Overview

The article delineates four essential steps to enhance custom blister packaging for nutraceuticals, concentrating on:

- Protection

- Convenience

- Shelf appeal

- Adherence to regulations

It underscores the necessity of comprehending product requirements and selecting appropriate materials and designs, which are vital for bolstering product integrity and market visibility—an imperative in the swiftly expanding nutraceutical industry.

Introduction

Blister packaging has emerged as a vital component in the nutraceutical industry, offering a blend of protection, convenience, and visual appeal that resonates with both manufacturers and consumers. As the market for nutraceuticals continues to expand, projected to surpass USD 1 trillion by 2032, understanding how to optimize custom blister packaging becomes crucial for brands aiming to stand out. However, with numerous options and regulatory considerations to navigate, how can companies ensure their packaging not only meets industry standards but also enhances product integrity and consumer trust?

Understand Blister Packaging and Its Benefits for Nutraceuticals

Blister packaging, a pre-formed plastic solution featuring cavities made from thermoformed sheets, offers numerous advantages specifically tailored for nutraceuticals:

- Protection: Blister packs create a robust barrier against moisture, light, and oxygen, safeguarding the integrity of dietary supplements. Advanced barrier technologies, such as nanocoatings, further enhance this protection, extending shelf life and preserving item potency during storage and distribution.

- Convenience: The design of blister packaging enables simple dispensing of individual doses, enhancing user-friendly experiences for customers. This convenience encourages consistent supplement usage, which is crucial for achieving better health outcomes.

- Shelf Appeal: The transparent nature of blister packs not only showcases the product but also significantly enhances brand visibility. This visual appeal plays a vital role in attracting consumers on retail shelves, influencing purchasing decisions. At Western Packaging, we specialize in innovative design solutions that enhance brand recognition and shelf appeal through custom blister packaging options tailored to your needs.

- Tamper Resistance: Blister wrapping can include tamper-evident features, ensuring that items remain secure and unaltered prior to purchase. This aspect is especially significant for health-related goods, as it enhances consumer trust in safety.

- Customization enables brands to create distinctive custom blister packaging that aligns with their marketing strategies, enhancing overall item appeal. This customization can include vibrant graphics and essential product information, further engaging potential buyers. Western Packaging's expertise in crafting compelling graphic assets ensures a cohesive and captivating brand identity.

- Eco-Friendliness: Blister containers can also be created with eco-friendly materials and processes, aligning with the growing demand for sustainable practices in the nutraceutical industry. This not only satisfies customer expectations but also aids in environmental preservation.

Comprehending these advantages is essential for manufacturers seeking to enhance their methods in the competitive nutraceutical market. With the and expected to exceed USD 1 trillion by 2032, effective blister encasement will be crucial for preserving item integrity and improving buyer satisfaction. Furthermore, case studies like 'Enhanced Product Protection' and 'Improved Medication Adherence' demonstrate the real-world advantages of blister containers, while the environmentally friendly features of this approach correspond with the increasing demand for sustainable practices in the industry. As highlighted by Western Packaging, "At Western Packaging, we focus on tailored flexible solutions that improve appeal while guaranteeing the integrity and safety that consumers anticipate.

