Overview

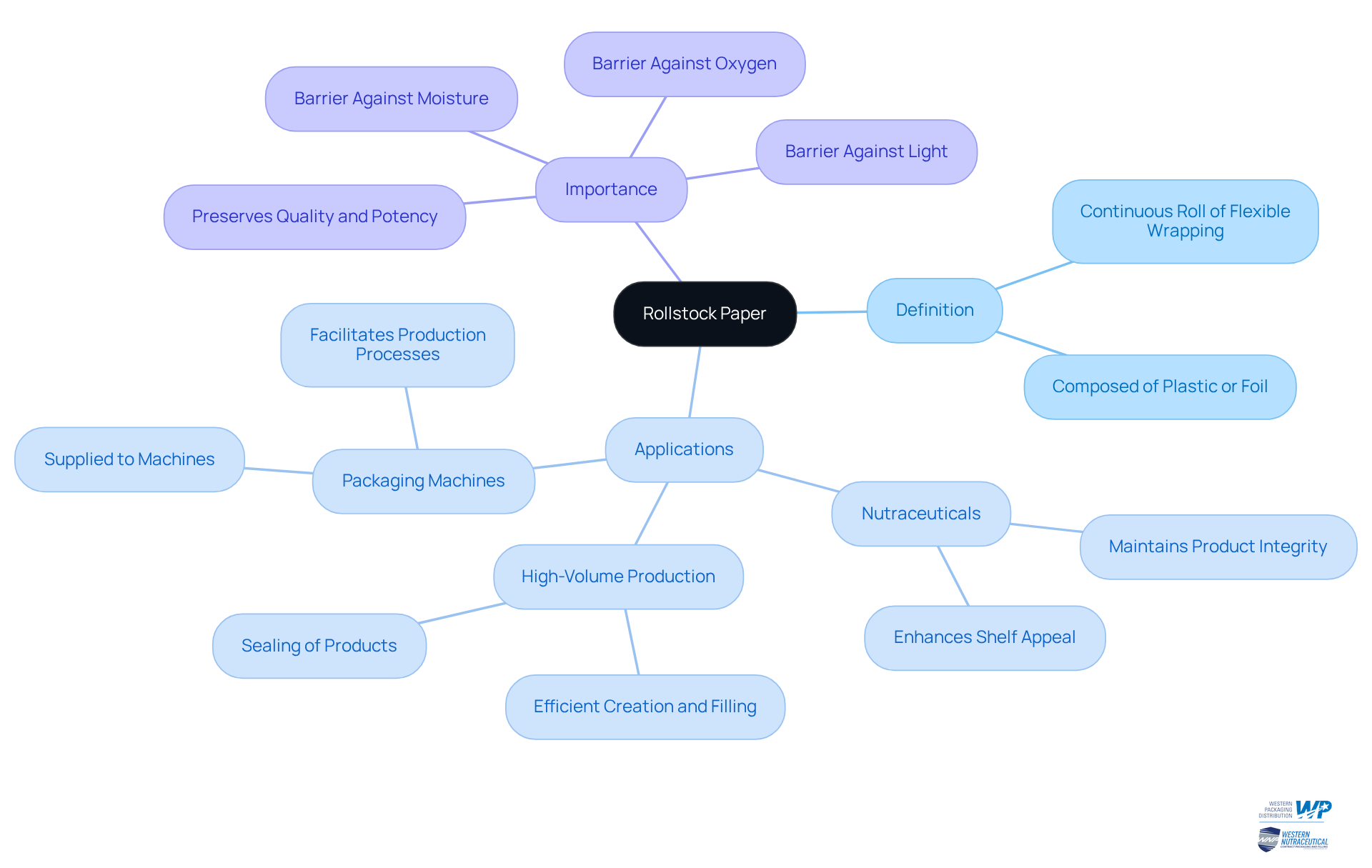

Rollstock paper serves as a flexible wrapping material that is indispensable for nutraceutical packaging. It provides crucial barriers against moisture, oxygen, and light, thereby preserving product quality and potency. This article underscores its significance by outlining the manufacturing process, various types, and key benefits of rollstock paper. By enhancing packaging efficiency and boosting consumer appeal, rollstock paper plays a vital role in the nutraceutical sector.

