Overview

The article titled "10 Product Assembly Companies to Streamline Your Manufacturing" identifies key players in the industry that enhance manufacturing efficiency through specialized assembly services. Companies such as Western Packaging and Joncoind are highlighted for their unique capabilities, demonstrating the advantages of outsourcing assembly tasks. These partnerships can lead to:

- Reduced costs

- Improved operational efficiency

- Enhanced product quality

By leveraging these services, manufacturers can significantly optimize their processes. Explore how these assembly solutions can transform your operations and drive success.

Introduction

In an increasingly competitive manufacturing landscape, the efficiency of product assembly is pivotal to a company's success. As businesses strive to optimize their operations, the strategic decision to partner with specialized product assembly companies has emerged as a vital solution. This article explores ten notable companies offering innovative assembly services, showcasing how their expertise can streamline processes and enhance overall productivity.

What challenges might companies encounter when outsourcing their assembly needs, and how can these partnerships revolutionize their operational capabilities?

Western Packaging: Integrated Packaging Solutions for Enhanced Supply Chain Efficiency

Western Packaging distinguishes itself in the market by delivering integrated packaging solutions that seamlessly combine design, filling, and logistics. Our filling process accommodates a range of items, from powders to gummies and soft-gels, ensuring that we fulfill the diverse requirements of nutraceutical manufacturers. This holistic approach not only enhances item appeal but also significantly streamlines the supply chain, leading to reduced lead times and improved delivery efficiency.

Notably, businesses that adopt outsourcing report operational cost reductions averaging between 20% and 30%. Furthermore, companies leveraging integrated logistics—including our comprehensive 3PL services that encompass warehousing, inventory management, and distribution—also report enhanced operational agility and reduced costs, which are critical in today's competitive landscape.

By providing tailored solutions for diverse sectors, including nutraceuticals and consumer goods, Western Packaging empowers clients to concentrate on their core competencies. This cohesive service model effectively addresses unique packaging needs, ensuring that businesses can optimize their operations while maintaining high standards of quality and compliance.

As industry leaders emphasize, "Integrated packaging solutions are essential for driving efficiency and sustainability in today’s competitive market." Additionally, the integration of advanced technologies such as AI and IoT further enhances the effectiveness of these logistics solutions. Thus, Western Packaging stands as a preferred partner for those looking to enhance their supply chain efficiency.

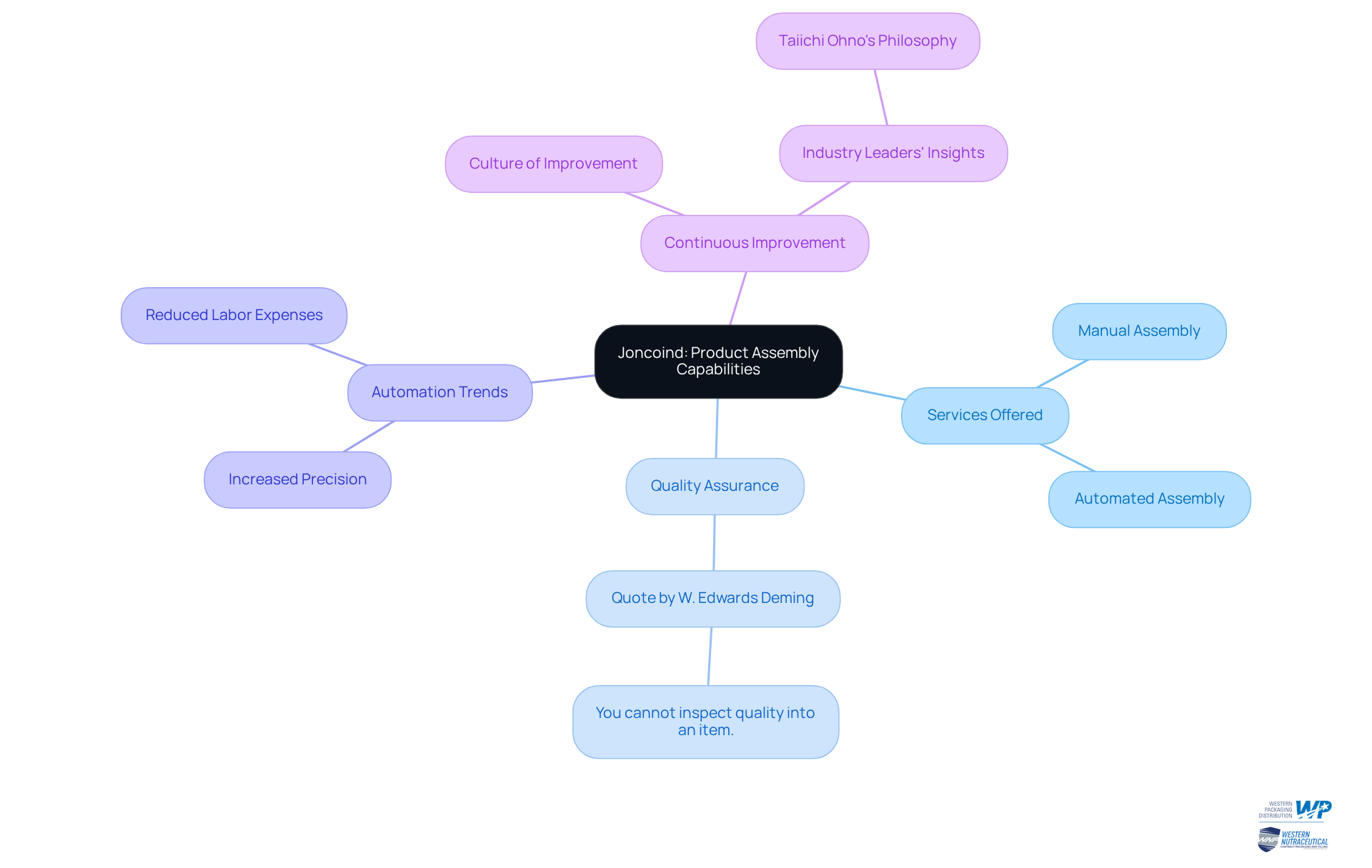

Joncoind: Comprehensive Product Assembly Capabilities for Streamlined Manufacturing

Joncoind excels in providing comprehensive services for product assembly companies tailored to meet diverse manufacturing needs. Their offerings encompass both manual and automated assembly processes, ensuring flexibility and efficiency. By combining advanced technologies with skilled labor, Joncoind not only improves operational efficiency but also maintains strict assurance standards. As W. Edwards Deming observed, "You cannot inspect quality into an item," emphasizing the importance of incorporating quality from the beginning.

