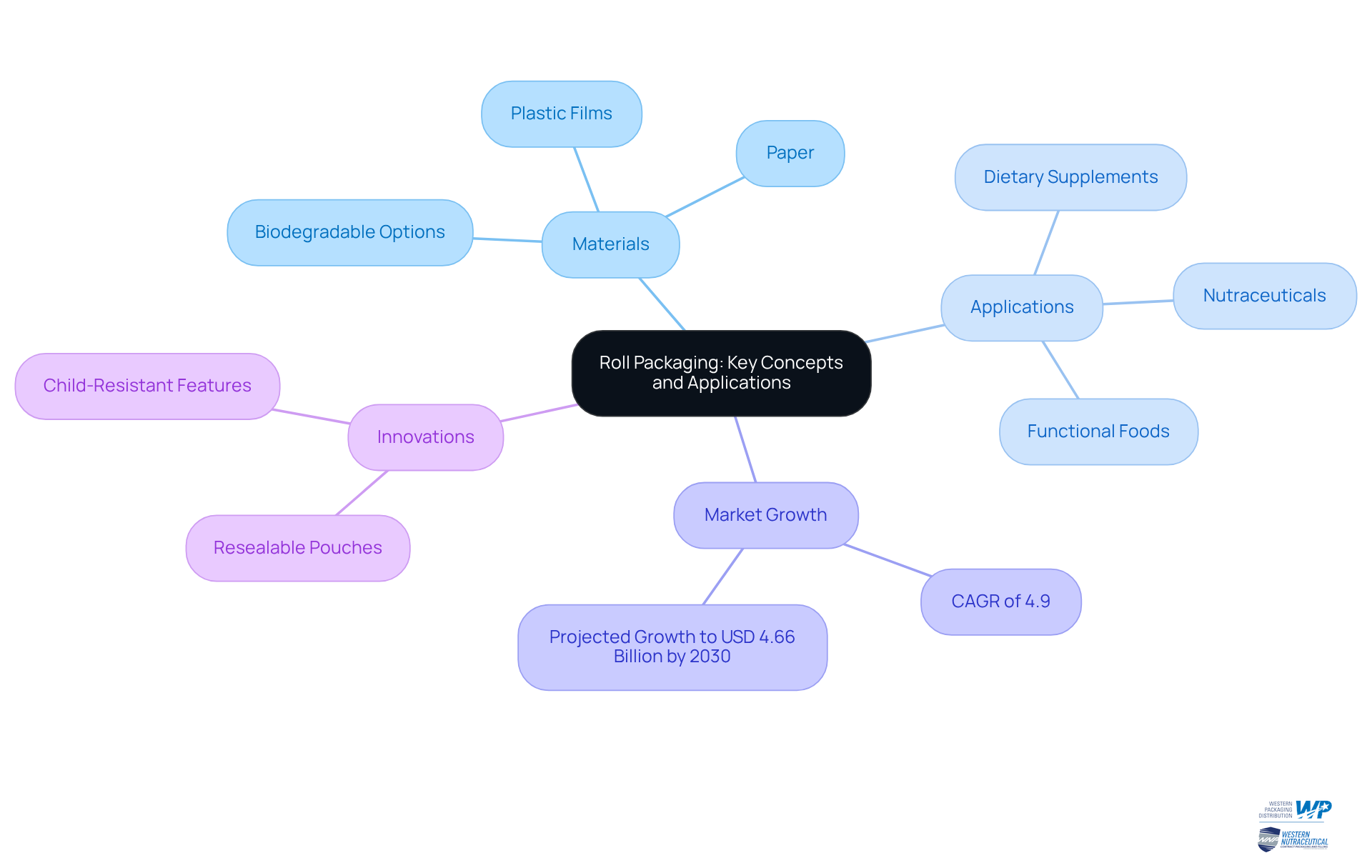

Define Roll Packaging: Key Concepts and Applications

Flexible wrapping is a versatile solution crafted in large coils of material, ideal for continuously enclosing items. This wrapping technique proves particularly advantageous in the dietary supplement industry, where it is frequently employed for products such as powders, capsules, and gummies. Constructed from materials like plastic films and paper, stock material provides essential barriers against moisture, oxygen, and light, ensuring the integrity of health products is preserved.

