Overview

Contract supplement manufacturing plays a pivotal role for nutraceutical producers, enabling them to outsource production to specialized manufacturers. This strategic move not only enhances operational efficiency but also ensures the delivery of high-quality products without the burden of significant capital investment. Such an approach effectively reduces costs and grants access to advanced technology. Moreover, it empowers companies to concentrate on marketing and sales efforts, thereby positioning themselves competitively in a rapidly evolving market. By leveraging this model, nutraceutical producers can achieve a remarkable balance of quality and efficiency, driving their success in an increasingly competitive landscape.

Introduction

Contract supplement manufacturing has emerged as a pivotal strategy in the rapidly evolving nutraceutical landscape. The demand for high-quality dietary products continues to surge, prompting companies to partner with specialized manufacturers. This collaboration allows them to harness advanced technologies and expertise while avoiding the hefty investments typically associated with production facilities.

However, as the market grows, questions arise regarding how this outsourcing model can enhance product offerings and challenge traditional manufacturing paradigms. What are the implications for quality control, innovation, and competitive advantage in an industry increasingly reliant on these collaborations? The answers to these questions are crucial for companies seeking to navigate this dynamic environment.

Defining Contract Supplement Manufacturing

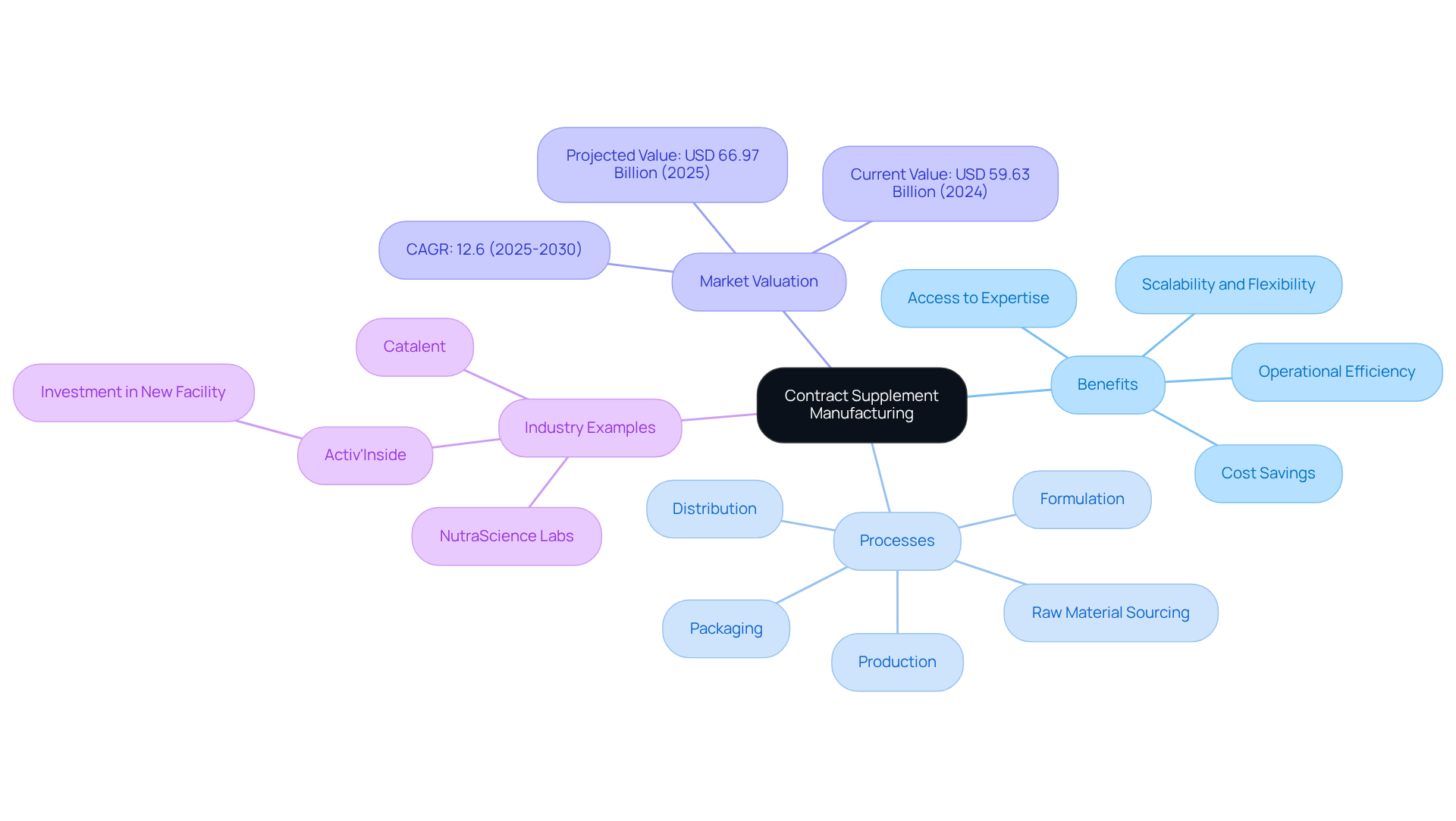

Contract supplement manufacturing represents a strategic procedure wherein a firm delegates the creation of dietary products to a specialized producer. This setup not only facilitates access to the contractor's expertise, advanced facilities, and resources but also enables the production of