Overview

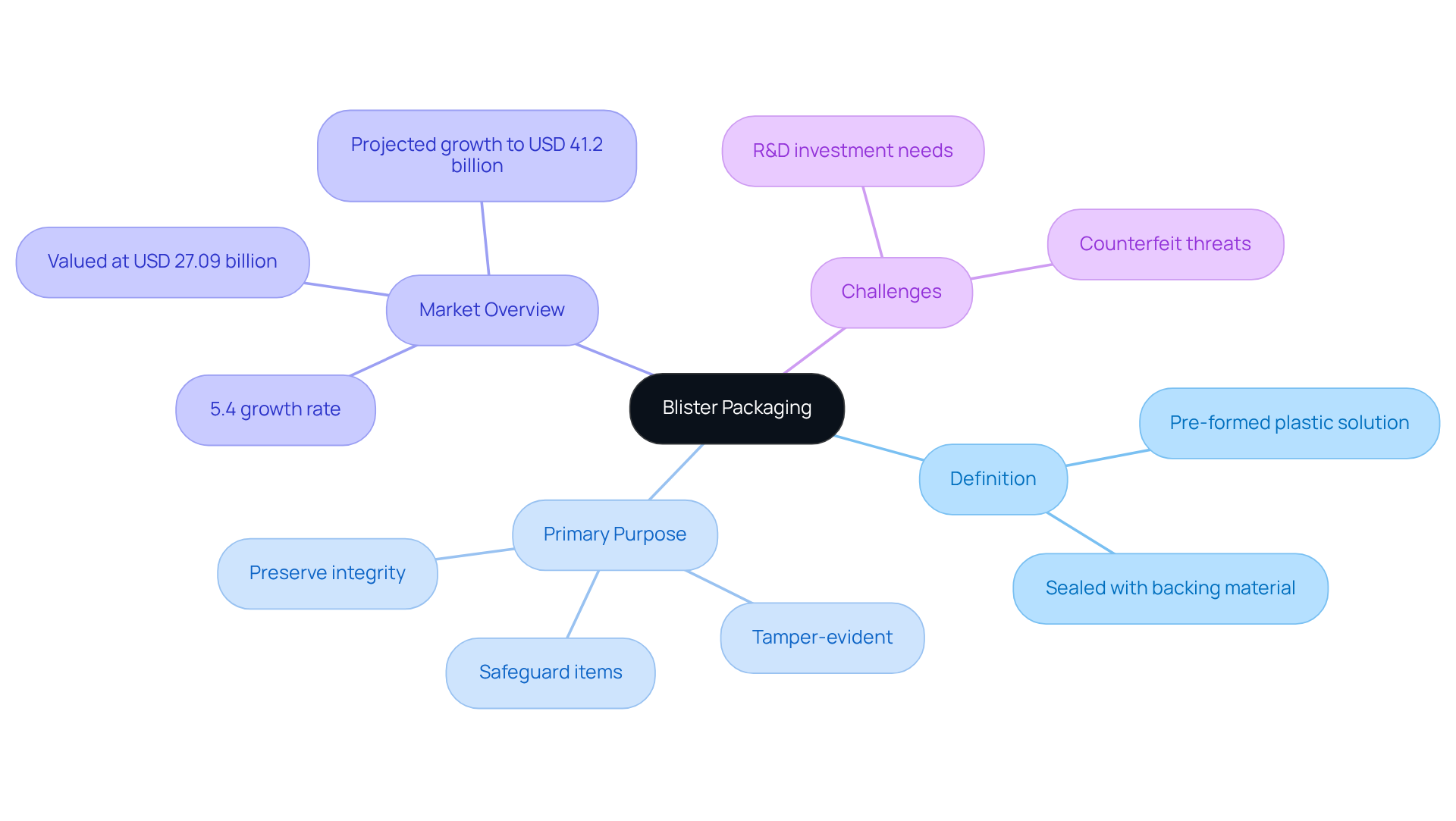

Blister packaging serves as a pre-formed plastic container meticulously designed to safeguard items, particularly within the pharmaceutical and nutraceutical sectors, from moisture, light, and contamination while ensuring tamper evidence. This article delves into its historical evolution, key components, and significant benefits. Notably, it emphasizes how blister packaging enhances product integrity and safety through advanced barrier properties and precise dosage management. Such features contribute to improved medication adherence and foster consumer trust, ultimately underscoring the critical role of blister packaging in modern logistics.

