Overview

Package manufacturers are pivotal entities in the design, production, and supply of containers that not only protect but also promote products, all while ensuring compliance with industry standards.

Their critical role in the supply chain cannot be overstated, as they significantly impact logistics efficiency and product integrity.

Moreover, their commitment to integrating sustainability practices is essential for meeting the evolving demands of modern consumers.

By prioritizing these elements, package manufacturers not only enhance their service offerings but also position themselves as leaders in the industry.

Introduction

The realm of package manufacturing is integral to the complex network of supply chains, influencing aspects ranging from product protection to brand visibility. As industries progress, package manufacturers lead the charge, converting raw materials into innovative solutions that not only comply with regulatory standards but also address consumer demands for sustainability.

However, what challenges confront these manufacturers as they strive to balance efficiency, customization, and environmental responsibility? A thorough exploration of the multifaceted roles and historical evolution of package manufacturers unveils critical insights into their substantial impact on contemporary logistics and market dynamics.

Define Package Manufacturer: Core Functions and Responsibilities

An entity dedicated to creating materials and solutions for a diverse range of items is known as a package manufacturer. Their core functions encompass the design, production, and supply of containers that meet specific requirements for protection, branding, and compliance. This process involves transforming raw materials—such as paper, plastic, glass, or metal—into finished containers like boxes, bottles, and pouches.

Moreover, as a package manufacturer, Western Packaging often collaborates with clients to develop customized flexible solutions that enhance product attractiveness and functionality. For instance, Western Packaging specializes in tailored flexible solutions that preserve the integrity of dietary supplements while boosting brand recognition and shelf appeal. This approach ensures that the packaging aligns with the brand's identity and market demands, making it visually appealing to consumers.

Additionally, Western Packaging provides graphic assets, such as labels and brochures, to create a cohesive and captivating brand identity.