In 2025, the trend towards automation in manufacturing processes continues to grow, driven by the need for increased precision and reduced labor expenses. Companies in the nutraceutical industry have effectively utilized Joncoind's capabilities to optimize their operations, benefiting from both the effectiveness of automated procedures and the expertise of product assembly companies in constructing intricate items. This dual strategy enables producers to concentrate on their essential operations while guaranteeing their offerings meet the highest quality standards.

To remain competitive, manufacturers should evaluate their current production processes for opportunities to integrate automation and adopt a culture of continuous improvement, as highlighted by industry leaders like Taiichi Ohno.

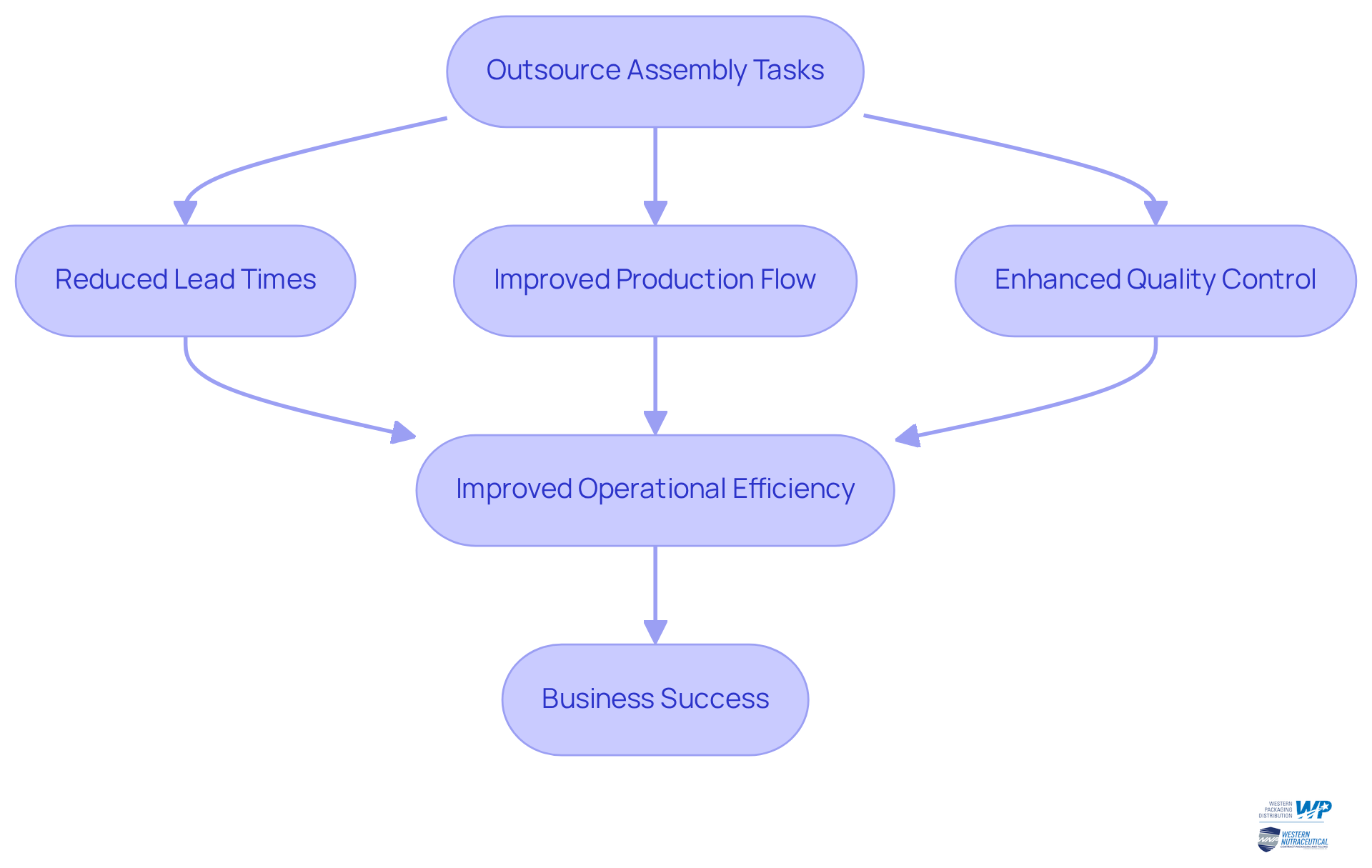

Karkhana.io: Essential Product Assembly Benefits for Business Success

Karkhana.io provides essential product construction services that significantly enhance business success. By outsourcing assembly tasks to product assembly companies, companies can achieve reduced lead times, improved production flow, and enhanced quality control. For example, Nike Inc. has effectively outsourced its athletic footwear production to manufacturers in Vietnam and Indonesia, leveraging cost-effective labor while upholding high-quality standards. This strategic approach allows product assembly companies to concentrate on their core operations while benefiting from Karkhana.io's specialized knowledge, ensuring efficient assembly of products that meet precise specifications.

