Overview

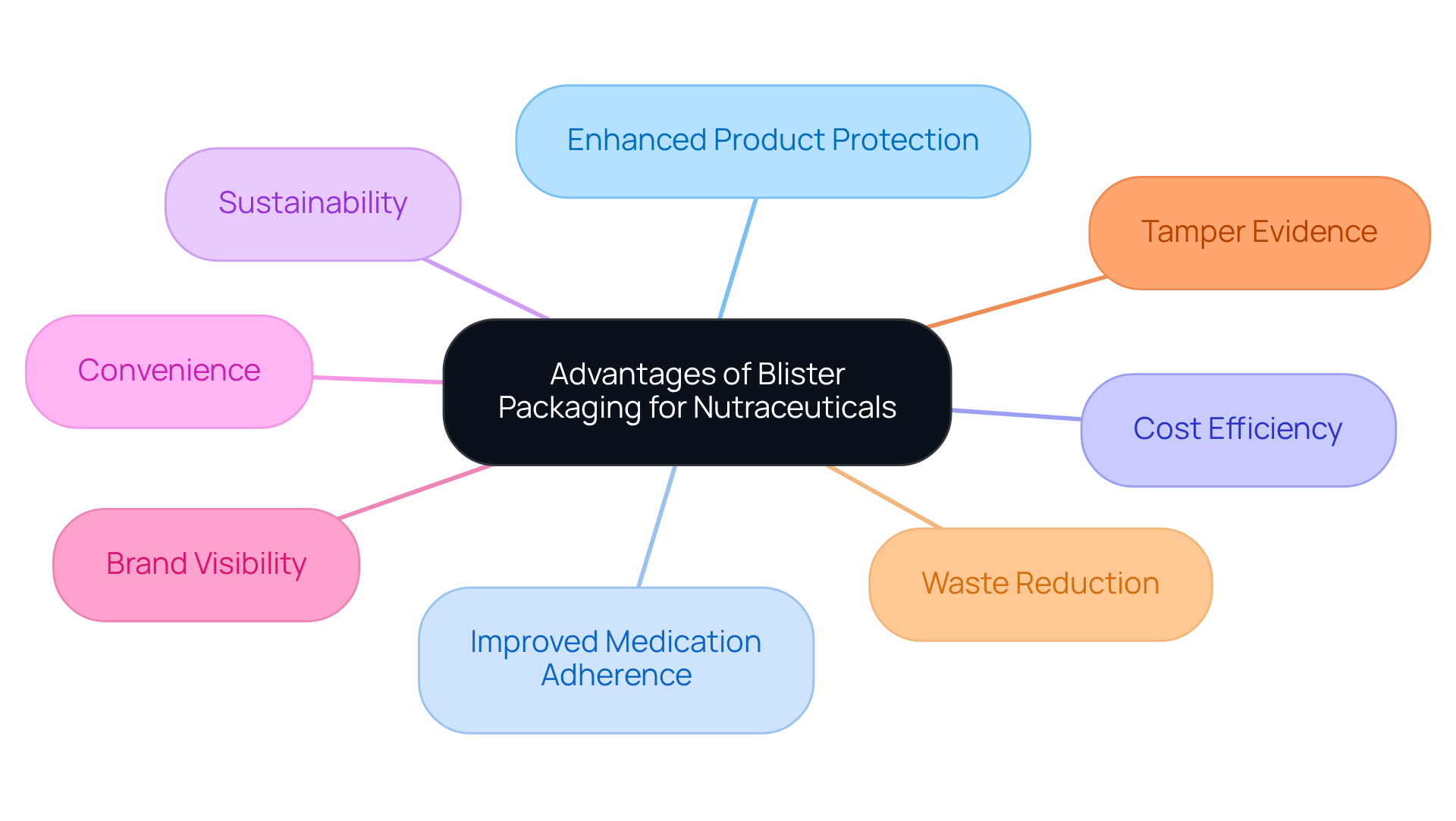

The article delineates seven pivotal benefits of blister pack packaging for nutraceuticals, underscoring its significance in enhancing product protection, improving medication adherence, and promoting sustainability. Each benefit is substantiated by compelling evidence, including:

- Increased shelf life

- Superior consumer compliance

- Utilization of eco-friendly materials

This demonstrates how blister packaging effectively addresses both market demands and consumer expectations within the nutraceutical industry.