Introduction

Blister packaging is a vital safeguard for a variety of products, especially within the pharmaceutical and nutraceutical sectors, where the protection of items from moisture, light, and contamination is essential. This article explores the definition, historical evolution, and multiple advantages of blister packaging, demonstrating its role in enhancing product integrity and building consumer trust. As the market for blister solutions continues to grow, manufacturers face significant challenges in ensuring the effectiveness and security of their packaging, particularly in light of increasing concerns regarding counterfeit products and environmental sustainability.

Define Blister Packaging and Its Primary Purpose

What is blister packaging? It refers to blister containers, which represent a pre-formed plastic solution characterized by a cavity or pocket crafted from a formable web, typically plastic, and sealed with a backing material such as aluminum or paperboard. Their primary purpose is to safeguard items, particularly pharmaceuticals and nutraceuticals, from external factors like moisture, light, and contamination. This type of container establishes a secure, tamper-evident environment that preserves product integrity until it reaches the consumer. Commonly utilized for tablets, capsules, and other small objects, blister packaging is especially favored in the health and wellness industry.

In 2022, the protective wrap market was valued at approximately USD 27.09 billion, with significant growth projected to reach USD 41.2 billion by 2033. This expansion is driven by the increasing demand for secure wrapping solutions, with a forecasted growth rate of 5.4% from 2026 to 2033. Notably, medication packaging has been linked to a 30% increase in adherence rates among individuals managing chronic conditions, as reported by the CDC, underscoring their role in enhancing healthcare outcomes.

Furthermore, the use of sealed containers in nutraceuticals not only protects items but also extends their longevity and fosters buyer trust, establishing it as a vital option for producers in this sector. However, the blister wrapping market faces challenges, including the need for continuous investment in R&D and the threat of counterfeit medications, which manufacturers must navigate to maintain product integrity and consumer confidence.

