Overview

This article delineates a three-step process for mastering dietary supplements contract manufacturing. It underscores the critical importance of selecting a qualified manufacturer and optimizing packaging and distribution strategies. Such an approach is bolstered by comprehensive guidance on essential factors, including:

- Certifications

- Quality control

- Innovative packaging

These elements collectively enhance product quality and bolster brand competitiveness within the burgeoning nutritional market.

Introduction

Navigating the dynamic world of dietary supplements demands a strategic approach, especially regarding contract manufacturing. This essential process empowers brands to leverage the expertise of specialized manufacturers, ensuring high-quality production while minimizing capital investments. As the nutritional enhancement sector continues its impressive growth, understanding how to effectively select a qualified contract manufacturer and optimize packaging and distribution strategies becomes paramount.

What key factors can make or break a partnership in this competitive landscape? How can companies ensure they distinguish themselves in a crowded market? These are critical questions that require thoughtful consideration.

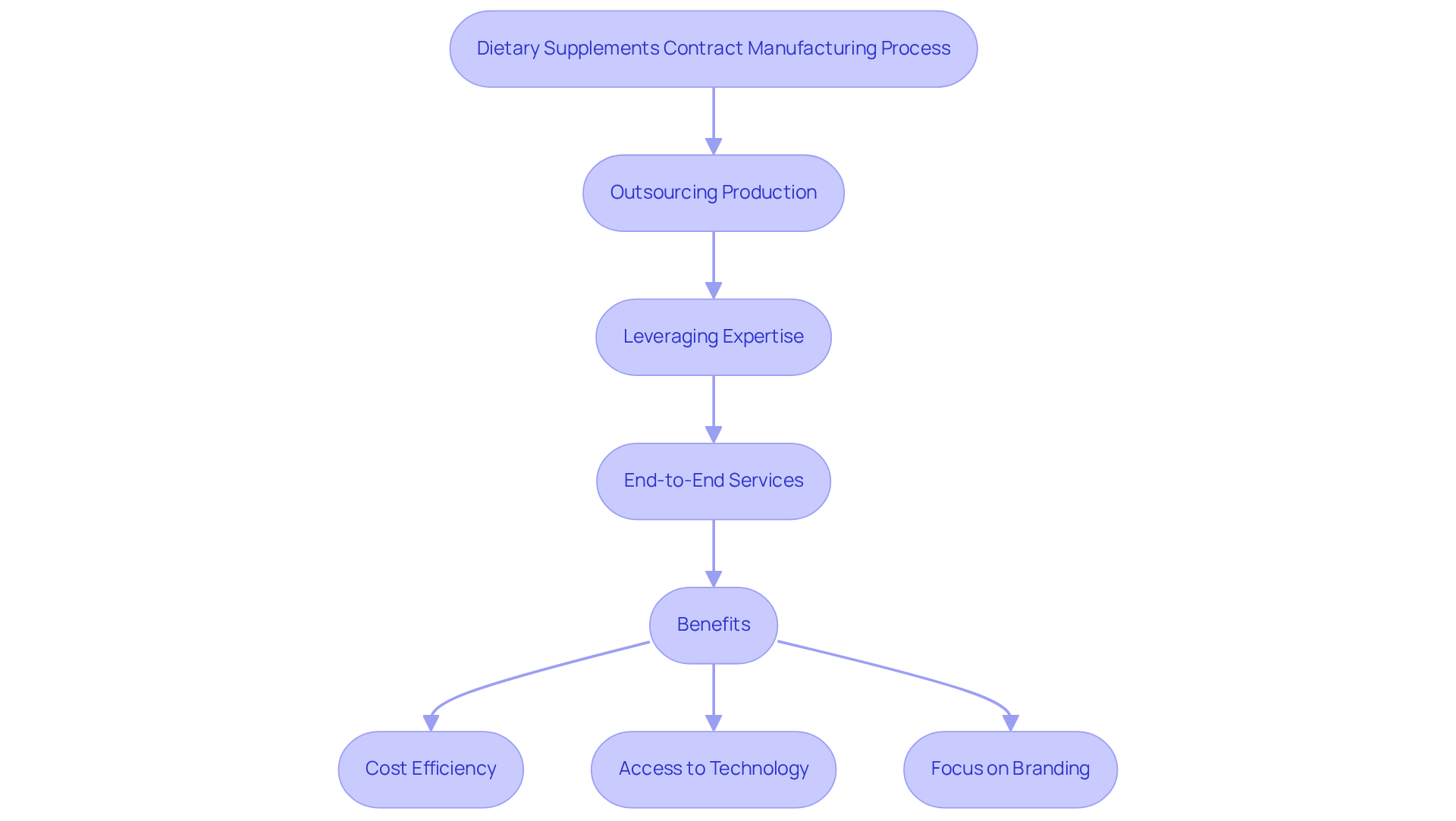

Understand Dietary Supplements Contract Manufacturing

The process of is crucial as companies outsource the production of to specialized manufacturers such as Western Packaging. This strategic arrangement allows brands to leverage our expertise in integrated solutions, guaranteeing high-quality production without the burden of substantial capital investment in manufacturing infrastructure. Our comprehensive end-to-end services encompass innovative packaging design, filling a diverse range of products such as powders, gummies, and soft gels, alongside extensive 3PL services for warehousing and distribution.

