Overview

This article delves into the identification of effective packaging solutions tailored for nutraceutical manufacturers, underscoring the critical integration of design, filling, and logistics services. It asserts that specialized providers, such as Western Packaging, significantly enhance operational efficiency and product appeal through bespoke packaging strategies. These strategies are not merely advantageous but essential for satisfying market demands and sustaining competitiveness within the nutraceutical sector. By leveraging tailored solutions, companies can elevate their market presence and ensure reliability in their operations.

Introduction

Navigating the competitive landscape of nutraceutical manufacturing presents unique challenges, particularly in the realm of packaging solutions. As consumer preferences evolve and sustainability becomes paramount, manufacturers are increasingly seeking innovative and efficient packaging options that not only protect their products but also enhance brand visibility. This article explores ten standout packaging solutions tailored specifically for nutraceutical manufacturers, highlighting how these options can streamline operations and elevate product appeal.

What key factors should manufacturers consider when choosing packaging solutions that align with both market demands and regulatory standards?

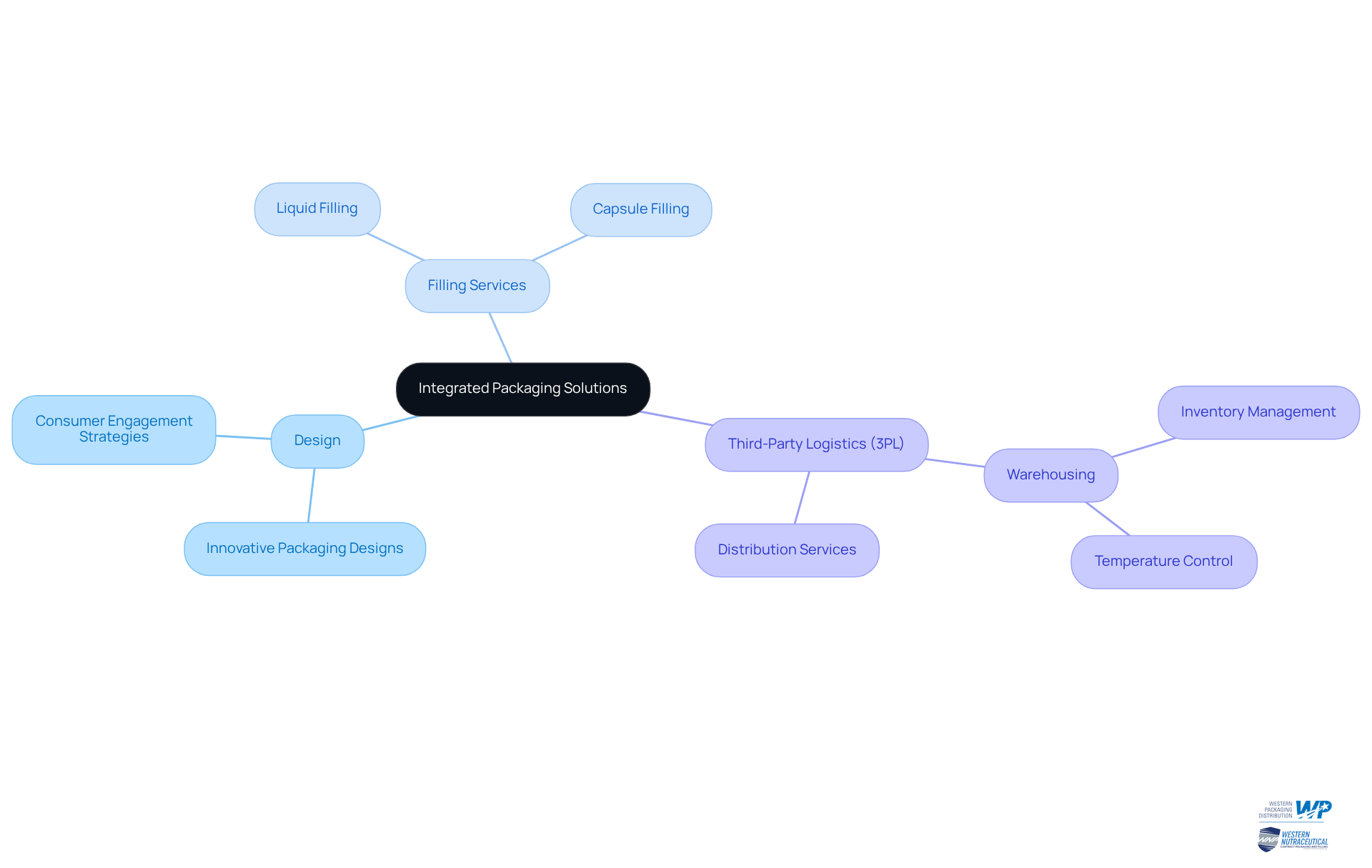

Western Packaging: Integrated Packaging Solutions for Enhanced Efficiency

Western Packaging provides a robust array of services that expertly integrates design, filling services, and comprehensive third-party logistics (3PL), which includes warehousing and inventory management. This holistic approach empowers supplement manufacturers to streamline their supply chains, ensuring that every facet of packaging and distribution is executed with precision. By emphasizing operational efficiency, Western Packaging allows clients to significantly minimize lead times and improve product delivery. This capability positions Western Packaging as a preferred partner in the dietary supplement sector and demonstrates how integrated packaging solutions near me enhance supply chain efficiency. Companies that adopt these strategies experience improved efficiency and responsiveness in their operations, underscoring the crucial role of cohesive handling and logistics in today’s competitive landscape.

Atlantic Packaging: Sustainable Solutions for a Healthy Supply Chain

Western Packaging specializes in customized flexible wraps tailored specifically for the nutraceutical sector. Our commitment to innovative design not only enhances product appeal but also elevates brand recognition on the shelf. By utilizing our tailored adaptable options—such as large bags for protein products and stick packs for nutraceuticals—manufacturers can create containers that stand out, meet specific needs, and engage consumers effectively.