Trace the History and Evolution of Blister Packaging

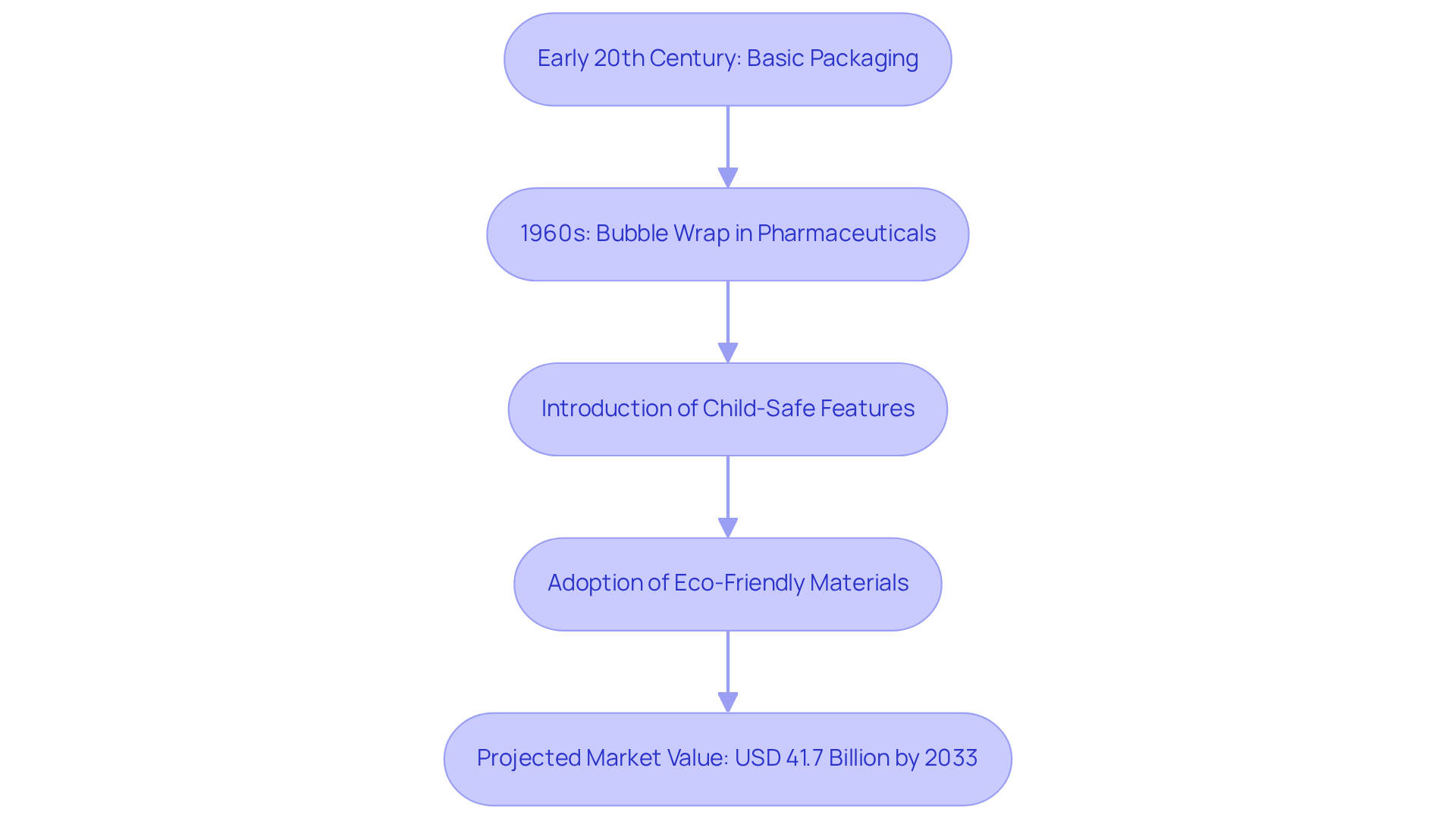

To understand what is blister packaging, one must look at its rich history, which traces back to the early 20th century when it primarily served to enclose small retail items. The initial technology was rudimentary, relying on simple plastic films and manual sealing processes. However, as the demand for advanced wrapping solutions surged, significant advancements in materials and manufacturing techniques emerged.

By the 1960s, bubble wrap gained widespread acceptance in the pharmaceutical sector, driven by the increasing demand for enhanced product security and consumer safety. Key milestones in this evolution include the introduction of child-safe features and the adoption of environmentally friendly materials, transforming container solutions into a versatile option across various sectors, particularly in nutraceuticals and pharmaceuticals, which raises the question of what is blister packaging.

Notably, statistics indicate that the sealed container market is projected to reach USD 41.7 billion by 2033, underscoring its vital role in improving medication adherence and safety. Continuous advancements in bubble wrap technology further influence its evolution, ensuring it meets the ever-changing requirements of the sector.