The key benefits of this approach include:

- Cost efficiency

- Access to cutting-edge technology

- The ability to concentrate on branding and marketing while we expertly manage production and logistics

Understanding the process of dietary supplements contract manufacturing is crucial for companies seeking to enter or expand within the nutritional enhancement sector, as it significantly impacts quality, brand awareness, and market readiness. By partnering with us, businesses can ensure a reliable and effective pathway to success in a competitive landscape.

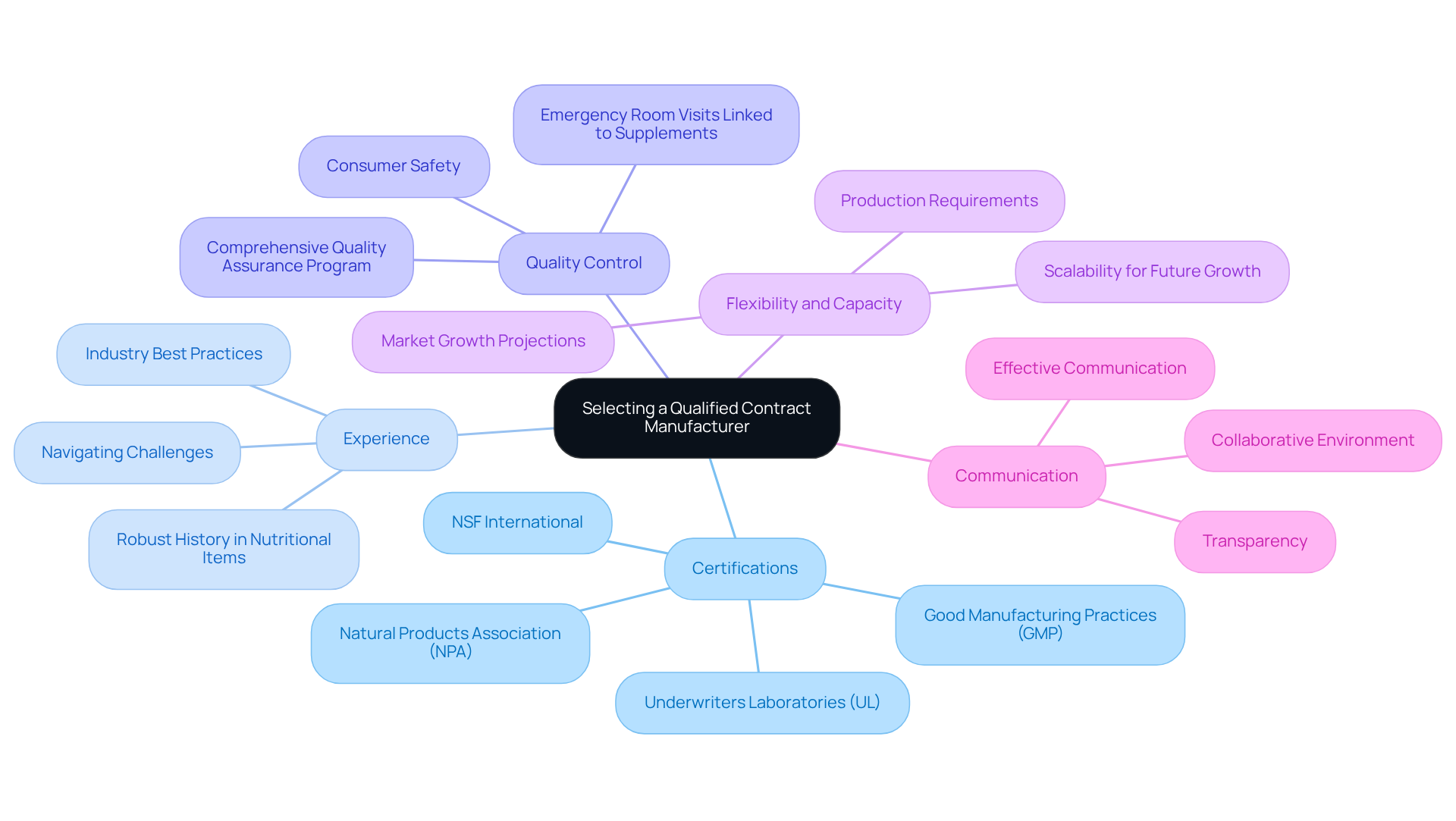

Select a Qualified Contract Manufacturer

When selecting a contract manufacturer for dietary supplements, several key factors must be prioritized:

- Certifications: It is imperative to verify that the manufacturer possesses essential certifications, particularly Good Manufacturing Practices (GMP). Adhering to FDA regulations guarantees conformity to strict quality standards that protect safety and effectiveness. Trusted certifications may include NSF International, Underwriters Laboratories (UL), or the Natural Products Association (NPA).