Furthermore, we develop compelling graphic assets, ranging from labels to brochures, ensuring a cohesive and captivating brand identity. This approach not only draws attention but also aligns with the growing demand for efficient and attractive containers in the health supplement market.

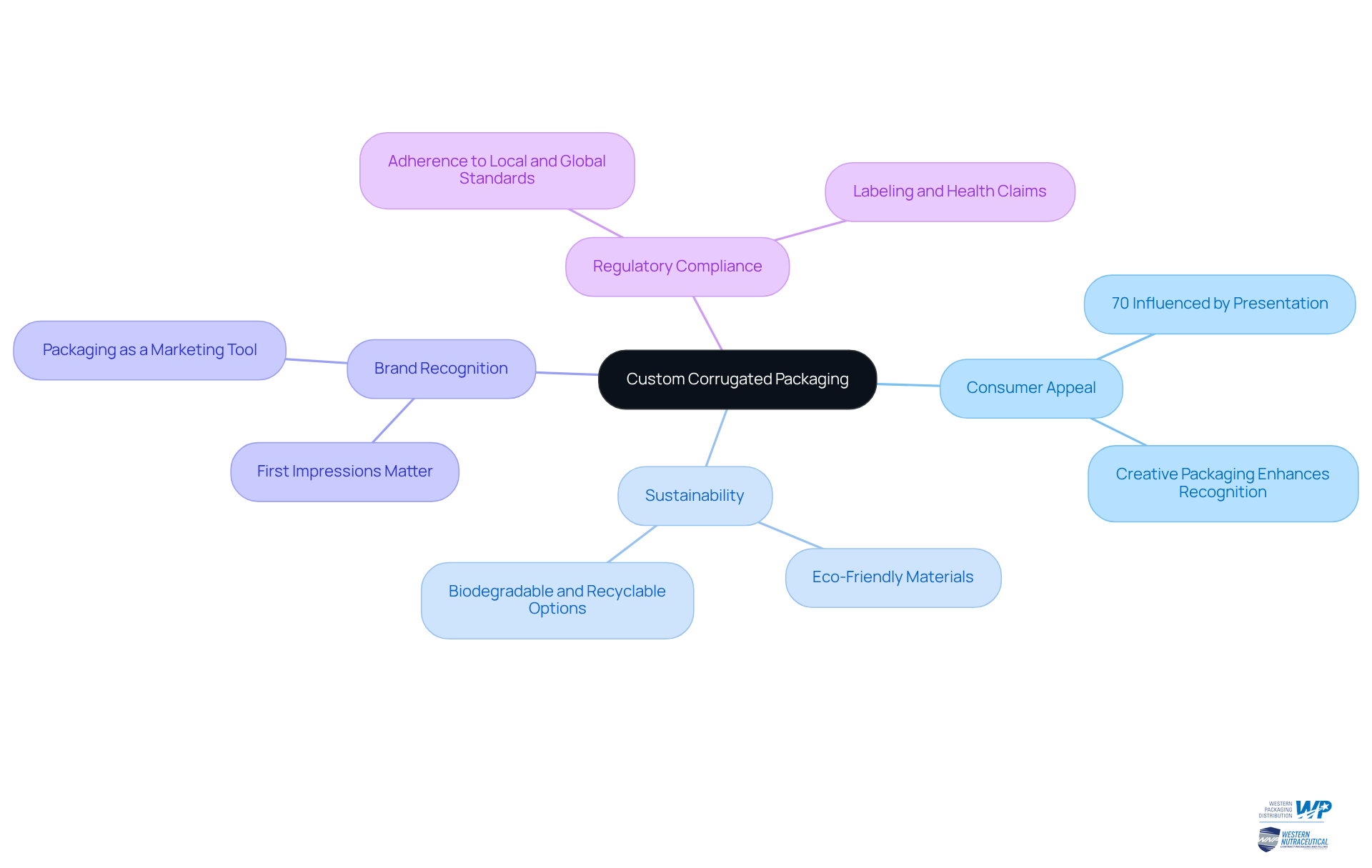

Packaging Corporation of America: Custom Corrugated Packaging for Every Application

Packaging Corporation of America specializes in custom corrugated containers tailored specifically for nutraceutical items. This expertise not only ensures that products stand out on retail shelves but also significantly boosts brand recognition and consumer appeal. Notably, 70% of customers report that they purchase a product based on its presentation, underscoring the critical role that appearance plays in purchasing decisions.

By leveraging these customized approaches, manufacturers can effectively convey their brand message, attract a broader customer base, and ultimately enhance sales. Furthermore, as the trend towards sustainable solutions grows, using eco-friendly materials can better align brands with consumer preferences.

The strategic application of customized containers is vital in the competitive nutraceutical market, where first impressions are paramount and the effective communication of product benefits is essential. Additionally, adhering to local, national, or global regulations is crucial, ensuring that materials meet required standards while appealing to consumers.

