Overview

The article presents four key strategies aimed at enhancing pharmaceutical success through printed flexible packaging, highlighting its essential dual role in product protection and consumer appeal. It elaborates on the critical importance of:

- Regulatory compliance

- Innovative design

- Sustainability practices

These elements collectively contribute to improved product quality, brand differentiation, and heightened market competitiveness within the pharmaceutical industry.

Introduction

The pharmaceutical industry is increasingly recognizing the critical role of printed flexible packaging. This solution not only protects sensitive medications from environmental factors but also enhances brand visibility on crowded shelves. By effectively marrying compliance with consumer appeal, printed flexible packaging offers pharmaceutical companies a unique opportunity to improve product integrity while capturing consumer attention through innovative designs and clear labeling.

As the market evolves and sustainability becomes paramount, companies face the challenge of integrating printed flexible packaging. How can they ensure both regulatory adherence and environmental responsibility? This question underscores the need for strategic solutions that balance compliance with eco-friendly practices.

Understand the Importance of Printed Flexible Packaging in Pharmaceuticals

Printed flexible packaging for pharmaceutical products is pivotal in the industry, serving as a robust barrier against environmental factors like moisture, light, and oxygen that can compromise product integrity. This wrapping not only safeguards the contents but also offers substantial branding opportunities through high-quality graphics. The incorporation of vibrant colors and clear labeling significantly enhances shelf appeal, effectively attracting consumer attention while conveying essential information, including dosage instructions and expiration dates. This dual functionality—protection and promotion—positions printed flexible packaging for pharmaceutical as a vital component in the medicine supply chain, ensuring safe delivery while standing out in a competitive marketplace.

The impact of printed flexible coverings on item integrity is underscored by their ability to maintain the stability of delicate medications. A notable case study highlighted the effectiveness of printed flexible packaging for pharmaceutical applications in preserving the quality of biologics, which require stringent environmental controls. As the market evolves, the integration of innovative container solutions will be crucial for pharmaceutical companies aiming to enhance product safety and consumer engagement. Moreover, the adaptable wrapping market is projected to reach $325.8 billion by 2032, growing at a CAGR of 5.1%, underscoring its increasing significance in the industry. Addressing medication non-adherence, which costs the Canadian healthcare system billions annually, further emphasizes the need for efficient container solutions that improve therapeutic outcomes. As companies pursue sustainability, it is essential to consider the challenges related to recycling plastic materials, which can affect the overall efficacy of printed flexible products.

Leverage Benefits of Printed Flexible Packaging for Compliance and Appeal

Printed flexible packaging for pharmaceutical purposes offers significant advantages that align with regulatory compliance and consumer appeal. The ability to incorporate comprehensive item details, such as ingredient lists and safety warnings, directly on the container is essential for meeting stringent regulatory standards. Furthermore, tamper-evident features and serialization enhance security and traceability, increasingly demanded by regulatory bodies.

Western Packaging excels in creating customized flexible solutions that not only comply with these standards but also elevate product appeal through innovative design. The aesthetic aspect of adaptable containers can be tailored to reflect brand identity, utilizing unique designs and finishes that resonate with target audiences. This combination of compliance and visual attractiveness not only fulfills legal requirements but also fosters customer trust and loyalty.

Notably, 70% of customers make purchases based on presentation, while 63% consider appearance as crucial as the brand itself, underscoring the pivotal role of product presentation in consumer decision-making. Additionally, case studies like Delhaize's successful reduction of plastic consumption through design optimization exemplify effective containerization strategies in action.

It is imperative to consider specific regulatory criteria for printed flexible packaging for pharmaceutical drug containers to ensure that all legal standards are met. Finally, a focus on typography legibility and clarity is vital to avoid common design pitfalls, guaranteeing that all information remains easily accessible to consumers.

Implement Effective Strategies for Printed Flexible Packaging Integration

To effectively integrate printed flexible packaging into pharmaceutical operations, companies must implement several key strategies:

- Early Collaboration with Suppliers: Involving material suppliers early in the product development process is crucial. This collaboration ensures that wrapping solutions not only meet functional requirements but also comply with regulatory standards, which is vital in the highly regulated pharmaceutical sector.

- Investment in Digital Printing Technologies: Embracing digital printing technologies can greatly enhance flexibility in container solutions. These technologies enable shorter print runs and customization, allowing companies to quickly adapt to market changes and evolving consumer preferences. The digital printing market for containers is projected to grow from $30.2 billion in 2024 to $46.2 billion by 2029, reflecting a CAGR of 8.9%. Moreover, the broader pharmaceutical container market is expected to reach USD 356.69 billion by 2037, expanding at a CAGR of over 8.3%, underscoring the increasing demand for such innovations.