Statistics indicate that outsourcing manufacturing can drastically reduce production costs, making it an appealing option for companies seeking to optimize their operations. Industry experts emphasize that utilizing product assembly companies for outsourced production services can lead to improved operational efficiency and quicker time-to-market. As noted by a leading expert, "Outsourcing allows companies to focus on innovation and market expansion rather than managing manufacturing operations."

However, it is vital for businesses to carefully select their manufacturing partners to mitigate potential risks associated with outsourcing. Companies that have adopted this model report smoother production processes and a significant reduction in delays, highlighting the transformative impact of outsourcing on manufacturing dynamics.

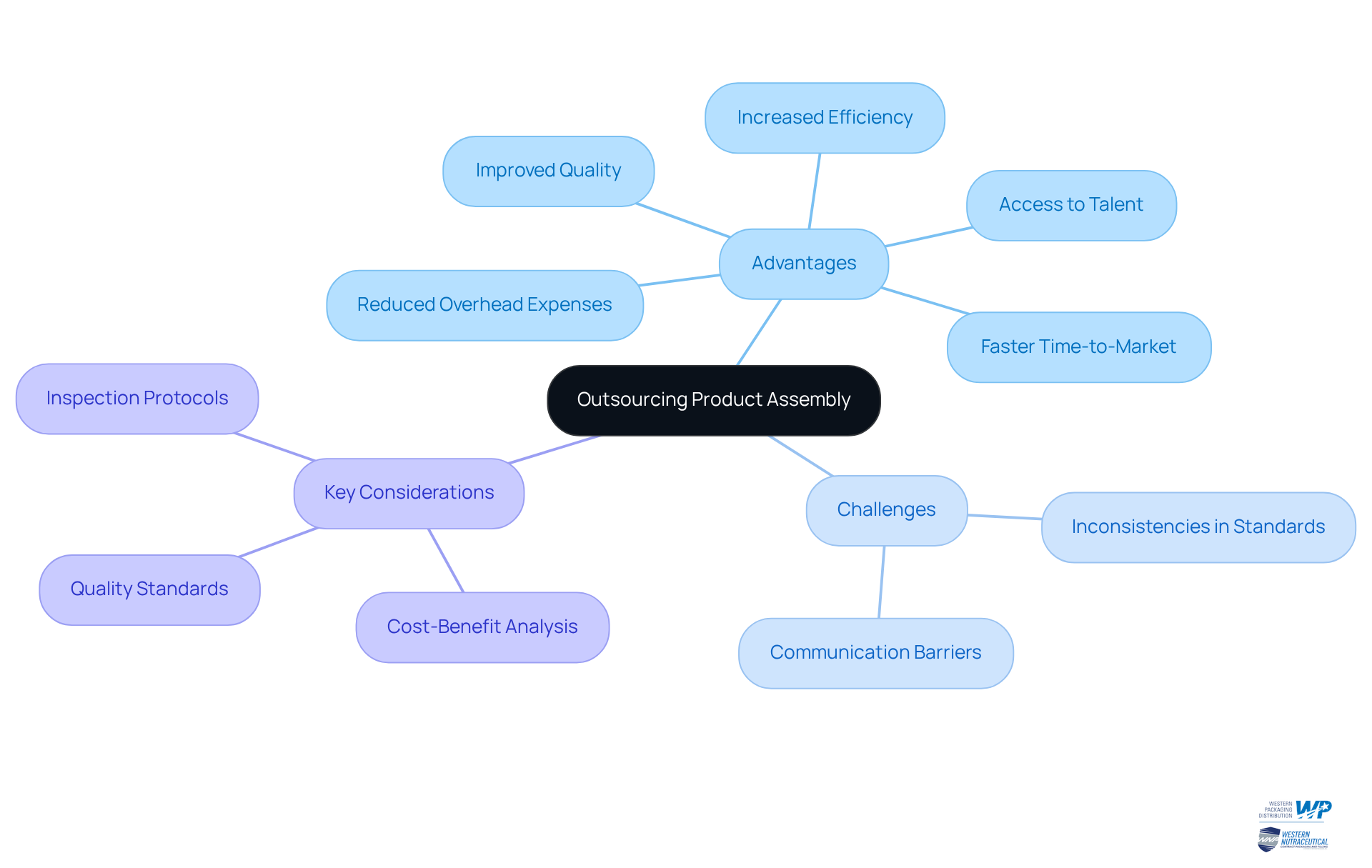

PBZ Manufacturing: Expert Insights on Outsourcing Product Assembly

PBZ Manufacturing underscores the strategic advantages of outsourcing assembly to product assembly companies, allowing firms to leverage specialized expertise and resources that may not be available internally. By collaborating with specialized producers, companies can significantly reduce overhead expenses—often by as much as 16%—while enhancing production efficiency and focusing on their core strengths.

Moreover, product assembly companies can accelerate time-to-market and improve the quality of offerings, making outsourcing a compelling option for manufacturers aiming to optimize operations. As Anna Taylor points out, the primary benefits businesses seek from outsourcing include:

- Enhanced access to talent

- The ability to meet increasing customer demands

However, it is crucial to recognize the challenges associated with outsourcing, such as potential inconsistencies in standards and communication barriers. Conducting a thorough cost-benefit analysis before engaging in outsourcing is vital, as is establishing clear quality standards and stringent inspection protocols to maintain quality.

As the manufacturing landscape evolves in 2025, product assembly companies are increasingly embracing the trend toward outsourcing, driven by the necessity for flexibility and access to advanced technologies. By embracing this approach, manufacturers can not only streamline their processes but also position themselves competitively in a rapidly changing market.