Introduction

Blister pack packaging has emerged as a transformative force in the nutraceutical industry, offering a compelling combination of protection, efficiency, and consumer appeal. As the nutraceutical market is projected to surpass USD 1 trillion by 2032, it is essential for manufacturers to grasp the multifaceted advantages of blister packaging to elevate product quality and enhance consumer satisfaction. This innovative packaging not only safeguards the integrity of sensitive ingredients but also promotes cost efficiency and sustainability within a fiercely competitive landscape. Understanding these dynamics is crucial for any manufacturer seeking to thrive in this evolving market.

Western Packaging: Comprehensive Blister Pack Solutions for Nutraceuticals

Western Packaging delivers tailored packaging solutions meticulously crafted for the nutraceutical sector. By merging innovative design with robust filling services, we guarantee that each blister pack packaging aligns with the distinct requirements of dietary supplements. This approach not only enhances product appeal but also streamlines the wrapping process, enabling the efficient delivery of high-quality goods to the market.

Additionally, our comprehensive 3PL services—including warehousing, inventory management, and logistics—optimize your supply chain. This allows you to concentrate on your core competencies, confident in the reliability of our solutions.

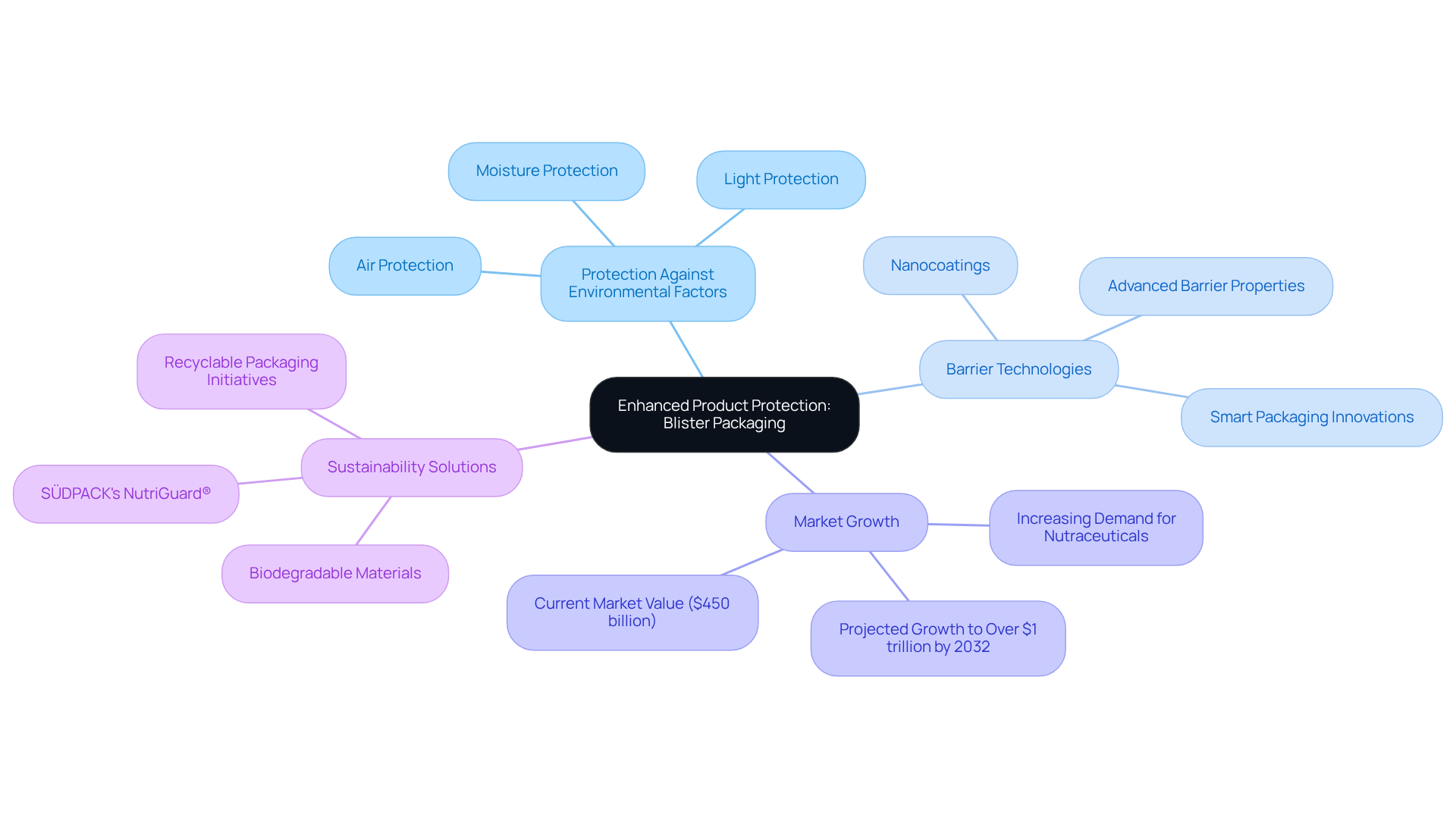

Enhanced Product Protection: Safeguarding Nutraceuticals with Blister Packaging

Blister pack packaging provides exceptional protection against environmental factors such as moisture, light, and air, which are known to compromise the quality of nutraceuticals. Each separate pouch section serves as a robust barrier, preserving the freshness and effectiveness of the product until it is ready for use. This protective feature is vital for sensitive ingredients commonly found in dietary supplements, as it minimizes the risk of degradation.

For example, advanced barrier technologies, including innovations like nanocoatings, guarantee that sensitive nutraceuticals remain stable and potent, even under challenging conditions. Furthermore, the impermeable quality of packaging significantly extends the shelf life of dietary supplements, allowing manufacturers to maintain product integrity during distribution and storage.

As the nutraceutical market, currently valued at approximately USD 450 billion, continues to expand with projections suggesting it could surpass USD 1 trillion by 2032, the demand for effective packaging solutions that protect product quality is more critical than ever. Solutions like SÜDPACK's NutriGuard®, which features recyclable blister pack packaging, exemplify the industry's shift towards sustainability while ensuring optimal protection for nutraceuticals.

