Overview

The article underscores the ten benefits of contract manufacturing dietary supplements, with a focus on:

- Cost efficiency

- Regulatory compliance

- Flexibility

- Access to specialized expertise

Each benefit is substantiated by evidence illustrating how outsourcing production enables companies to:

- Reduce costs

- Uphold high-quality standards

- Adapt to market trends

- Concentrate on their core competencies

This strategic approach ultimately enhances their competitiveness in an industry that is rapidly evolving.

Introduction

The dietary supplement industry is witnessing remarkable growth, with a surge in companies striving to efficiently meet the escalating consumer demands. Contract manufacturing emerges as a compelling solution, delivering numerous advantages that can significantly enhance both operational efficiency and product quality.

Nevertheless, as brands navigate this intricate landscape, they must confront the complexities of outsourcing production and its implications on their market strategy.

What are the pivotal advantages of contract manufacturing dietary supplements?

How can companies harness these benefits to maintain a competitive edge in the market?

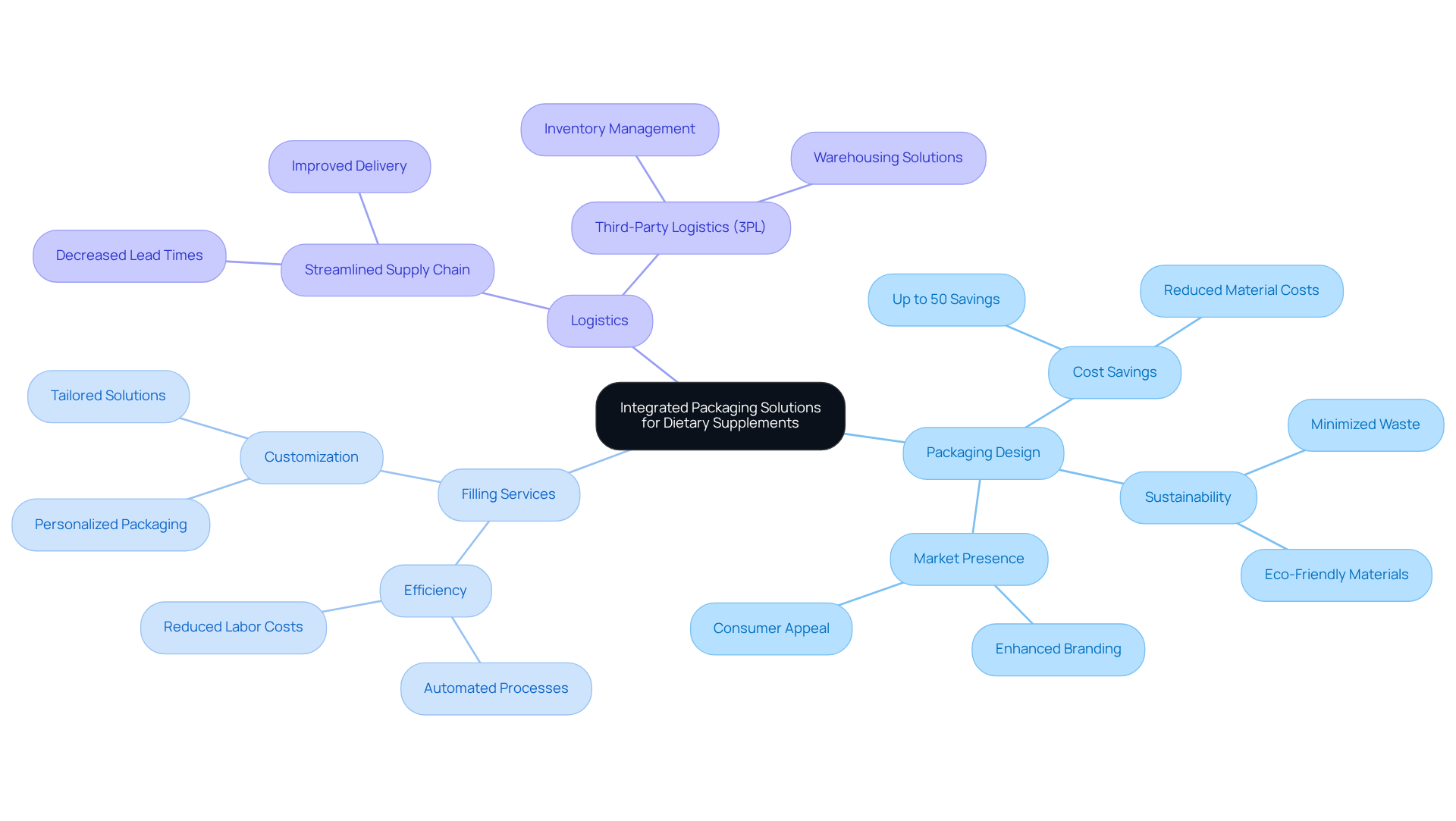

Western Packaging: Integrated Packaging Solutions for Dietary Supplements

Western Packaging delivers an extensive range of integrated packaging solutions meticulously tailored for health products. By merging expert packaging design, filling services, and robust third-party logistics (3PL), the company streamlines the supply chain for manufacturers and distributors. This integrated approach significantly decreases lead times and enhances the appeal of offerings, ensuring that contract manufacturing dietary supplements effectively meet market demands.

Recent statistics reveal that companies utilizing integrated packaging solutions can achieve cost savings of up to 50% compared to traditional methods, while also improving sustainability by minimizing waste and optimizing resource use.

With a steadfast commitment to creativity and precision, Western Packaging empowers companies to enhance their market presence and optimize operational processes, addressing the rising consumer demand for health and wellness items.

Industry leaders acknowledge that such comprehensive packaging services not only bolster product safety and compliance but also act as critical marketing touchpoints that influence purchasing decisions.