high-quality items without the significant capital investment typically required for production infrastructure. The contractor oversees all aspects of the process, including formulation, raw material sourcing, production, packaging, and, in some cases, distribution. This arrangement allows the client to focus on marketing and sales, ultimately enhancing operational efficiency.

The dietary supplement production market was valued at USD 59.63 billion in 2024 and is projected to reach USD 66.97 billion in 2025, expanding at a compound annual growth rate of 12.6% from 2025 to 2030. This growth is driven by the increasing demand for nutraceuticals and heightened health awareness among consumers. Industry leaders emphasize that collaborating with manufacturing partners not only provides scalability and flexibility but also ensures strict adherence to quality standards and regulatory obligations.

Numerous successful instances illustrate the benefits of manufacturing agreements in enhancing product offerings. For instance, Activ'Inside's investment in a new manufacturing facility in France aims to accelerate the creation of customized dietary products, showcasing how strategic alliances can foster innovation and market adaptability. Other significant players in the market, such as NutraScience Labs and Catalent, also demonstrate how outsourcing manufacturing enables health brands to concentrate on their core strengths, thereby facilitating more effective marketing and sales strategies while ensuring high-quality items reach consumers.

As Mark Potocnjak, CFO, noted, "Collaborating with a manufacturing partner can offer significant cost reductions as the manufacturer will supply already established machinery, laboratory services, and skilled, well-trained personnel." By engaging in contract supplement manufacturing, wellness brands can ensure compliance with regulatory requirements and meet consumer expectations for quality and effectiveness.