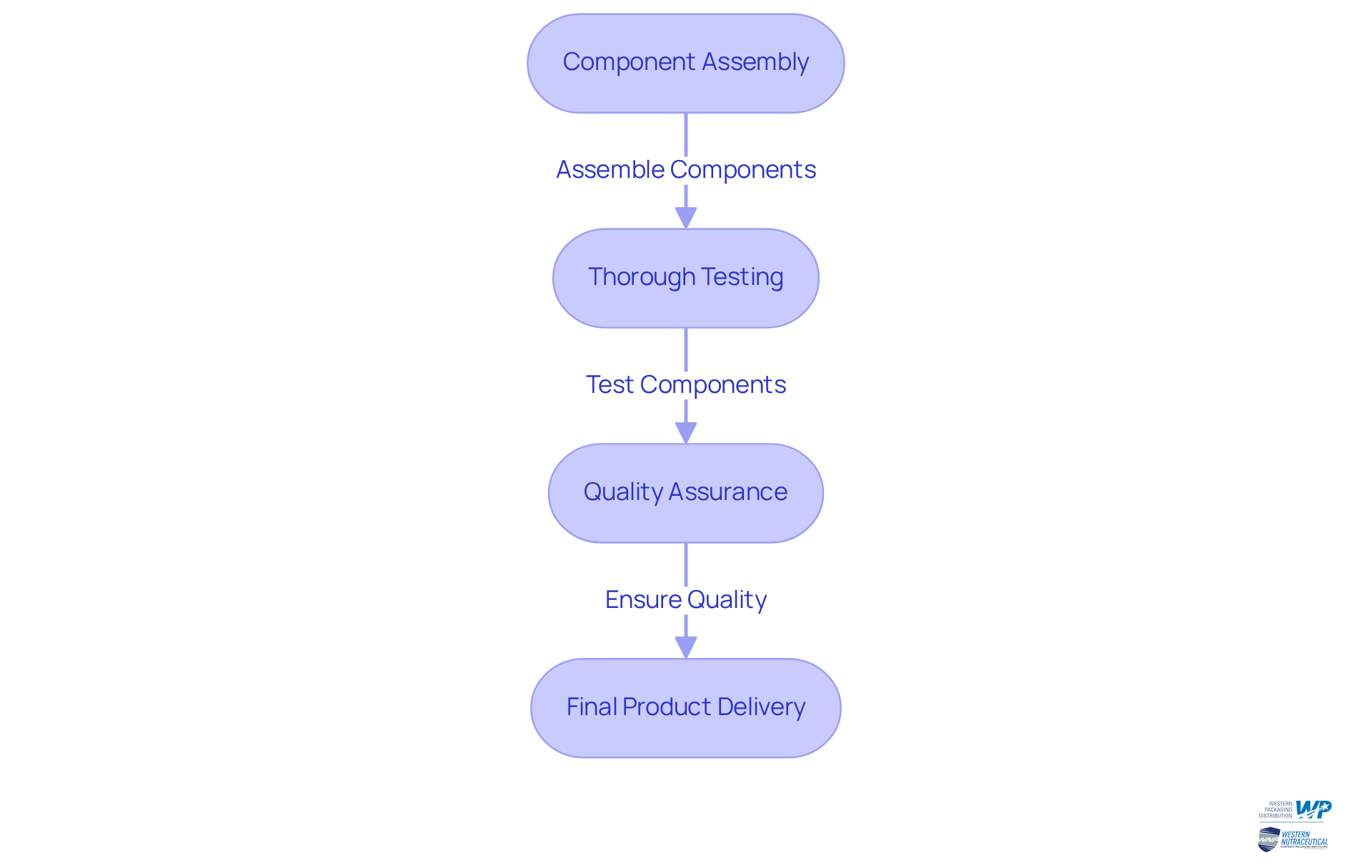

Vergent Products: Final Product Assembly for Enhanced Production Efficiency

Vergent Products excels in final item integration, meticulously combining all components to deliver high-quality finished goods. Their extensive services encompass thorough testing and assurance, which are crucial for enhancing production efficiency. By concentrating on the final construction stage, Vergent Products significantly reduces mistakes and enhances overall product excellence. This commitment to quality positions them as a reliable partner for producers aiming to refine their production processes.

Industry leaders emphasize that comprehensive testing not only guarantees excellence but also optimizes operations, reinforcing the notion that assurance in final production is essential for achieving outstanding manufacturing results. As producers increasingly recognize the importance of these services, Vergent Products stands out as a pivotal contributor to elevating product standards and operational efficiency in product assembly companies.

As William A. Foster aptly states, 'Quality is never an accident; it is always the result of high intention, sincere effort, intelligent direction and skillful execution.' Furthermore, the integration of automation in manufacturing processes has become indispensable in the workforce, enhancing production efficiency. Continuous improvement remains a vital aspect of assurance, enabling producers to adapt to evolving industry practices. Instances of manufacturers successfully enhancing quality through final construction services further illustrate the impact of these practices.

Xpress 360: Comprehensive Packaging and Assembly Services for Supply Chain Management

Xpress 360 provides a comprehensive array of packaging and construction services specifically designed to enhance supply chain management. Their offerings range from innovative custom packaging design to efficient production methods, ensuring that items are market-ready with minimal delay. By integrating these services, Xpress 360 significantly reduces lead times and enhances product delivery efficiency. This integrated approach not only bolsters operational efficiency but also aligns with the increasing demand for customized solutions within the packaging sector.

With the custom packaging market projected to reach $63.07 billion by 2030, companies that leverage such comprehensive services are strategically positioned to excel in a competitive landscape. Notably, organizations that have implemented integrated packaging and integration solutions report substantial improvements in their supply chain performance, emphasizing the critical role of effective packaging design in achieving operational success.

