Overview

Roll stock is a flexible packaging material supplied in large coils, playing a crucial role in the nutraceutical industry. This material significantly enhances production efficiency for pouches and bags tailored to various products. Notably, roll stock not only improves product protection and extends shelf life but also aligns with sustainability initiatives, making it indispensable in addressing the increasing consumer demand for health-focused and eco-friendly offerings. As the industry evolves, the adoption of high-quality roll stock solutions is essential for businesses aiming to meet these challenges effectively.

Introduction

Roll stock has emerged as a pivotal element in the nutraceutical industry, revolutionizing the packaging and preservation of products. This flexible packaging solution not only enhances efficiency but also empowers manufacturers to create customized designs that captivate consumers. As the demand for sustainable and effective packaging escalates, manufacturers face critical challenges in adopting roll stock. By delving into the intricacies of this innovative material, we uncover its essential role in fulfilling modern consumer expectations while navigating the complexities of production and sustainability.

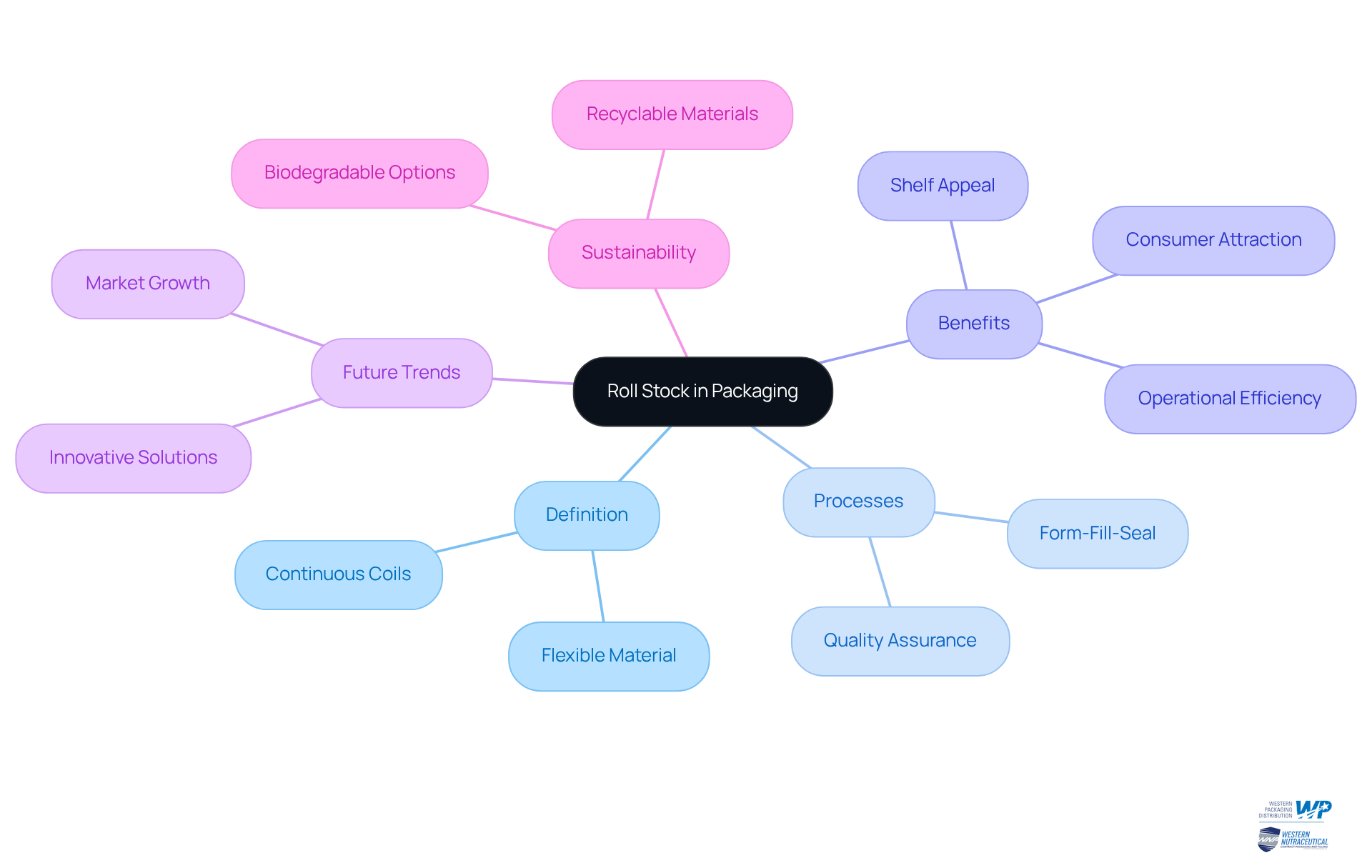

Define Roll Stock: Understanding Its Role in Packaging

Rollable material refers to a flexible substance provided in large, continuous coils, extensively utilized in the nutraceutical industry. This type of wrapping is processed through form-fill-seal (FFS) machines to create pouches or bags, making it highly adaptable for various items, including powders, gummies, and liquids. What is roll stock allows manufacturers to create tailored solutions, such as large pouches for protein items and stick packs for nutraceuticals, thereby boosting efficiency and lowering expenses.