Introduction

Rollstock paper serves a vital function in the packaging landscape, particularly within the nutraceutical industry, where product integrity and visual appeal are paramount. This continuous roll of flexible wrapping material not only streamlines production processes but also safeguards health products from environmental factors that could jeopardize their quality. As the demand for sustainable and effective packaging solutions continues to rise, manufacturers must adeptly navigate the complexities of rollstock paper types and their specific applications to align with consumer expectations and regulatory standards.

Define Rollstock Paper and Its Importance in Packaging

Rollstock paper is defined as a continuous roll of flexible wrapping substance, typically composed of plastic or foil, utilized across various wrapping applications. This type of wrapping plays a crucial role in sectors such as nutraceuticals, where the integrity of items and shelf appeal are paramount. Supplied to packaging machines, rollstock paper enables the efficient creation, filling, and sealing of products, making it a preferred choice for high-volume production. Its importance lies in its ability to create a robust barrier against moisture, oxygen, and light, thereby preserving the quality and potency of health products.

Explore Types of Rollstock Paper and Their Applications

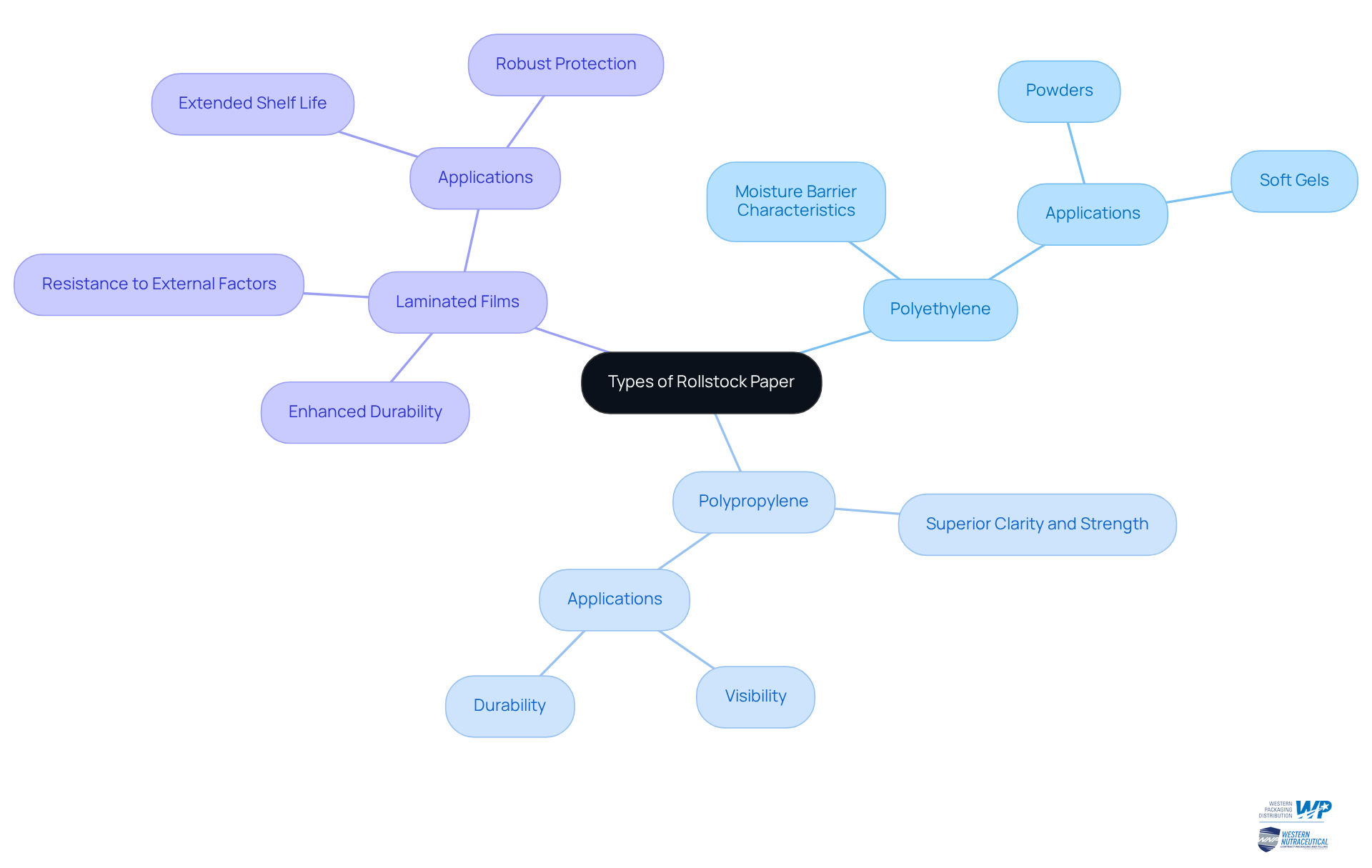

Rollstock paper includes various types, such as polyethylene, polypropylene, and laminated films, each carefully designed for specific applications in the nutraceutical sector.

