Overview

The role of a pharmaceutical packer in supply chains is paramount, ensuring the safe and effective packaging of medications. This process not only preserves the integrity of the products but also ensures compliance with regulatory standards. Pharmaceutical packers are tasked with several critical functions, including:

- Container design

- Quality control

- Logistics coordination

These responsibilities are vital in preventing contamination and guaranteeing the timely delivery of products to healthcare providers and patients. Thus, the expertise of pharmaceutical packers is essential for maintaining the reliability and safety of medication distribution.

Introduction

The pharmaceutical industry operates within a complex web of regulations and expectations, where even the smallest oversight can significantly impact patient safety and product integrity. Central to this intricate system are pharmaceutical packers, whose roles extend far beyond mere packaging. They serve as guardians of medication safety, ensuring compliance with stringent standards while enhancing the overall efficiency of the supply chain. As the industry evolves with technological advancements, the pressing question arises: how will the responsibilities of pharmaceutical packers adapt to meet the challenges of tomorrow?

Define Pharmaceutical Packer: Role and Importance

A pharmaceutical packer plays a specialized role that is crucial for the secure and efficient wrapping of pharmaceutical goods, which is essential for maintaining the integrity of the healthcare supply chain. This responsibility encompasses not only the physical wrapping of medications but also compliance with stringent regulatory standards established by organizations such as the FDA and EMA. It is vital for pharmaceutical packers to safeguard products against contamination, degradation, and tampering in order to preserve the efficacy and safety of medications.

The significance of medical containerization is underscored by the fact that effective solutions can enhance patient adherence and safety. For instance, child-proof containers are essential in preventing accidental consumption by children, ensuring that medications are accessible only to intended users. Moreover, the implementation of tamper-evident seals instills confidence in consumers regarding the safety of their medications.

Statistics reveal that in 2022, Americans spent an average of $1,432 per person on medications, highlighting the crucial importance of efficient wrapping in protecting these valuable items. Furthermore, the anticipated rise in chronic diseases, projected to increase by 99.5% among individuals aged 50 and above by 2035, accentuates the necessity for reliable and efficient medication delivery systems.

In conclusion, the role of pharmaceutical packers is vital in the healthcare supply chain, as they ensure that items reach healthcare providers and patients in optimal condition while adhering to regulatory requirements. Their responsibilities extend beyond mere wrapping, significantly contributing to the overall safety and efficacy of medications.

Outline Responsibilities: Key Functions of Pharmaceutical Packers

The role of pharmaceutical packers is essential in ensuring that products are packaged effectively and safely. Their key responsibilities encompass several critical areas:

- Container Design: They create container solutions that are both functional and compliant with regulatory standards. This process includes integrating features such as child resistance, tamper evidence, and user-friendly designs, all aimed at enhancing safety and accessibility for the pharmaceutical packer.

- Quality Control: Establishing rigorous quality assurance protocols is vital to verify that wrapping materials and processes meet industry standards. This involves comprehensive testing for contamination and ensuring that the containers maintain product integrity throughout their shelf life.

- Labeling: Accurate labeling of all containers with essential information—including dosage instructions, expiration dates, and safety warnings—is crucial. Proper labeling is crucial for a pharmaceutical packer to safeguard patient safety and ensure compliance with regulatory requirements.

- Regulatory Compliance: Navigating the complex landscape of local and international regulations governing pharmaceutical packaging is imperative. These regulations can vary significantly across markets, making it essential for a pharmaceutical packer to stay informed to maintain compliance and avoid potential legal issues.

- Logistics Coordination: Collaborating with logistics suppliers guarantees the timely and effective delivery of packaged goods. Efficient logistics management is vital for a pharmaceutical packer to preserve supply chain integrity, ensuring that products arrive at their destinations without delay.