As Brian O. from Disney remarked, 'The quality is excellent and no doubt your company prides itself on using the best processes to produce.' Furthermore, the global packaging design services market was estimated at $24.63 billion in 2023 and is forecasted to reach $32.42 billion by 2030, underscoring the broader growth trajectory within the packaging industry.

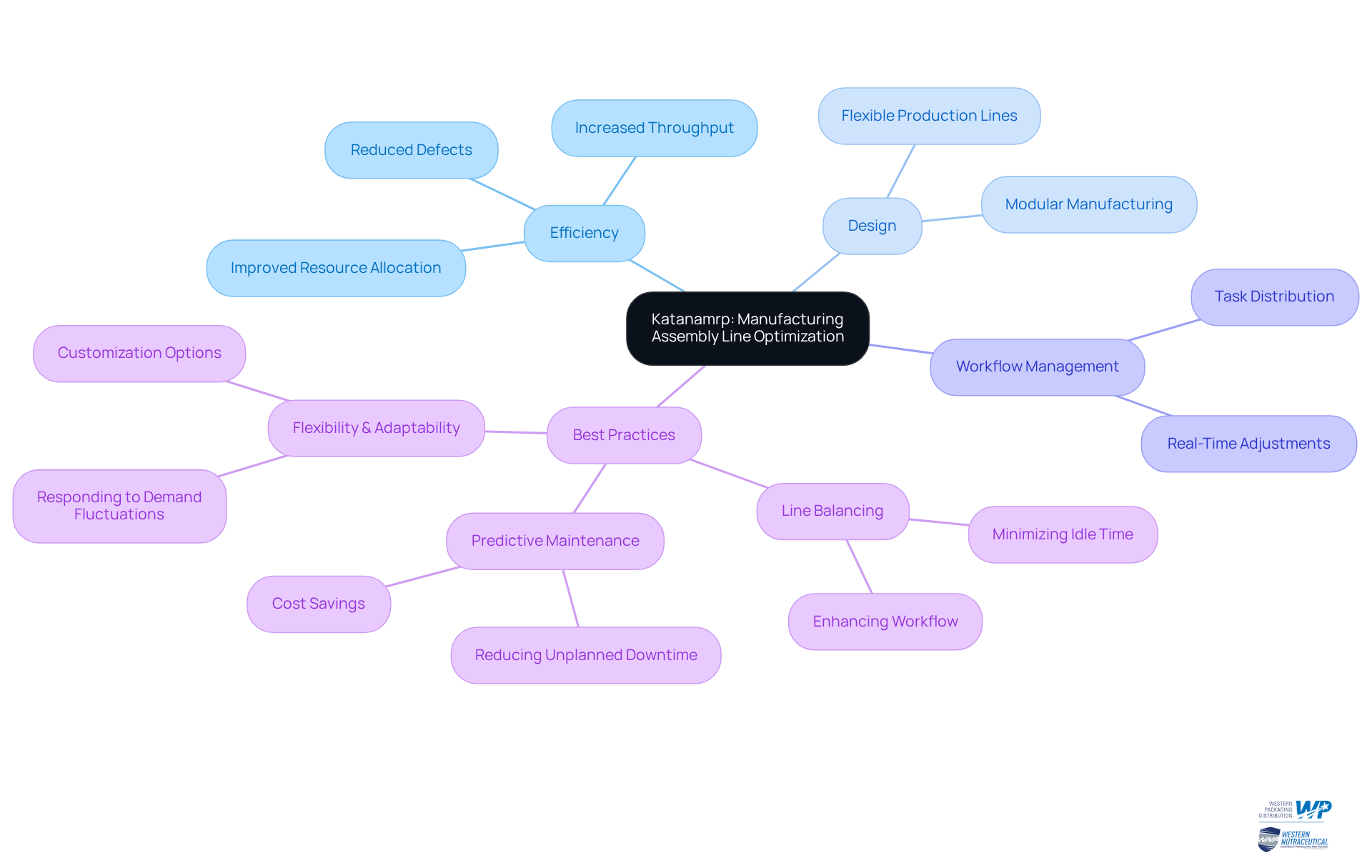

Katanamrp: Insights into Manufacturing Assembly Lines for Efficient Production

Katanamrp excels in optimizing manufacturing production lines, focusing on enhancing efficiency through innovative design and workflow management strategies. Their expertise enables producers to streamline processes, minimize waste, and significantly boost output. As we approach 2025, the emphasis on production line design increasingly centers on flexibility and adaptability, allowing producers to respond swiftly to fluctuating demands.

By adopting best practices such as effective line balancing and leveraging advanced technologies, including predictive maintenance, Katanamrp empowers businesses to achieve remarkable efficiency and productivity gains. For instance, manufacturers implementing systematic line balancing techniques have reported up to a 30% increase in throughput and a notable reduction in defects.

Furthermore, a well-structured production line contributes to improved employee satisfaction, resulting in reduced turnover rates. As industry leaders recognize the essential function of well-organized production lines, Katanamrp's insights serve as a vital resource for those seeking to enhance their operational capabilities and maintain a competitive edge in the evolving manufacturing landscape.