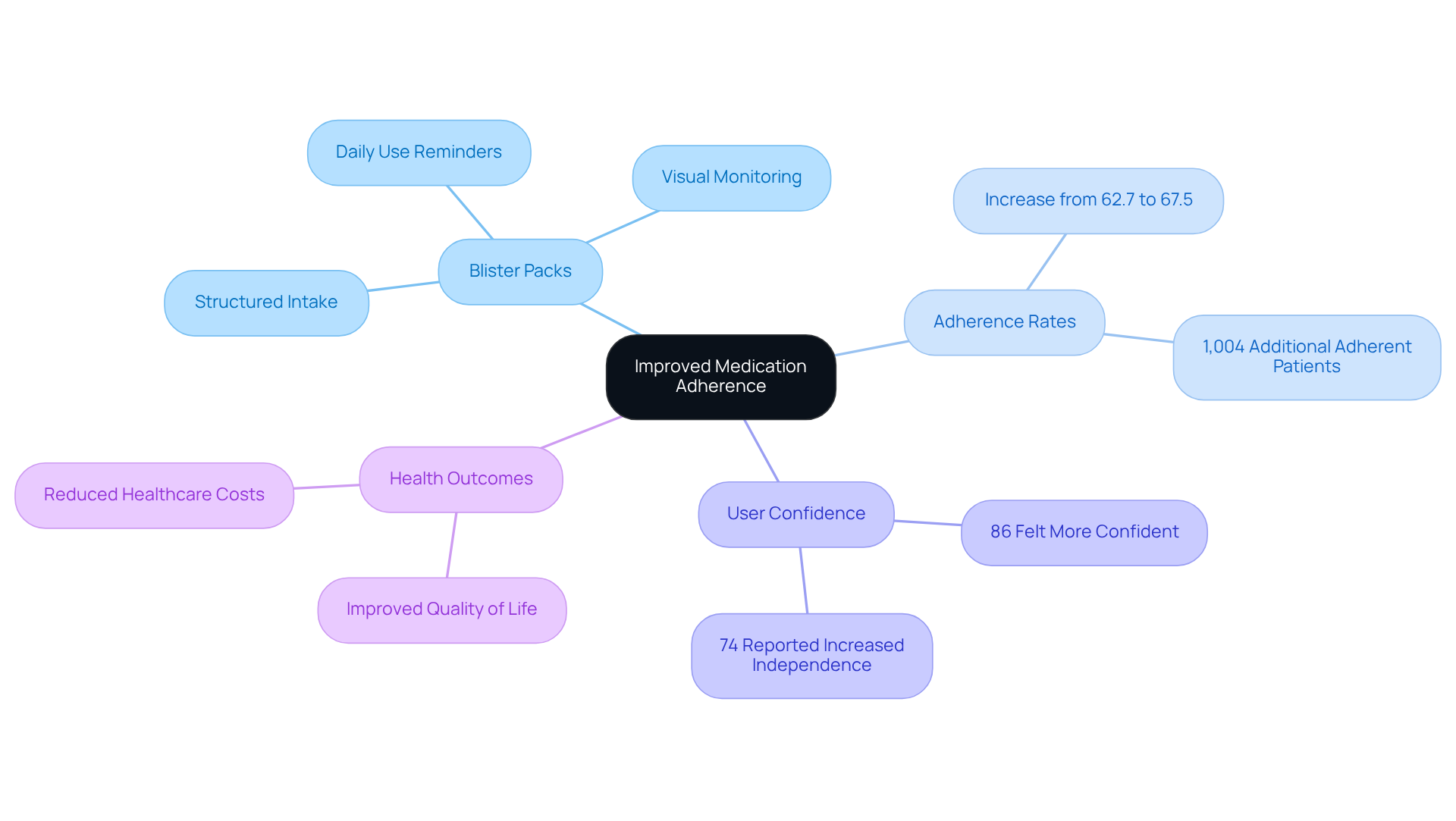

Improved Medication Adherence: Boosting Compliance with Blister Packs

Blister pack packaging significantly enhances medication adherence by offering a structured and visually appealing method for consumers to manage their supplement intake. Each dose is individually sealed, allowing users to easily monitor their consumption and see how many doses remain. This clear visual representation serves as a powerful reminder, particularly for products that necessitate consistent daily use.

Studies indicate that adherence rates can rise by up to 13% with the introduction of sealed containers, underscoring their efficiency in encouraging compliance. Healthcare professionals have observed that such containers not only simplify the medication regimen but also foster greater confidence among users in managing their health.

By optimizing the intake process, medication containers play a vital role in ensuring that consumers follow their dietary supplement routines, ultimately resulting in better health outcomes.

