Overview

Pharmaceutical packaging plays a critical role in safeguarding medications from contamination, ensuring adherence to regulatory standards, and enhancing both patient safety and compliance. Effective packaging not only protects drug integrity through innovative designs and materials but also cultivates consumer trust and adherence by providing clear usage instructions and security features. This multifaceted approach is vital in the healthcare system, underscoring the importance of reliable packaging solutions that contribute to overall health outcomes.

Introduction

Pharmaceutical packaging serves as a critical line of defense against contamination and degradation of medications, underscoring its importance in the healthcare industry. As the market for pharmaceutical products expands, it becomes increasingly vital to understand the multifaceted functions of packaging—ensuring safety and compliance while enhancing patient experience. With rapid advancements in technology and evolving regulatory demands, stakeholders face the challenge of navigating the complexities of pharmaceutical packaging to ensure efficacy and security. This exploration delves into the essential elements of pharmaceutical packaging, highlighting its role in safeguarding drug integrity and promoting patient adherence.

Define Pharmaceutical Packaging and Its Core Functions

Pharmaceutical packaging encompasses the materials and methods designed to enclose and protect medicinal items throughout their lifecycle, which includes storage, handling, transport, and usage. Their core functions are multifaceted: they safeguard products from contamination and degradation, provide essential information about the medication, ensure safe delivery, and promote patient compliance. Effective wrapping not only preserves the integrity of the medication but also enhances the user experience by delivering clear instructions and dosage information.

For instance, the emergence of pre-filled syringes demonstrates , such as those offered by Western Packaging, can minimize drug waste and extend shelf life, thereby bolstering security and effectiveness. Furthermore, the introduction of tamper-evident features and child-resistant closures underscores the industry's commitment to drug protection, ensuring that medications remain secure from counterfeiting and unauthorized access.

As the global pharmaceutical packaging market is projected to grow significantly, reaching USD 356.7 billion by 2034, the importance of , including from Western Packaging, in preserving drug quality and security cannot be overstated.