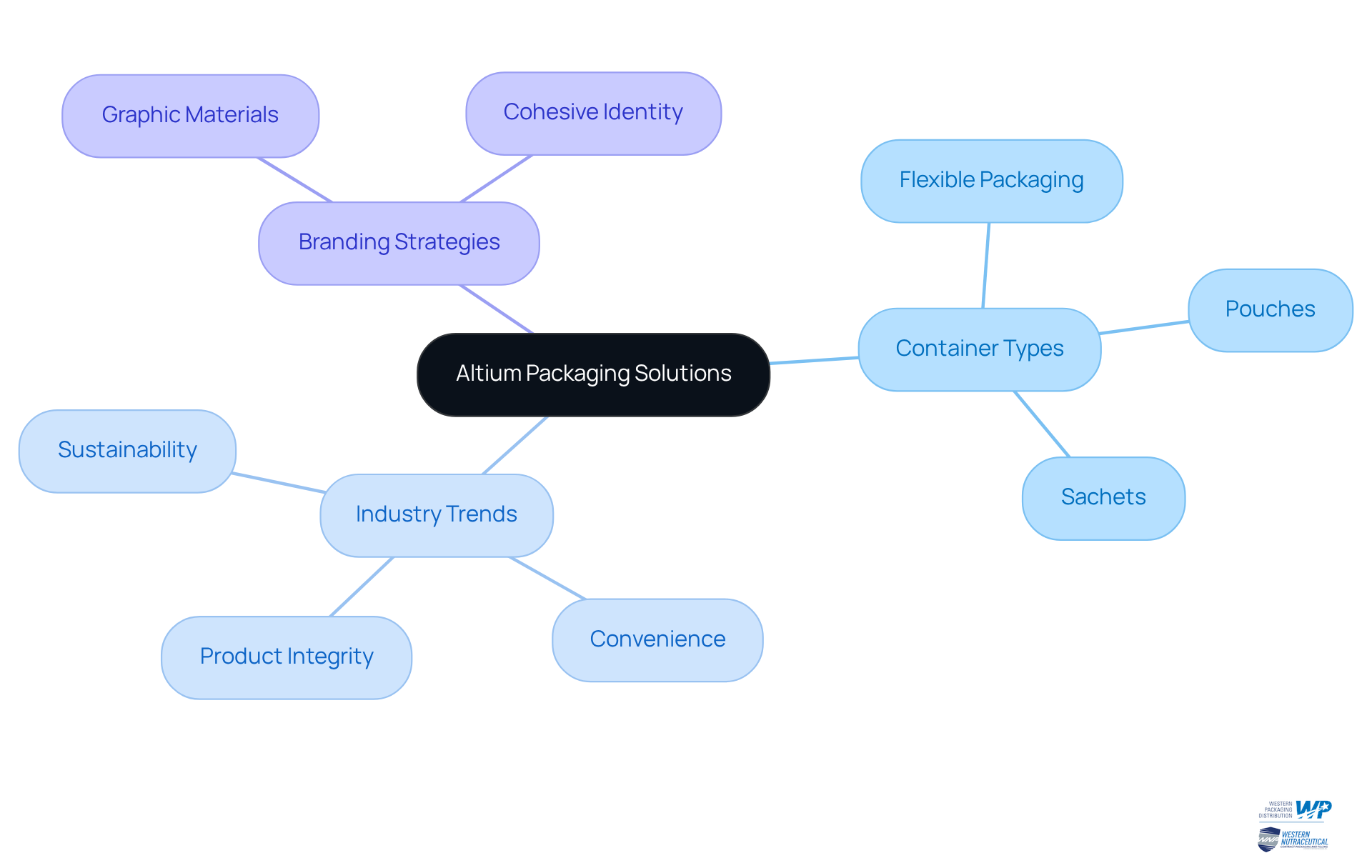

Altium Packaging: Diverse Packaging Solutions for Multiple Industries

Western Packaging stands out with its extensive array of solutions tailored for diverse industries, particularly nutraceuticals. Their offerings encompass a variety of container types, empowering manufacturers to choose the most suitable options for their products, which is crucial for ensuring optimal protection and presentation.

As we look ahead to 2025, the demand for adaptable materials is projected to rise, driven by consumer preferences for convenience and sustainability. Notably, flexible packaging formats such as pouches and sachets are gaining traction due to their lightweight nature and ability to preserve product integrity.

Western Packaging emphasizes that adopting innovative packaging methods is vital for maintaining competitiveness in the dietary supplement sector. Their commitment to developing captivating graphic materials and cohesive brand identities enhances product appeal while aligning with the growing emphasis on sustainability in the health supplement industry.

