Overview

Aseptic filling stands as a pivotal packaging method for nutraceutical manufacturers, ensuring that dietary supplements remain devoid of harmful microorganisms. This process not only extends shelf life but also preserves product efficacy. The intricacies of aseptic filling involve the sterilization of both the product and its packaging within a meticulously controlled environment. Such measures significantly minimize contamination risks and guarantee compliance with stringent safety regulations. By implementing this specialized technique, manufacturers can confidently deliver high-quality supplements that consumers can trust.

Introduction

Aseptic filling stands as a pivotal process that guarantees the safety and efficacy of products within the nutraceutical and pharmaceutical industries, where sterility is non-negotiable. This specialized technique not only safeguards dietary supplements from harmful microorganisms but also significantly extends their shelf life, making it essential for manufacturers striving to meet stringent safety standards.

As the demand for high-quality nutraceuticals continues to rise, the pressing question emerges: how can companies effectively implement aseptic filling processes to adeptly navigate the complexities of contamination risks and regulatory compliance?

Define Aseptic Filling and Its Role in Manufacturing

What is aseptic filling? It represents a specialized method essential for the containment of items in the food and pharmaceutical sectors, where maintaining sterility is paramount.

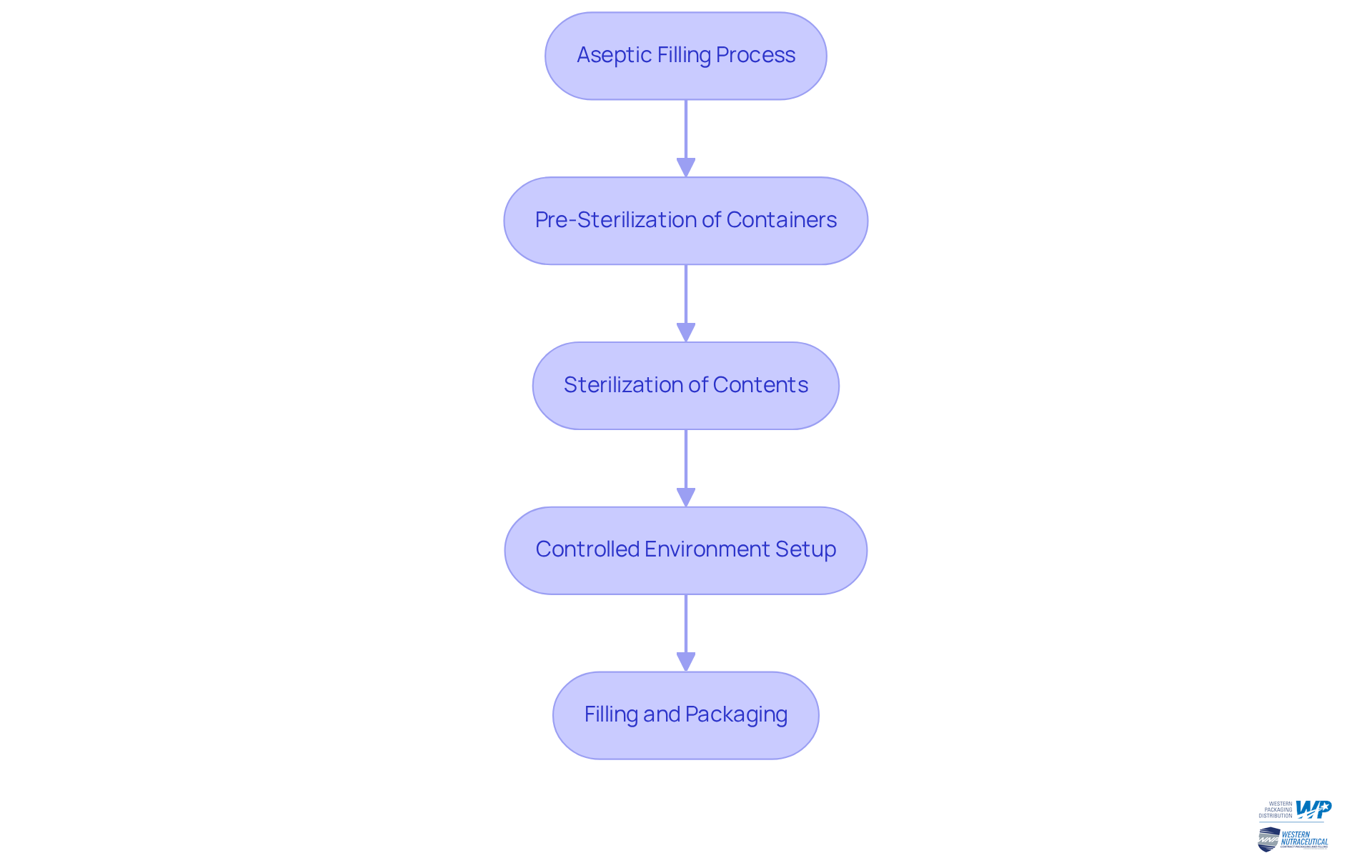

What is aseptic filling? This technique involves placing pre-sterilized containers with sterilized items in a controlled environment to prevent contamination.

For nutraceutical manufacturers, the sterile packaging process is vital as it ensures that dietary supplements and health products—such as powders, gummies, and soft-gels—remain free from harmful microorganisms. This not only extends shelf life but also preserves product efficacy.

By minimizing the risk of contamination, aseptic processes are crucial in safeguarding consumer safety and ensuring compliance with regulatory standards.

Furthermore, Western Packaging's integrated packaging solutions work in tandem with our comprehensive 3PL services, enhancing your supply chain management. Our end-to-end solutions streamline your production process, empowering you to concentrate on delivering high-quality nutraceutical products with efficiency.