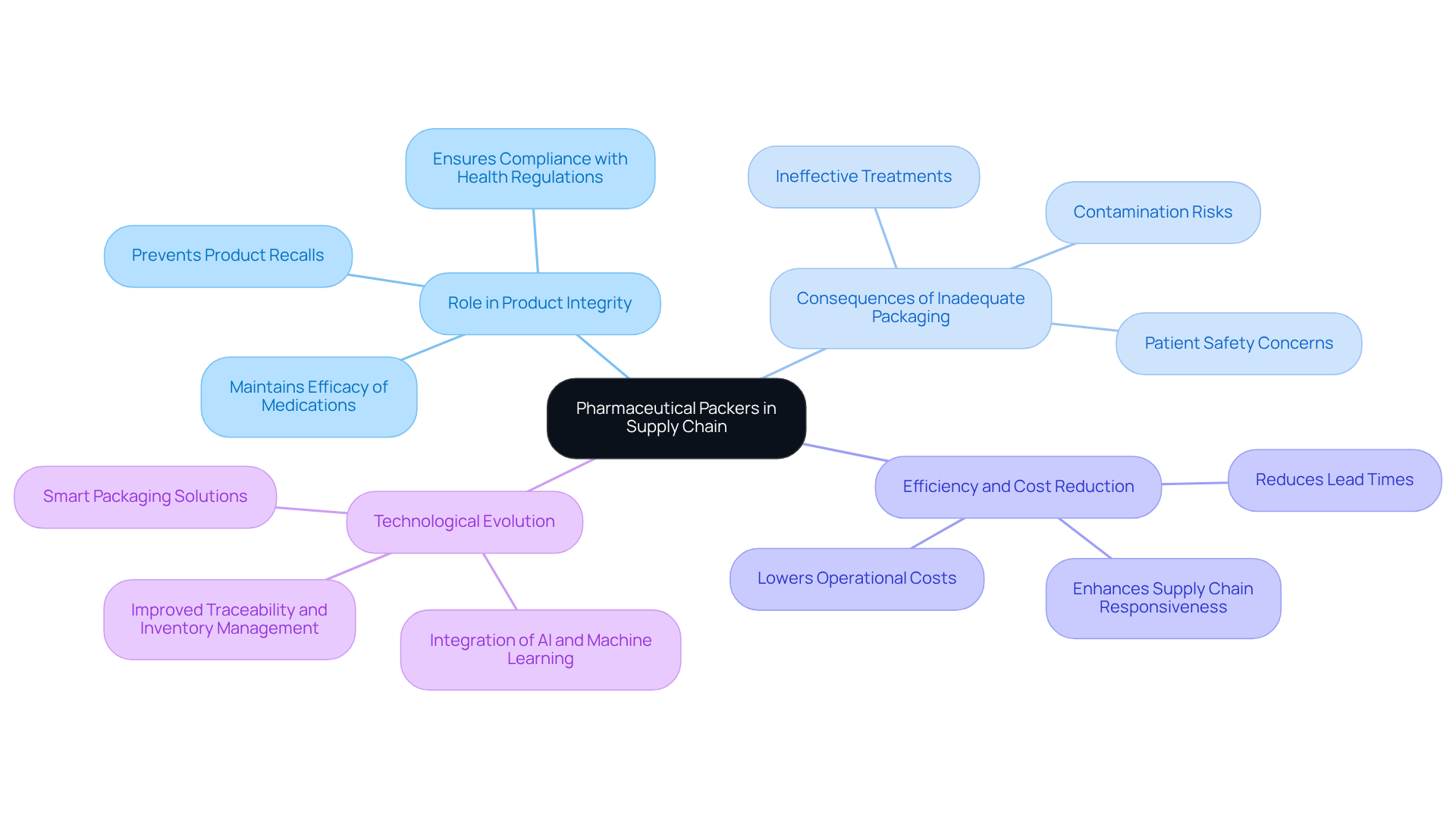

Examine Impact: Pharmaceutical Packers in the Supply Chain

The role of pharmaceutical packers is pivotal in the supply chain, as they ensure that products are packaged in a manner that preserves their integrity and efficacy. This responsibility is critical in preventing product recalls and ensuring compliance with health regulations, which can have significant implications for public health.

For instance, inadequate wrapping can lead to contamination or degradation of medications, resulting in ineffective treatments and potential harm to patients. Moreover, efficient wrapping processes not only reduce lead times and costs but also enhance the overall responsiveness of the supply chain.

As the pharmaceutical industry increasingly integrates advanced technologies such as AI and machine learning, the role of pharmaceutical packers is evolving to include smart packaging solutions that enhance traceability and inventory management. This evolution streamlines operations and fosters greater collaboration across the supply chain, ultimately benefiting manufacturers, distributors, and patients alike.

Conclusion

The role of pharmaceutical packers is indispensable within the healthcare supply chain, functioning as crucial protectors of medication integrity and safety. Their responsibilities extend beyond basic packaging; they encompass compliance with rigorous regulatory standards and the implementation of innovative solutions that enhance patient care. As the industry encounters evolving challenges, the importance of pharmaceutical packers in maintaining the efficacy and safety of medications cannot be overstated.

Throughout this article, we explored the key functions of pharmaceutical packers, including:

- Container design

- Quality control

- Accurate labeling

- Regulatory compliance

- Logistics coordination

Each of these responsibilities plays a vital role in ensuring that medications are delivered in optimal condition, free from contamination and degradation. Furthermore, the integration of advanced technologies into their operations signifies a shift towards smarter packaging solutions that improve traceability and efficiency within the supply chain.

Reflecting on the broader implications, the significance of pharmaceutical packers extends beyond their immediate tasks; they are integral to fostering trust in the healthcare system. As patient safety hinges on the effectiveness of medications, continued investment in the training and technology of pharmaceutical packers will be essential. By prioritizing their role in the supply chain, stakeholders can ensure that the healthcare industry adapts to future challenges while safeguarding the health and well-being of patients.

Frequently Asked Questions

What is the role of a pharmaceutical packer?

A pharmaceutical packer is responsible for the secure and efficient wrapping of pharmaceutical goods, ensuring compliance with regulatory standards and safeguarding products against contamination, degradation, and tampering.

Why is the role of pharmaceutical packers important in the healthcare supply chain?

Pharmaceutical packers play a crucial role in maintaining the integrity of the healthcare supply chain by ensuring that medications reach healthcare providers and patients in optimal condition while adhering to strict regulatory requirements.

How do pharmaceutical packers contribute to patient safety?

They use specialized packaging solutions, such as child-proof containers and tamper-evident seals, to prevent accidental consumption and instill confidence in consumers regarding the safety of their medications.

What are the regulatory standards that pharmaceutical packers must comply with?

Pharmaceutical packers must comply with stringent regulatory standards established by organizations such as the FDA (Food and Drug Administration) and EMA (European Medicines Agency).

What statistics highlight the importance of pharmaceutical packaging?

In 2022, Americans spent an average of $1,432 per person on medications, emphasizing the need for efficient wrapping to protect these valuable items.

What future trends underscore the necessity for reliable medication delivery systems?

The anticipated rise in chronic diseases, projected to increase by 99.5% among individuals aged 50 and above by 2035, highlights the growing need for reliable and efficient medication delivery systems.