- Staff Training on Compliance and Quality Control: Educating personnel on the importance of regulatory adherence and quality management is essential. This training minimizes errors and ensures that all containers meet industry standards, thereby enhancing safety and effectiveness.

- Focus on Sustainability: As sustainability trends gain momentum, incorporating eco-friendly solutions for product wrapping is becoming increasingly critical. Businesses should consider sustainable practices in their material strategies to meet consumer demand for environmentally friendly products.

By implementing these strategies, drug manufacturers can optimize their wrapping processes using printed flexible packaging for pharmaceuticals, reduce lead times, and significantly improve overall product quality. The integration of intelligent wrapping technologies and a commitment to sustainability are also emerging trends that can further boost operational efficiency and market competitiveness.

Adopt Sustainable Practices in Printed Flexible Packaging

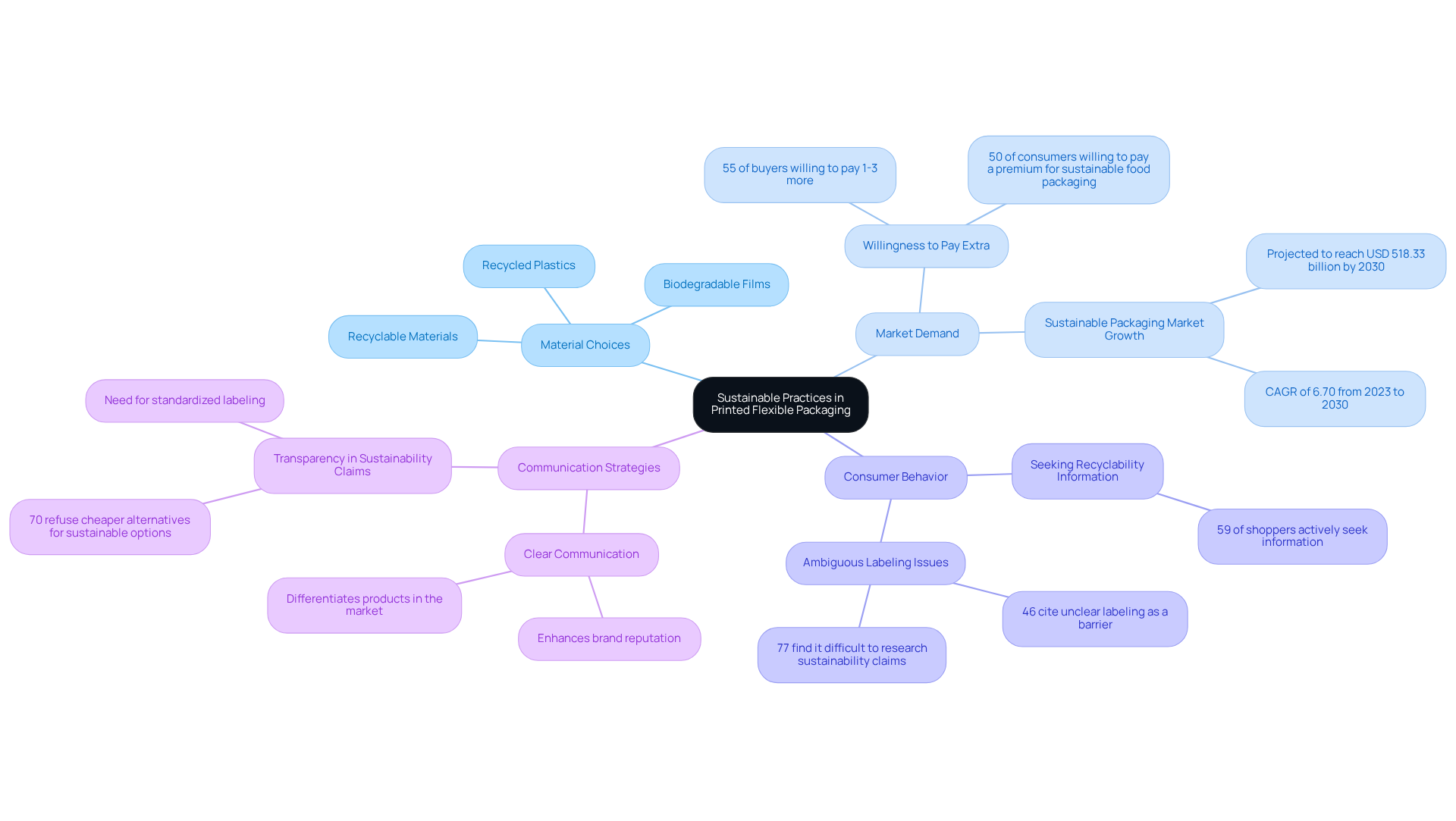

Adopting sustainable practices in printed flexible packaging for pharmaceutical companies is essential for enhancing their environmental responsibility. A strategic starting point involves selecting recyclable materials or those derived from renewable resources, such as biodegradable films and recycled plastics. The demand for recycled plastic containers is surging, driven by its environmental benefits and cost-effectiveness, particularly in the food and beverage sectors. Notably, 55% of buyers are prepared to spend 1-3% extra for sustainable food containers, indicating a strong market inclination towards eco-friendly choices. Furthermore, optimizing production processes to reduce waste and energy use can significantly lessen the environmental impact of such operations.

Clear communication about sustainability efforts is crucial for improving brand reputation and attracting environmentally aware individuals. Brands that clearly indicate their products as recyclable or made of sustainable materials can effectively differentiate themselves in a competitive market. However, 46% of shoppers cite ambiguous labeling as an obstacle to purchasing sustainable items, underscoring the necessity for transparency in sustainability assertions. This approach resonates with the growing consumer preference for environmentally responsible products, as evidenced by the fact that 59% of shoppers actively seek information on packaging recyclability. By prioritizing these sustainable practices, pharmaceutical companies not only contribute to environmental stewardship but also align with the evolving expectations of their customer base regarding printed flexible packaging for pharmaceutical products.

Conclusion

The significance of printed flexible packaging in the pharmaceutical industry cannot be overstated. This innovative solution not only provides essential protection for sensitive medications but also enhances brand visibility in a competitive marketplace. By effectively combining compliance with consumer appeal, printed flexible packaging serves as a vital tool for pharmaceutical companies to ensure product integrity while attracting consumer attention through thoughtful design and clear labeling.