At Western Packaging, we prioritize customized flexible solutions that not only meet your specific needs but also enhance your item's shelf appeal and brand visibility. Our innovative container design solutions ensure that your items stand out on the shelf, capturing consumer attention with striking designs and cohesive graphic materials, from labels to brochures.

By 2025, what is roll stock is expected to capture a significant portion of the flexible market, driven by the increasing demand for dietary supplements and functional foods. The benefits of flexible packaging for nutraceutical producers include improved product protection, extended shelf life, and heightened consumer attraction through our engaging design solutions. Additionally, containment materials support sustainability efforts, as many resources are recyclable or sourced from sustainable origins, aligning with consumer preferences for eco-friendly options. Western Packaging is committed to addressing these challenges by offering sustainable solutions that fulfill the rising demand for biodegradable and recyclable materials in the industry.

The effective implementation of flexible materials in adaptable solutions requires a careful selection of substances, design enhancement, and investment in advanced equipment. Optimal methods for efficient material wrapping involve conducting regular quality inspections and adhering to comprehensive quality assurance procedures, which can increase consumer confidence by 28%. By following these guidelines, manufacturers can significantly improve their operational efficiency and market presence, ultimately satisfying the growing consumer demand for health-focused products. As the nutraceutical container market continues to evolve, flexible material will play a crucial role in shaping the future of container options.