Historical Context and Evolution of Contract Supplement Manufacturing

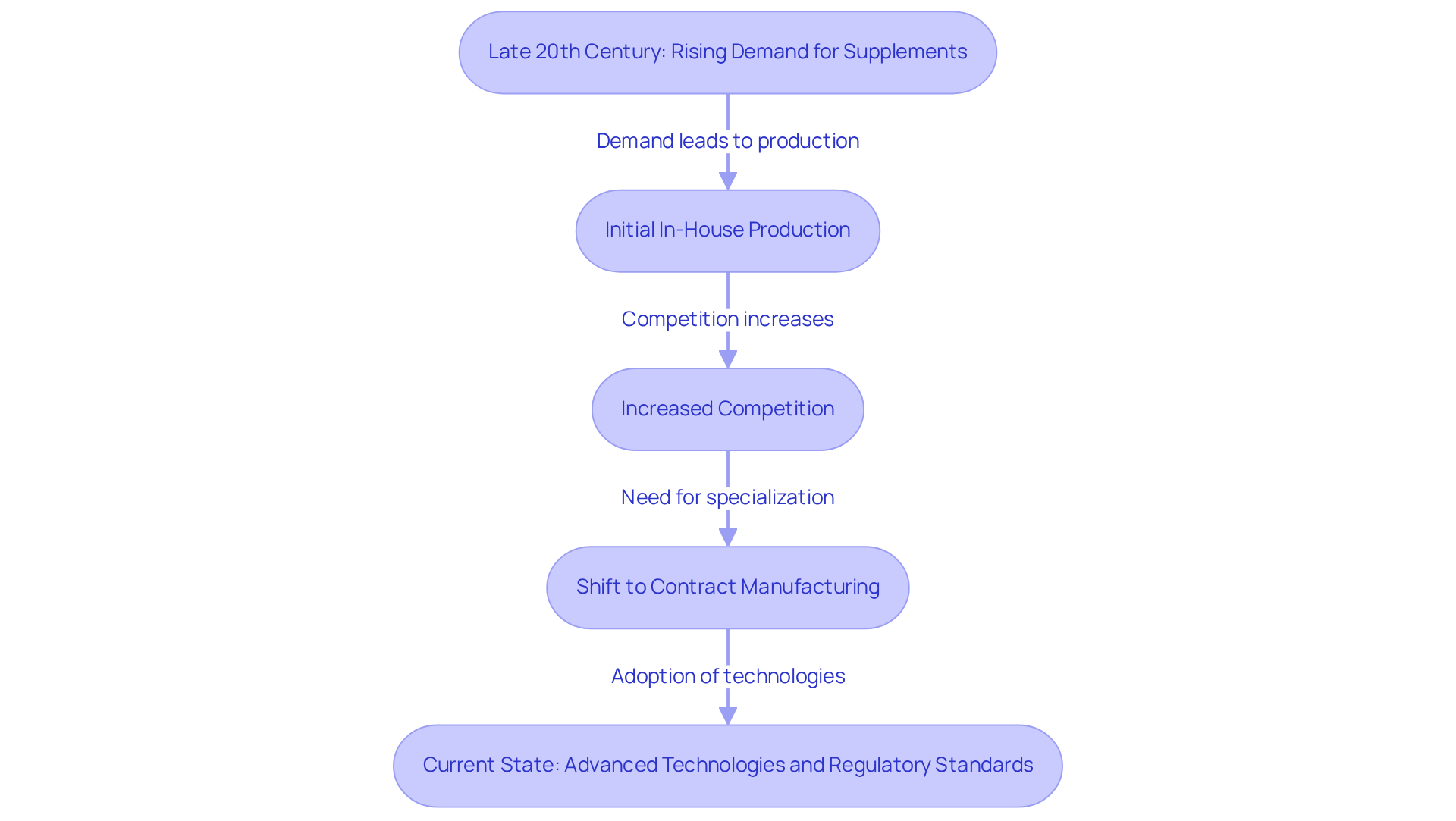

The origins of contract supplement manufacturing can be traced to the increasing demand for dietary supplements that emerged in the late 20th century. As consumers grew more health-conscious, the nutraceutical market experienced rapid expansion, compelling manufacturers to adopt efficient production methods. Initially, many companies opted for in-house production; however, as competition intensified and the need for specialization became more pronounced, they began to consider contract supplement manufacturing as a practical solution. Today, enhancement production stands as a multi-billion dollar sector, with firms leveraging advanced technologies and adhering to regulatory standards to meet consumer expectations and market demands.

Key Characteristics of Contract Supplement Manufacturing

Key characteristics of supplement manufacturing encompass flexibility, scalability, and specialized expertise. Flexibility empowers manufacturers to swiftly adapt to evolving market demands and client specifications—an essential capability in a rapidly changing industry where consumer preferences can shift overnight. Scalability enables manufacturers to efficiently increase output volumes, accommodating growth without necessitating substantial capital investment.

The Contract Manufacturing Market is projected to grow from USD 0.74 trillion in 2025 to USD 1.12 trillion by 2030, boasting a compound annual growth rate (CAGR) of 8.7%. This statistic underscores the market's potential relevance for nutraceutical producers. Furthermore, manufacturers often possess specialized knowledge in formulation, regulatory compliance, and quality control processes, ensuring that products meet both safety and efficacy requirements.

Western Packaging enhances this process with tailored flexible packaging solutions and integrated filling services, streamlining production while elevating brand recognition through innovative packaging design. However, challenges such as maintaining quality control and protecting intellectual property present critical considerations for nutraceutical producers.

The combination of these attributes renders contract supplement manufacturing an appealing choice for nutraceutical producers seeking to innovate and broaden their product lines. As Will Durant noted, excellence is a habit, emphasizing the importance of continuous quality improvement in this sector.