Trace the History and Development of Aseptic Filling Techniques

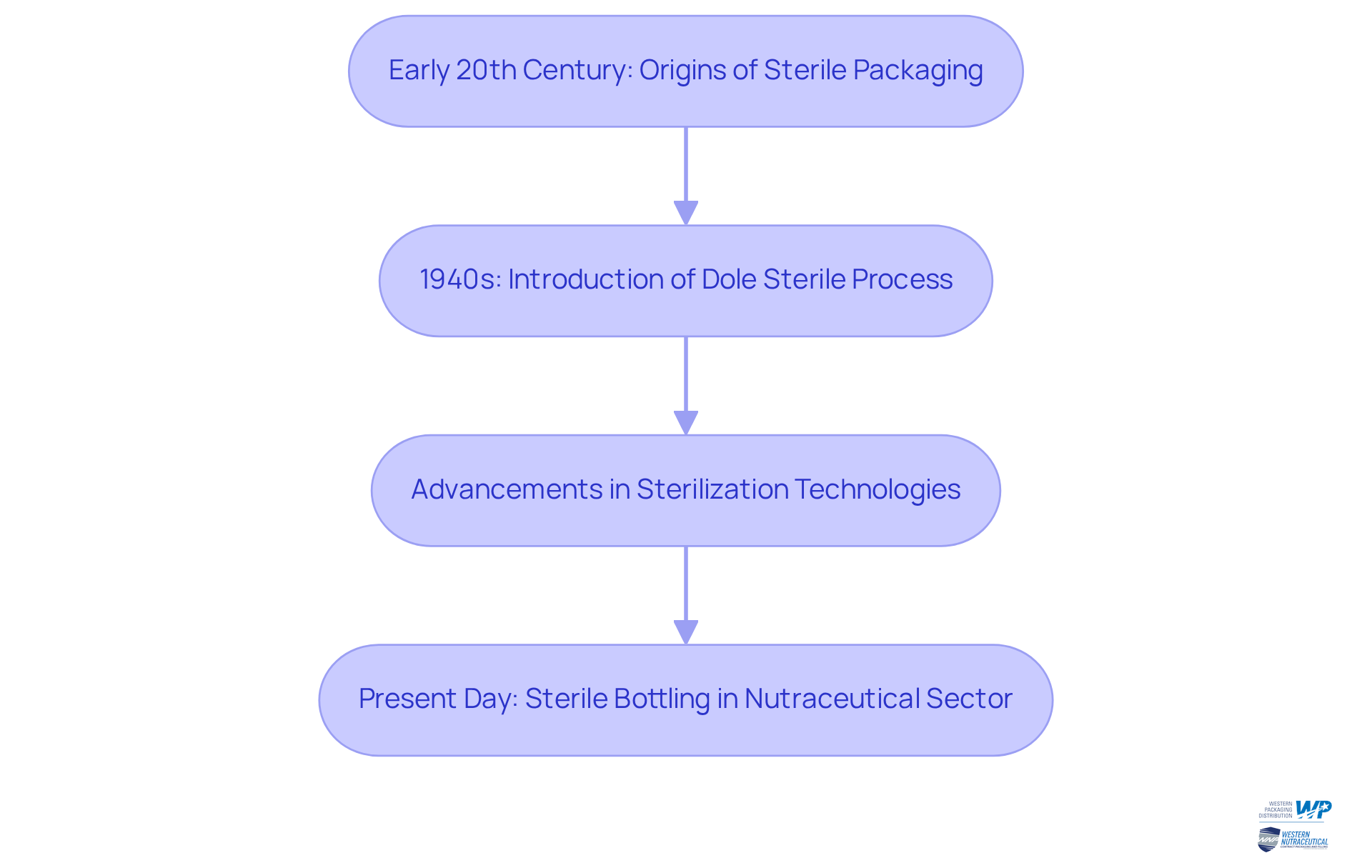

The origins of sterile packaging can be traced back to the early 20th century, when the need for hygienic containers became increasingly clear, particularly in response to contamination events within the medical sector.

The evolution of sterile techniques gained significant momentum in the 1940s, notably with the introduction of the Dole Sterile Process, which transformed food preservation methods.

Over the years, advancements in sterilization technologies, including steam and chemical methods, have substantially improved the efficiency and effectiveness of sterile packaging processes.

Today, sterile bottling is a prevalent practice in the nutraceutical sector, ensuring that products are packaged in a manner that upholds their safety and quality.