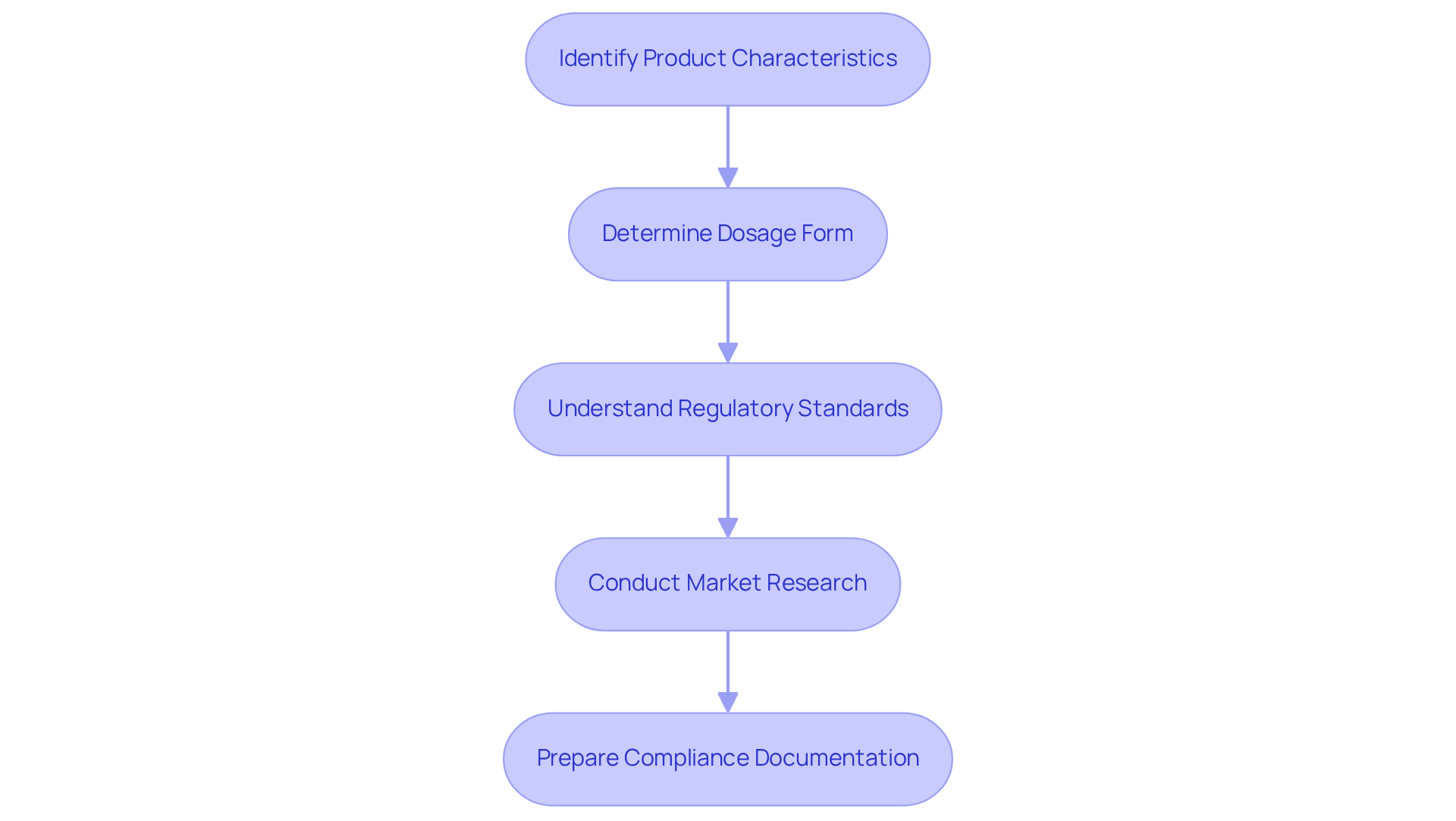

Identify Your Product Requirements and Regulatory Compliance Needs

Before selecting blister containers, it is essential to assess the specific needs of your item and ensure compliance with applicable regulations. Follow these steps:

- Product Characteristics: Identify the physical and chemical properties of your nutraceuticals, such as sensitivity to moisture or light, as these will influence material selection.

- Dosage Form: Determine whether your product is in tablet, capsule, or gummy form, as this will impact the blister pack design.

- Regulatory Standards: Acquaint yourself with the regulations established by the FDA or other relevant authorities concerning dietary supplements. This includes labeling requirements, child-resistant containers, and safety standards.

- Market Research: Conduct research to grasp consumer preferences and trends within the nutraceutical market, which will guide your container choices.

- Ensure that all necessary compliance documentation is prepared, including safety data sheets and specifications.

By meticulously evaluating these factors, you can ensure that your container not only protects your item but also adheres to industry regulations.