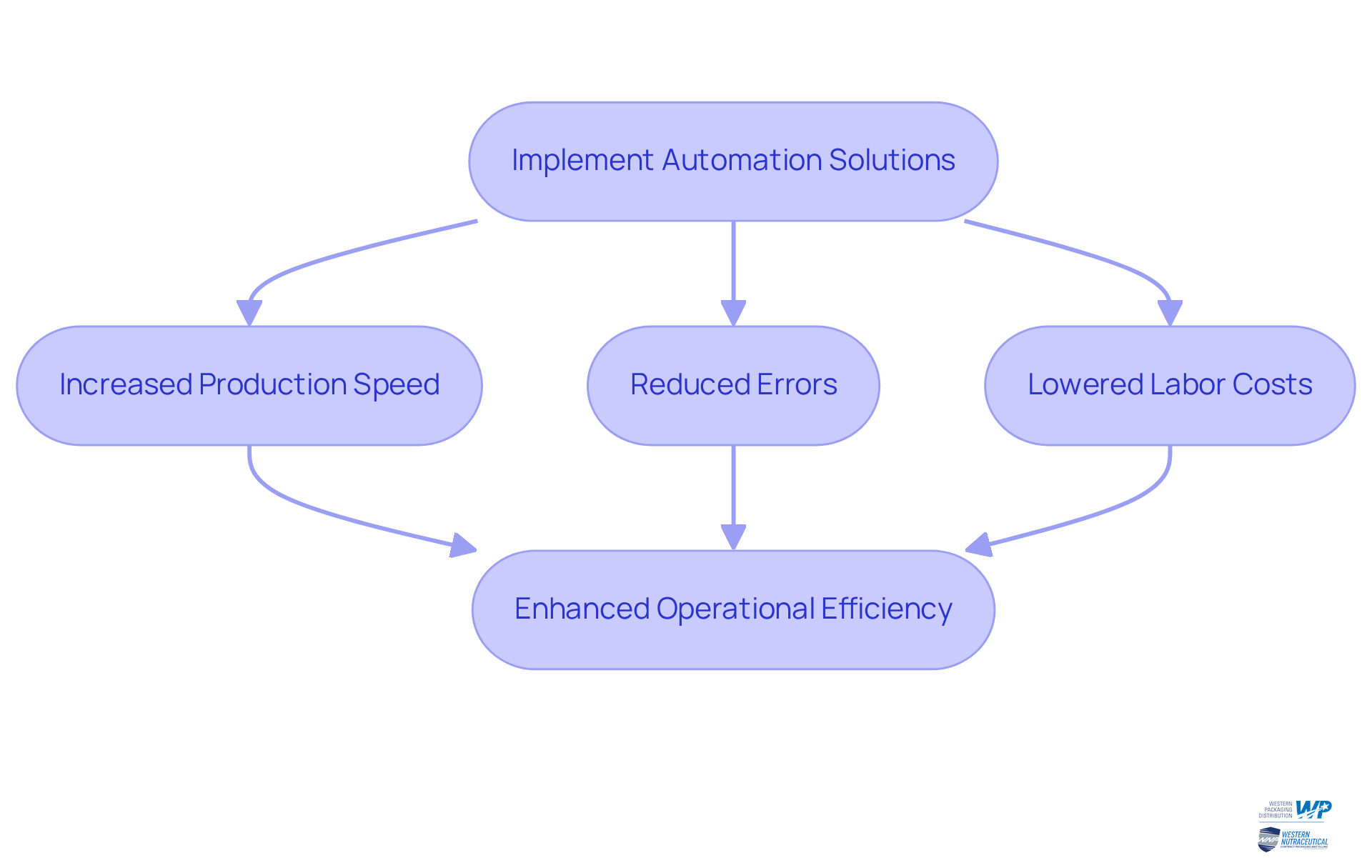

Kyana Packaging: Automation Solutions for Streamlined Packaging Processes

Western Packaging specializes in automation solutions that significantly enhance the processes for health product manufacturers. By implementing automated systems, businesses can achieve increased production speed, reduced errors, and lowered labor costs. This technological advancement is vital for manufacturers striving to enhance operational efficiency and meet the escalating demands of the market.

As Parata states, "Secure, effective containers that include brand recognition for your business and customization for your clients is essential in the health supplement market."

Statistics reveal that automation can lead to production efficiency improvements of up to 30%, enabling companies to streamline workflows and decrease labor costs. With the dietary supplement market projected to exceed $270 billion in the coming year, incorporating automated wrapping processes is not just beneficial; it is a strategic necessity for remaining competitive and fulfilling consumer expectations.

Innovative Packaging Design: Elevate Your Brand with Creative Solutions

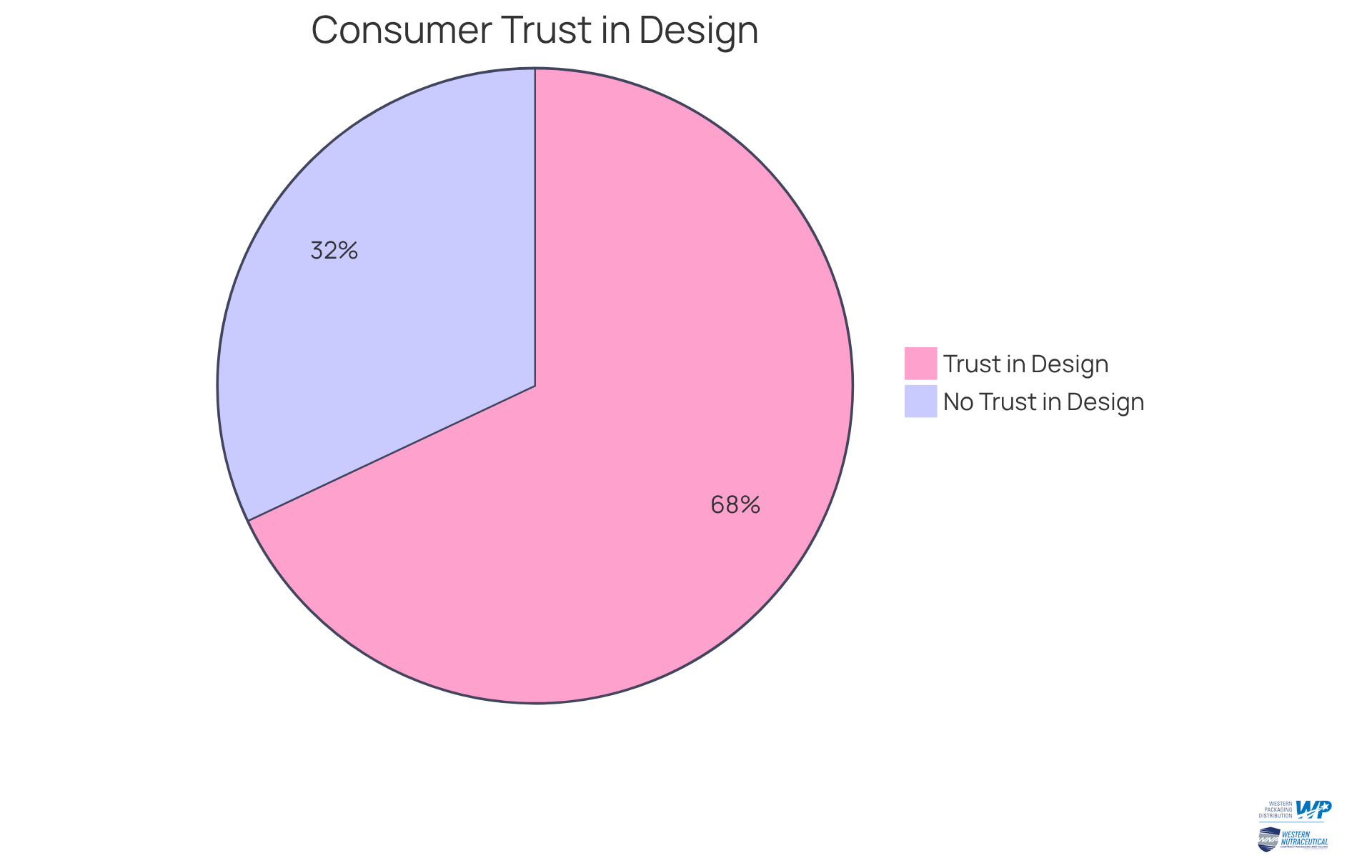

Innovative container design is essential for nutraceutical manufacturers seeking to elevate their brand presence. By implementing creative solutions that resonate with consumers, businesses can significantly boost their product's shelf appeal and stimulate interest. Effective presentation not only captures attention but also communicates the brand's values and benefits, making it a vital component of any marketing strategy.