Identify Key Characteristics and Components of Aseptic Filling

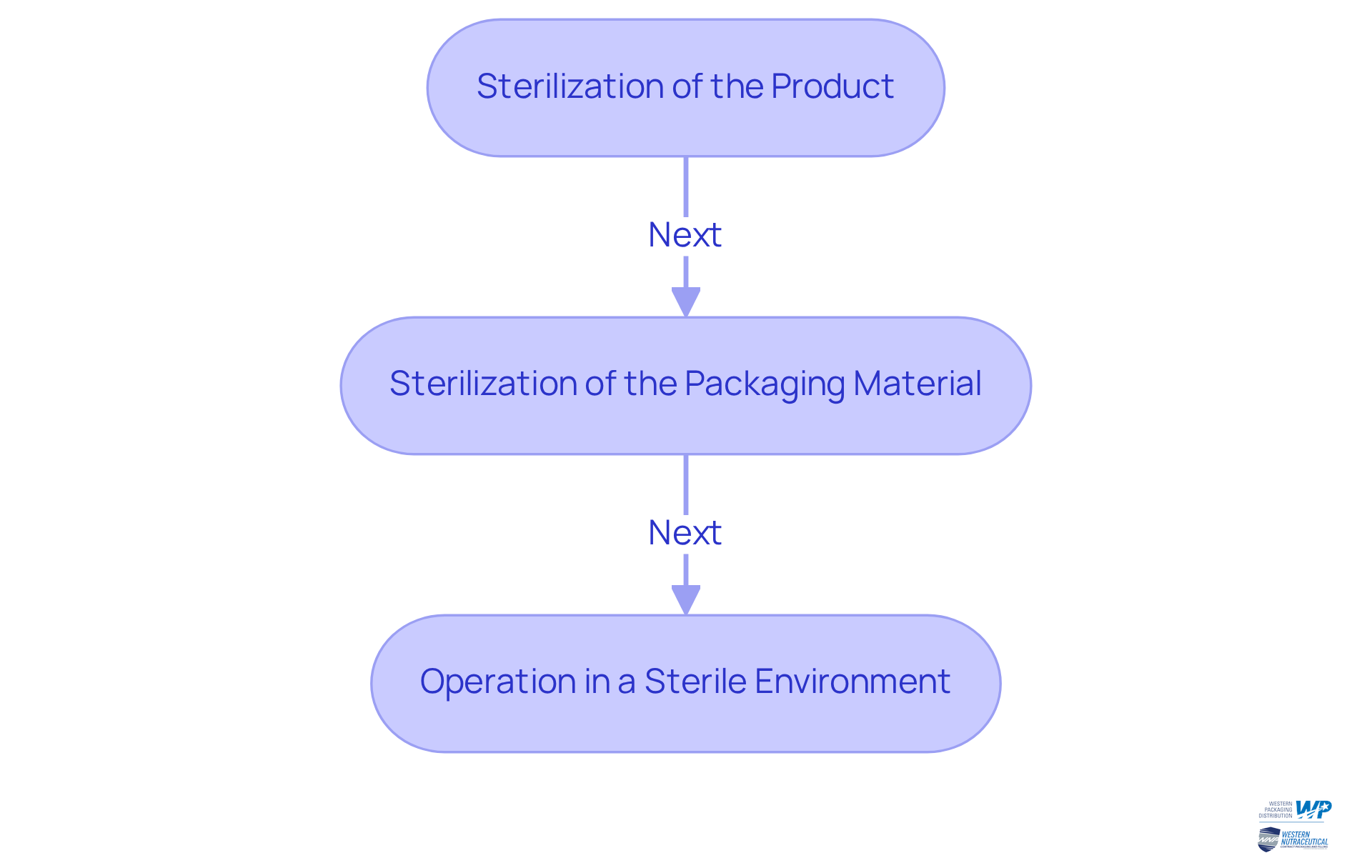

Essential traits of sterile packaging encompass the utilization of sterilized apparatus, regulated environments, and strict adherence to hygiene standards. The procedure fundamentally consists of three primary elements:

- The sterilization of the product

- The sterilization of the packaging material

- The operation itself, all conducted within a sterile setting

Devices such as sterile packaging machines, which leverage advanced technologies like isolators and Restricted Access Barrier Systems (RABS), play a vital role in preserving sterility. These machines are engineered to minimize human intervention, thereby significantly reducing the risk of contamination. Understanding these elements is imperative for nutraceutical producers aiming to implement effective practices, particularly in relation to what is aseptic filling.