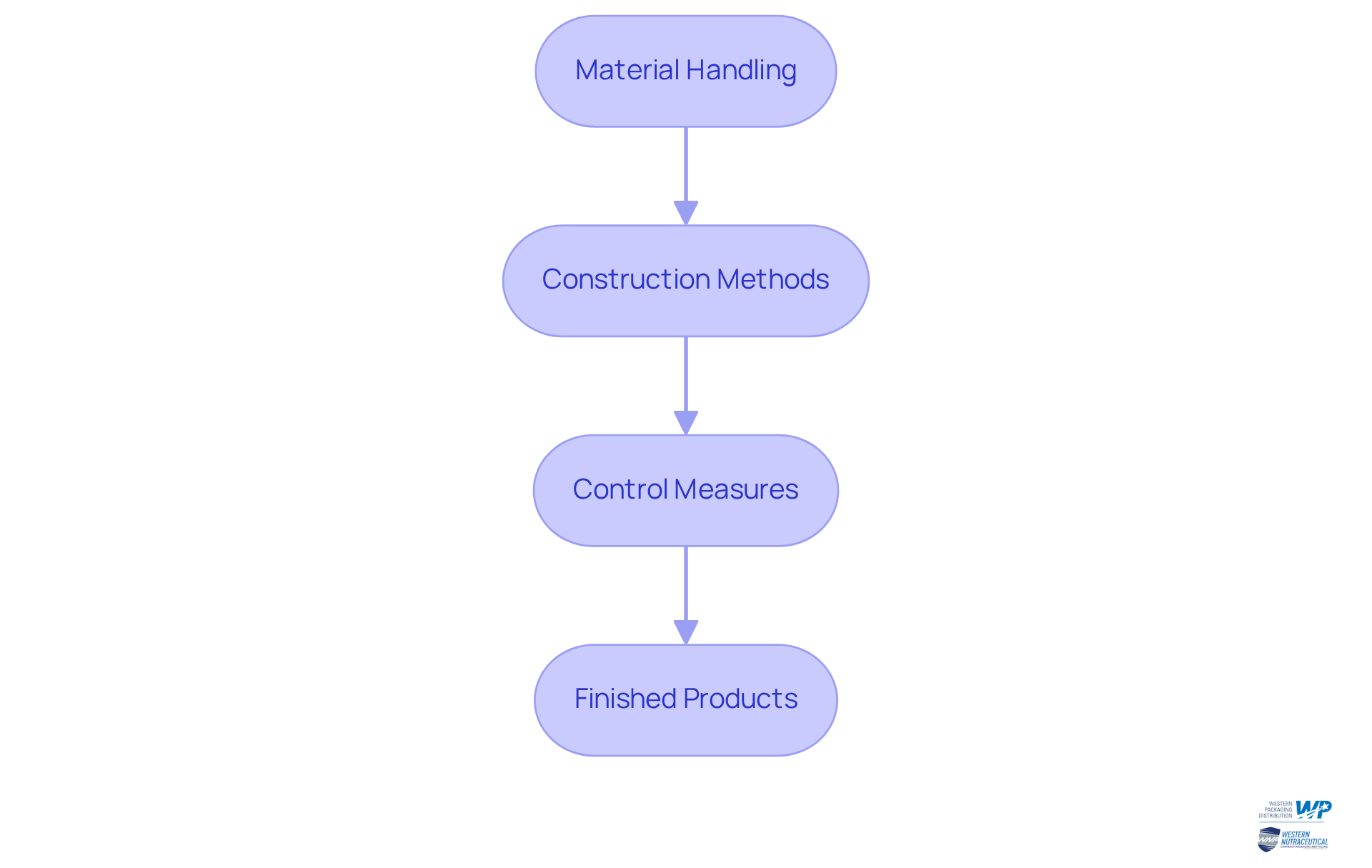

Whse.com: Detailed Overview of the Assembly Process in Manufacturing

Whse.com provides a detailed overview of the construction process in manufacturing, outlining the critical steps necessary to transform components into finished products. This includes:

- Material handling

- Construction methods

- Control measures for maintaining standards

By understanding the intricacies of the construction process, manufacturers can identify opportunities for improvement and implement strategies that enhance efficiency and quality.

