Overview

The key benefits of printed folding boxes for pharmaceutical use are multifaceted. They provide essential protection against environmental factors, enhance marketing potential, ensure compliance with regulatory standards, allow for customization that fosters brand recognition, and improve operational efficiency.

These boxes are designed to safeguard medications effectively, serving as powerful marketing tools that adhere to strict regulations. Furthermore, they foster brand loyalty through personalization and streamline manufacturing processes, ultimately driving sales and operational success in the pharmaceutical industry.

Embracing printed folding boxes is a strategic move that not only meets industry standards but also positions brands for increased market competitiveness.

Introduction

Printed folding boxes are essential assets in the pharmaceutical industry; they safeguard medications while enhancing brand visibility. These boxes not only protect products from environmental factors but also serve as effective marketing tools that convey crucial information to consumers. As competition intensifies, the challenge lies in balancing compliance with innovation.

How can pharmaceutical companies leverage the benefits of printed folding boxes to ensure safety and enhance brand recognition in a rapidly evolving market? This question underscores the importance of integrating quality packaging solutions that meet regulatory standards while standing out in the marketplace.

Understand the Role of Printed Folding Boxes in Pharmaceutical Packaging

Printed folding boxes for pharmaceutical packaging serve as a cornerstone, providing essential protection against environmental factors such as moisture, light, and air. These boxes not only safeguard medications but also function as potent marketing tools, effectively conveying crucial product information to customers. Their lightweight and stackable design promotes efficient storage and transportation, presenting a cost-effective solution for pharmaceutical companies. Moreover, the visual appeal of printed designs significantly boosts recognition and fosters customer trust—an essential aspect in a competitive market.

Research underscores that well-designed folding cartons can elevate shelf presence and enhance consumer engagement, ultimately driving sales. As the pharmaceutical sector evolves, the importance of printed folding boxes for pharmaceutical use in ensuring medication protection and bolstering product integrity will continue to grow.

At Western Packaging, we specialize in innovative design solutions that enhance your product's shelf appeal and identity. Our tailored flexible containers, including large pouches for protein items and stick packs for nutraceuticals, not only enhance product attractiveness but also ensure a cohesive and captivating brand identity.

Ensure Regulatory Compliance with Folding Box Packaging

Pharmaceutical containers must adhere to stringent regulations established by authorities such as the FDA. Printed folding boxes for pharmaceutical products are required to be designed according to specific guidelines regarding materials, labeling, and safety features. For instance, the wrapping must not only safeguard the product but also provide clear directions and alerts to consumers.

In 2022, the pharmaceutical sector withdrew 567.3 million units, marking a 114% rise from 2021, which underscores the essential requirement for adherence in container creation. Producers should conduct comprehensive evaluations of their printed folding boxes for pharmaceutical to ensure compliance with all regulatory requirements, including those concerning child safety and tamper-proofing.

Collaborating with compliance specialists during the planning stage can streamline this process and mitigate risks associated with non-compliance. A case study from the FDA illustrates how companies prioritizing compliance in their packaging can avoid costly recalls and enhance their market reputation. As Eric F. Greenberg noted, almost all recalls are voluntary on the part of the manufacturer or distributor, highlighting the significance of proactive compliance measures.

Additionally, the FDA's extended enforcement deadline for enhanced drug distribution requirements offers a timely opportunity for manufacturers to address compliance. By tackling common pitfalls, such as inadequate responses to Form-483 observations, companies can further fortify their compliance efforts.

Leverage Customization for Enhanced Brand Recognition

The personalization of printed folding boxes for pharmaceutical companies empowers them to establish a distinctive identity that captures attention on retail shelves. By integrating company colors, emblems, and unique styles, businesses can significantly enhance their visibility and foster customer loyalty.