Statistics reveal that 68% of buyers trust health-related products with visually appealing designs, underscoring the impact of aesthetics on consumer choices. Furthermore, as consumer preferences shift towards sustainable and eco-friendly materials, companies like Amcor and SÜDPACK Medica exemplify this trend by offering innovative solutions such as SÜDPACK Medica's NutriGuard, a recyclable blister solution for dietary supplements.

With the nutraceutical container market projected to reach USD 4.66 billion by 2030, growing at a CAGR of 4.9%, the emphasis on innovative and attractive designs will remain pivotal in shaping consumer perceptions and driving sales.

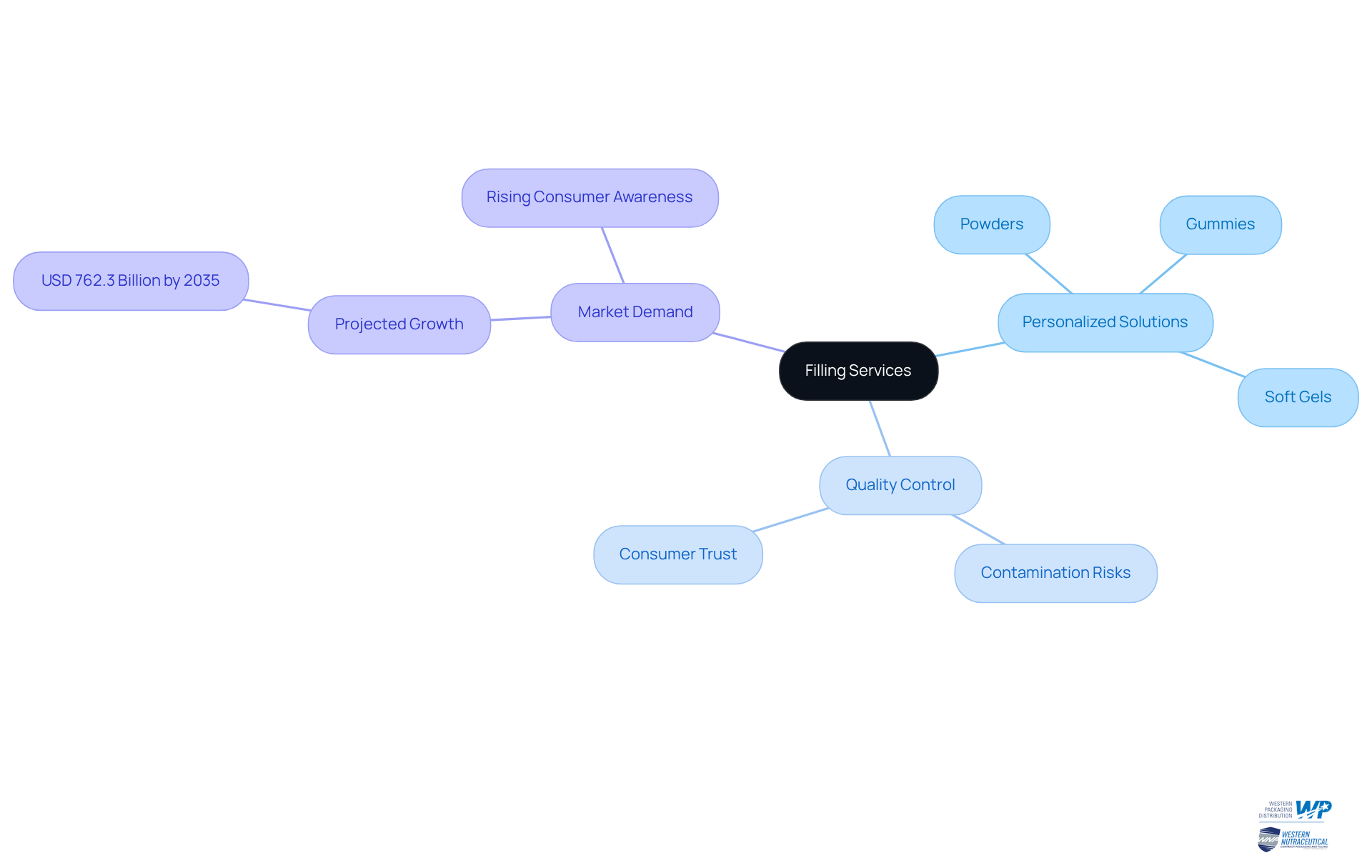

Filling Services: Tailored Solutions for Diverse Product Needs

Filling services are essential in the packaging process for nutraceuticals, significantly impacting quality and consumer trust. Companies like Western Packaging provide personalized filling solutions tailored for various products, including powders, gummies, and soft gels. This customized approach ensures that filling processes align with specific product requirements, which is vital for maintaining consistency and quality.

Industry leaders emphasize that rigorous quality control during filling not only enhances product integrity but also builds consumer confidence. For example, organizations that prioritize meticulous filling processes can greatly minimize the risk of contamination and variability, ensuring that each product meets the highest standards.

As the demand for nutraceuticals continues to rise, with projections indicating the market will reach USD 762.3 billion by 2035, the importance of efficient filling methods becomes increasingly clear. W. Edwards Deming aptly stated, 'Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction, and skillful execution.' This highlights the necessity for manufacturers to collaborate with providers that excel in quality assurance and tailored services.