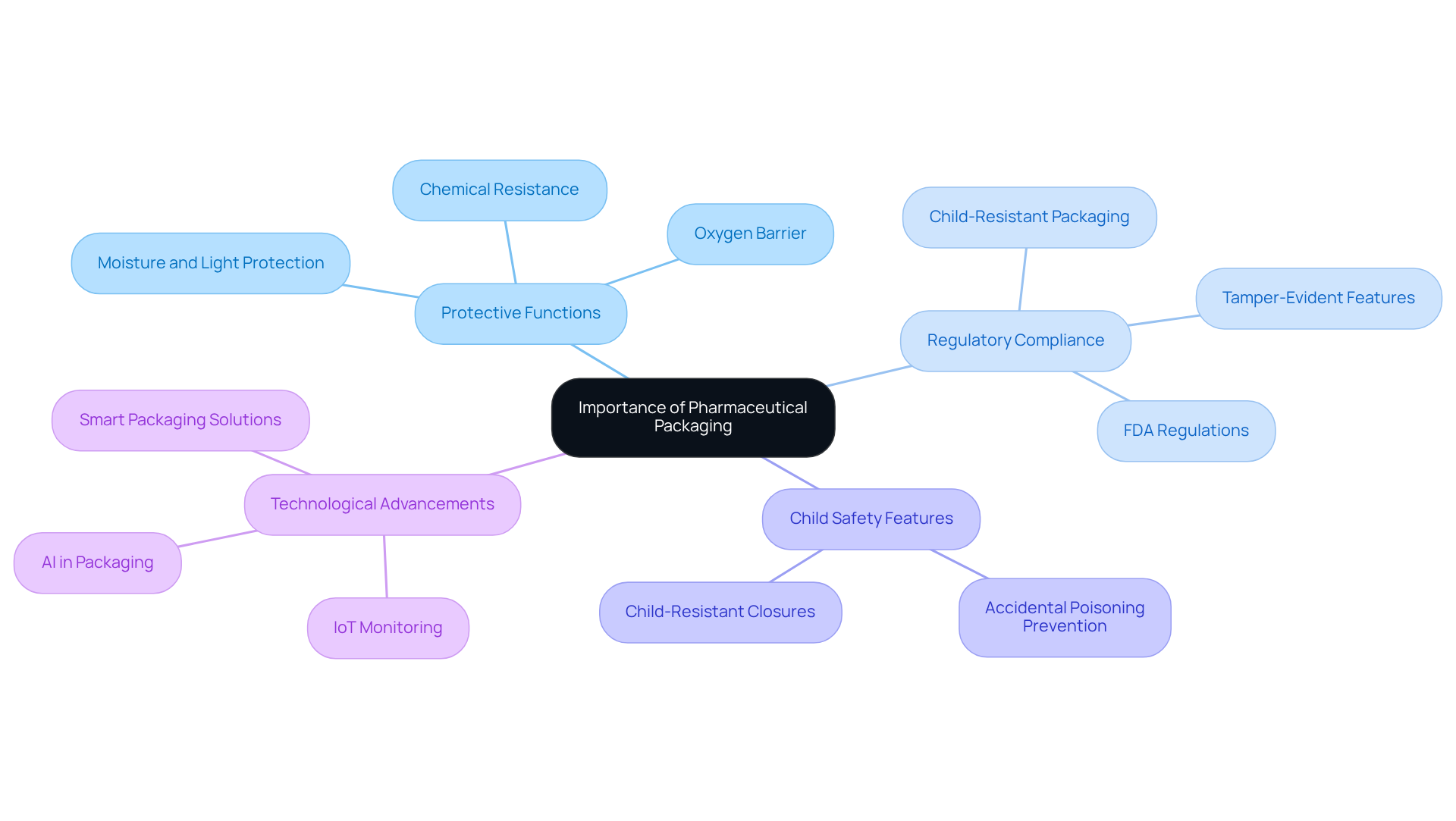

Explain the Importance of Pharmaceutical Packaging in Product Safety and Compliance

Safeguarding drug integrity and ensuring compliance with regulatory standards is essential in pharmaceutical packaging. It acts as a protective barrier against environmental factors such as moisture, light, and oxygen, which can severely impact the efficacy of medications. The choice of materials—plastics, glass, and aluminum foil—plays a critical role in maintaining the integrity of pharmaceutical packaging.

Adhering to stringent regulations set forth by health authorities is crucial; these regulations often require features such as child-resistant closures and tamper-evident seals in pharmaceutical packaging to enhance safety. For instance, child-resistant containers are specifically designed to prevent accidental poisoning, particularly in prescription and certain over-the-counter products.

Moreover, the FDA mandates that container suppliers submit a drug master file detailing all raw materials and formulations, which underscores the significance of regulatory compliance in pharmaceutical packaging. Effective pharmaceutical packaging not only fosters trust among consumers but also significantly enhances adherence among patients.

Studies demonstrate that well-designed containers can lead to a marked increase in , thereby reducing the likelihood of medication errors. Furthermore, advancements in IoT and AI technologies are bolstering drug security by monitoring temperature sensitivity and detecting tampering. By ensuring that medications remain safe for consumption throughout their shelf life, pharmaceutical packaging ultimately contributes to improved health outcomes and reinforces the integrity of the healthcare system.

Identify Different Types of Pharmaceutical Packaging and Their Applications

Pharmaceutical containers are categorized into three primary types: primary, secondary, and tertiary, each fulfilling distinct roles within the industry.

- Primary Packaging: This is the initial layer that directly interacts with the drug, ensuring its integrity and safety. Common examples include blister packs, vials, and bottles. The main container is vital as it protects the medication from contamination and physical damage during transit. For instance, plastic bottles are widely utilized for various drugs due to their lightweight and cost-effective nature, which also lowers shipping expenses. Western Packaging's filling process is designed to accommodate a variety of product forms, including powders, gummies, and soft-gels, ensuring optimal protection and appeal.

- Secondary Packaging: This layer offers additional protection and branding, often manifesting as boxes or cartons. Secondary wrapping not only safeguards the primary container but also enhances brand visibility through printed designs and information. It plays a crucial role in marketing and consumer engagement, often serving as the first point of interaction for customers. The FDA mandates that drug container labels include essential details such as administration guidelines and exact doses, typically found on secondary containers.