The widespread application of roll packaging significantly enhances production efficiency, markedly reducing waste and costs associated with materials. For instance, the health product container market is projected to grow from USD 3.52 billion in 2024 to USD 4.66 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.9%. This growth is fueled by increasing consumer demand for dietary supplements and functional foods, which often require specialized solutions.

At Western Packaging, we offer tailored flexible solutions, including large pouches for protein products and stick packs for nutraceuticals, designed to boost product appeal and meet the unique needs of nutraceutical manufacturers. Our effective wrapping solutions for powders and gummies feature innovations such as resealable pouches and child-resistant characteristics, addressing both safety and convenience. As sustainability becomes more critical, manufacturers are increasingly adopting biodegradable and recyclable materials in their wraps, aligning with consumer preferences for eco-friendly options. In summary, roll packaging emerges as a flexible and effective choice in the dietary supplement sector, supporting both product integrity and market growth.

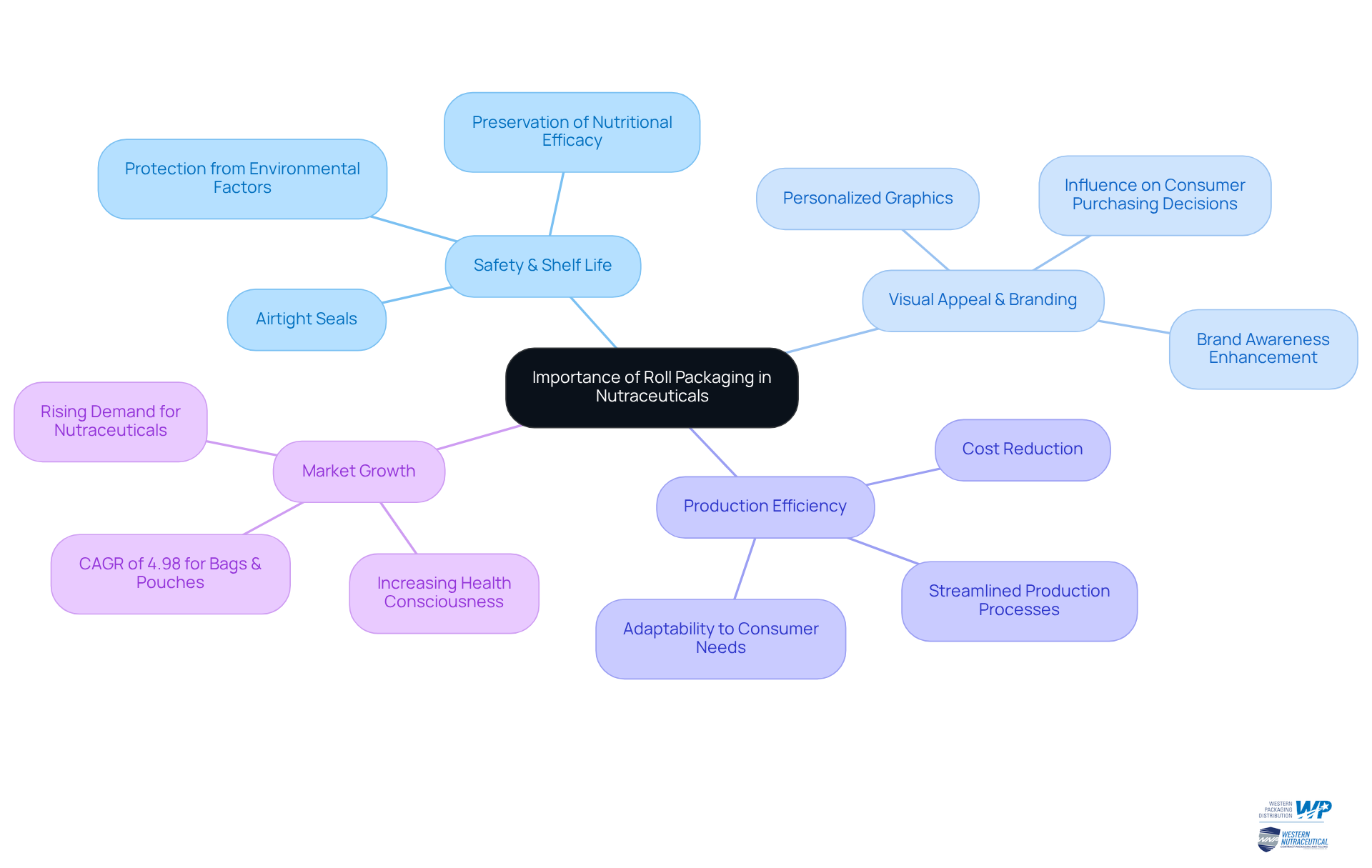

Explore the Importance of Roll Packaging in Nutraceuticals

In the nutraceutical sector, the importance of roll packaging lies mainly in ensuring item safety and extending shelf life. Its adaptable design facilitates the creation of airtight seals in roll packaging, effectively safeguarding products from environmental factors that could compromise their quality. This protective feature is indispensable, as nutritional items often necessitate stringent roll packaging to maintain their efficacy.

Additionally, the visual appeal of the wrap plays a vital role in a competitive market; it allows for personalized graphics and branding that enhance brand awareness and influence consumer purchasing decisions. Western Packaging offers a diverse array of stock solutions, including large pouches for protein products and stick packs for nutraceuticals, catering to various consumer needs.

The efficiency of cylindrical wrapping processes not only streamlines production but also reduces costs, making it an attractive option for manufacturers. As consumer preferences increasingly lean toward visually appealing and functional containers, health supplement brands are adopting roll packaging as a strategic choice to bolster item safety and market visibility.

Notably, the bags and pouches category is projected to grow at a CAGR of 4.98% during the forecast period, underscoring the shift towards effective containment solutions that Western Packaging can provide.