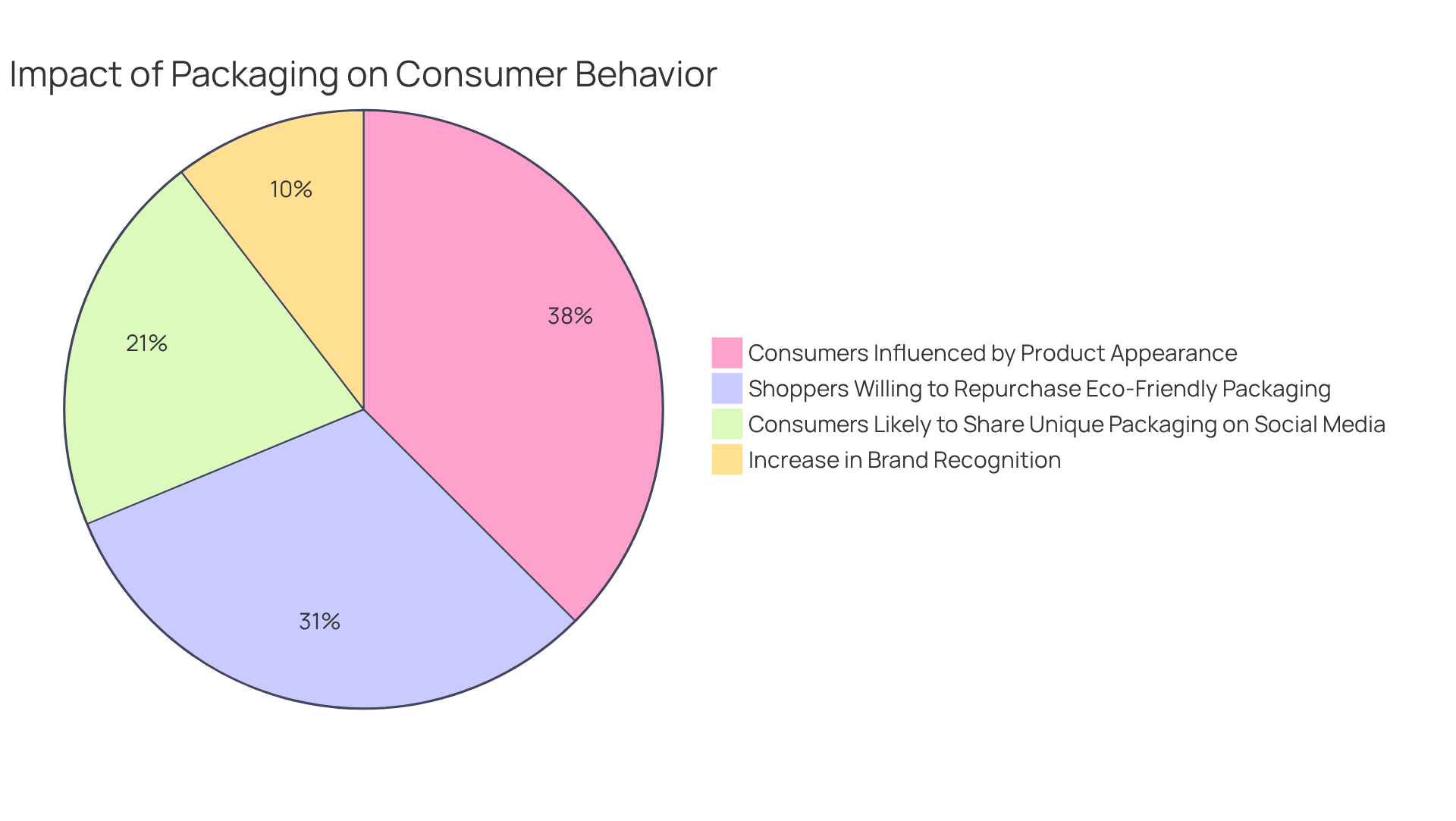

Research indicates that products with tailored packaging can achieve a 20% increase in brand recognition compared to their standard counterparts. Furthermore, 72% of American consumers report that product appearance influences their purchasing decisions, underscoring the importance of personalization in driving sales.