- Experience: Opt for manufacturers with a robust history in creating nutritional items that align with your specifications. Their extensive experience can provide valuable insights into industry best practices and enable you to navigate potential challenges effectively.

- Quality Control: Scrutinize the manufacturer's quality control protocols. A comprehensive quality assurance program is vital for preserving product integrity and ensuring consumer safety, especially in a market where over 74% of U.S. adults utilize nutritional aids. Notably, nutritional additives are linked to approximately 23,000 emergency room visits annually, underscoring the critical importance of quality control in production.

- Flexibility and Capacity: Evaluate the manufacturer's ability to meet your production requirements, including scalability to accommodate future growth. This flexibility is crucial, as the nutrition product market is projected to expand significantly, reaching an estimated USD 121.2 billion by 2030, with the global dietary supplements contract manufacturing market size anticipated at USD 59.63 billion in 2024 and expected to grow at a CAGR of 12.6% from 2025 to 2030.

- Communication: Select a manufacturer that emphasizes transparency and effective communication. This approach fosters a collaborative environment, ensuring that any issues are promptly addressed and that proceeds smoothly.

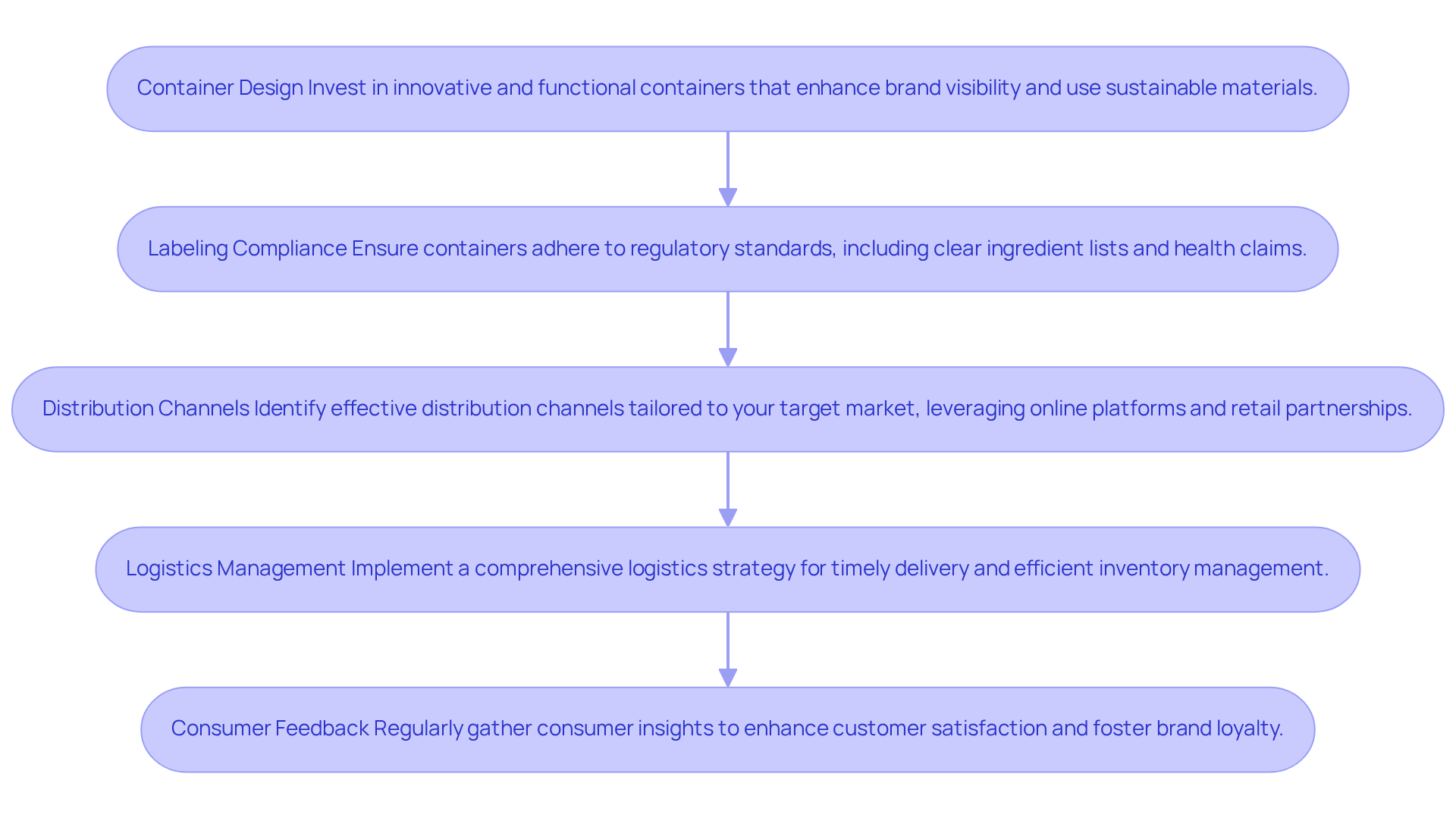

Optimize Packaging and Distribution Strategies

To optimize packaging and distribution strategies for dietary supplements, consider the following steps:

- Container Design: Invest in innovative and functional containers that not only protect the product but also enhance brand visibility. Using sustainable materials aligns with the increasing consumer demand for eco-friendly choices, as 50% of U.S. consumers are ready to spend extra for sustainable solutions.

- Labeling Compliance: Ensure that all containers adhere to regulatory standards, including clear ingredient lists, nutritional information, and health claims. Adherence is crucial for establishing consumer confidence and preventing legal problems, since research indicates that 72% of buyers are affected by design in their purchasing choices.

- Distribution Channels: Identify the most effective distribution channels tailored to your target market. This may involve leveraging online platforms, establishing retail partnerships, or adopting direct-to-consumer sales strategies. Successful brands distinguish themselves through innovative product designs and unique branding elements, enhancing market appeal.

- Logistics Management: Implement a comprehensive logistics strategy that guarantees timely delivery and efficient inventory management. Consider collaborating with a third-party logistics provider, like Western Packaging, which offers for a range of items, including dietary supplements contract manufacturing for powders, gummies, and soft-gels, along with extensive 3PL services. This partnership can optimize operations and lower expenses, enabling businesses to concentrate on improving their product attractiveness and brand visibility through customized flexible solutions.