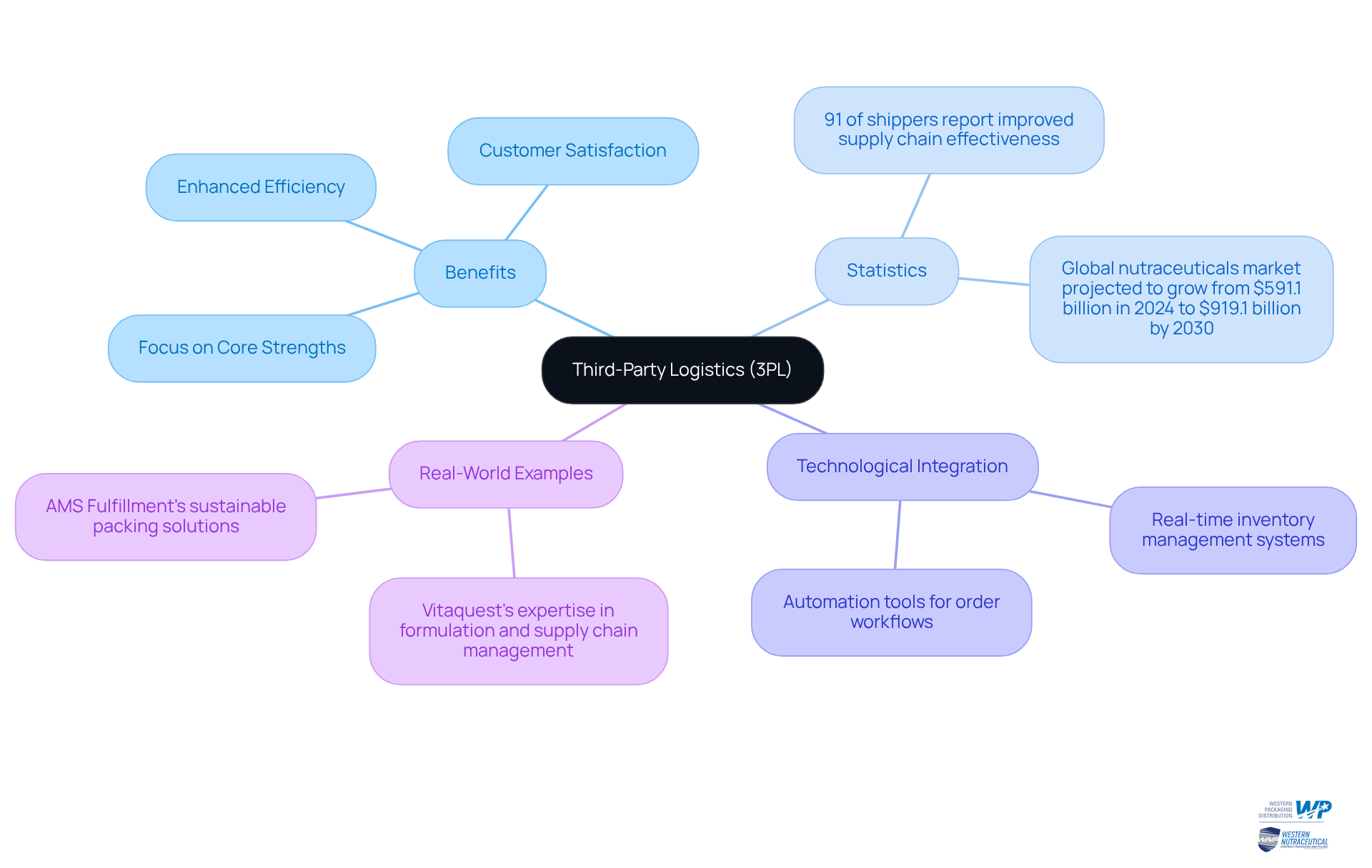

Third-Party Logistics (3PL): Optimize Your Supply Chain with Expert Solutions

Third-party logistics (3PL) services are pivotal for nutraceutical manufacturers aiming to enhance their supply chain efficiency. Collaborating with logistics experts like Western Packaging empowers companies to refine warehousing, inventory management, and distribution processes through tailored 3PL services. This strategic alliance alleviates operational challenges, allowing manufacturers to concentrate on their core strengths and ensure timely delivery to market.

Statistics reveal that:

- 91% of shippers report improved supply chain effectiveness and customer satisfaction after outsourcing logistics functions to 3PL providers.

- The global nutraceuticals market is projected to grow from $591.1 billion in 2024 to $919.1 billion by 2030, making the demand for efficient logistics solutions more pressing than ever.

For instance, firms like Vitaquest leverage their extensive knowledge in formulation and supply chain management to optimize operations, ensuring adherence to stringent FDA regulations while preserving item integrity. As logistics experts emphasize, viewing logistics as a core capability rather than merely a service can significantly enhance a company's market resilience and scalability.

Moreover, the integration of advanced technologies, such as real-time inventory management systems, enables 3PLs like Western Packaging to maintain accurate inventory counts and manage product recalls effectively. This precision is essential in the dietary supplement industry, where quality control measures are paramount. By adopting these expert logistics strategies, supplement manufacturers can enhance their distribution processes and prepare themselves for sustained growth in a competitive market.