Benefits of Contract Supplement Manufacturing for Nutraceutical Producers

Contract supplement manufacturing presents a multitude of benefits for nutraceutical producers, encompassing significant cost reductions, access to cutting-edge technology, and expedited time to market. By outsourcing production, companies can bypass the considerable capital expenditures associated with establishing and maintaining manufacturing facilities. This strategic move not only alleviates financial burdens but also allows producers to leverage the advanced equipment and expertise of their contract supplement manufacturing partners, thereby ensuring the delivery of high-quality products.

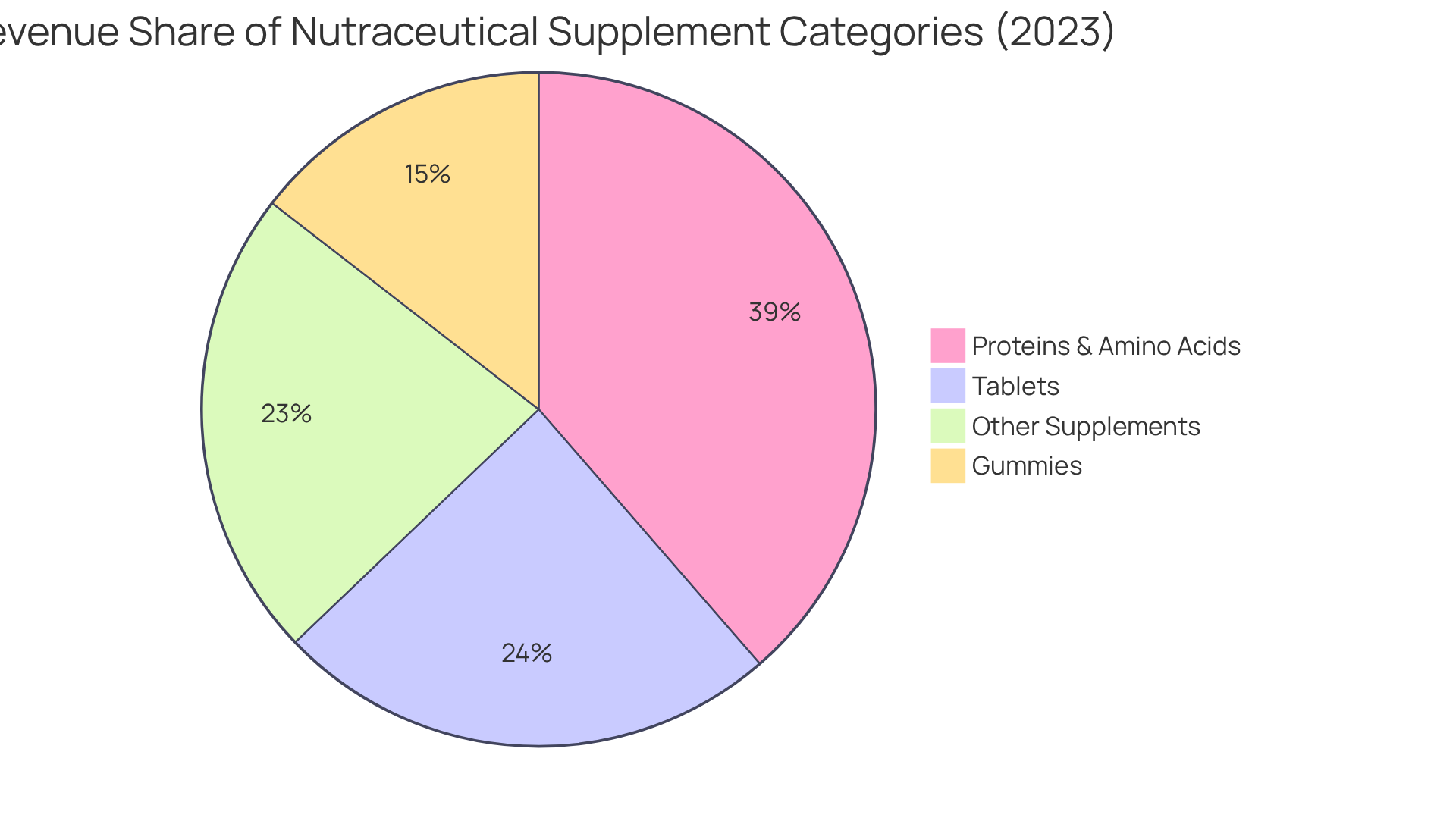

For instance, the proteins and amino acid supplements category, which accounted for a 35.8% revenue share in 2022, is projected to retain the largest market share of 39% in 2023. This trend underscores the increasing reliance on contract supplement manufacturing to satisfy the surging demand for health-oriented products.