- Tertiary Wrapping: Primarily used for bulk handling and transportation, tertiary wrapping encompasses pallets and shipping containers. This form of wrapping is essential for the effective delivery of medical items, ensuring they arrive securely and undamaged. It streamlines the logistics process by facilitating easier handling and storage. Tertiary containment solutions, such as temperature-controlled shipping containers, are increasingly employed to maintain the efficacy of sensitive biologics during transport. Western Packaging's comprehensive 3PL services optimize supply chain management, offering warehousing, inventory management, and distribution tailored to the specific needs of nutraceutical manufacturers.

Every type of container is integral to , enhancing product security, compliance with regulatory requirements, and overall market appeal. Real-world applications underscore the significance of these container types. For injectables, primary containers must guarantee sterility and protection from degradation, while secondary enclosures often incorporate tamper-evident features to bolster safety.

Understanding the unique functions of primary, secondary, and tertiary containers is essential for drug manufacturers aiming to refine their container strategies and efficiently meet regulatory standards.

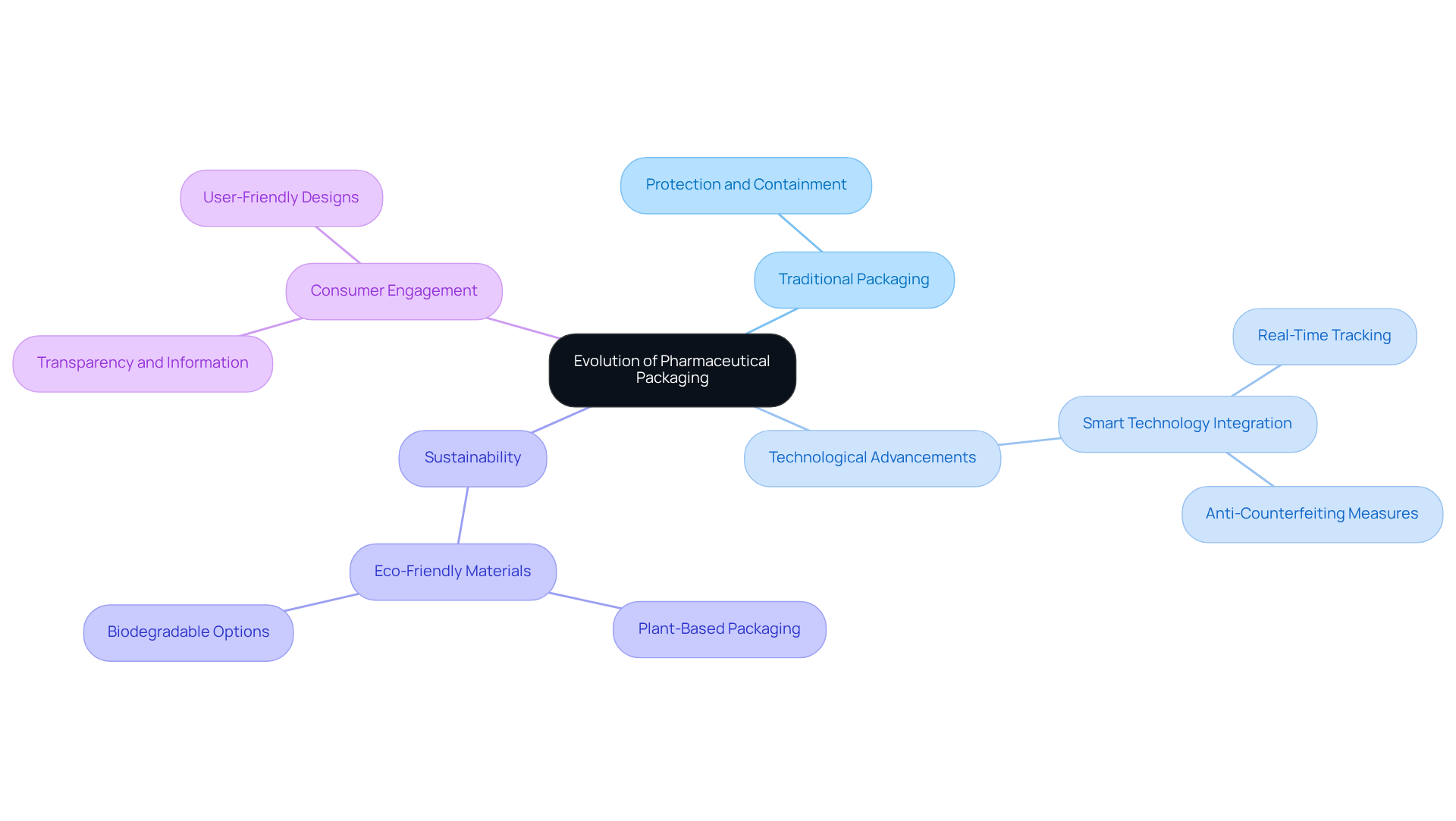

Trace the Evolution of Pharmaceutical Packaging and Its Impact on the Industry

The evolution of pharmaceutical packaging has been profoundly shaped by technological advancements, regulatory requirements, and shifting consumer preferences. Traditionally, packaging focused primarily on protection and containment. However, the emergence of biopharmaceuticals and personalized medicine has led to advanced solutions in pharmaceutical packaging that integrate smart technology for tracking and monitoring.

Innovations in pharmaceutical packaging, such as eco-friendly materials and user-friendly designs, are now at the forefront, reflecting a growing emphasis on sustainability and patient-centered care. This evolution not only enhances product safety but also aligns with the industry's shift towards greater transparency and consumer engagement.

For instance, the incorporation of intelligent container technologies, including real-time tracking and anti-counterfeiting measures, has become essential in pharmaceutical packaging to maintain the integrity of medications. As the market continues to expand, with projections indicating a compound annual growth rate of 16.1% through 2030, the focus on will remain critical in meeting both regulatory standards and consumer expectations.

Conclusion