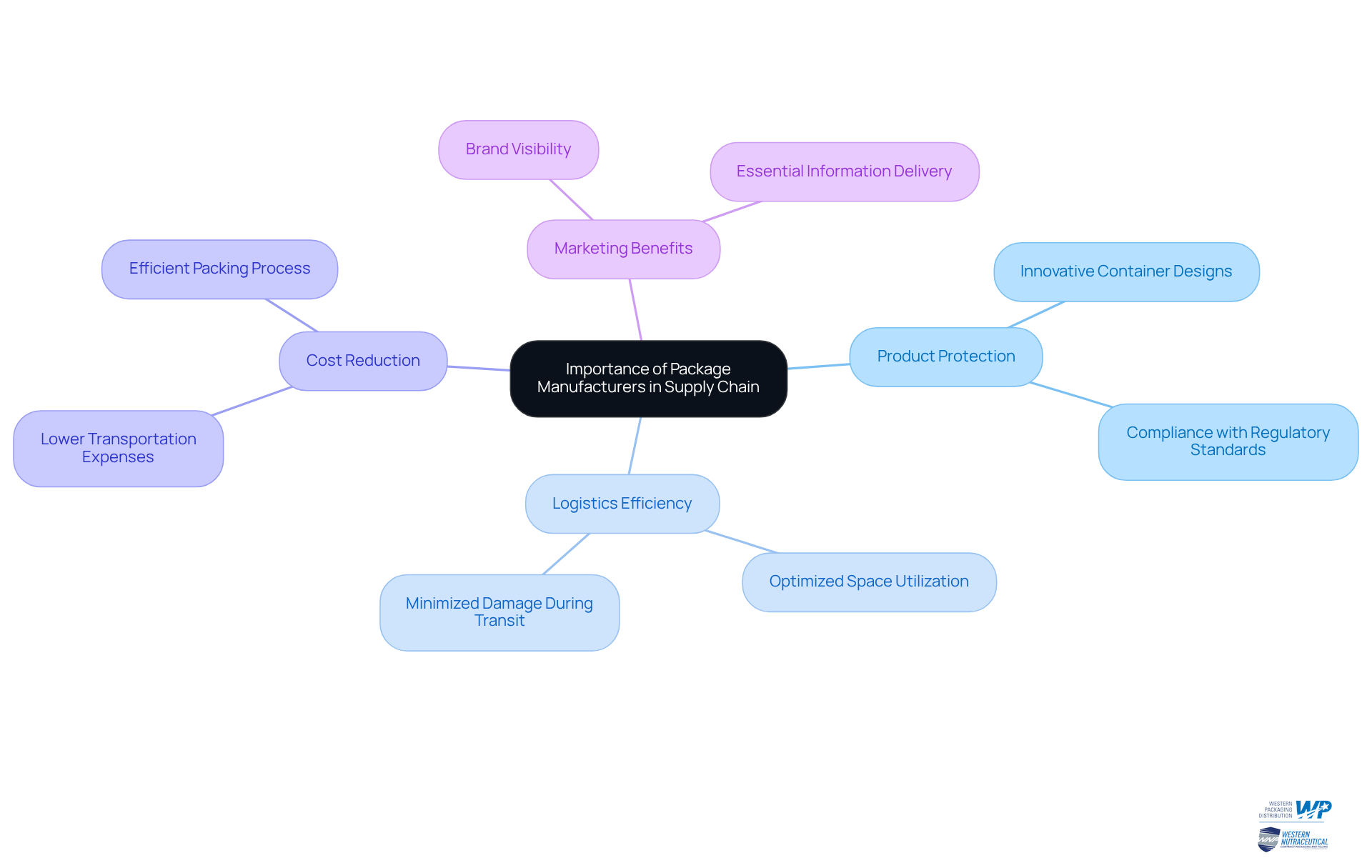

Explore the Importance of Package Manufacturers in Supply Chain Dynamics

The role of package manufacturers is pivotal in the supply chain, ensuring that products are adequately protected during transit and storage. Their innovative container designs not only optimize space but also minimize damage, significantly enhancing logistics efficiency and reducing waste.

For instance, well-crafted containers simplify the packing process, allowing for more efficient use of shipping boxes and ultimately lowering transportation expenses. Furthermore, effective wrapping acts as a marketing tool, delivering essential information while boosting brand visibility.

In sectors such as nutraceuticals, where product integrity is paramount, package manufacturers ensure their solutions comply with regulatory standards and resonate with health-conscious consumers. This commitment to quality and reliability makes them indispensable partners in the logistics landscape.