Identify Key Components and Materials in Blister Packaging

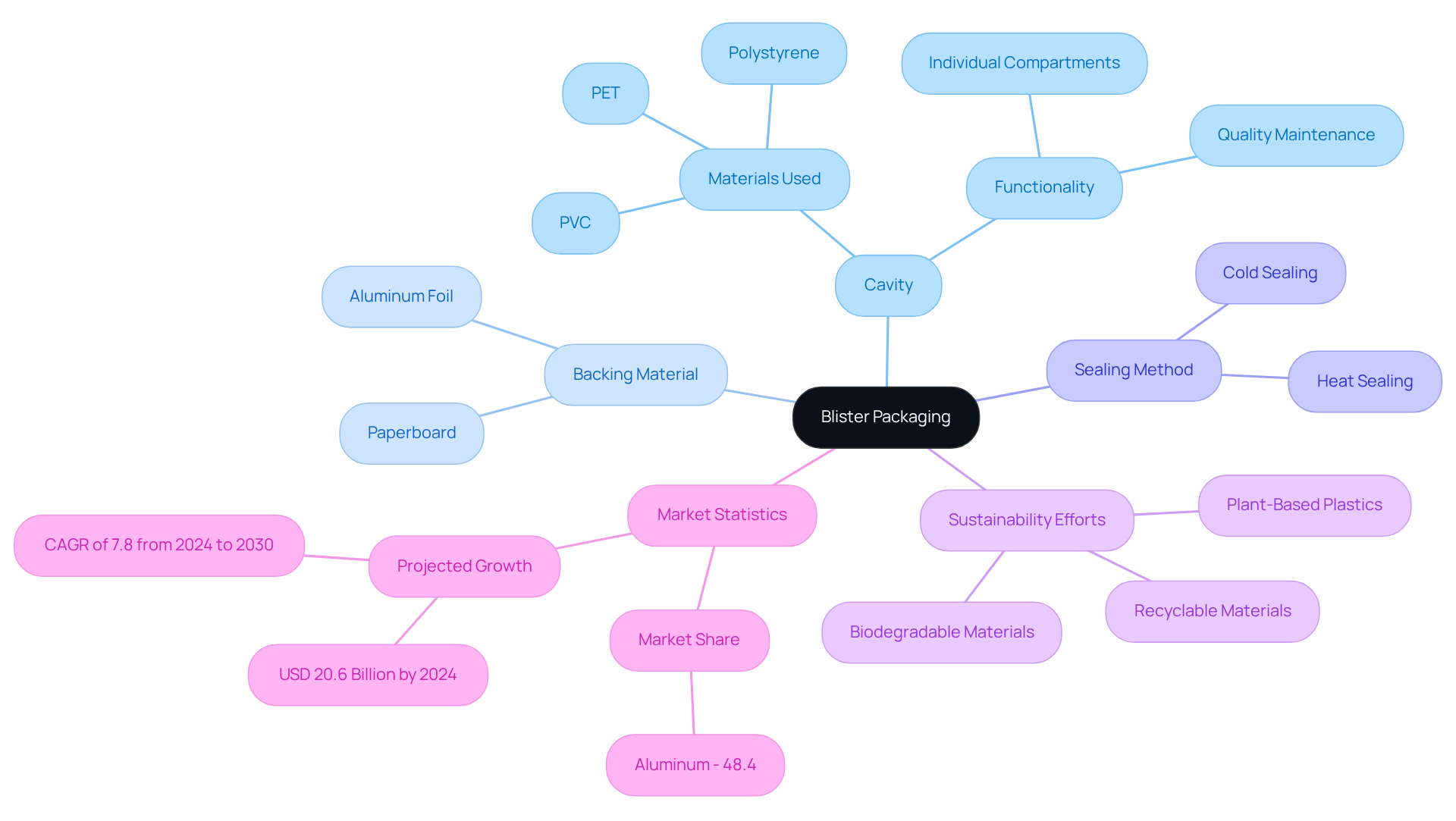

To understand what is blister packaging, one must consider the essential elements, which encompass the cavity, backing material, and sealing method. The blister cavity is typically crafted from thermoformed plastics such as PVC or PET, which are recognized for their clarity and durability. The backing material, often aluminum foil or paperboard, acts as a barrier against moisture and light, thereby ensuring the integrity of the item. Sealing techniques vary, with heat sealing and cold sealing being popular choices, each presenting unique advantages in production efficiency and item protection.

As sustainability gains prominence, many manufacturers are actively exploring biodegradable and recyclable materials, including plant-based plastics, to meet consumer demand for eco-friendly solutions. This transition not only addresses environmental challenges but also enhances the overall appeal of protective wrapping, as it complies with regulatory standards while ensuring product safety and effectiveness.

The environmental impact of various materials is significant; for instance, aluminum, which accounted for approximately 48.4% of the healthcare container market share in 2023, is favored for its recyclability and barrier properties. The healthcare bubble wrap market is projected to reach around USD 20.6 billion in 2024, indicating a growing demand for efficient wrapping solutions. By adopting sustainable practices, the blister wrapping sector is poised to reduce its environmental footprint while effectively catering to the diverse needs of both individuals and businesses.