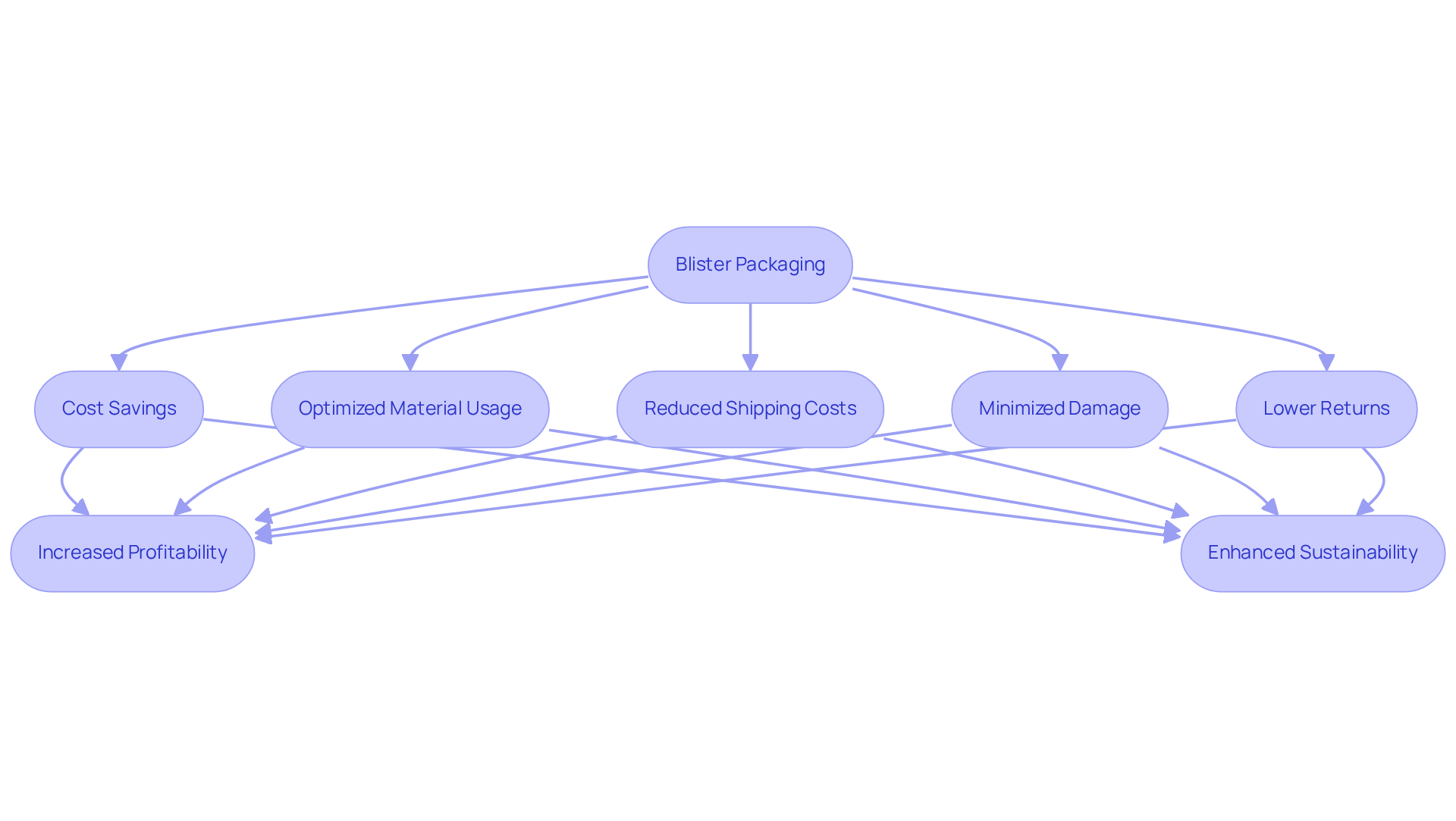

Cost Efficiency: Reducing Production and Distribution Expenses with Blister Packaging

Blister containers deliver substantial cost savings in both production and distribution for nutraceuticals. By optimizing material usage and storage space, companies can significantly lower shipping costs. The compact and uniform packaging maximizes transport efficiency and minimizes the risk of damage during transit, which is crucial for maintaining product integrity. This durability results in reduced costs associated with returns and replacements, thereby enhancing overall profitability.

Moreover, the efficient filling process associated with pouch containers minimizes labor costs, allowing producers to allocate resources more effectively. For instance, companies employing integrated wrapping solutions have reported up to a 30% reduction in lead times, directly contributing to cost efficiency. As the global protective film market is projected to grow at a CAGR of 7.4% from 2024 to 2030, the shift towards adopting such economical solutions is increasingly evident, particularly in response to the rising demand for sustainable practices, given that less than 30% of plastic generated by the supplement sector is recycled.

Supply chain specialists emphasize that effective packaging not only enhances product visibility but also aligns with consumer preferences for safety and sustainability. Gunakesh Parmar highlights that the combination of bubble wrap can foster a more sustainable approach, ultimately benefiting both profit margins and the environment. This dual focus on cost reduction and consumer satisfaction positions blister solutions as a strategic choice for nutraceutical producers seeking to optimize their operations while meeting market demands.