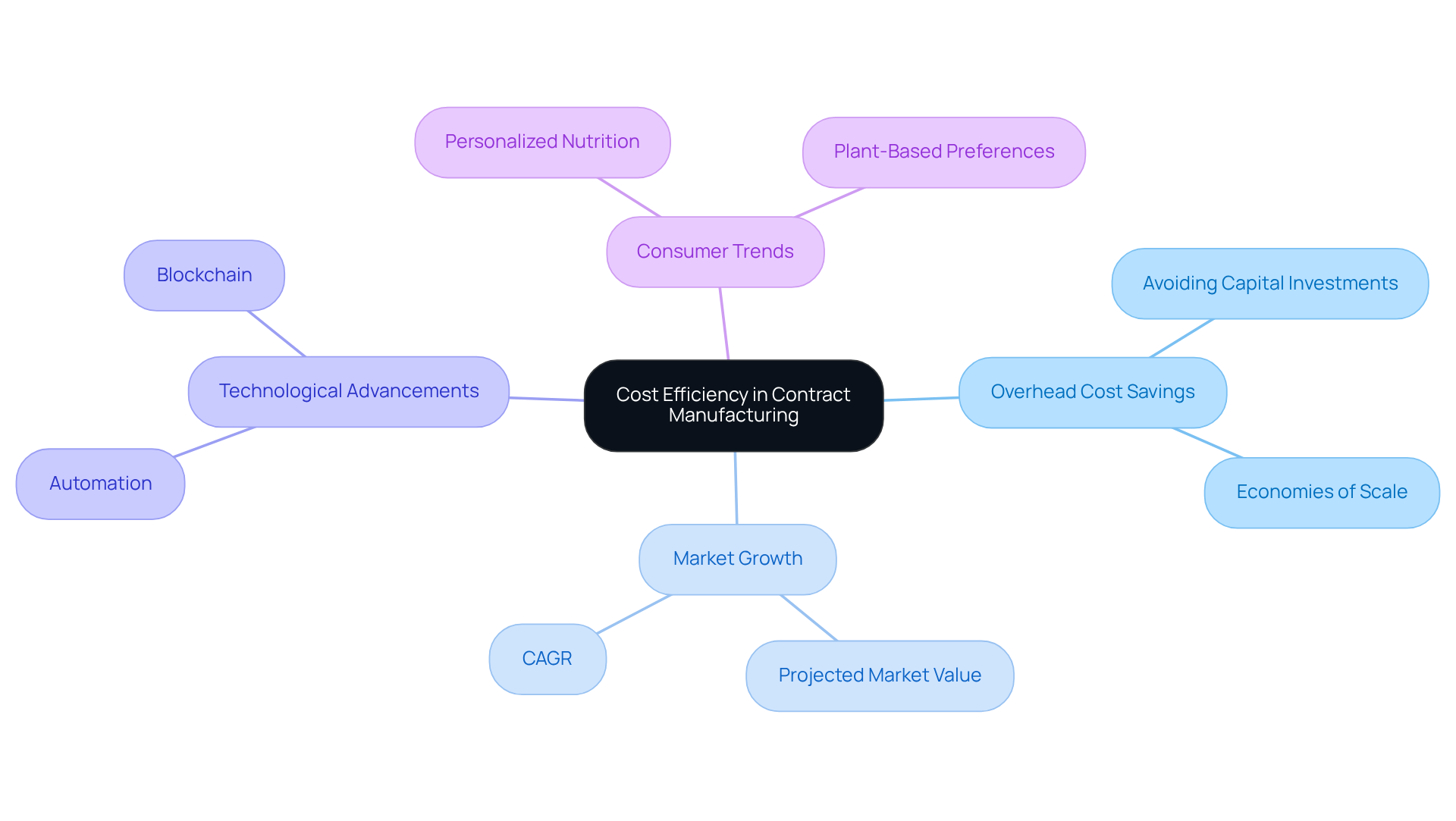

Cost Efficiency: Reducing Overhead with Contract Manufacturing

Contract manufacturing dietary supplements offers substantial overhead cost savings for dietary supplement companies. By outsourcing production, these companies can avoid the significant investments typically required for establishing manufacturing facilities and acquiring equipment. This strategic move allows them to leverage economies of scale, resulting in lower production costs per unit. Moreover, contract manufacturers often have established supply chains and operational efficiencies that further enhance these cost savings. Technological advancements in manufacturing, including automation and blockchain, improve efficiency and traceability, making outsourcing even more beneficial. As a result, companies can allocate their resources more effectively towards marketing and development, ultimately strengthening their competitive edge in the market.

The market for contract manufacturing dietary supplements is projected to reach USD 121.2 billion by 2030, expanding at a compound annual growth rate of 12.6% from 2025 to 2030. This trend towards outsourcing production is increasingly advantageous for companies aiming to optimize their operations. Additionally, the rising consumer preference for plant-based options and the growing focus on mental wellness are trends that brands should consider when outsourcing manufacturing, as they reflect evolving market demands. Regulatory compliance and quality assurance remain critical factors driving the need for contract manufacturing dietary supplements, ensuring that products meet safety and efficacy standards.