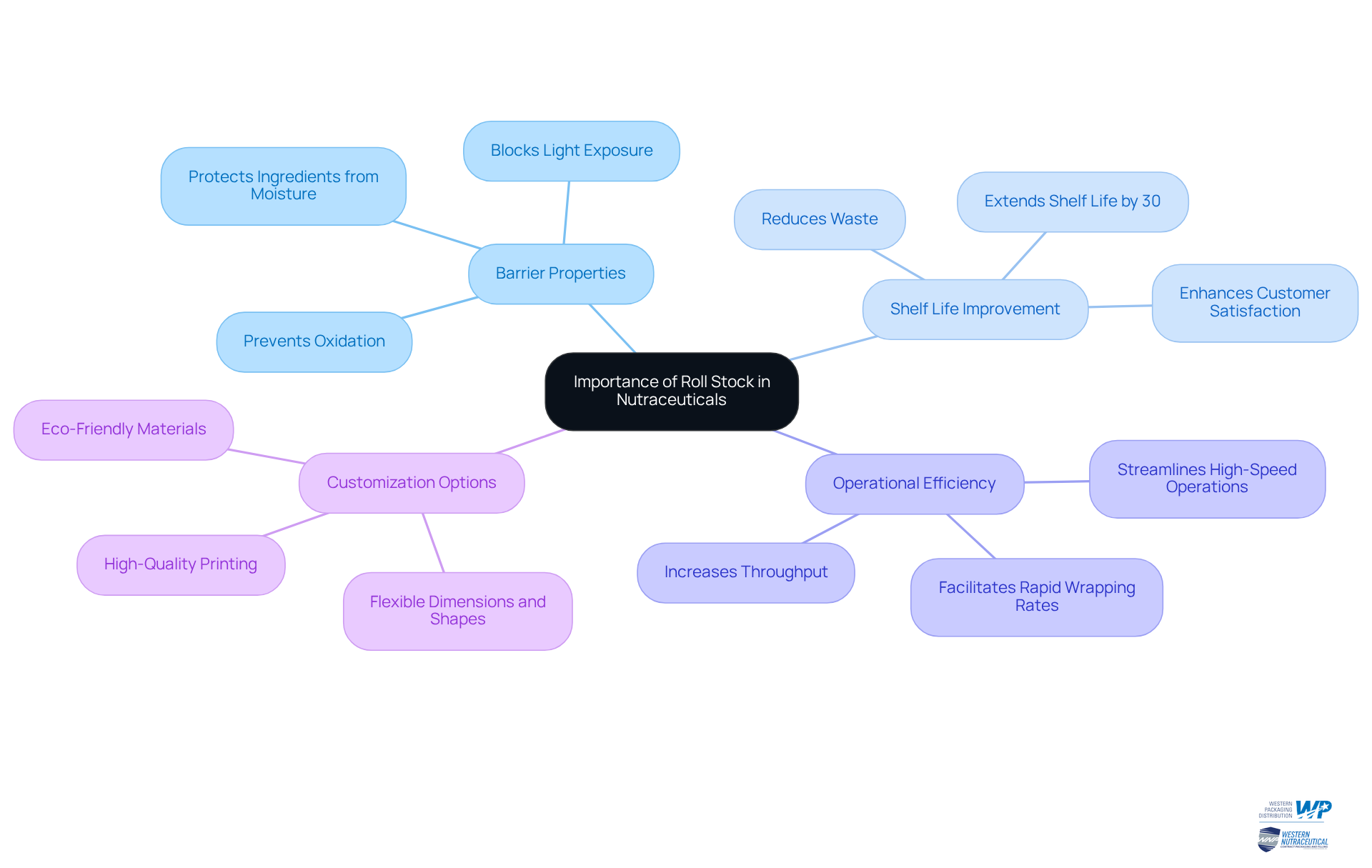

Contextualize Roll Stock: Importance in the Nutraceutical Sector

In the nutraceutical industry, flexible material plays a crucial role by providing exceptional barrier properties that safeguard sensitive ingredients from moisture, oxygen, and light. These protective attributes are vital for dietary supplements and health products, which necessitate stringent preservation methods to maintain their efficacy and extend shelf life.

Research shows that compliant nutraceutical containers can enhance shelf life by as much as 30% and boost consumer trust by 28% compared to non-compliant alternatives. This improvement significantly reduces waste and elevates customer satisfaction.

Furthermore, the ongoing cylindrical design of material containers streamlines high-speed operations, enhancing efficiency and throughput, thereby empowering manufacturers to meet the increasing consumer demand for health-oriented products.

The inherent adaptability of the material also offers extensive customization options regarding dimensions, shape, and printing, enabling brands to create distinctive containers that enhance visual appeal and align with market trends. This versatility not only differentiates products in a competitive landscape but also resonates with consumers' growing preference for visually attractive and eco-friendly solutions.