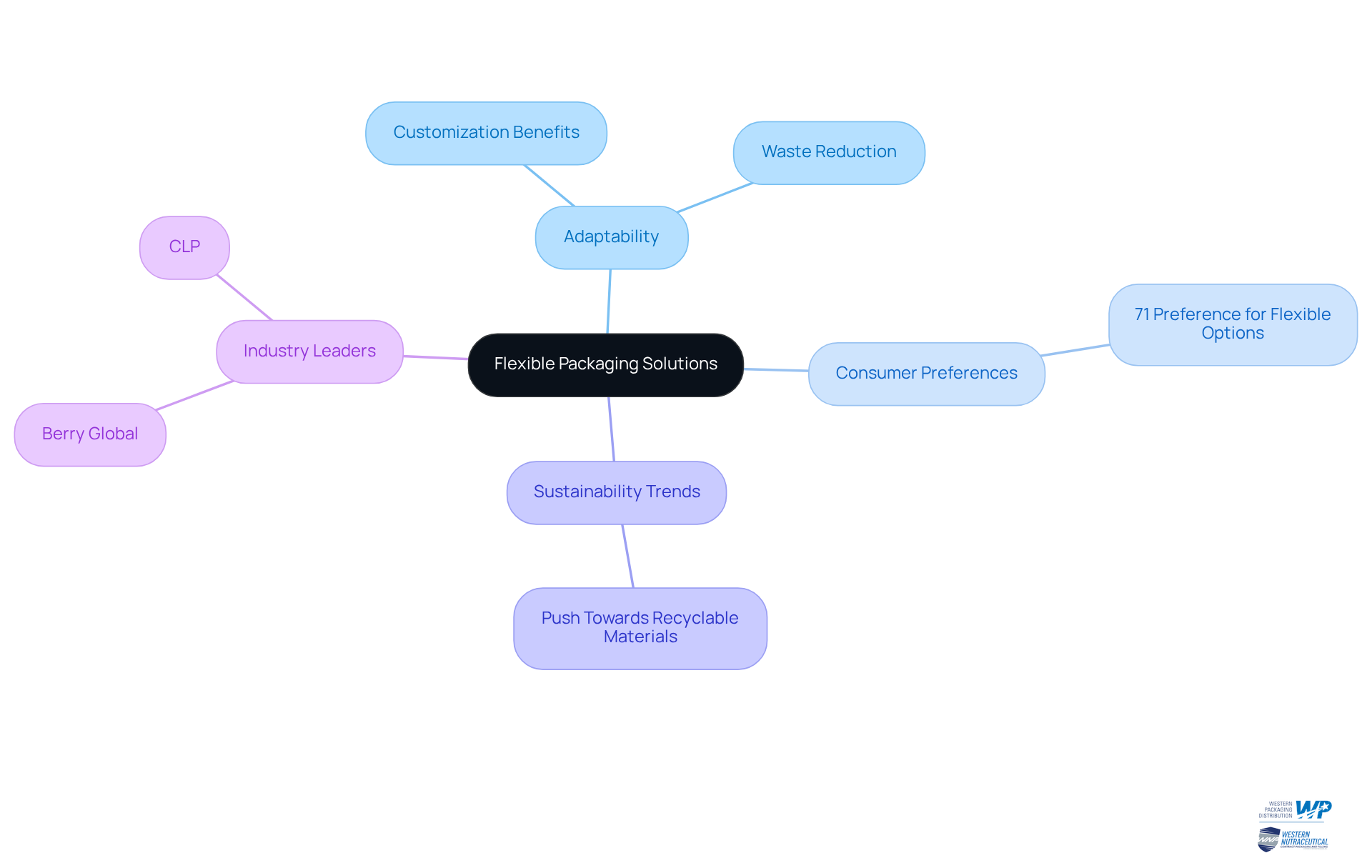

Flexible Packaging Solutions: Adaptable Options for Modern Businesses

Flexible wrapping solutions are increasingly favored by nutraceutical manufacturers due to their remarkable adaptability and convenience. These versatile options can be tailored into various shapes and sizes, effectively catering to a wide range of product requirements. This adaptability not only enhances shelf life but also significantly reduces waste, aligning with the growing consumer demand for sustainable practices. In 2025, trends suggest that adaptable materials will maintain their leading position in the market, propelled by advancements that emphasize sustainability and practicality.

Consumer preferences are shifting towards flexible options, with 71% of respondents indicating a preference for these alternatives over conventional rigid choices. This trend is further supported by industry leaders who acknowledge the benefits of flexible containers. For instance, Berry Global's launch of lightweight closures and biodegradable pouches illustrates effective uses of flexible containers.

Companies like CLP are at the forefront of this movement, providing FDA-compliant flexible solutions that merge aesthetics with functionality. Their commitment to sustainability is evident in their development of recyclable films and reduced-waste options, which resonate with the eco-conscious consumer.

As the dietary supplement market evolves, manufacturers utilizing adaptable containers not only enhance their product appeal but also position themselves advantageously in a landscape increasingly shaped by consumer desires for convenience and sustainability.