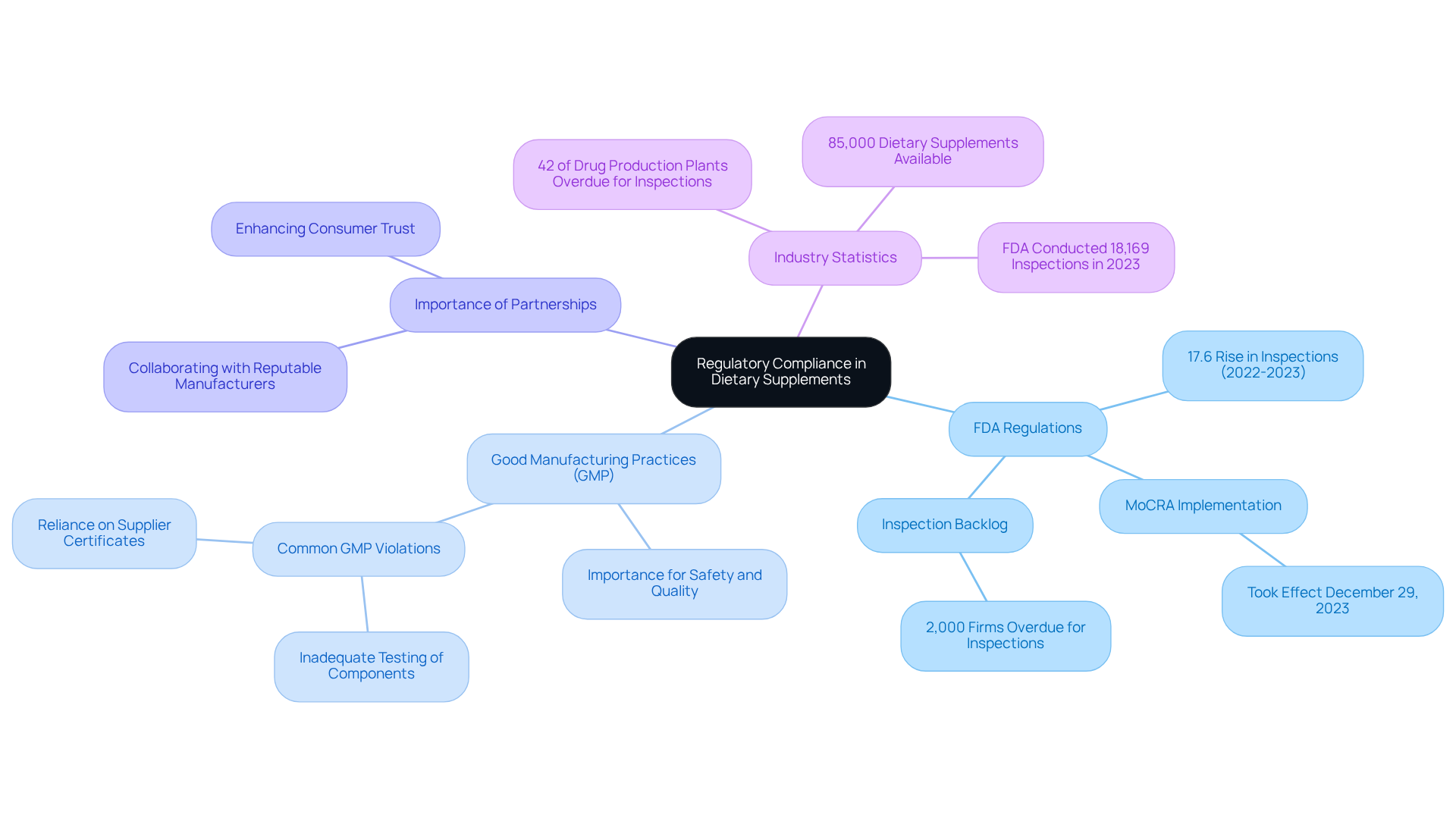

Regulatory Compliance: Ensuring Safety and Quality Standards

Contract manufacturing dietary supplements is essential for ensuring adherence to stringent regulatory compliance standards. Their expertise in the latest FDA regulations and Good Manufacturing Practices (GMP) is critical for guaranteeing safety and quality. By partnering with a reputable company specializing in contract manufacturing dietary supplements, brands can produce their items in compliant facilities, effectively reducing the risk of non-compliance and enhancing consumer trust in their offerings.

The FDA's increasing focus on regulatory oversight is underscored by a notable 17.6% rise in inspections from 2022 to 2023. As the nutrition enhancement sector continues to expand—boasting over 85,000 offerings available in the U.S.—compliance with these regulations becomes indispensable.

The impact of GMP on health product safety is profound; it ensures that products are consistently manufactured to high standards, safeguarding public health and reinforcing the industry's integrity. Therefore, it is imperative for companies to prioritize collaborations with compliant contract manufacturing dietary supplements.