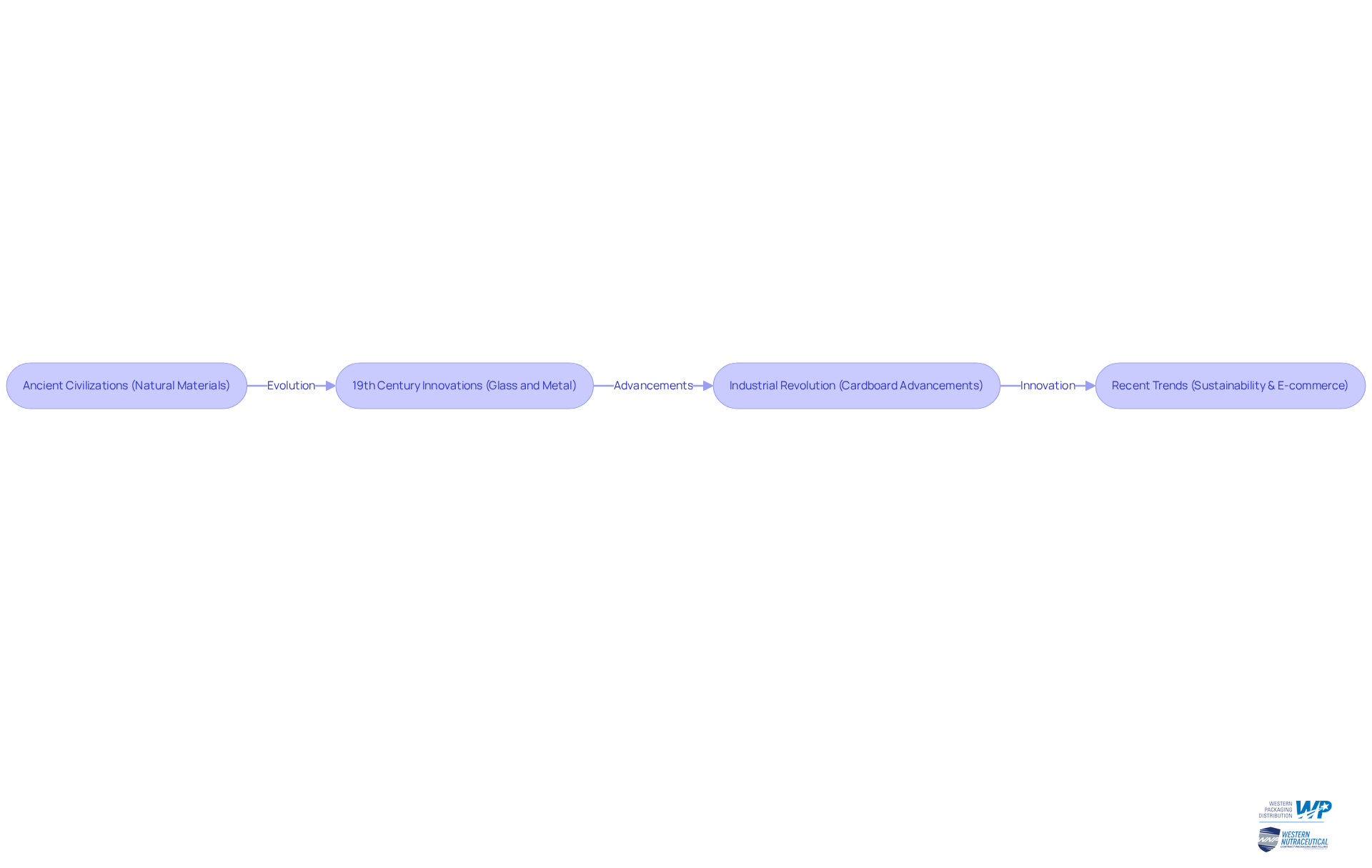

Trace the Evolution of Package Manufacturing: Historical Context and Trends

The evolution of package manufacturing can be traced back to ancient civilizations, where early humans used natural materials like leaves and animal skins as packaging to protect and transport food. As societies progressed, methods of containment developed, particularly with the introduction of materials such as glass and metal by package manufacturers in the 19th century.

The Industrial Revolution represented a significant turning point, resulting in mass production methods and advancements made by package manufacturers in cardboard containers. In recent decades, the rise of e-commerce and growing sustainability concerns have driven package manufacturers to innovate in packaging materials and designs, including biodegradable plastics and smart packaging technologies.

Today, product creators are at the forefront of integrating sustainability into their processes, effectively addressing consumer demand for eco-friendly solutions.