- Polyethylene is highly valued for its moisture barrier characteristics, rendering it an exceptional option for containing powders and soft gels that require protection from humidity to preserve their integrity.

- In contrast, polypropylene offers superior clarity and strength, making it particularly suitable for applications where visibility and durability are paramount.

- Laminated films stand out for their enhanced durability and resistance to external factors, ensuring that items maintain their quality over an extended shelf life.

This attribute makes them particularly advantageous for nutraceuticals that demand robust protection against environmental influences. By comprehending the distinct features of these materials, manufacturers can make informed choices about the most appropriate supply for their specific requirements. This understanding ultimately enhances packaging efficiency and boosts consumer attraction.

Understand the Manufacturing Process of Rollstock Paper

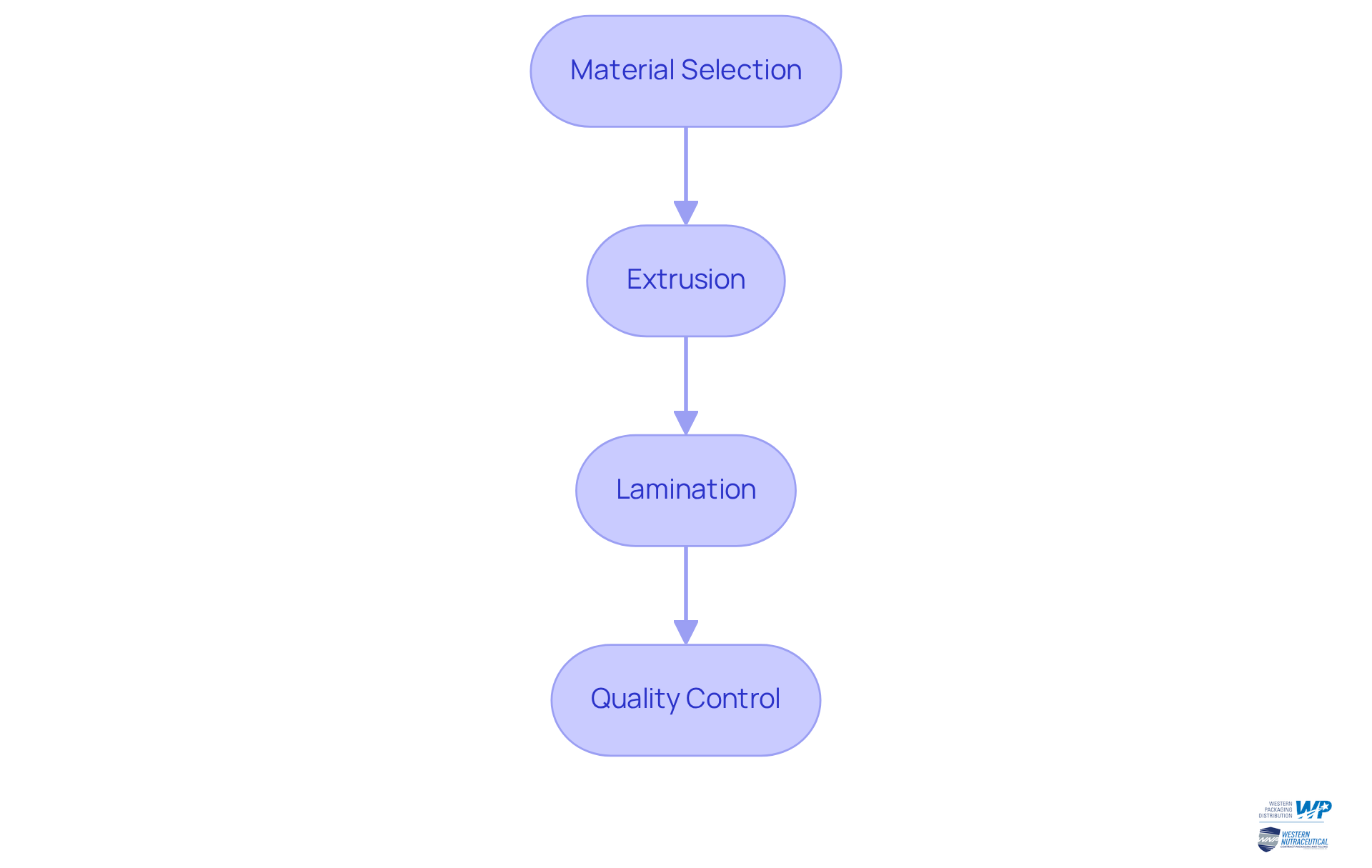

The creation of substrate material encompasses several critical stages, beginning with material selection, followed by extrusion and lamination. Manufacturers initially select raw materials, such as plastic pellets or paper fibers, tailored to achieve specific characteristics in the final product. During the extrusion phase, these materials are melted and formed into a continuous sheet, which is then cooled and rolled into large rolls. For laminated materials, additional layers are incorporated to enhance barrier characteristics, which are vital for maintaining product integrity.

Quality control is paramount throughout this manufacturing process, ensuring that the material adheres to stringent industry standards for strength, flexibility, and barrier performance. In the nutraceutical sector, where safety and efficacy are of utmost importance, rigorous testing protocols are established to guarantee that materials meet required specifications. For instance, manufacturers often conduct tensile strength tests and moisture barrier assessments to ensure compliance with quality standards specific to nutraceutical applications. This meticulous approach not only enhances product reliability but also bolsters consumer confidence in the solutions provided.

As the demand for high-quality wrapping solutions escalates, the market for metallized rollstock paper is projected to reach USD 10.3 billion by 2035, underscoring the growing significance of quality in production. Furthermore, with metallized PET anticipated to dominate the market with over 58% share in 2025, the choice of materials becomes increasingly critical. The sector's focus on sustainability and recyclable films further emphasizes the necessity for stringent quality control measures, ensuring that solutions not only meet performance standards but also comply with regulatory expectations.