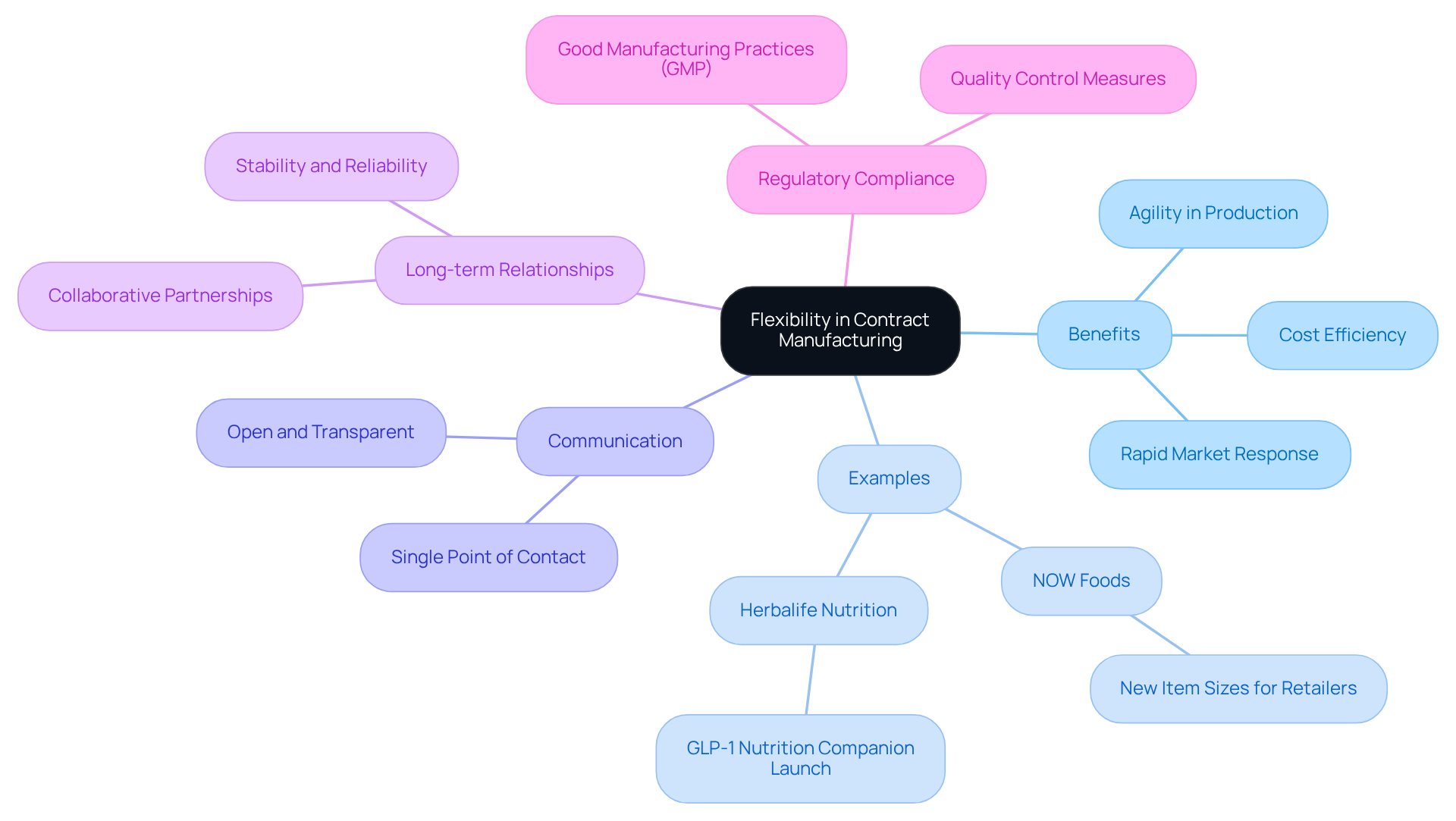

Flexibility: Adapting to Market Trends and Consumer Needs

Flexibility in contract manufacturing dietary supplements stands as a pivotal advantage for nutritional product companies, enabling them to swiftly adapt to evolving consumer preferences and emerging market trends. With the dietary supplements market projected to grow at a CAGR of 6.8% from 2024 to 2033, it is imperative for companies to remain agile to capitalize on new opportunities. Contract manufacturers can seamlessly adjust production quantities and formulations, allowing companies to introduce innovative products or refine existing offerings without incurring significant retooling costs or financial burdens.

For example, NOW Foods has effectively launched new item sizes tailored specifically for independent retailers, illustrating how contract manufacturing can expedite market entry. This adaptability not only aids companies in fulfilling consumer demands but also enhances their ability to respond to competitive pressures.

Industry leaders assert that robust communication and collaboration with contract manufacturers are vital for navigating these shifts. By cultivating strong partnerships, companies can align their manufacturing processes with market trends, ultimately resulting in improved product availability and heightened customer satisfaction. Such adaptability is crucial in a fragmented market characterized by constantly changing consumer preferences, making contract manufacturing dietary supplements an invaluable strategy for health product companies seeking to excel in a dynamic landscape.

Furthermore, establishing long-term relationships with contract manufacturers fosters stability and reliability, essential components for executing effective business strategies. Western Packaging's commitment to quality and customized solutions further amplifies this flexibility, ensuring that companies can meet their distinct packaging requirements while adapting to market demands. Additionally, adhering to regulatory standards and implementing rigorous quality control measures are critical factors that companies must consider when navigating the complexities of the nutritional product sector.

Expertise Access: Leveraging Specialized Knowledge in Supplement Manufacturing

Collaborating with a contract manufacturing dietary supplements provider gives dietary product brands access to specialized knowledge and expertise that may not be available internally. These manufacturers employ experienced professionals who possess a deep understanding of the complexities involved in supplement formulation, ingredient sourcing, and production processes. This level of expertise can lead to superior-quality products and innovative formulations that effectively satisfy consumer needs. By leveraging this specialized knowledge in contract manufacturing dietary supplements, companies can significantly enhance their product offerings and strengthen their competitive edge in the market.