Examine Applications of Aseptic Filling in Various Industries

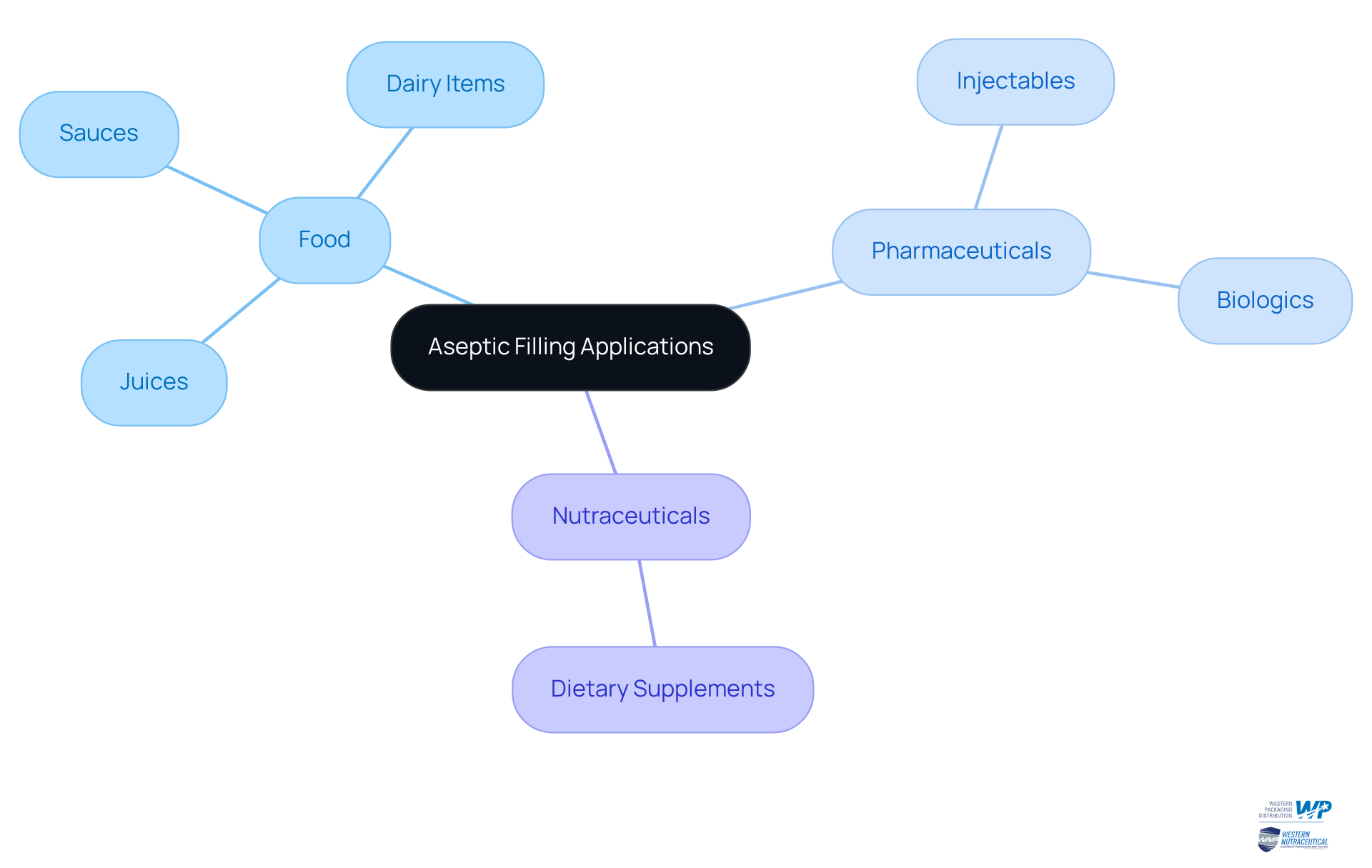

Aseptic packaging stands as a cornerstone in diverse sectors, including food, pharmaceuticals, and nutraceuticals. In the food industry, it is employed to package products such as juices, sauces, and dairy items, ensuring their safety and shelf stability without the need for preservatives. In pharmaceuticals, sterile packaging is crucial for injectables and biologics, where maintaining cleanliness is essential for patient safety. For nutraceutical manufacturers, sterile packaging allows for the secure wrapping of dietary supplements, ensuring that products retain their efficacy and are free from contamination. The adaptability of aseptic filling techniques highlights what is aseptic filling and renders them indispensable in any industry prioritizing product safety and quality.

Conclusion

Aseptic filling stands as a pivotal process, ensuring the safe packaging of nutraceutical products while preserving their integrity and sterility. This specialized technique not only protects against contamination but also prolongs the shelf life and efficacy of dietary supplements. For nutraceutical manufacturers, comprehending and executing aseptic filling processes is vital for compliance with industry regulations and for safeguarding consumer safety.

This article explores the historical evolution of aseptic filling, tracing its origins from the hygiene needs of the early 20th century to contemporary advancements in sterilization technologies. Key characteristics, such as the sterilization of both products and packaging materials, alongside the utilization of advanced machinery, are underscored as essential components of effective aseptic filling systems. The diverse applications of this technique across various sectors, including food and pharmaceuticals, highlight its indispensable role in upholding product quality and safety.