Moreover, the gummies segment is anticipated to grow at a CAGR of approximately 14.66%, propelled by consumer preferences for more palatable options, particularly among children and those who prefer not to swallow pills. This collaboration empowers nutraceutical companies to swiftly adapt to market trends and consumer demands, thereby enhancing their competitiveness in a rapidly changing landscape.

With the global contract supplement manufacturing services market expected to reach USD 362.24 billion by 2031, following an estimated size of USD 133.34 billion in 2022 and a growth rate of 11.8% CAGR during the forecast period from 2023 to 2031, the advantages of outsourcing production become increasingly apparent, positioning companies for success in a dynamic market.

Conclusion

Contract supplement manufacturing serves as a vital strategy for companies aiming to optimize their production processes in the nutraceutical industry. By entrusting the creation of dietary products to specialized manufacturers, businesses can tap into expert knowledge, advanced technologies, and efficient production capabilities, all while minimizing significant capital investment. This collaborative approach not only enhances operational efficiency but also allows companies to focus on their core competencies, such as marketing and sales.

Key insights throughout the article highlight the historical evolution of contract supplement manufacturing, its defining characteristics, and the numerous benefits it offers to nutraceutical producers. The growth of this sector, driven by rising health awareness and consumer demand for high-quality supplements, underscores the importance of strategic partnerships in facilitating innovation and adaptability. The ability to scale production, maintain flexibility, and ensure compliance with regulatory standards are critical advantages that reinforce the value of outsourcing manufacturing.

As the nutraceutical market continues to expand, embracing contract supplement manufacturing emerges as a strategic imperative for producers seeking to thrive in a competitive landscape. By leveraging the expertise and resources of contract manufacturers, companies can enhance their product offerings and position themselves for long-term success in meeting the evolving needs of health-conscious consumers. Engaging in this collaborative model is not merely a trend; it is a cornerstone of sustainable growth in the health industry.

Frequently Asked Questions

What is contract supplement manufacturing?

Contract supplement manufacturing is a strategic process where a company delegates the production of dietary products to a specialized manufacturer, allowing access to their expertise, facilities, and resources while reducing capital investment in production infrastructure.

What aspects of production does the contractor oversee?

The contractor manages all aspects of the production process, including formulation, raw material sourcing, production, packaging, and sometimes distribution.

How does contract supplement manufacturing benefit companies?

It allows companies to focus on marketing and sales, increases operational efficiency, and provides access to high-quality production without the need for significant capital investment.

What is the current market value of dietary supplement production?

The dietary supplement production market was valued at USD 59.63 billion in 2024 and is projected to reach USD 66.97 billion in 2025.

What is the projected growth rate for the dietary supplement production market?

The market is expected to expand at a compound annual growth rate of 12.6% from 2025 to 2030.

What factors are driving the growth of the dietary supplement market?

The growth is driven by increasing demand for nutraceuticals and heightened health awareness among consumers.

How do manufacturing partnerships enhance product offerings?

Collaborating with manufacturing partners allows for scalability, flexibility, innovation, and adherence to quality standards and regulatory obligations.

Can you provide an example of a successful contract manufacturing partnership?

Activ'Inside's investment in a new manufacturing facility in France illustrates how strategic alliances can accelerate the creation of customized dietary products.

What advantages do companies gain by outsourcing manufacturing?

Outsourcing manufacturing enables health brands to focus on their core strengths, leading to more effective marketing and sales strategies while ensuring high-quality products for consumers.

What cost benefits can be realized through contract supplement manufacturing?

Companies can achieve significant cost reductions as manufacturers provide established machinery, laboratory services, and skilled personnel.