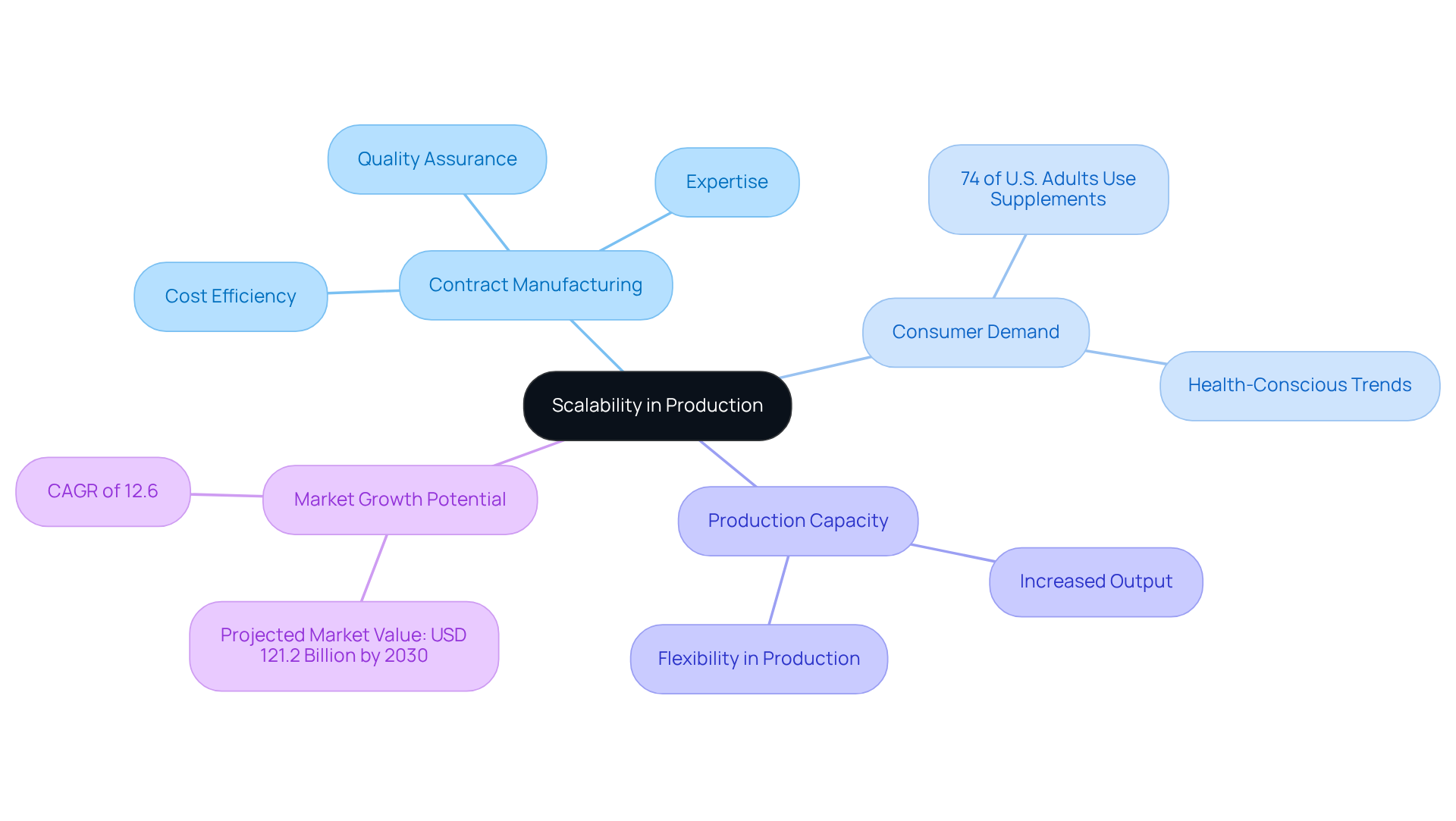

Scalability: Growing Production Capacity Without Major Investments

Contract manufacturing dietary supplements allows nutritional product companies to effectively enhance their production capacity, eliminating the need for substantial investments. With consumer demand on the rise—over 74% of the adult population in the U.S. utilizing dietary supplements—companies can seamlessly increase output by collaborating with firms specializing in contract manufacturing dietary supplements that possess the necessary infrastructure and expertise.

This adaptability enables businesses to respond to market fluctuations and consumer preferences without incurring the financial risks tied to establishing new facilities or acquiring equipment. By leveraging contract manufacturing dietary supplements, companies can focus on expansion while ensuring high product quality, thereby meeting the evolving demands of health-conscious consumers.

Industry leaders assert that this strategy not only bolsters production capabilities but also facilitates sustainable growth, enabling brands to excel in a competitive marketplace. The market for contract manufacturing dietary supplements is projected to reach USD 121.2 billion by 2030, underscoring the significant growth potential within this sector.

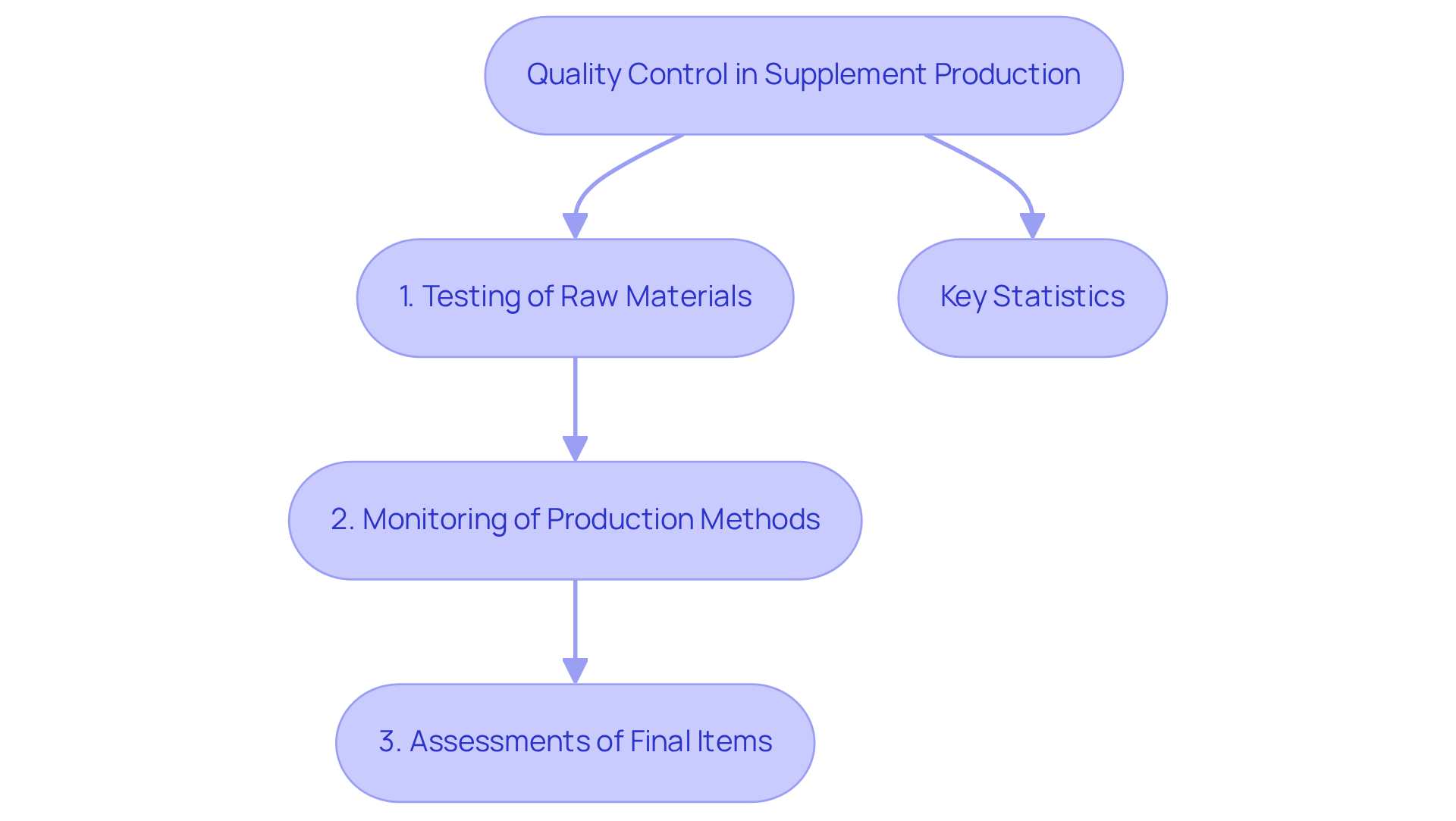

Quality Control: Maintaining High Standards in Supplement Production

Ensuring high standards of quality control is paramount in dietary supplement production. In contract manufacturing dietary supplements, manufacturers adopt stringent quality assurance protocols to guarantee that each batch adheres to established safety and efficacy standards. This process includes:

- Thorough testing of raw materials

- Vigilant monitoring of production methods

- Comprehensive assessments of final items

By partnering with a company specializing in contract manufacturing dietary supplements that prioritizes quality control, companies can confidently deliver products that are safe, effective, and compliant with regulatory requirements. This commitment enhances consumer trust—evidenced by 87% of U.S. adults expressing confidence in the safety, quality, and effectiveness of nutritional supplements—and strengthens company reputation in a competitive market.