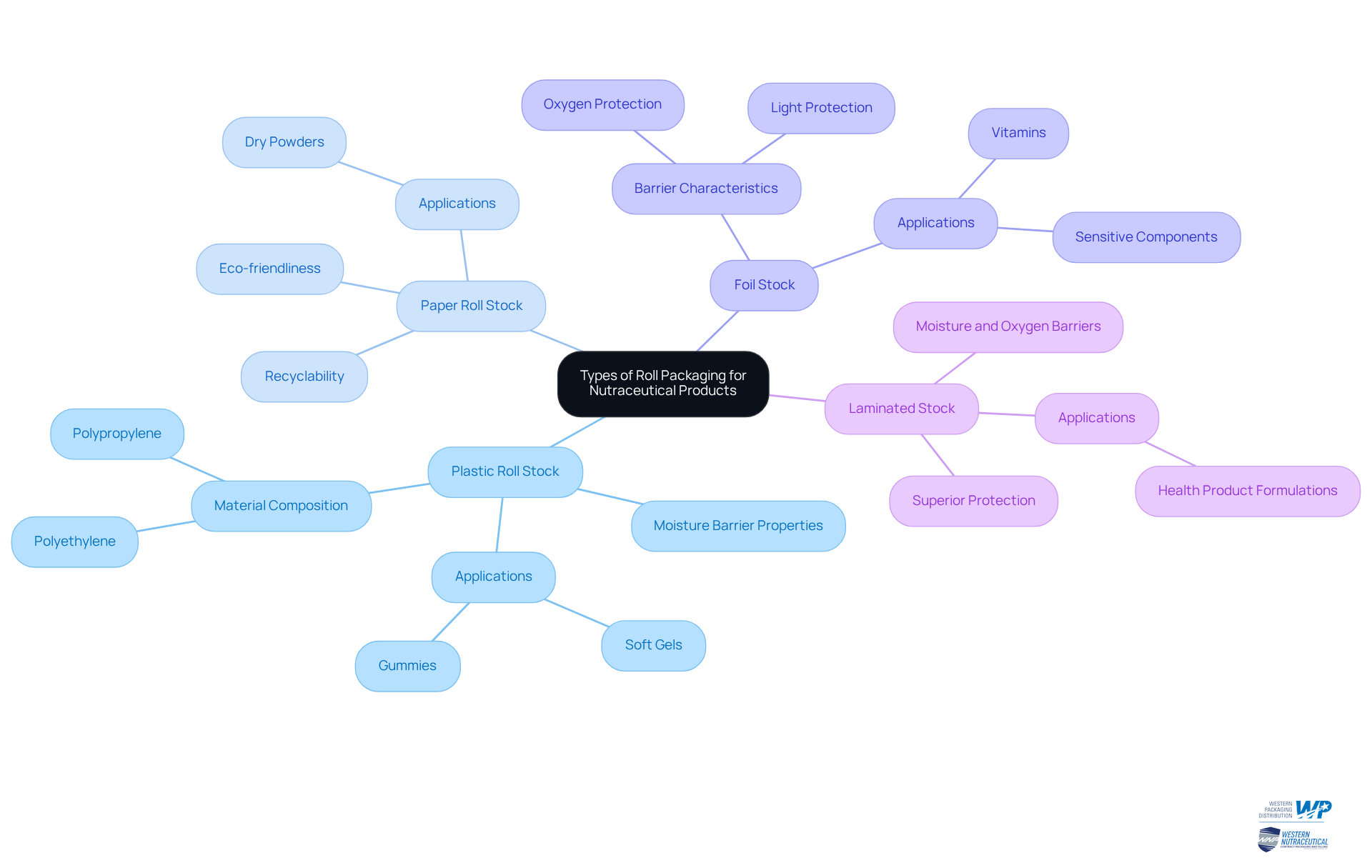

Identify Types of Roll Packaging: Options for Nutraceutical Products

In the nutraceutical sector, various forms of roll packaging are utilized, each tailored to meet specific product requirements. The primary types include:

-

Plastic Roll Stock: Renowned for its moisture barrier properties, plastic roll stock is particularly effective for packaging gummies and soft gels. Typically made from lightweight and flexible materials such as polyethylene or polypropylene, it ensures product integrity while enhancing shelf life. As the nutraceutical container market is projected to grow from USD 3.27 billion in 2023 to USD 5.07 billion by 2032, the demand for effective plastic solutions is expected to rise.

-

Paper Roll Stock: This option is commonly employed for dry powders and can be coated to improve its barrier capabilities. Its eco-friendliness and recyclability make it a favored choice for manufacturers seeking to align with sustainable practices, reflecting the increasing consumer preference for environmentally friendly solutions.

-

Foil Stock: With outstanding barrier characteristics against light and oxygen, foil stock is perfect for delicate nutraceuticals that require extended shelf life. This form of packaging is essential for preserving the effectiveness of vitamins and other sensitive components, meeting the industry's demand for dependable item protection.

-

Laminated Stock: By combining multiple materials, laminated stock offers superior protection, making it suitable for items that require both moisture and oxygen barriers. This versatility is crucial for maintaining the stability of different health product formulations.

Each type of roll packaging serves unique needs, allowing producers to select the most suitable option based on their specific product specifications. The increasing demand for efficient and eco-friendly container solutions in the dietary supplement industry underscores the importance of understanding these alternatives.