Evaluate Different Blister Packaging Options and Materials

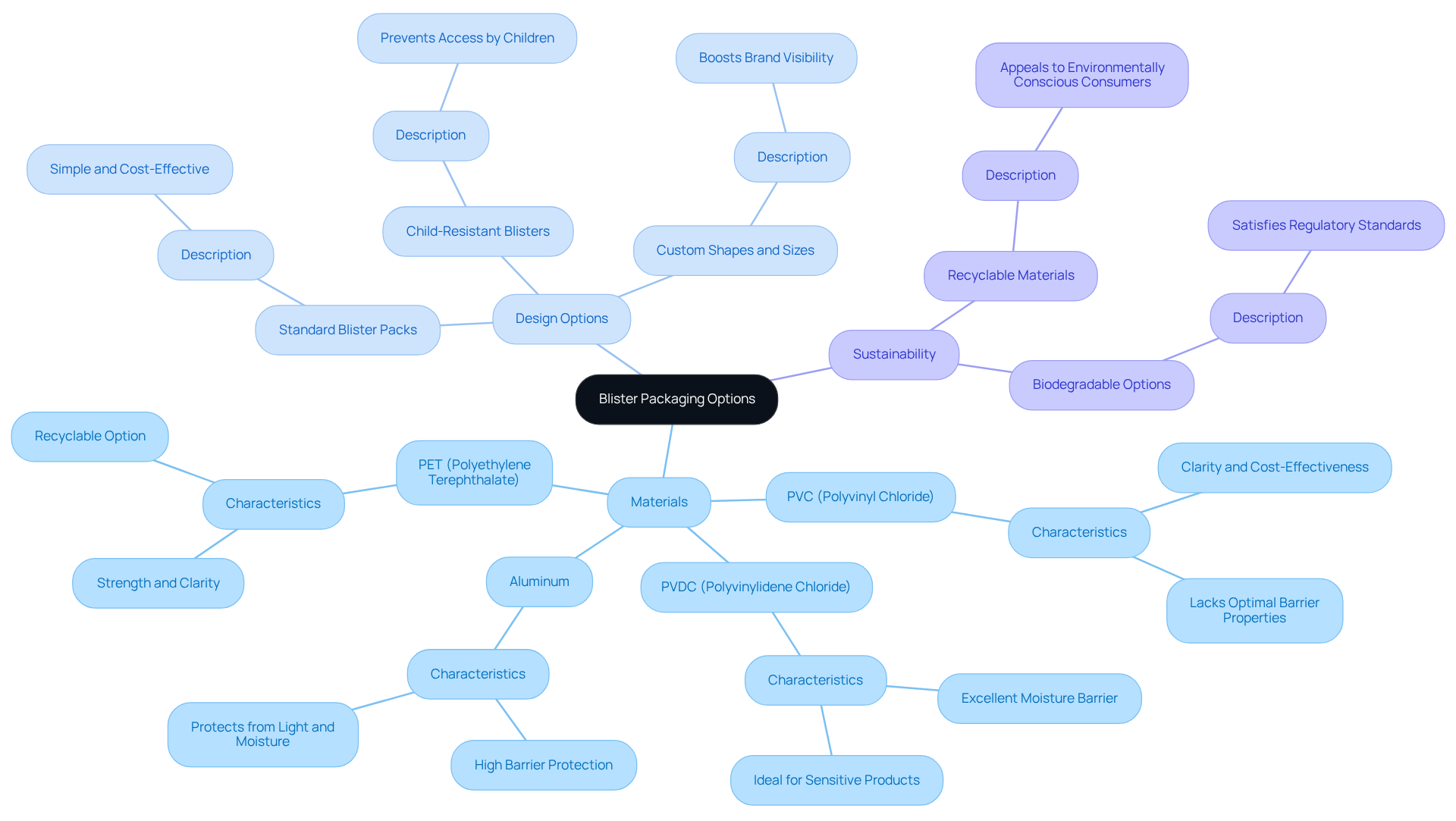

When evaluating blister packaging options for nutraceuticals, it is essential to consider various materials and innovative designs that meet both functional and market demands:

-

Materials: The most common materials used in blister packaging include:

- PVC (Polyvinyl Chloride): Known for its clarity and cost-effectiveness, PVC is widely used but may lack optimal barrier properties for sensitive products.

- PVDC (Polyvinylidene Chloride): This material excels in moisture barrier capabilities, making it ideal for protecting sensitive nutraceuticals.

- Aluminum: Frequently employed in high-barrier applications, aluminum blisters effectively protect items from light and moisture, ensuring integrity.

- PET (Polyethylene Terephthalate): Recognized for its strength and clarity, PET is a recyclable option that appeals to environmentally conscious consumers, aligning with the growing trend towards sustainability.

-

Design Options: Various design formats can enhance product appeal and safety:

- Standard Blister Packs: These are simple and cost-effective, suitable for a wide range of products.

- Child-Resistant Blisters: Specifically designed to prevent access by children, these packs ensure safety for potentially dangerous items.

- Custom Shapes and Sizes: Tailored designs can significantly boost brand visibility and customer engagement, making items stand out on the shelf. At Western Packaging, we focus on creating innovative wrapping concepts, including graphic materials such as labels and brochures, that enhance your product's shelf appeal and brand awareness.

-

Sustainability: With rising public demand for environmentally friendly containers, it is essential to assess choices such as recyclable substances or biodegradable substitutes. Employing eco-friendly wrapping options not only satisfies regulatory standards but also appeals to health-aware individuals. For example, NutriGuard® provides a sustainable substitute for traditional PVC/PVDC/aluminum containers, attracting health-aware customers while offering outstanding barrier characteristics.