Significantly, consumer confidence in health products has increased from 84% in 2009 to 87% in 2018, emphasizing the rising trust in the sector. Moreover, with 75% of U.S. adults using nutritional products, upholding high standards becomes vital for companies looking to succeed in this changing environment. Industry leaders stress that nutritional products have become an essential part of many Americans' health routines, highlighting the significance of quality assurance in fulfilling consumer expectations.

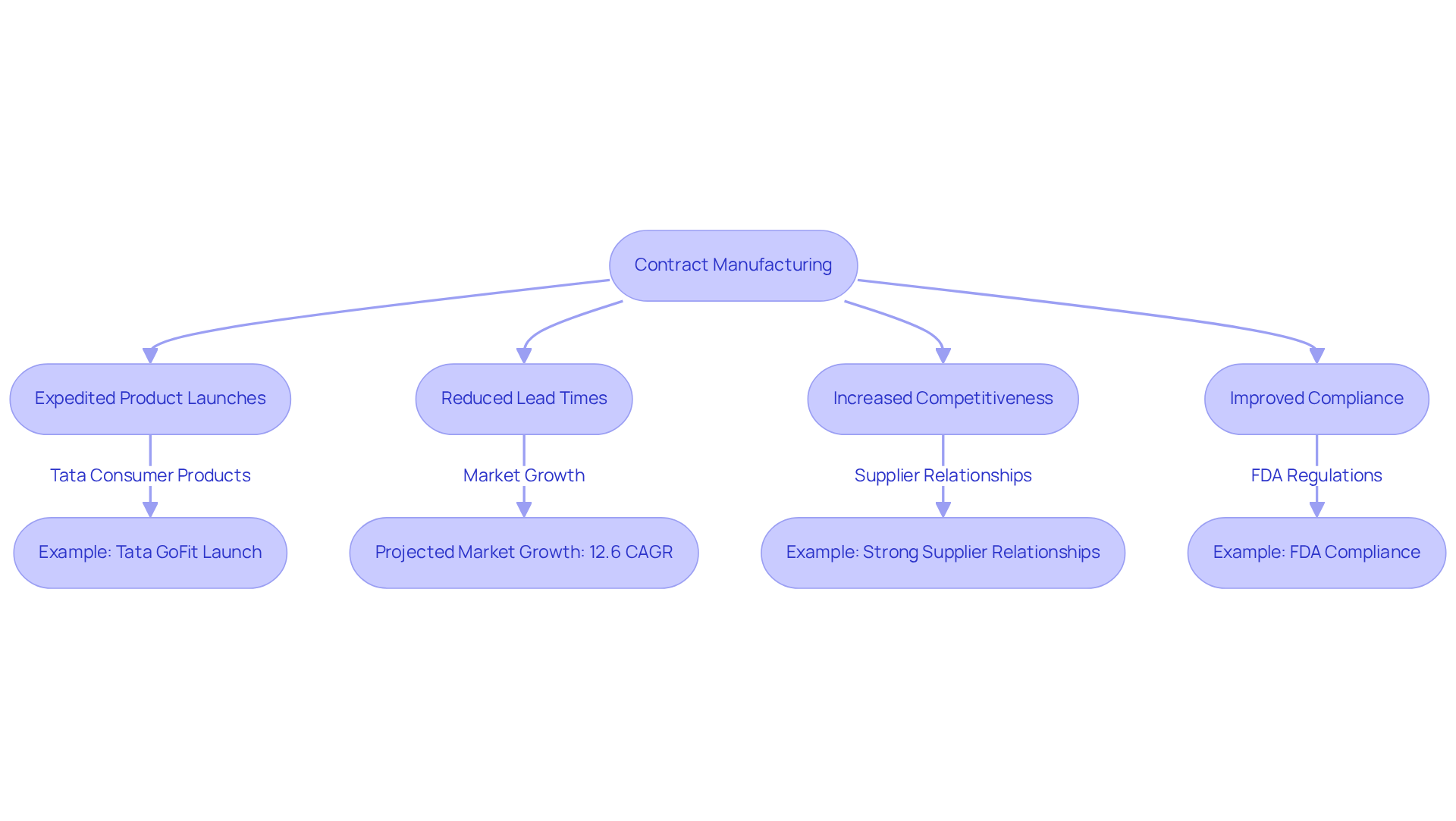

Speed to Market: Accelerating Product Launches with Contract Manufacturing

Contract manufacturing dietary supplements is crucial in expediting the market entry for dietary supplement companies. By outsourcing production to specialized manufacturers, these companies can enhance their development processes, significantly reducing lead times. This efficiency empowers them to swiftly introduce new products, allowing them to capitalize on emerging trends and evolving consumer needs. The global contract manufacturing market for nutritional products is projected to grow at a compound annual growth rate of 12.6% from 2025 to 2030, reaching an estimated USD 121.2 billion by 2030. This growth underscores the increasing reliance on contract manufacturing as a strategic advantage in enhancing competitiveness.

Moreover, successful companies exemplify the effectiveness of this approach. For instance, Tata Consumer Products recently launched Tata GoFit, a plant protein powder, which mirrors the rising demand for innovative, plant-based dietary supplements. Through contract manufacturing dietary supplements, brands not only expedite their product launches but also ensure compliance with regulatory standards set by the FDA, thereby enhancing consumer confidence.

Industry leaders emphasize that outsourcing manufacturing processes allows companies to focus on their core competencies while expertly navigating the complexities of development. This collaborative model fosters transparency and efficiency, ultimately leading to quicker market availability and improved responsiveness. Additionally, maintaining strong supplier relationships is vital for securing access to high-quality ingredients and packaging, which enhances product quality and builds consumer trust. As the nutritional product landscape continues to evolve, the ability to rapidly introduce items to market will remain a pivotal factor for success.