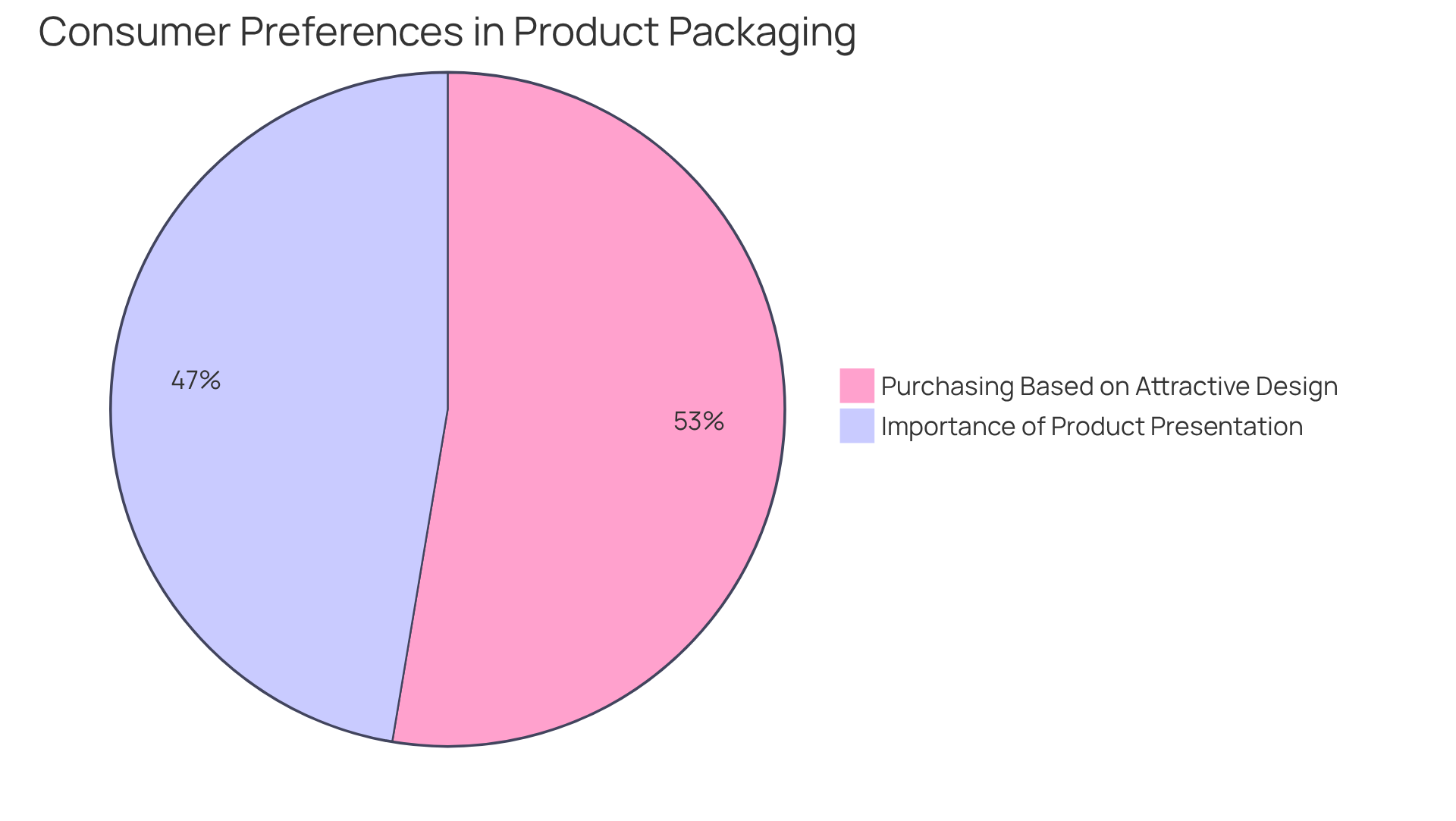

Sustainability: Eco-Friendly Benefits of Blister Pack Packaging

Blister pack packaging can be crafted with sustainability at its core, employing recyclable materials and reducing waste throughout the production process. By opting for eco-friendly solutions, manufacturers not only cater to a burgeoning consumer base that prioritizes sustainability but also enhance their brand image. This strategic choice aligns with market trends;

- 63% of customers view product presentation as essential as the brand itself,

- 70% acknowledge purchasing items based solely on attractive design.

As the sustainable pharmaceutical container market is anticipated to attain USD 99.18 billion by 2024, the adoption of eco-friendly pill packs becomes a crucial step towards a more sustainable future for the nutraceutical sector. Employing materials like biodegradable plastics and recycled paper for blister pack packaging not only satisfies regulatory requirements but also appeals to environmentally aware consumers, ultimately promoting a beneficial effect on both brand reputation and the planet.

Moreover, Western Packaging provides customized flexible solutions, including large pouches and stick containers, that enhance product appeal while aligning with sustainability objectives. Manufacturers are encouraged to explore these innovative options to ensure a cohesive and captivating brand identity.

Convenience: Easy Access to Individual Doses with Blister Packaging

Blister pack packaging offers exceptional convenience, allowing consumers to easily obtain individual doses without the need for additional tools or cumbersome materials. This user-friendly design is particularly beneficial for individuals on the move, facilitating seamless supplement intake while traveling or at work. Nutritionists underscore that easy access to supplements is vital for sustaining a healthy lifestyle. Dr. Josh Axe aptly states, "Health is not about the weight you lose, but about the life you gain." By streamlining the process of supplement consumption, blister pack packaging not only encourages consistent usage but also contributes to improved health outcomes, as regular intake is linked to enhanced overall wellness.