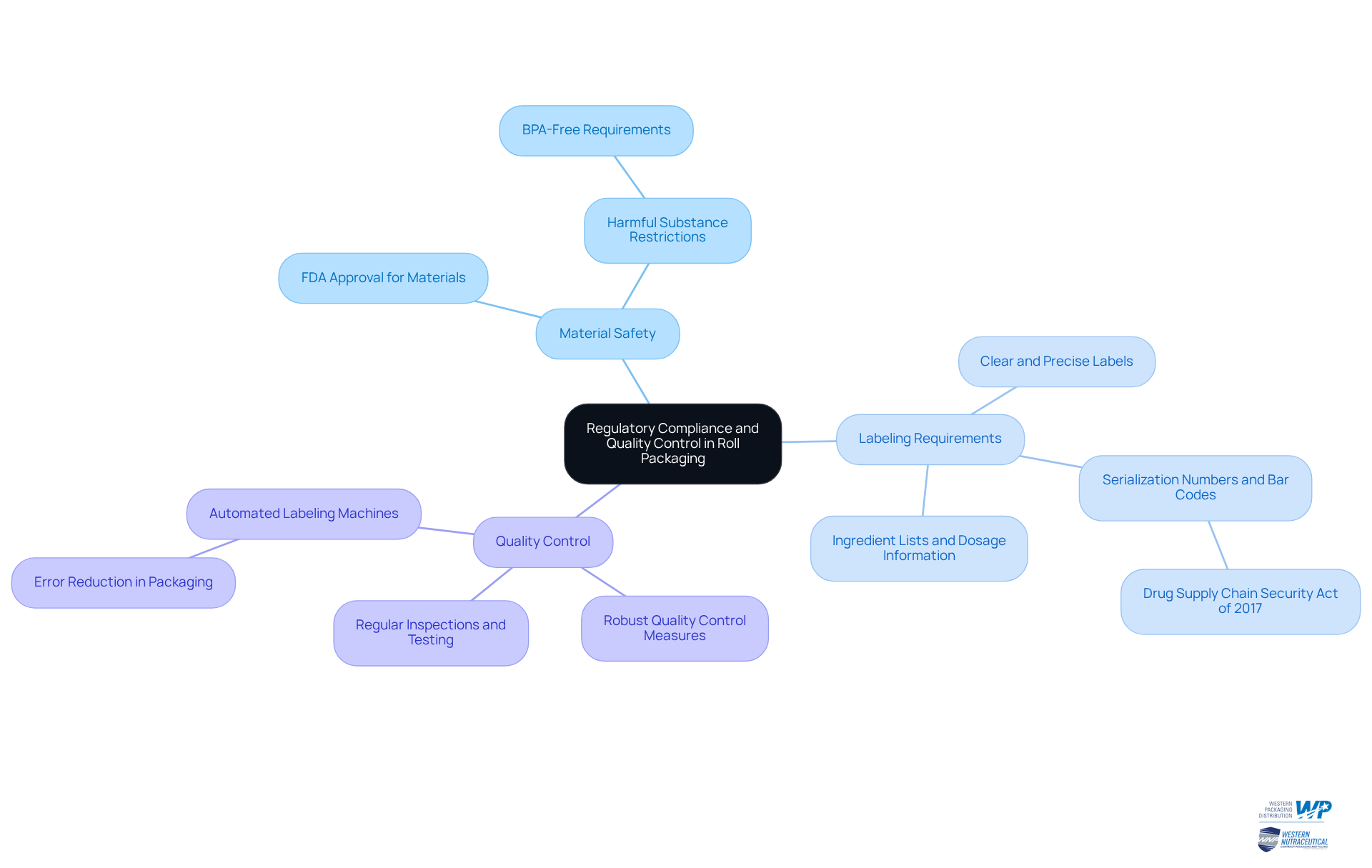

Examine Regulatory Compliance and Quality Control in Roll Packaging

Regulatory compliance is paramount in roll packaging within the nutraceutical industry. Manufacturers are required to follow stringent guidelines established by the FDA, which outline safety and labeling standards for dietary supplements. Key considerations include:

- Material Safety: All packaging materials must be FDA-approved and devoid of harmful substances, such as BPA, to safeguard consumer health.