- Consumer Feedback: Regularly gather consumer insights concerning product presentation and distribution experiences. This information is invaluable for making informed adjustments that enhance customer satisfaction and foster brand loyalty. Research indicates that 63% of customers consider packaging as important as the brand itself, highlighting the need for continuous improvement in this area.

Conclusion

Understanding dietary supplements contract manufacturing is crucial for companies striving to excel in the competitive nutritional enhancement sector. By leveraging the expertise of specialized manufacturers, brands can ensure high-quality production while concentrating on their core competencies in branding and marketing. This strategic partnership alleviates the burden of significant capital investment and positions businesses for success in a rapidly evolving market.

Key insights emphasize the necessity of selecting a qualified contract manufacturer, which involves evaluating:

- Certifications

- Experience

- Quality control

- Flexibility

- Communication

Each factor plays a pivotal role in maintaining product integrity and ensuring compliance with industry standards. Furthermore, optimizing packaging and distribution strategies is vital for enhancing brand visibility and meeting consumer expectations, particularly in a landscape where sustainability and compliance are increasingly prioritized.

In conclusion, mastering dietary supplements contract manufacturing transcends mere outsourcing; it involves forging partnerships that drive quality, efficiency, and market readiness. As the dietary supplements industry continues to expand, businesses are encouraged to prioritize these strategies and insights to navigate challenges effectively and seize growth opportunities. Embracing these practices will not only enhance product appeal but also cultivate enduring relationships with consumers who value quality and innovation in their nutritional choices.

Frequently Asked Questions

What is dietary supplements contract manufacturing?

Dietary supplements contract manufacturing is the process where companies outsource the production of their dietary supplements to specialized manufacturers, allowing them to benefit from expert production services without investing heavily in manufacturing infrastructure.

What services are included in dietary supplements contract manufacturing?

The services include innovative packaging design, filling various product types such as powders, gummies, and soft gels, as well as extensive third-party logistics (3PL) services for warehousing and distribution.

What are the benefits of using contract manufacturing for dietary supplements?

The benefits include cost efficiency, access to cutting-edge technology, and the ability for companies to focus on branding and marketing while the manufacturer handles production and logistics.

Why is understanding dietary supplements contract manufacturing important for companies?

Understanding this process is crucial for companies looking to enter or expand in the nutritional enhancement sector, as it significantly affects product quality, brand awareness, and market readiness.

How can partnering with a contract manufacturer impact a business's success?

Partnering with a contract manufacturer can provide a reliable and effective pathway to success in a competitive landscape, ensuring high-quality production and efficient logistics management.