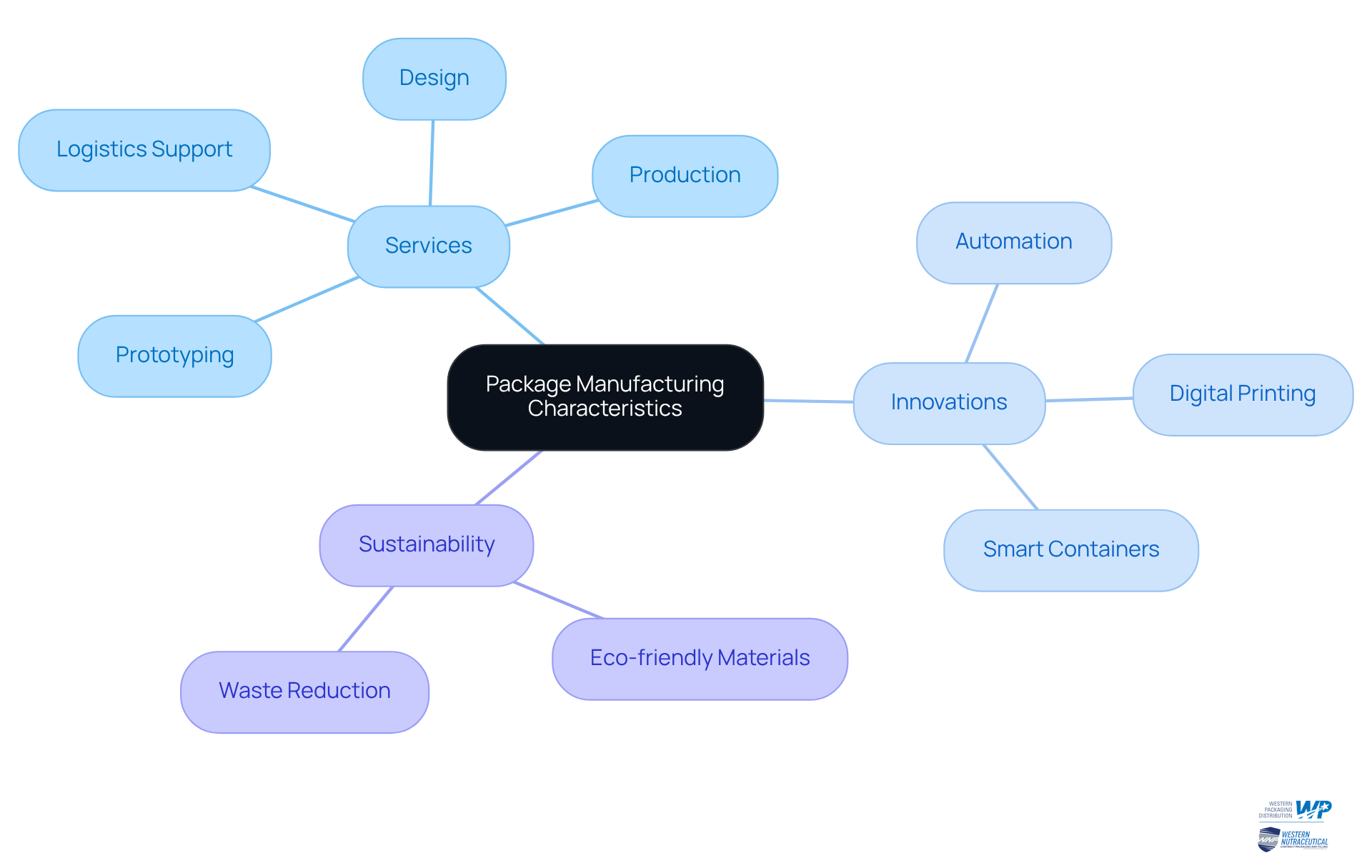

Examine Key Characteristics: Services and Innovations in Package Manufacturing

The key characteristics of package producers are their capacity to deliver a comprehensive array of services, encompassing design, prototyping, production, and logistics support. Many manufacturers are now leveraging advanced technologies, including automation and digital printing, to enhance both efficiency and customization capabilities. Noteworthy innovations, such as smart containers equipped with sensors and QR codes, facilitate improved tracking and foster consumer engagement.

Furthermore, a heightened focus on sustainability has spurred the development of eco-friendly materials and practices, such as the use of recycled content and the reduction of packaging waste. These characteristics not only bolster operational efficiency but also resonate with the increasing consumer preference for sustainable products, positioning package manufacturers as essential partners for businesses aiming to excel in today’s competitive market.

Conclusion

The role of package manufacturers is integral to the broader landscape of product distribution and branding. By focusing on the design, production, and supply of protective and appealing packaging solutions, these manufacturers not only enhance product integrity but also play a crucial role in shaping consumer perceptions and experiences.

Throughout the article, we have explored the multifaceted responsibilities of package manufacturers, highlighting their collaboration with clients for customized solutions, their impact on logistics efficiency, and their commitment to sustainability. Innovations in packaging materials and technologies, such as smart containers and eco-friendly practices, further underscore their significance in meeting modern consumer demands and regulatory standards.

As industries continue to evolve, the importance of package manufacturers will only grow. Embracing advancements in technology and sustainability will be key for businesses looking to thrive in a competitive market. Engaging with package manufacturers can lead to not just improved operational efficiency but also a stronger brand presence and a positive environmental impact, making them vital partners in today's supply chain dynamics.

Frequently Asked Questions

What is a package manufacturer?

A package manufacturer is an entity dedicated to creating materials and solutions for various items, focusing on the design, production, and supply of containers that meet specific requirements for protection, branding, and compliance.

What materials do package manufacturers typically use?

Package manufacturers typically use raw materials such as paper, plastic, glass, or metal to create finished containers like boxes, bottles, and pouches.

What are the core functions of a package manufacturer?

The core functions of a package manufacturer include designing, producing, and supplying containers that meet specific requirements for protection, branding, and compliance.

How does Western Packaging differentiate itself as a package manufacturer?

Western Packaging collaborates with clients to develop customized flexible solutions that enhance product attractiveness and functionality, while also ensuring the packaging aligns with the brand's identity and market demands.

What specific expertise does Western Packaging have?

Western Packaging specializes in tailored flexible solutions that preserve the integrity of dietary supplements while boosting brand recognition and shelf appeal.

Does Western Packaging provide additional services beyond packaging?

Yes, Western Packaging provides graphic assets, such as labels and brochures, to create a cohesive and captivating brand identity.