- Labeling Requirements: Nutraceutical items must display clear and precise labels that comply with regulatory standards, including comprehensive ingredient lists, dosage information, and substantiated health claims. The Drug Supply Chain Security Act of 2017 mandates unique serialization numbers and bar codes for prescription drugs, enhancing traceability and compliance.

- Quality Control: Implementing robust quality control measures throughout the wrapping process is vital for maintaining product integrity. This includes regular inspections and testing of container materials to ensure compliance with safety and quality standards. Automated labeling machines can significantly reduce errors in packaging, further supporting quality control efforts.

By prioritizing regulatory adherence and rigorous quality assurance, manufacturers can enhance consumer confidence and ease the successful market introduction of their nutraceutical offerings. Given that the FDA estimates there are over 85,000 dietary supplement products currently available in the U.S., the stakes for compliance are high, as non-compliance can lead to fines, recalls, or damage to a brand's reputation.

Conclusion

Roll packaging emerges as a pivotal component in the nutraceutical industry, offering manufacturers flexible solutions that ensure product safety while enhancing marketability. This innovative packaging method not only safeguards the integrity of health products but also caters to consumer preferences for visually appealing and eco-friendly options. The versatility of roll packaging accommodates a range of materials and designs, addressing the distinct needs of various nutraceutical products.

Key aspects of roll packaging have been examined, including:

- Its significance in maintaining shelf life

- The diverse types available—such as plastic, paper, foil, and laminated stock

- The essential role of regulatory compliance in ensuring consumer safety

Insights indicate that as the demand for dietary supplements escalates, so too does the necessity for effective and sustainable packaging solutions that align with both market and regulatory standards.

In light of these considerations, it is imperative for manufacturers to prioritize innovative roll packaging strategies that not only adhere to regulations but also resonate with consumer expectations. By embracing the latest trends in roll packaging, brands can significantly influence product success in the nutraceutical market, ensuring that health products remain safe, effective, and appealing to consumers. The pursuit of excellence in packaging is a continuous journey, and staying abreast of advancements in roll packaging will be crucial for any brand striving to excel in this competitive landscape.

Frequently Asked Questions

What is roll packaging?

Roll packaging is a flexible wrapping solution made in large coils of material, designed for continuously enclosing items, particularly in the dietary supplement industry.

What materials are commonly used in roll packaging?

Roll packaging is typically constructed from materials like plastic films and paper, which provide essential barriers against moisture, oxygen, and light.

How does roll packaging benefit the dietary supplement industry?

Roll packaging enhances production efficiency, reduces waste and costs, and helps preserve the integrity of health products such as powders, capsules, and gummies.

What is the projected growth of the health product container market?

The health product container market is projected to grow from USD 3.52 billion in 2024 to USD 4.66 billion by 2030, reflecting a compound annual growth rate (CAGR) of 4.9%.

What types of flexible solutions does Western Packaging offer?

Western Packaging offers tailored flexible solutions such as large pouches for protein products and stick packs for nutraceuticals, designed to enhance product appeal.

What innovations are included in roll packaging solutions for powders and gummies?

Innovations include resealable pouches and child-resistant features, which address safety and convenience for consumers.

How is sustainability addressed in roll packaging?

Manufacturers are increasingly adopting biodegradable and recyclable materials in their wraps to align with consumer preferences for eco-friendly options.

Why is roll packaging considered effective in the dietary supplement sector?

Roll packaging is effective because it supports product integrity while accommodating market growth and evolving consumer demands.