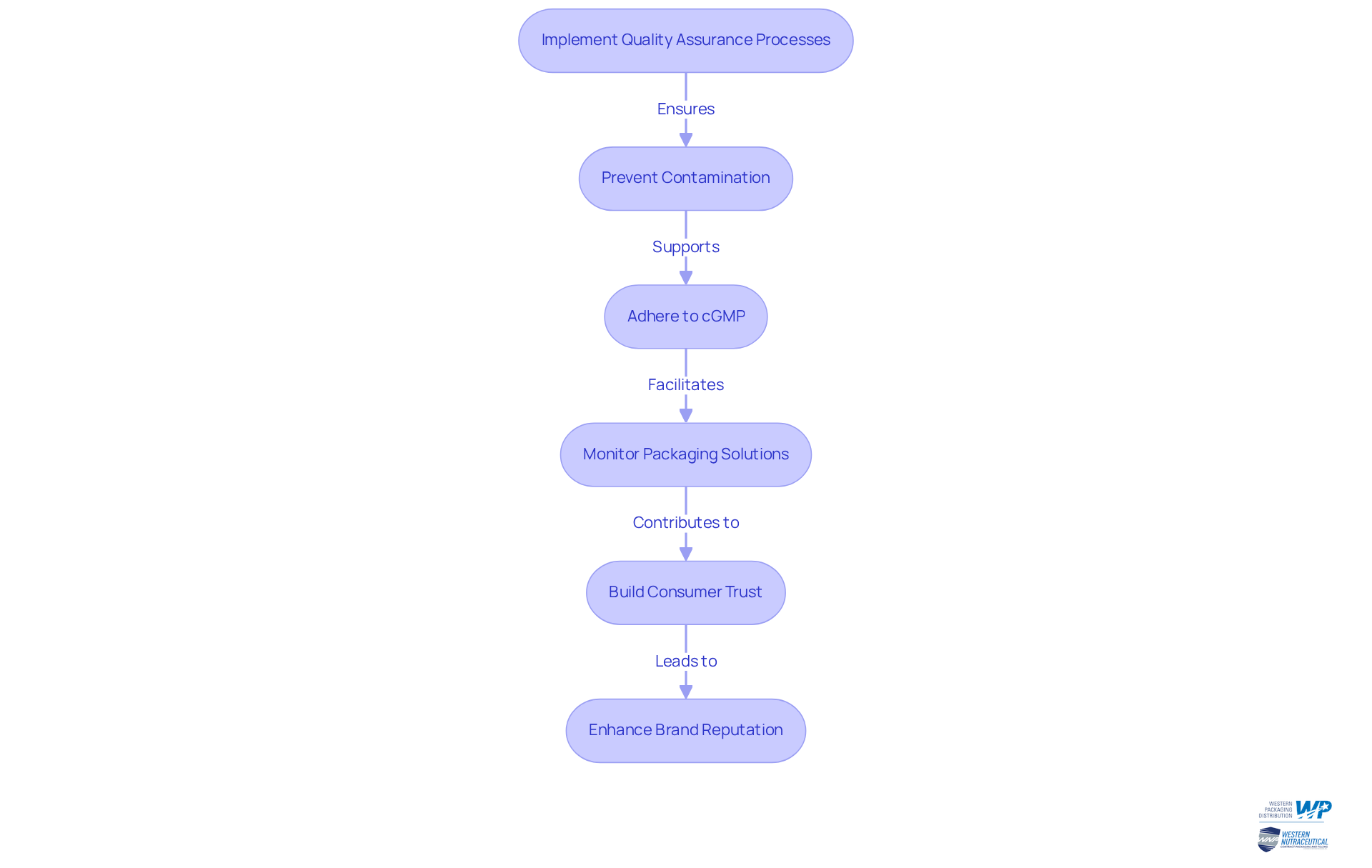

Quality Control in Packaging: Ensuring Safety and Compliance for Your Products

Quality assurance in wrapping is crucial for nutraceutical producers, as it directly affects item safety and adherence to industry regulations. Implementing stringent quality assurance processes is vital to prevent contamination and ensure that products adhere to established standards. Recent data indicates that 58% of inspected dietary supplement facilities were cited for violations of current Good Manufacturing Practices (cGMP), underscoring the critical need for robust compliance measures to avoid such violations.

Firms such as American Nutritional Corporation and Arizona Nutritional Supplements LLC demonstrate optimal methods in ensuring safety and compliance in their wrapping processes. For instance, American Nutritional Corporation employs sustainable container solutions and adheres to rigorous testing protocols, which have led to a significant decrease in compliance issues. Arizona Nutritional Supplements LLC has implemented advanced quality control systems that monitor every stage of the packaging solutions near me process, ensuring integrity and safety.

Industry experts emphasize the importance of quality assurance in building consumer trust. As Karen Howard, CEO of the Organic & Natural Health Association, states, "Our capacity to maintain the integrity of our offerings is of paramount importance as we continue to work to educate legislators and regulators on regulatory changes that will ensure shelves are stocked with quality, safe, and effective goods."

By prioritizing quality control, manufacturers not only protect their brand reputation but also contribute to the overall safety of the nutraceutical market, which is projected to approach $70 billion. As consumer awareness of product safety increases, the demand for transparency and scientifically validated products will continue to shape the industry landscape.

Conclusion

The exploration of packaging solutions for nutraceutical manufacturers underscores the critical importance of effective and innovative packaging in driving success within this rapidly expanding industry. By leveraging integrated, sustainable, and customizable packaging strategies, manufacturers can enhance product appeal while streamlining operations and addressing the evolving demands of consumers.

Key insights from the article highlight the necessity of collaboration with specialized packaging providers, such as Western Packaging and Atlantic Packaging, which deliver tailored solutions that enhance both operational efficiency and environmental sustainability. The advantages of automation, quality control, and flexible packaging are emphasized, illustrating how these components contribute to a competitive edge in the nutraceutical market.

As the industry evolves, manufacturers are urged to prioritize innovative packaging designs and robust quality assurance practices to ensure product safety and compliance. Embracing these strategies not only fosters consumer trust but also positions brands favorably in a marketplace increasingly driven by sustainability and aesthetic appeal. The commitment to effective packaging solutions is essential for manufacturers aiming to thrive in the dynamic landscape of nutraceuticals.

Frequently Asked Questions

What services does Western Packaging offer?

Western Packaging provides integrated packaging solutions that include design, filling services, and comprehensive third-party logistics (3PL), which encompasses warehousing and inventory management.

How does Western Packaging enhance supply chain efficiency for supplement manufacturers?

By integrating various services, Western Packaging helps supplement manufacturers streamline their supply chains, minimize lead times, and improve product delivery, thereby emphasizing operational efficiency.

What is the focus of Atlantic Packaging in the nutraceutical sector?

Atlantic Packaging specializes in customized flexible wraps designed specifically for the nutraceutical sector, enhancing product appeal and brand recognition.

How does Atlantic Packaging help manufacturers with product presentation?

Atlantic Packaging offers tailored options such as large bags for protein products and stick packs for nutraceuticals, along with graphic assets like labels and brochures, to create cohesive and attractive brand identities.

What type of packaging does Packaging Corporation of America specialize in?

Packaging Corporation of America specializes in custom corrugated containers specifically designed for nutraceutical items.

Why is product presentation important in the nutraceutical market?

Product presentation is crucial because 70% of customers report making purchases based on a product's appearance, highlighting the role of visual appeal in purchasing decisions.

How can customized packaging benefit manufacturers in the nutraceutical sector?

Customized packaging can help manufacturers effectively convey their brand message, attract a broader customer base, enhance sales, and align with the growing trend towards sustainable solutions.

What regulations must manufacturers consider when using packaging materials?

Manufacturers must adhere to local, national, or global regulations to ensure that packaging materials meet required standards while also appealing to consumers.