By meticulously evaluating these materials and design alternatives, along with our cohesive filling services, manufacturers can choose custom blister packaging solutions that not only safeguard their nutraceuticals but also enhance brand visibility in a competitive market. As per industry reports, the worldwide nutraceuticals market is presently estimated at approximately USD 450 billion and is expected to double by 2032, highlighting the significance of efficient presentation in this expanding sector. Furthermore, the revised ASTM F2338-24 standard establishes in non-porous flexible containers, further highlighting the necessity for dependable solutions.

Select a Reliable Packaging Provider with Integrated Services

Selecting the appropriate provider for your nutraceutical products is essential for their success. To ensure effective packaging that enhances safety and market appeal, follow these steps:

- Research Potential Providers: Seek firms that specialize in nutraceutical containers and possess a proven track record in the industry.

- Evaluate Integrated Services: Choose providers that offer a comprehensive range of services, including design, filling, logistics, and 3PL services. For instance, Western Packaging provides that can streamline your supply chain and reduce lead times.

- Check Compliance and Quality Standards: Confirm that the provider adheres to industry regulations and quality standards, such as Good Manufacturing Practices (GMP).

- Request Samples: Before making a decision, request samples of their packaging solutions to assess quality and suitability for your products.

- Consider Customer Support: A dependable provider should deliver excellent customer service, including assistance with design modifications and troubleshooting during production.

By selecting a packaging provider that meets these criteria, you can ensure that your nutraceutical products are packaged effectively, enhancing both safety and market appeal.

Conclusion

Blister packaging emerges as an essential solution for nutraceuticals, delivering protection, convenience, and heightened brand visibility. By grasping its multifaceted benefits, manufacturers can harness this innovative packaging to preserve product integrity and engage consumers effectively. The significance of blister packaging in the nutraceutical market is paramount, particularly as the industry continues to expand and evolve.

This article outlines critical steps for optimizing custom blister packaging. These steps include:

- Assessing product requirements and regulatory compliance

- Evaluating various materials and designs

- Selecting a reliable packaging provider

Each of these elements is crucial for ensuring that the packaging not only adheres to safety standards but also aligns with consumer preferences, ultimately driving sales and nurturing brand loyalty.

As the nutraceutical market approaches a valuation of USD 1 trillion by 2032, the importance of effective packaging solutions becomes increasingly evident. Manufacturers are urged to adopt innovative blister packaging strategies that not only protect their products but also promote sustainability and enhance user experience. By embracing these practices, brands will not only meet consumer demands but also position themselves favorably in a competitive landscape.

Frequently Asked Questions

What is blister packaging?

Blister packaging is a pre-formed plastic solution featuring cavities made from thermoformed sheets, designed to protect and showcase products, particularly dietary supplements.

What are the main benefits of blister packaging for nutraceuticals?

The main benefits include protection against moisture, light, and oxygen, convenience in dispensing individual doses, enhanced shelf appeal, tamper resistance, customization options, and eco-friendliness.

How does blister packaging protect nutraceuticals?

Blister packs create a robust barrier that safeguards the integrity of dietary supplements, with advanced barrier technologies like nanocoatings further enhancing protection and extending shelf life.

Why is convenience an important aspect of blister packaging?

The design of blister packaging allows for simple dispensing of individual doses, which enhances user experience and encourages consistent supplement usage, crucial for better health outcomes.

How does blister packaging enhance brand visibility?

The transparent nature of blister packs showcases the product, significantly enhancing brand visibility and influencing purchasing decisions on retail shelves.

What features do blister packs have for tamper resistance?

Blister wrapping can include tamper-evident features that ensure items remain secure and unaltered prior to purchase, enhancing consumer trust in the safety of health-related goods.

How can brands customize blister packaging?

Brands can create distinctive custom blister packaging that aligns with their marketing strategies, including vibrant graphics and essential product information to engage potential buyers.

Are there eco-friendly options for blister packaging?

Yes, blister containers can be made with eco-friendly materials and processes, meeting the growing demand for sustainable practices in the nutraceutical industry.

Why is understanding the advantages of blister packaging important for manufacturers?

Understanding these advantages is essential for manufacturers to enhance their methods in the competitive nutraceutical market, which is valued at around USD 450 billion and expected to exceed USD 1 trillion by 2032.

What are some real-world advantages of blister packaging?

Case studies such as 'Enhanced Product Protection' and 'Improved Medication Adherence' demonstrate the practical benefits of using blister containers in the nutraceutical industry.