Highlight Benefits of Rollstock Paper in Modern Packaging

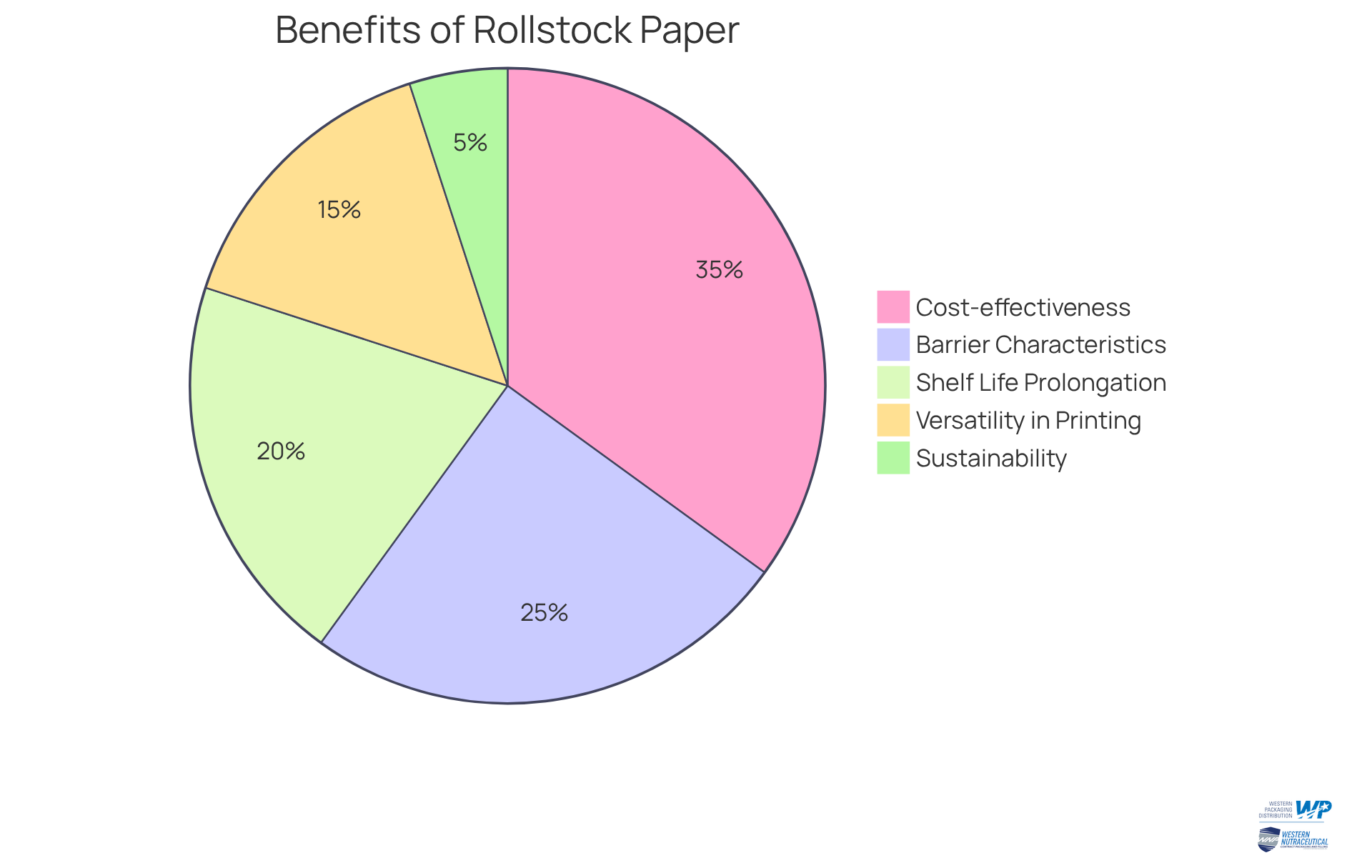

Rollstock paper presents numerous advantages in modern wrapping, particularly for nutraceuticals. Its cost-effectiveness enables manufacturers to produce packaging at scale, thereby reducing overall production costs. Furthermore, the exceptional barrier characteristics of the paper significantly prolong shelf life by protecting contents from moisture, oxygen, and UV light. This aspect is essential for health products, where the integrity of ingredients is paramount. Additionally, the versatility of the material allows for high-quality printing, empowering brands to enhance their visibility and appeal on retail shelves. In summary, rollstock paper is recognized as a sustainable and efficient solution for modern packaging needs.

Conclusion

Rollstock paper stands as a vital element in the packaging landscape, particularly within the nutraceutical sector, where the preservation of product integrity and shelf appeal is paramount. Its inherent flexibility and robust barrier properties render it the preferred choice for manufacturers dedicated to ensuring the longevity and quality of health products. By streamlining packaging processes, rollstock paper not only enhances production capabilities but also plays a crucial role in safeguarding the potency of nutraceuticals.

This article explores the diverse types of rollstock paper, including polyethylene, polypropylene, and laminated films, each offering unique advantages tailored to specific applications. Key insights highlight the moisture barrier capabilities of polyethylene, the clarity and