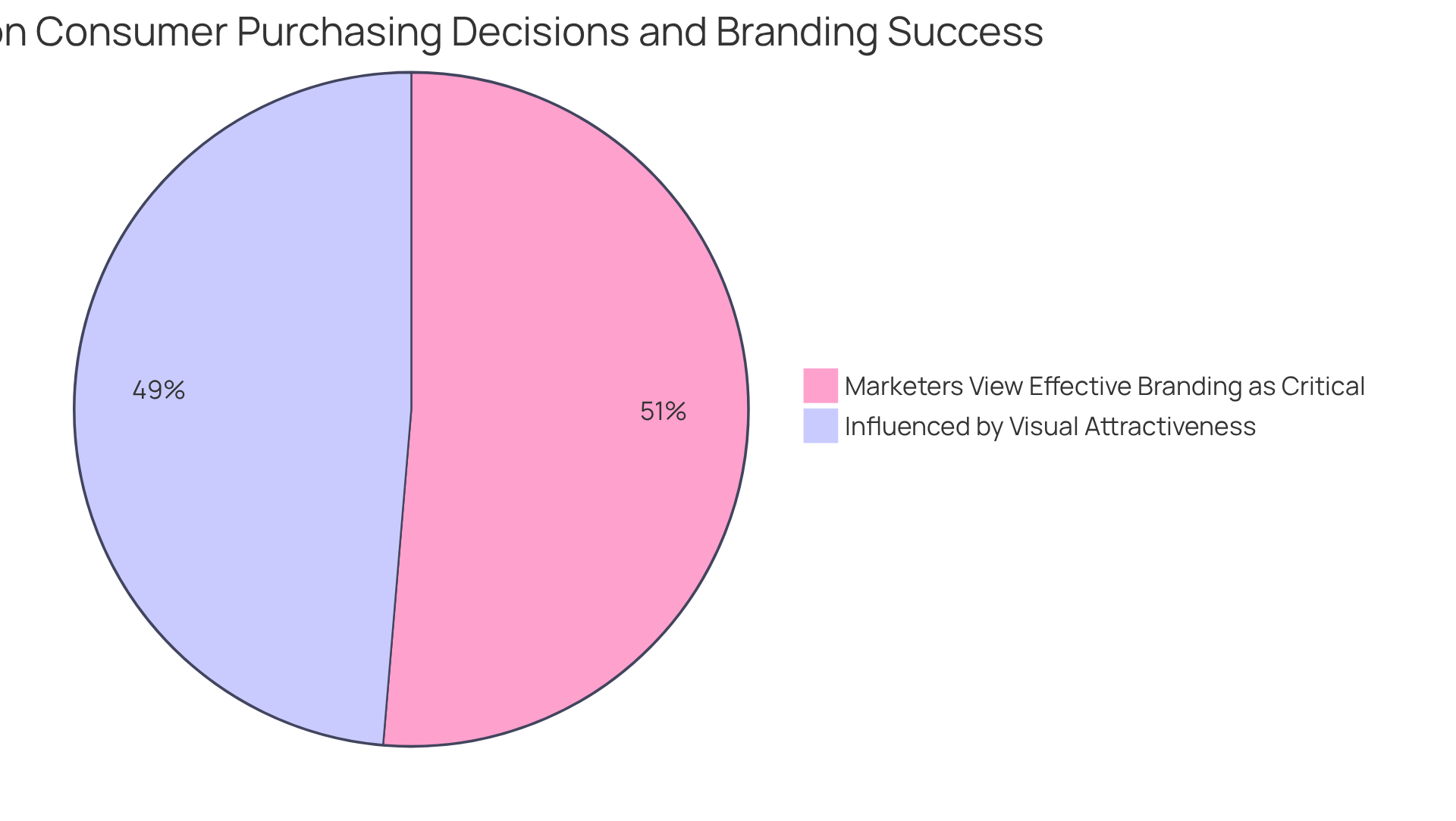

Brand Visibility: Enhancing Product Appeal through Blister Packaging

Blister pack packaging serves as a powerful branding tool, allowing manufacturers to effectively showcase their products. The transparent design of blister pack packaging enables consumers to see the item inside, significantly enhancing visual appeal and promoting impulse purchases. Research indicates that 73% of consumers make purchasing decisions based on visual attractiveness, underscoring the importance of appealing presentation in influencing buyer behavior.

Moreover, customers need to encounter your brand at least seven times before they are ready to commit to a purchase decision, emphasizing the necessity of consistent visual branding. The capability to print vibrant graphics and essential information directly on the containers not only communicates brand values but also clearly highlights product benefits.

This strategic design approach aligns with insights from marketing experts like Zig Ziglar, who asserts that brand trust is vital for driving business success. Additionally, 77% of marketers agree that effective branding is critical for long-term success, reinforcing the notion that leveraging the unique features of blister pack packaging can create lasting impressions that resonate with consumers.

By cultivating stronger connections and encouraging repeat purchases, nutraceutical brands can significantly enhance their market presence.

Tamper Evidence: Ensuring Consumer Safety with Blister Packs

Blister pack packaging frequently includes tamper-evident features, such as secure seals and specialized materials, providing an essential layer of security for consumers. These features play a critical role in confirming that the item remains unaltered and uncontaminated prior to acquisition, an aspect particularly vital for health-related products packaged in blister pack packaging. By prioritizing consumer safety through these innovative design elements, manufacturers not only foster trust but also encourage repeat purchases.