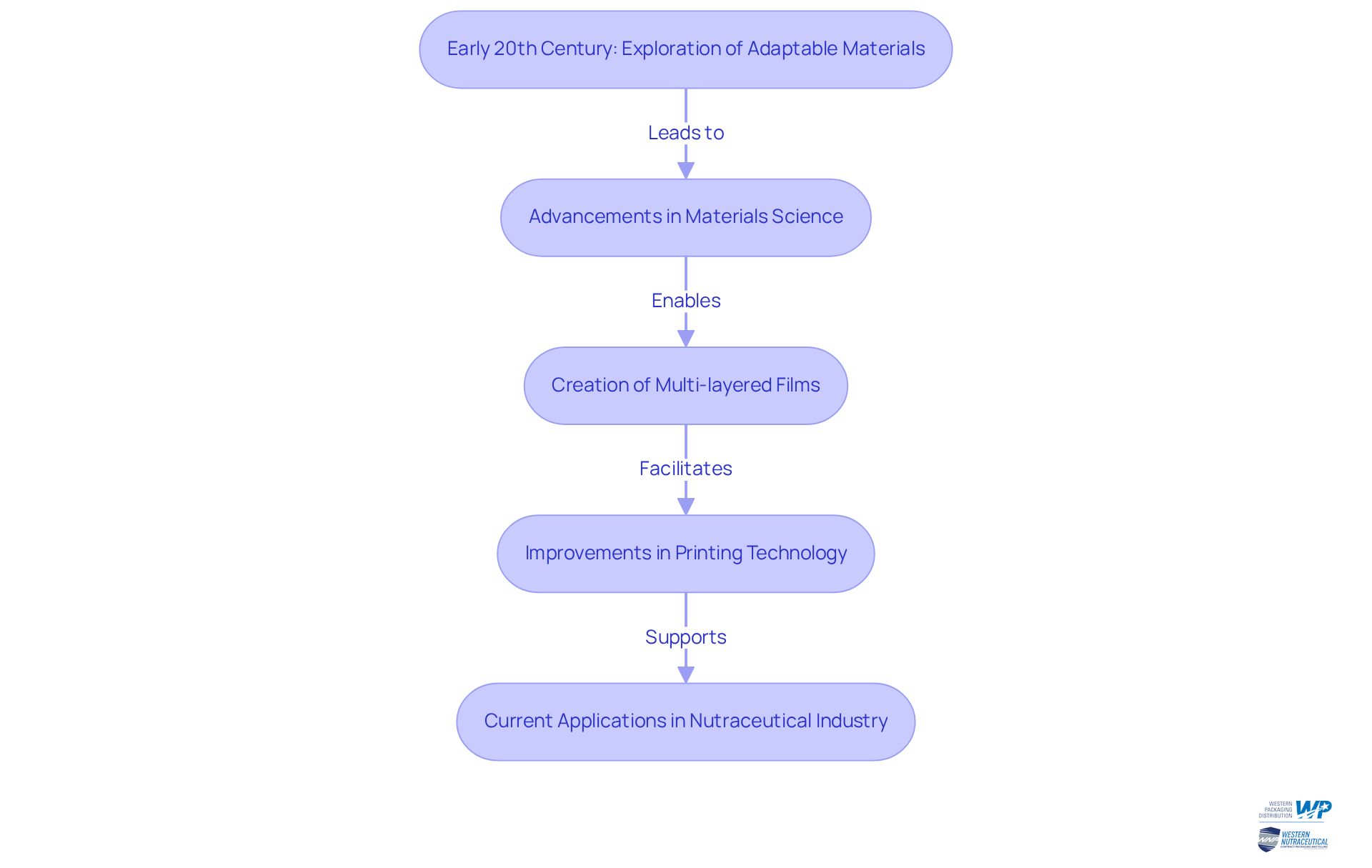

Trace the Origins of Roll Stock: Historical Development and Innovations

The origins of flexible packaging can be traced back to the early 20th century, when producers began exploring adaptable materials for innovative packaging solutions. Advances in materials science have led to the creation of multi-layered films that significantly enhance barrier properties, ensuring product integrity. Over the years, improvements in printing technology and equipment have expanded applications, facilitating high-speed manufacturing and a diverse array of customization options.

Presently, what is roll stock is a crucial component of flexible containers, particularly within the nutraceutical industry, where the preservation of quality and safety is paramount. The integration of these innovations has revolutionized packaging methods, empowering nutraceutical manufacturers to fulfill consumer demands for both functionality and visual appeal.

Identify Key Characteristics of Roll Stock: Components and Functionality

Roll packaging stands out due to its flexibility, durability, and exceptional barrier protection capabilities, establishing it as a prime choice for nutraceutical products. The materials typically employed in this packaging—plastic films, paper, and aluminum foil—are selected for their specific advantages. For example, plastic films deliver superior moisture and oxygen barriers, whereas aluminum foil offers unmatched light protection, which is critical for maintaining product integrity.