Ultimately, the importance of aseptic filling in nutraceutical manufacturing cannot be overstated. With the escalating demand for high-quality health products, manufacturers must prioritize sterile packaging solutions. By embracing aseptic filling, they not only enhance product safety but also cultivate consumer trust and satisfaction. Investing in robust aseptic processes enables nutraceutical producers to meet the highest standards of quality and efficacy in an increasingly competitive market.

Frequently Asked Questions

What is aseptic filling?

Aseptic filling is a specialized method used in the food and pharmaceutical sectors to contain items while maintaining sterility.

How does the aseptic filling process work?

The process involves placing pre-sterilized containers with sterilized items in a controlled environment to prevent contamination.

Why is aseptic filling important for nutraceutical manufacturers?

It is vital for ensuring that dietary supplements and health products, such as powders, gummies, and soft-gels, remain free from harmful microorganisms, extending shelf life and preserving product efficacy.

How does aseptic filling contribute to consumer safety?

By minimizing the risk of contamination, aseptic processes are crucial in safeguarding consumer safety and ensuring compliance with regulatory standards.

What additional services does Western Packaging offer related to aseptic filling?

Western Packaging provides integrated packaging solutions that work with comprehensive 3PL services to enhance supply chain management and streamline production processes for high-quality nutraceutical products.