Risk Mitigation: Navigating Supply Chain Challenges with Contract Manufacturing

Contract manufacturing dietary supplements serves as a crucial strategy for risk mitigation in the dietary supplement industry. By collaborating with established manufacturers, companies can effectively navigate supply chain challenges, including fluctuations in raw material availability and production disruptions. These manufacturers typically maintain diversified supply chains and robust contingency plans, enabling companies to sustain consistent production levels and minimize the impact of unforeseen events.

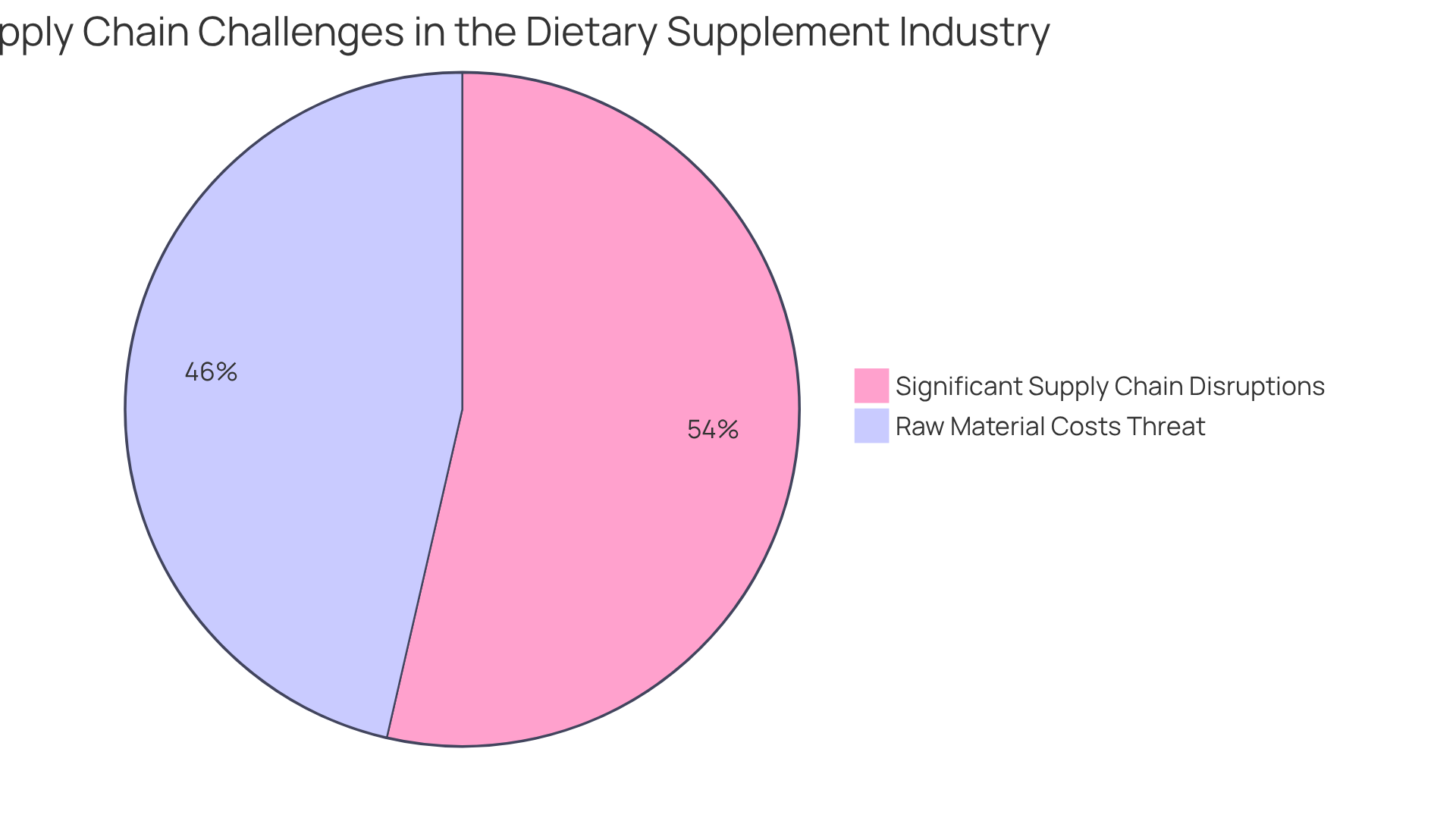

This proactive risk management approach is essential, as:

- 71% of global companies identified raw material costs as their primary supply chain threat for 2023.

- 82% of organizations faced at least one significant supply chain disruption in 2022, highlighting the critical need for effective risk management strategies.

By leveraging the expertise of contract manufacturing dietary supplements, companies can ensure they meet consumer demand without significant interruptions, ultimately improving their market competitiveness. As industry leaders emphasize, efficient supply chain management is vital for sustaining operational flow and fulfilling customer expectations, which makes contract manufacturing dietary supplements an indispensable component of contemporary nutritional product strategies.