This continuous material format not only streamlines production processes but also minimizes waste and reduces costs. Such efficiency is vital, as manufacturers have reported production efficiency improvements of up to 30% when utilizing flexible materials. These materials are utilized in form-fill-seal machines, enhancing the speed and effectiveness of wrapping operations. Furthermore, the materials can be customized in terms of thickness, width, and barrier properties, providing tailored solutions that meet diverse product requirements.

Sustainability plays a significant role in material selection, with manufacturers increasingly opting for recyclable substances to mitigate environmental impact. High-quality graphics can be printed directly on the materials, boosting brand visibility and attracting consumer interest. This customization capability extends to various shapes and sizes, making flexible materials a versatile choice for packaging a broad spectrum of nutraceutical items. The amalgamation of these attributes positions roll stock packaging as a premier option in the nutraceutical sector, enhancing both operational efficiency and providing clarity on what is roll stock in product marketing.

Conclusion

Roll stock stands as a cornerstone in the packaging landscape, particularly within the nutraceutical industry. Its flexible and durable nature empowers manufacturers to craft tailored packaging solutions that not only enhance product protection but also elevate brand visibility. By leveraging roll stock, companies can efficiently produce pouches and bags that cater to a diverse array of nutraceutical products, thereby addressing the growing consumer demand for health-oriented items.

The article elucidates several key insights into the role of roll stock in nutraceutical packaging. From its historical development to the innovative materials employed, roll stock has evolved to provide superior barrier properties that safeguard sensitive ingredients. The customization options available further enable brands to distinguish themselves in a competitive market, while sustainability initiatives align with consumer preferences for eco-friendly packaging solutions. The advantages of roll stock, including heightened production efficiency and extended shelf life, underscore its significance for manufacturers striving to enhance operational effectiveness and customer satisfaction.

In conclusion, the importance of roll stock in the nutraceutical sector is paramount. As manufacturers endeavor to meet consumer demands for quality and sustainability, embracing flexible packaging solutions will be essential. By investing in advanced roll stock technologies and prioritizing eco-friendly materials, companies can not only bolster their market presence but also contribute positively to environmental efforts. The future of nutraceutical packaging hinges on the continued innovation and adaptation of roll stock, establishing it as a vital focus for manufacturers pursuing success in this dynamic industry.

Frequently Asked Questions

What is roll stock in packaging?

Roll stock refers to a flexible material provided in large, continuous coils, commonly used in the nutraceutical industry for creating pouches or bags through form-fill-seal (FFS) machines.

How is roll stock utilized in the nutraceutical industry?

Roll stock is used to create tailored packaging solutions for various products, including powders, gummies, and liquids, allowing for items like large pouches for protein and stick packs for nutraceuticals.

What are the advantages of using roll stock for manufacturers?

Using roll stock boosts efficiency and lowers expenses by allowing manufacturers to produce customized packaging solutions that meet specific needs.

How does Western Packaging enhance product visibility?

Western Packaging focuses on customized flexible solutions that enhance shelf appeal and brand visibility through innovative container designs, striking visuals, and cohesive graphic materials.

What is the expected market trend for roll stock by 2025?

By 2025, roll stock is anticipated to capture a significant portion of the flexible packaging market, driven by the increasing demand for dietary supplements and functional foods.

What are the benefits of flexible packaging for nutraceutical producers?

Benefits include improved product protection, extended shelf life, and enhanced consumer attraction through engaging design solutions.

How does roll stock support sustainability efforts?

Many roll stock materials are recyclable or sourced from sustainable origins, aligning with consumer preferences for eco-friendly options.

What factors contribute to the effective implementation of flexible materials?

Effective implementation requires careful selection of substances, design enhancement, and investment in advanced equipment, along with regular quality inspections and adherence to quality assurance procedures.

How can manufacturers improve consumer confidence in their products?

By conducting regular quality inspections and following comprehensive quality assurance procedures, manufacturers can increase consumer confidence by 28%.

What role will flexible materials play in the future of the nutraceutical container market?

Flexible materials are expected to play a crucial role in shaping the future of container options as the nutraceutical container market continues to evolve.