Examine the Advantages of Blister Packaging for Product Integrity

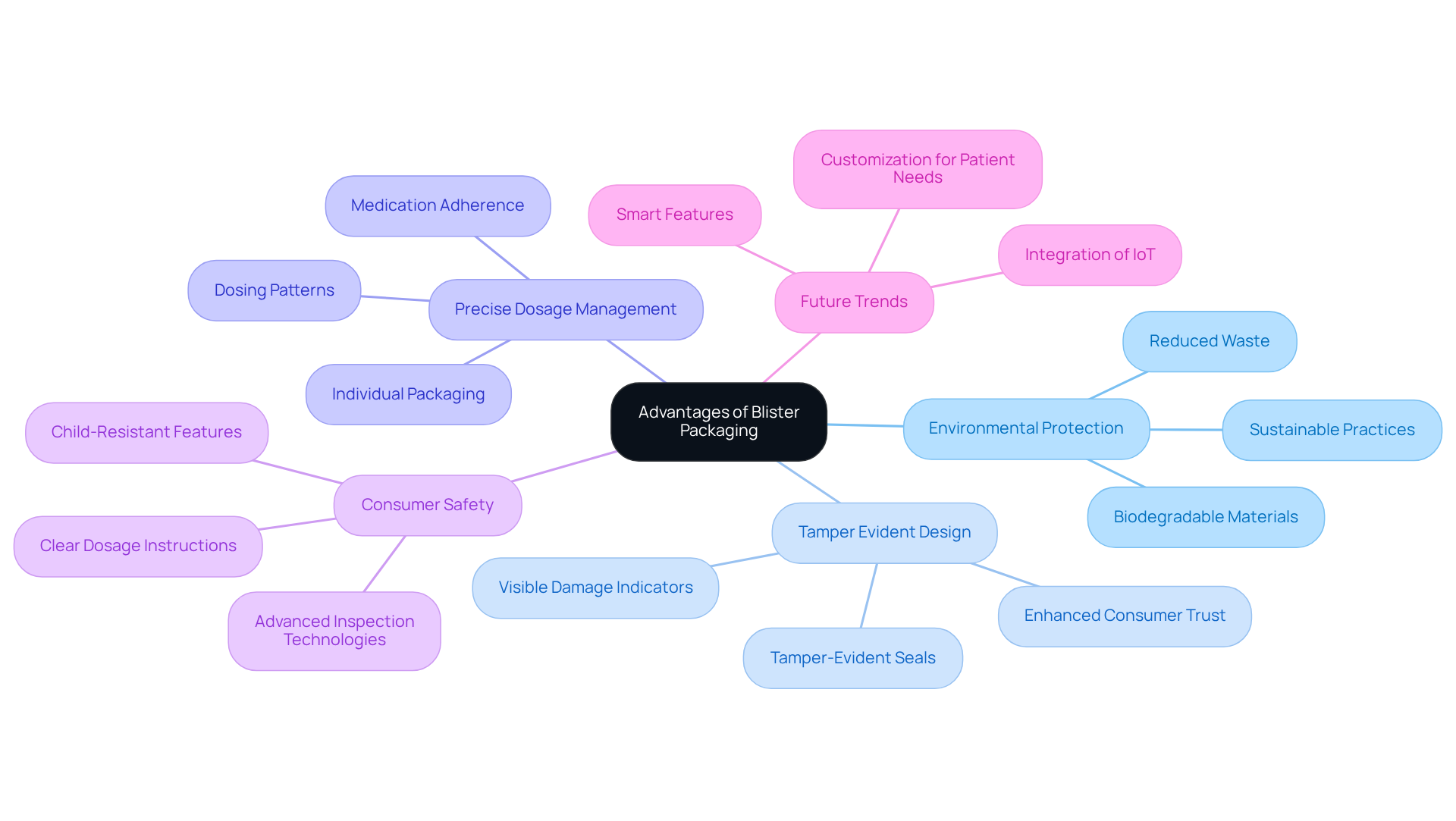

What is blister packaging, and how does it offer numerous benefits that uphold product integrity and enhance consumer safety? Firstly, it establishes a robust barrier against environmental factors such as moisture, oxygen, and light, which can compromise delicate items like vitamins and dietary supplements. The incorporation of hard-tempered foils, typically around 0.8 mils thick, further fortifies this barrier, ensuring that products remain protected throughout their shelf life. Secondly, the tamper-evident design of the packaging significantly boosts buyer safety by confirming that products have not been altered prior to purchase. Moreover, advanced inspection technologies facilitate 100% in-line integrity checks of each pocket or cavity in the pouch, thereby substantially improving safety measures.