At Western Packaging, we specialize in customized flexible solutions that enhance product appeal while ensuring the integrity and safety that consumers expect. Our innovative designs guarantee that your nutraceutical products stand out on the shelf, seamlessly integrating safety with brand recognition.

Waste Reduction: Minimizing Environmental Impact with Blister Packaging

Blister pack packaging significantly reduces waste by utilizing materials more efficiently and minimizing surplus containers. By creating blister pack packaging that requires less material while still offering adequate protection, manufacturers can effectively lower their overall environmental impact.

At Western Packaging, we excel in providing customized flexible solutions, including:

- Large pouches for protein items

- Stick packs for nutraceuticals

These options not only enhance product appeal but also align with sustainability objectives. Our innovative designs guarantee that your containers are both efficient and eco-friendly, resonating with consumers who are increasingly concerned about sustainability.

Discover how our solutions can elevate your brand's presence while contributing to a greener future.

Overall Advantages: Why Blister Packaging is Essential for Nutraceuticals

In summary, sealed containers offer a multitude of advantages for nutraceuticals, including:

- Enhanced product protection

- Improved medication adherence

- Cost efficiency

- Sustainability

- Convenience

- Brand visibility

- Tamper evidence

- Waste reduction

By adopting sealed containers, manufacturers not only meet consumer demands but also position themselves as leaders in the competitive nutraceutical market. The innovative design of bubble containers, featuring customizable forms and environmentally friendly materials, significantly enhances their appeal. This comprehensive integration of benefits establishes blister packaging as an indispensable choice for businesses aiming to optimize their product offerings.

Conclusion

Blister pack packaging emerges as a vital solution for the nutraceutical industry, offering a range of benefits that enhance product integrity, consumer safety, and brand visibility. This innovative packaging not only protects sensitive ingredients from environmental factors but also streamlines the consumption process, ultimately fostering better health outcomes for users. By prioritizing these advantages, businesses can effectively meet the growing demands of health-conscious consumers while establishing a strong market presence.

The article outlines several key benefits of blister packaging, including:

- Enhanced product protection

- Improved medication adherence

- Cost efficiency

- Sustainability

These features collectively position blister packs as an essential component for nutraceutical manufacturers looking to optimize their offerings. Furthermore, the convenience of easy access to individual doses, combined with the visual appeal of blister packs, significantly influences consumer purchasing decisions and encourages repeat business.

As the nutraceutical market continues to expand, adopting blister packaging solutions becomes increasingly important. Companies are encouraged to explore these innovative options to not only improve their operational efficiency but also contribute to a more sustainable future. By embracing the multifaceted advantages of blister packaging, manufacturers can ensure they remain competitive while promoting the health and well-being of their consumers.

Frequently Asked Questions

What packaging solutions does Western Packaging offer for the nutraceutical sector?

Western Packaging delivers tailored blister pack solutions that merge innovative design with robust filling services, specifically crafted to meet the distinct requirements of dietary supplements.

How does blister pack packaging protect nutraceuticals?

Blister pack packaging provides exceptional protection against environmental factors such as moisture, light, and air, preserving the freshness and effectiveness of nutraceuticals until they are ready for use.

What technologies are used in blister packaging to ensure product stability?

Advanced barrier technologies, including innovations like nanocoatings, are employed to maintain the stability and potency of sensitive nutraceuticals, even under challenging conditions.

How does blister packaging affect the shelf life of dietary supplements?

The impermeable quality of blister packaging significantly extends the shelf life of dietary supplements, helping to maintain product integrity during distribution and storage.

What is the projected growth of the nutraceutical market, and how does it relate to packaging needs?

The nutraceutical market is currently valued at approximately USD 450 billion and is projected to surpass USD 1 trillion by 2032, highlighting the critical demand for effective packaging solutions that protect product quality.

How do blister packs improve medication adherence?

Blister packs enhance medication adherence by providing a structured and visually appealing way for consumers to manage their supplement intake, allowing them to easily monitor consumption and see how many doses remain.

What impact do sealed containers have on adherence rates?

Studies indicate that adherence rates can rise by up to 13% with the introduction of sealed containers, demonstrating their effectiveness in encouraging compliance with dietary supplement routines.

How do healthcare professionals view the use of blister packaging?

Healthcare professionals observe that blister packaging simplifies the medication regimen and fosters greater confidence among users in managing their health.