Pharmaceutical packaging serves a critical function in ensuring the safety, efficacy, and compliance of medications throughout their lifecycle. By protecting products from contamination and degradation, delivering essential information, and enhancing patient adherence, effective packaging is fundamental to the healthcare system. The evolution of packaging solutions underscores the industry's dedication to innovation and consumer safety, emphasizing the necessity of robust packaging strategies in today’s pharmaceutical landscape.

Key insights from this discussion reveal that pharmaceutical packaging includes various types—primary, secondary, and tertiary—each fulfilling distinct roles that contribute to product integrity, regulatory compliance, and market appeal. Advancements in materials and technologies, such as tamper-evident features and eco-friendly designs, highlight the ongoing transformation within the industry, aimed at satisfying both regulatory requirements and consumer expectations.

Ultimately, the significance of pharmaceutical packaging is paramount. As the market continues to expand, stakeholders must prioritize effective packaging solutions that not only safeguard medications but also promote patient safety and enhance overall health outcomes. By embracing innovation and adhering to regulatory standards, stakeholders will ensure that pharmaceutical packaging remains a cornerstone of quality care in the healthcare sector.

Frequently Asked Questions

What is pharmaceutical packaging?

Pharmaceutical packaging refers to the materials and methods used to enclose and protect medicinal items throughout their lifecycle, including storage, handling, transport, and usage.

What are the core functions of pharmaceutical packaging?

The core functions of pharmaceutical packaging include safeguarding products from contamination and degradation, providing essential information about the medication, ensuring safe delivery, and promoting patient compliance.

How does effective pharmaceutical packaging enhance user experience?

Effective packaging preserves the integrity of the medication and delivers clear instructions and dosage information, thereby enhancing the user experience.

What is an example of an innovative pharmaceutical packaging solution?

An example is the emergence of pre-filled syringes, which minimize drug waste and extend shelf life, contributing to security and effectiveness.

What features are included in pharmaceutical packaging to ensure drug protection?

Features such as tamper-evident designs and child-resistant closures are included to protect medications from counterfeiting and unauthorized access.

What is the projected growth of the global pharmaceutical packaging market?

The global pharmaceutical packaging market is projected to grow significantly, reaching USD 356.7 billion by 2034.

Why is robust pharmaceutical packaging important?

Robust pharmaceutical packaging solutions are crucial for preserving drug quality and security, ensuring that medications remain safe and effective throughout their lifecycle.