strength of polypropylene, and the durability of laminated films. A thorough understanding of these characteristics empowers manufacturers to make informed decisions that optimize packaging efficiency and attract consumers. Furthermore, the rigorous manufacturing process, bolstered by stringent quality control measures, guarantees that these materials meet the high standards essential for nutraceutical applications.

In conclusion, the significance of rollstock paper transcends mere packaging; it embodies a commitment to quality, safety, and sustainability within the nutraceutical industry. As the market continues to evolve, the adoption of innovative packaging solutions like rollstock paper will be critical for manufacturers striving to meet consumer demands while maintaining product integrity. Investing in high-quality rollstock paper not only enhances brand visibility but also cultivates consumer trust, ultimately driving success in an increasingly competitive marketplace.

Frequently Asked Questions

What is rollstock paper?

Rollstock paper is a continuous roll of flexible wrapping material, typically made of plastic or foil, used in various wrapping applications.

Why is rollstock paper important in packaging?

Rollstock paper is important because it helps maintain the integrity and shelf appeal of products, particularly in sectors like nutraceuticals. It enables efficient creation, filling, and sealing of products in high-volume production.

What are the protective qualities of rollstock paper?

Rollstock paper provides a robust barrier against moisture, oxygen, and light, which helps preserve the quality and potency of health products.