Throughout the article, several key strategies and insights have been discussed:

- The importance of early collaboration with suppliers

- Investment in digital printing technologies

- Staff training on compliance and quality control

These are crucial for successful integration of printed flexible packaging. Additionally, the focus on sustainability and the adoption of eco-friendly practices resonate with the growing consumer demand for environmentally responsible products, highlighting the dual responsibility of pharmaceutical companies to both protect their products and the planet.

Ultimately, embracing printed flexible packaging is essential for pharmaceutical companies aiming to thrive in an evolving market. By prioritizing compliance, consumer appeal, and sustainability, businesses can not only enhance their operational efficiency but also build stronger connections with their customers. As the industry progresses, the implementation of these strategies will be critical for driving success and ensuring that pharmaceutical products meet the expectations of both regulatory bodies and environmentally conscious consumers alike.

Frequently Asked Questions

Why is printed flexible packaging important in the pharmaceutical industry?

Printed flexible packaging is crucial as it acts as a robust barrier against environmental factors like moisture, light, and oxygen, which can compromise product integrity. It also provides substantial branding opportunities through high-quality graphics.

How does printed flexible packaging enhance shelf appeal?

The use of vibrant colors and clear labeling in printed flexible packaging significantly enhances shelf appeal by attracting consumer attention and conveying essential information, such as dosage instructions and expiration dates.

What dual functionalities does printed flexible packaging serve?

Printed flexible packaging serves the dual functions of protecting pharmaceutical products and promoting them through effective branding and clear information.

How does printed flexible packaging impact the integrity of medications?

Printed flexible packaging helps maintain the stability of delicate medications, ensuring their quality is preserved, particularly for biologics that require stringent environmental controls.

What is the projected market growth for printed flexible packaging?

The printed flexible packaging market is projected to reach $325.8 billion by 2032, growing at a CAGR of 5.1%, highlighting its increasing significance in the pharmaceutical industry.

What challenge does medication non-adherence present, and how does packaging address it?

Medication non-adherence costs the Canadian healthcare system billions annually, emphasizing the need for efficient container solutions that improve therapeutic outcomes.

What sustainability challenges are associated with printed flexible packaging?

As companies pursue sustainability, challenges related to recycling plastic materials can affect the overall efficacy of printed flexible products, which need to be addressed.