Customization transcends mere aesthetics; functional improvements such as easy-open features and child-resistant designs not only enhance user experience but also ensure adherence to safety regulations. Over 60% of US shoppers express a willingness to repurchase products if their packaging is eco-friendly, linking practicality and sustainability to customer loyalty.

Engaging customers through customized containers cultivates trust, with 74% of shoppers preferring to buy from transparent and genuine companies. This trust fosters repeat purchases, positioning printed folding boxes for pharmaceutical as a strategic investment for firms aiming to bolster their market presence.

Additionally, 40% of consumers are likely to share images of unique or branded packaging on social media, further amplifying brand visibility and engagement.

Integrate Filling Services for Streamlined Operations

Integrating filling services with printed folding boxes for pharmaceutical purposes significantly enhances operational efficiency for manufacturers. This coordination leads to shorter lead times and reduces the likelihood of errors during the final stages.

Western Packaging exemplifies this seamless solution by combining filling services with tailored wrapping and comprehensive 3PL services, including:

- Warehousing

- Inventory management

- Logistics

This results in a more efficient workflow. Such integration conserves time and lowers costs associated with the separate handling of filling and packaging of printed folding boxes for pharmaceutical. Clients have reported annual savings exceeding $2 million in material costs through improved processes, showcasing the financial benefits of streamlined operations within the industry.

Furthermore, implementing real-time tracking and inventory management ensures products are filled and packaged according to demand, further optimizing the supply chain. A notable case study from a leading pharmaceutical company revealed a remarkable 30% reduction in operational costs following the adoption of this integrated approach, underscoring the effectiveness of this strategy. This integration not only enhances efficiency but also positions companies to thrive in a competitive market.

Conclusion

Printed folding boxes play a pivotal role in the pharmaceutical industry, serving not only as protective packaging but also as vital marketing instruments. These boxes ensure that medications remain safe from environmental threats while effectively communicating essential product information to consumers. As competition intensifies, the integration of compliance with innovative packaging solutions becomes crucial for success.

The advantages of printed folding boxes are manifold. They enhance product safety, streamline operations through integrated filling services, and foster brand recognition through customization. These benefits underscore the necessity for pharmaceutical companies to invest in high-quality packaging that meets regulatory standards while appealing to consumers. The insights provided demonstrate how well-designed folding boxes can significantly impact sales and customer loyalty.

Ultimately, embracing the multifaceted benefits of printed folding boxes is not merely a choice but a strategic imperative for pharmaceutical companies. By prioritizing effective packaging solutions, businesses can strengthen their market presence, ensure compliance with regulations, and build lasting relationships with customers. The future of pharmaceutical packaging lies in the thoughtful integration of safety, compliance, and innovative design, making printed folding boxes an indispensable asset in the industry.

Frequently Asked Questions

What is the primary function of printed folding boxes in pharmaceutical packaging?

Printed folding boxes primarily provide protection against environmental factors such as moisture, light, and air, safeguarding medications.

How do printed folding boxes serve as marketing tools?

These boxes convey crucial product information to customers, enhancing product visibility and recognition, which helps foster customer trust.

What are the advantages of the design of printed folding boxes?

Their lightweight and stackable design promotes efficient storage and transportation, making them a cost-effective solution for pharmaceutical companies.

How do well-designed folding cartons impact sales in the pharmaceutical sector?

Research indicates that well-designed folding cartons can elevate shelf presence and enhance consumer engagement, ultimately driving sales.

Why is the role of printed folding boxes expected to grow in the pharmaceutical sector?

As the pharmaceutical sector evolves, the importance of printed folding boxes in ensuring medication protection and bolstering product integrity will continue to increase.

What services does Western Packaging offer related to packaging solutions?

Western Packaging specializes in innovative design solutions that enhance product shelf appeal and identity, including tailored flexible containers like large pouches and stick packs.