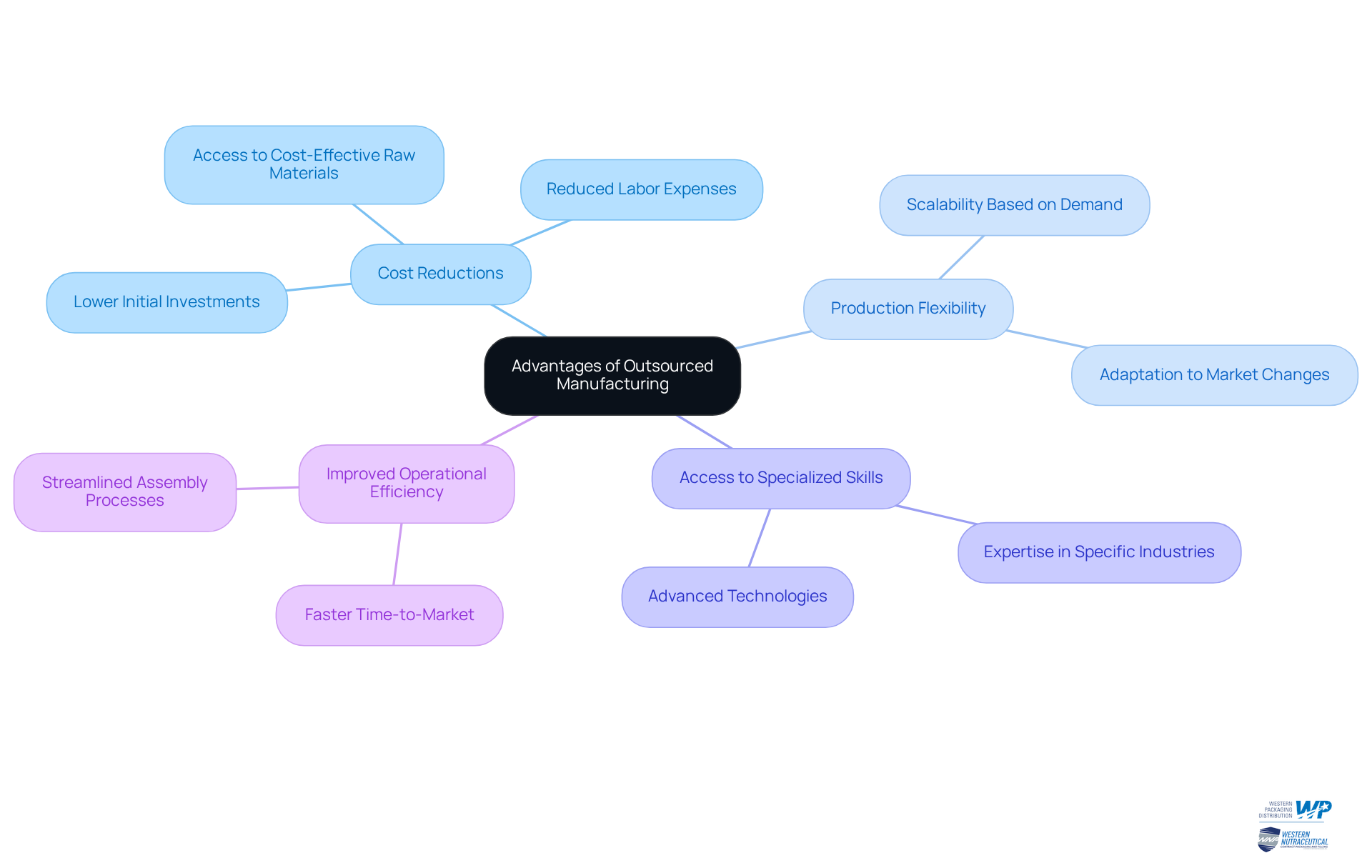

PBZ Manufacturing: Advantages of Outsourced Manufacturing for Product Assembly

PBZ Manufacturing underscores the significant advantages of outsourcing manufacturing to product assembly companies for item assembly. By leveraging external expertise, product assembly companies can achieve considerable cost reductions and enhance their production flexibility. This strategic decision empowers producers to effectively expand operations by collaborating with product assembly companies, adapting to market demands without the burden of substantial initial investments in facilities or equipment. Moreover, product assembly companies provide access to specialized skills and advanced technologies that may be prohibitively costly to develop in-house. As a result, producers can concentrate on their core competencies, ensuring that their products are assembled to the highest standards of excellence and efficiency.

Current trends reveal that businesses are increasingly acknowledging the value of outsourcing to product assembly companies, with many highlighting improved operational efficiency and reduced lead times as primary benefits. Indeed, 63% of companies view outsourcing as a means to significantly lower expenses. By 2025, the landscape of outsourced manufacturing continues to transform, with companies utilizing these partnerships to navigate the complexities of production and meet diverse customer needs. By cultivating collaborative relationships with product assembly companies, businesses can not only streamline their assembly processes but also enhance their overall market competitiveness. However, it is essential for businesses to evaluate potential collaborators based on their technical skills and control procedures to mitigate risks associated with outsourcing. Furthermore, performance monitoring and quality assurance are vital to ensure that the outsourcing relationship meets the established standards.