Additionally, blister wrapping allows for precise dosage management, enabling individuals to effectively regulate their intake of dietary supplements. Each dose is individually packaged, enhancing convenience and portability, which is especially beneficial for those on the move. This individual compartmentalization not only supports medication adherence but also mitigates the risk of overuse or underuse, addressing a prevalent concern in health management.

Data suggests that container types can greatly influence consumer safety, with incidents of improper dosage or contamination frequently associated with less secure methods. By utilizing protective wrapping, manufacturers can diminish these risks, ensuring that their products remain secure and effective throughout their shelf life. Furthermore, the future of protective wrapping is trending towards the integration of smart features that can track adherence and monitor temperature, alongside the use of biodegradable materials to tackle environmental issues. In summary, what is blister packaging highlights its advantages, making it an essential choice for manufacturers dedicated to delivering high-quality health products to the market.

Conclusion

Blister packaging stands as a critical solution in safeguarding products, particularly within the pharmaceutical and nutraceutical sectors. Its design not only shields items from external elements but also guarantees that they remain tamper-evident and secure until they reach the consumer. This packaging method has undergone significant evolution over the decades, adapting to the rising demands for safety, sustainability, and convenience.

This article outlines the historical progression of blister packaging, tracing its origins in the early 20th century and its transformation through technological advancements. Key components, such as the cavity, backing material, and sealing methods, are essential for grasping how blister packaging upholds product integrity. Furthermore, the advantages of blister packaging extend beyond mere protection; it enhances medication adherence, supports precise dosage management, and fosters consumer trust in product safety.

Upon reflecting on the significance of blister packaging, it becomes clear that this method not only addresses immediate consumer needs but also aligns with broader trends in sustainability and health management. As the industry continues to innovate, embracing eco-friendly materials and smart features, blister packaging will remain an indispensable choice for manufacturers dedicated to delivering high-quality and trustworthy products. Engaging with these advancements is essential for stakeholders aiming to enhance product safety and bolster consumer confidence in an ever-evolving market.

Frequently Asked Questions

What is blister packaging?

Blister packaging refers to pre-formed plastic containers characterized by a cavity or pocket made from a formable web, typically plastic, and sealed with a backing material such as aluminum or paperboard.

What is the primary purpose of blister packaging?

The primary purpose of blister packaging is to safeguard items, particularly pharmaceuticals and nutraceuticals, from external factors like moisture, light, and contamination, while establishing a secure, tamper-evident environment that preserves product integrity until it reaches the consumer.

What types of products commonly use blister packaging?

Blister packaging is commonly utilized for tablets, capsules, and other small objects, especially in the health and wellness industry.

What was the market value of the protective wrap market in 2022, and what is its projected growth?

In 2022, the protective wrap market was valued at approximately USD 27.09 billion, with significant growth projected to reach USD 41.2 billion by 2033, driven by increasing demand for secure wrapping solutions.

How does medication packaging impact adherence rates among individuals managing chronic conditions?

Medication packaging has been linked to a 30% increase in adherence rates among individuals managing chronic conditions, as reported by the CDC, highlighting its role in enhancing healthcare outcomes.

What benefits does blister packaging provide for nutraceuticals?

The use of sealed containers in nutraceuticals not only protects items but also extends their longevity and fosters buyer trust, making it a vital option for producers in this sector.

What challenges does the blister wrapping market face?

The blister wrapping market faces challenges such as the need for continuous investment in research and development (R&D) and the threat of counterfeit medications, which manufacturers must navigate to maintain product integrity and consumer confidence.