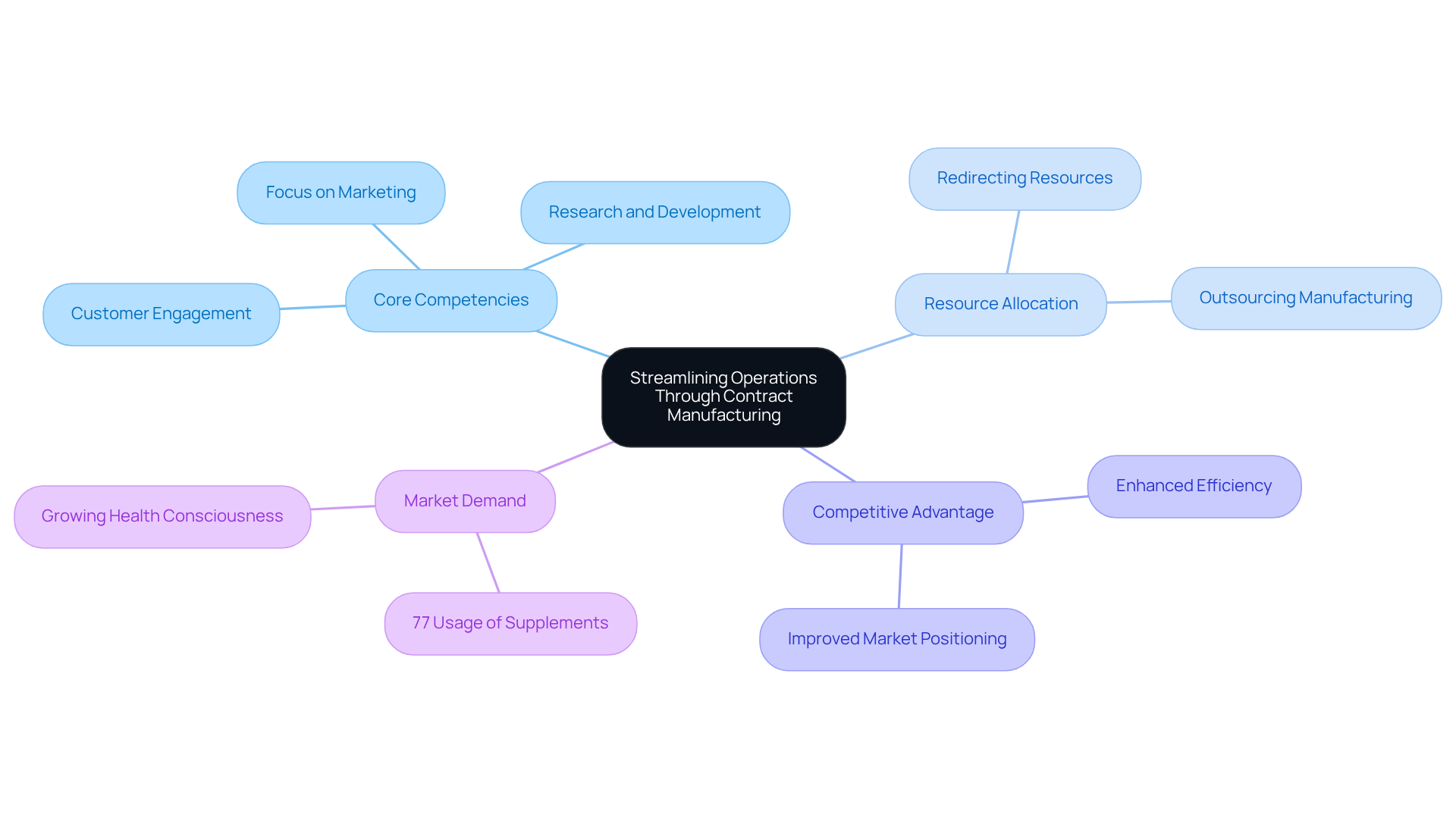

Core Competency Focus: Streamlining Operations Through Contract Manufacturing

Contract manufacturing dietary supplements empowers companies in this industry to streamline operations and focus on their core competencies. By outsourcing production, companies can redirect resources toward critical areas such as marketing, research and development, and customer engagement. This strategic shift not only enhances competitive advantage but also fosters growth by allowing companies to concentrate on their strengths while entrusting manufacturing complexities to specialized partners. Consequently, companies can significantly enhance their overall performance and market positioning.

With 77% of American adults using dietary supplements in 2021, the demand for effective and innovative products is evident, making it essential for brands to optimize their operations. Industry leaders underscore that focusing on core competencies through outsourcing, such as contract manufacturing dietary supplements, can lead to improved efficiency and responsiveness to market trends, ultimately driving success in a competitive landscape.

Conclusion

The advantages of contract manufacturing dietary supplements are numerous and significant, providing companies with the opportunity to optimize their operations while meeting the increasing consumer demand for health products. By outsourcing production, businesses can achieve cost efficiency, ensure regulatory compliance, and maintain high-quality standards, all while remaining agile to adapt to market trends and consumer preferences.

Throughout this discussion, key benefits such as access to specialized expertise, scalability of production, and enhanced speed to market have been highlighted. Companies leveraging contract manufacturing can effectively navigate supply chain challenges, mitigate risks, and focus on their core competencies, thus fostering growth and innovation in a competitive landscape. The projected growth of the contract manufacturing market underscores the importance of these strategies for dietary supplement brands aiming to succeed.

In light of these insights, it is essential for companies in the dietary supplement sector to consider the strategic advantages of contract manufacturing. By embracing this approach, they can not only enhance their product offerings but also position themselves for long-term success in a rapidly evolving market. The integration of expert knowledge, flexibility, and robust quality control measures will serve as a foundation for meeting the needs of health-conscious consumers and driving future growth in the industry.

Frequently Asked Questions

What integrated packaging solutions does Western Packaging offer for dietary supplements?

Western Packaging provides a range of integrated packaging solutions that include expert packaging design, filling services, and robust third-party logistics (3PL) to streamline the supply chain for manufacturers and distributors of health products.

How does the integrated approach of Western Packaging benefit companies?

The integrated approach significantly decreases lead times, enhances product appeal, and helps ensure that contract manufacturing of dietary supplements meets market demands effectively.

What are the cost savings associated with integrated packaging solutions?

Companies utilizing integrated packaging solutions can achieve cost savings of up to 50% compared to traditional methods while improving sustainability by minimizing waste and optimizing resource use.

What impact does contract manufacturing have on overhead costs for dietary supplement companies?

Contract manufacturing allows dietary supplement companies to avoid significant investments in manufacturing facilities and equipment, leveraging economies of scale to lower production costs per unit.

What technological advancements are enhancing contract manufacturing?

Technological advancements such as automation and blockchain improve efficiency and traceability in contract manufacturing, making outsourcing more beneficial for companies.

What is the projected market growth for contract manufacturing dietary supplements?

The market for contract manufacturing dietary supplements is projected to reach USD 121.2 billion by 2030, with a compound annual growth rate of 12.6% from 2025 to 2030.

Why is regulatory compliance important in contract manufacturing dietary supplements?

Regulatory compliance is essential to ensure adherence to safety and quality standards, reducing the risk of non-compliance and enhancing consumer trust in dietary supplement products.

What role do Good Manufacturing Practices (GMP) play in health product safety?

GMP ensures that health products are consistently manufactured to high standards, safeguarding public health and reinforcing the integrity of the dietary supplement industry.

How has FDA regulatory oversight changed recently?

The FDA has increased its focus on regulatory oversight, with a notable 17.6% rise in inspections from 2022 to 2023, highlighting the importance of compliance in the expanding nutrition enhancement sector.