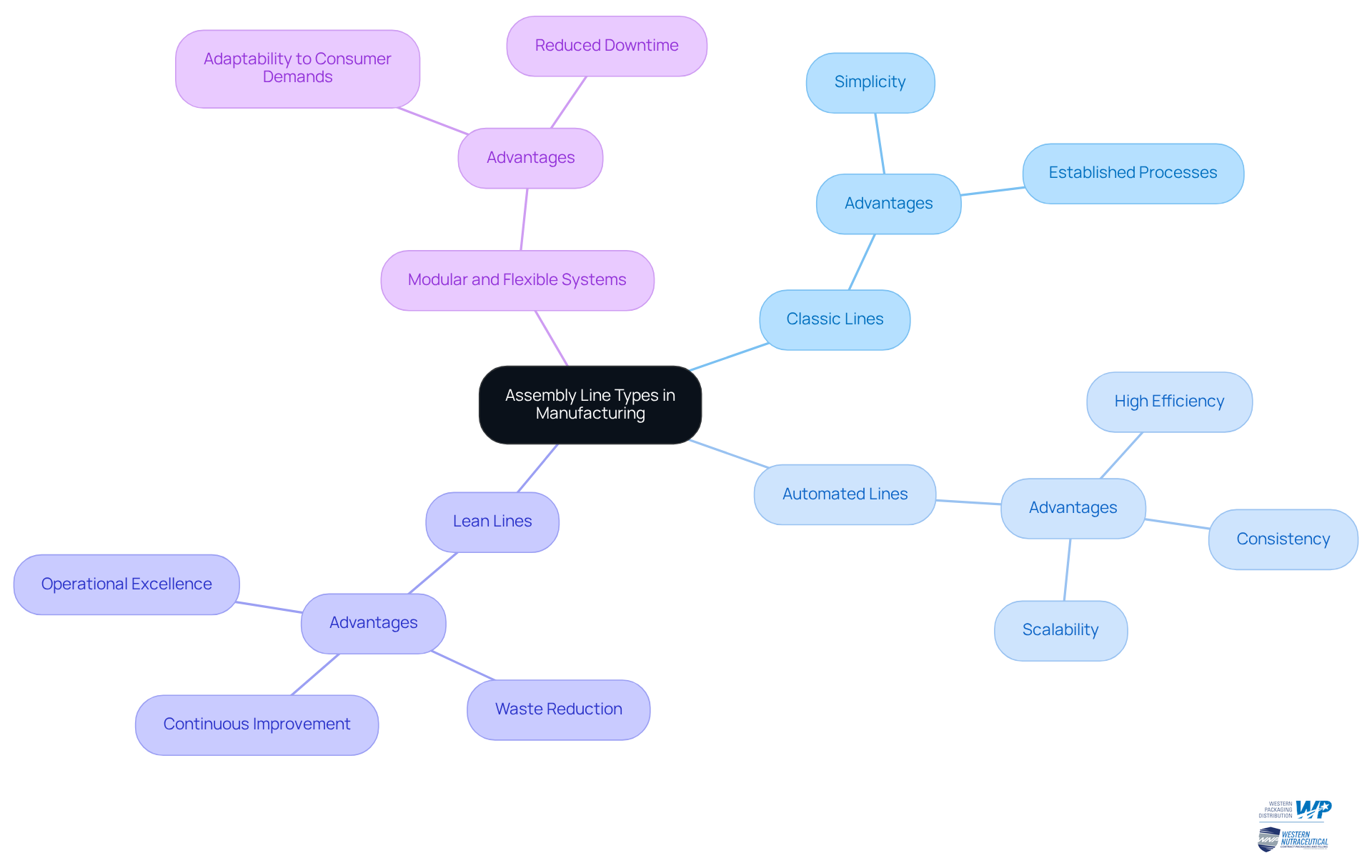

Katanamrp: Exploring Different Types of Assembly Lines in Manufacturing

Katanamrp explores various production line configurations employed in manufacturing, including classic, automated, and lean lines. Each type presents distinct advantages tailored to specific production requirements. For instance, automated production lines excel in high-volume manufacturing, significantly enhancing efficiency and consistency. Conversely, lean production lines concentrate on waste reduction and continuous improvement, fostering a culture of operational excellence. As W. Edwards Deming noted, 'If you can’t describe what you are doing as a process, you don’t know what you’re doing,' emphasizing the necessity of understanding these processes for effective implementation.

Manufacturers are increasingly adopting modular and flexible systems to adapt swiftly to changing consumer demands, which is crucial in today's fast-paced market. The global manufacturing machine market is anticipated to expand at a CAGR of 5.0% from 2025 to 2035, indicating a transition towards automation and lean methods across multiple sectors, including automotive and electronics. This growth trend may motivate nutraceutical producers to reassess their production strategies to remain competitive.

By comprehensively evaluating the advantages of classic versus automated assembly lines, product assembly companies can make informed decisions that optimize their production processes, enhance efficiency, and ultimately reduce costs. This strategic approach not only improves operational performance but also positions companies to respond adeptly to market fluctuations and consumer needs. Additionally, as Taiichi Ohno emphasized, 'All we are doing is looking at the timeline from the moment a customer gives us an order to the point we collect the cash,' highlighting the importance of minimizing waste throughout the production process.

Conclusion

Embracing the capabilities of product assembly companies is essential for manufacturers aiming to enhance efficiency and streamline operations. By outsourcing assembly tasks, businesses can focus on their core competencies while leveraging specialized expertise and advanced technologies that improve production quality and reduce costs.

Throughout the article, various companies exemplify the benefits of integrated packaging solutions, comprehensive assembly services, and the strategic advantages of outsourcing. From Western Packaging's holistic approach to logistics to Joncoind's automation capabilities and Katanamrp's insights into efficient assembly line configurations, each organization contributes uniquely to optimizing manufacturing processes. The emphasis on quality assurance, operational agility, and reduced lead times further underscores the transformative impact of these services on business success.

In conclusion, as the manufacturing landscape evolves, companies must consider the strategic value of partnering with product assembly firms. By doing so, they not only enhance their operational efficiency but also position themselves competitively in a rapidly changing market. Embracing these partnerships can lead to significant improvements in production capabilities, ultimately driving innovation and growth in the industry.

Frequently Asked Questions

What integrated solutions does Western Packaging offer?

Western Packaging provides integrated packaging solutions that combine design, filling, and logistics, accommodating a variety of items such as powders, gummies, and soft-gels.

How does Western Packaging enhance supply chain efficiency?

By offering a holistic approach that streamlines the supply chain, Western Packaging reduces lead times and improves delivery efficiency, benefiting nutraceutical manufacturers.

What are the cost benefits of outsourcing according to the article?

Businesses that adopt outsourcing report operational cost reductions averaging between 20% and 30%.

What services are included in Western Packaging's integrated logistics?

Western Packaging's comprehensive 3PL services include warehousing, inventory management, and distribution.

How does Western Packaging support businesses in maintaining quality and compliance?

By providing tailored solutions that address unique packaging needs, Western Packaging enables businesses to optimize operations while maintaining high standards of quality and compliance.

What role do advanced technologies play in Western Packaging's logistics solutions?

The integration of advanced technologies such as AI and IoT enhances the effectiveness of logistics solutions offered by Western Packaging.

What services does Joncoind provide for product assembly?

Joncoind offers comprehensive product assembly services that include both manual and automated assembly processes, ensuring flexibility and efficiency.

How does Joncoind ensure quality in its assembly processes?

By combining advanced technologies with skilled labor, Joncoind incorporates quality assurance from the beginning of the assembly process.

What is the trend in manufacturing processes as of 2025?

The trend towards automation in manufacturing processes is growing, driven by the need for increased precision and reduced labor expenses.

How can manufacturers remain competitive according to the article?

Manufacturers should evaluate their current production processes for opportunities to integrate automation and adopt a culture of continuous improvement.

What benefits does Karkhana.io provide for product assembly?

Karkhana.io offers essential product construction services that lead to reduced lead times, improved production flow, and enhanced quality control.

How has Nike Inc. utilized outsourcing in its operations?

Nike Inc. has outsourced its athletic footwear production to manufacturers in Vietnam and Indonesia, benefiting from cost-effective labor while maintaining high-quality standards.

What are the advantages of using product assembly companies for outsourcing?

Utilizing product assembly companies can lead to improved operational efficiency, quicker time-to-market, and allows companies to focus on innovation and market expansion.

What should businesses consider when selecting manufacturing partners for outsourcing?

It is vital for businesses to carefully select their manufacturing partners to mitigate potential risks associated with outsourcing.