Overview

The article delineates four pivotal strategies for effective roll stock packaging within the nutraceutical sector:

- Cost-effectiveness

- Extended shelf life

- Customization

- Sustainability

These strategies underscore the enhancement of production efficiency, preservation of product integrity, and alignment with consumer demands for environmentally friendly options.

Ultimately, these factors contribute to a fortified market presence for nutraceutical manufacturers, establishing a compelling case for adopting these innovative packaging solutions.

Introduction

The nutraceutical industry is witnessing a remarkable surge, with projections indicating a robust growth trajectory propelled by consumer demand for health-focused products. In this evolving landscape, roll stock packaging emerges as a crucial strategy for manufacturers, offering a unique blend of efficiency, customization, and sustainability. However, the challenge lies in navigating the complexities of effective implementation while ensuring compliance with stringent regulations.

How can companies harness the benefits of roll stock packaging to not only meet market demands but also enhance product integrity and consumer trust?

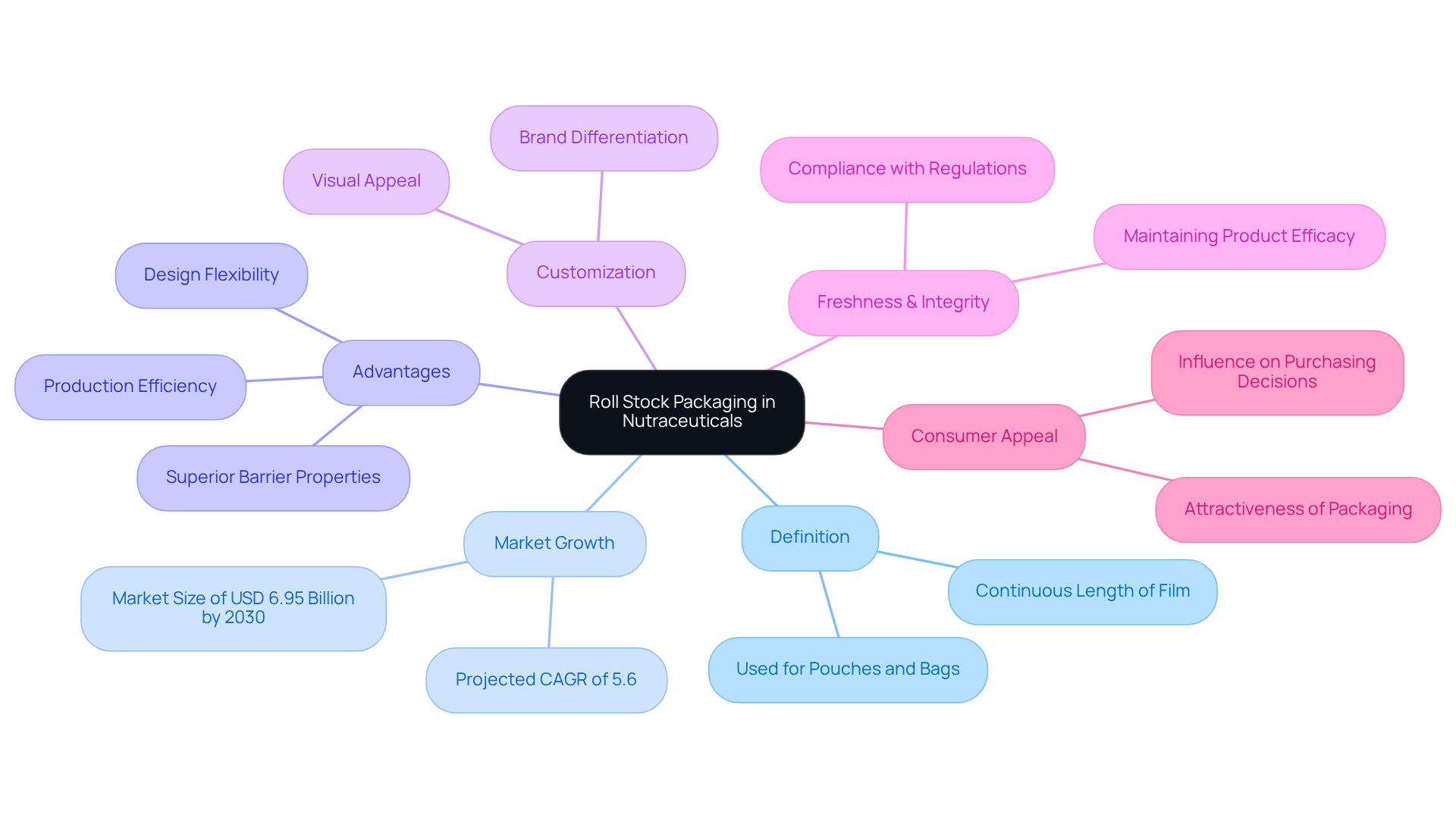

Define Roll Stock Packaging and Its Role in Nutraceuticals

This type of flexible covering refers to a continuous length of film or material, which is fed into a machine to create pouches or bags. This method is particularly advantageous in the , where products such as dietary supplements and health foods require efficient, high-speed wrapping solutions. The global nutraceutical container market is projected to grow at a compound annual growth rate of 5.6% from 2025 to 2030, reaching approximately USD 6.95 billion by 2030. This growth underscores the increasing reliance on innovative container techniques like flexible materials.

One of the primary advantages of using continuous material is its ability to enhance production efficiency. This method facilitates rapid wrapping rates, which are essential for meeting the rising consumer demand for nutraceutical products. Moreover, flexible material solutions offer significant customization options in design and functionality, enabling brands to distinguish themselves in a competitive landscape. The visual appeal of this type of packaging is critical in attracting consumers, especially in an industry where product presentation can significantly influence purchasing decisions.

Additionally, the design of roll stock packaging is crucial for maintaining freshness and integrity, which is essential for dietary supplements that often include sensitive ingredients. Packaging must ensure the efficacy of the product throughout its intended shelf life, necessitating superior barrier properties. This capability not only ensures compliance with industry regulations but also addresses consumer concerns regarding product quality and safety. As the nutraceutical market continues to expand, the importance of effective packaging solutions will only increase, establishing it as a crucial strategy for brands aiming to enhance their market presence and operational efficiency.

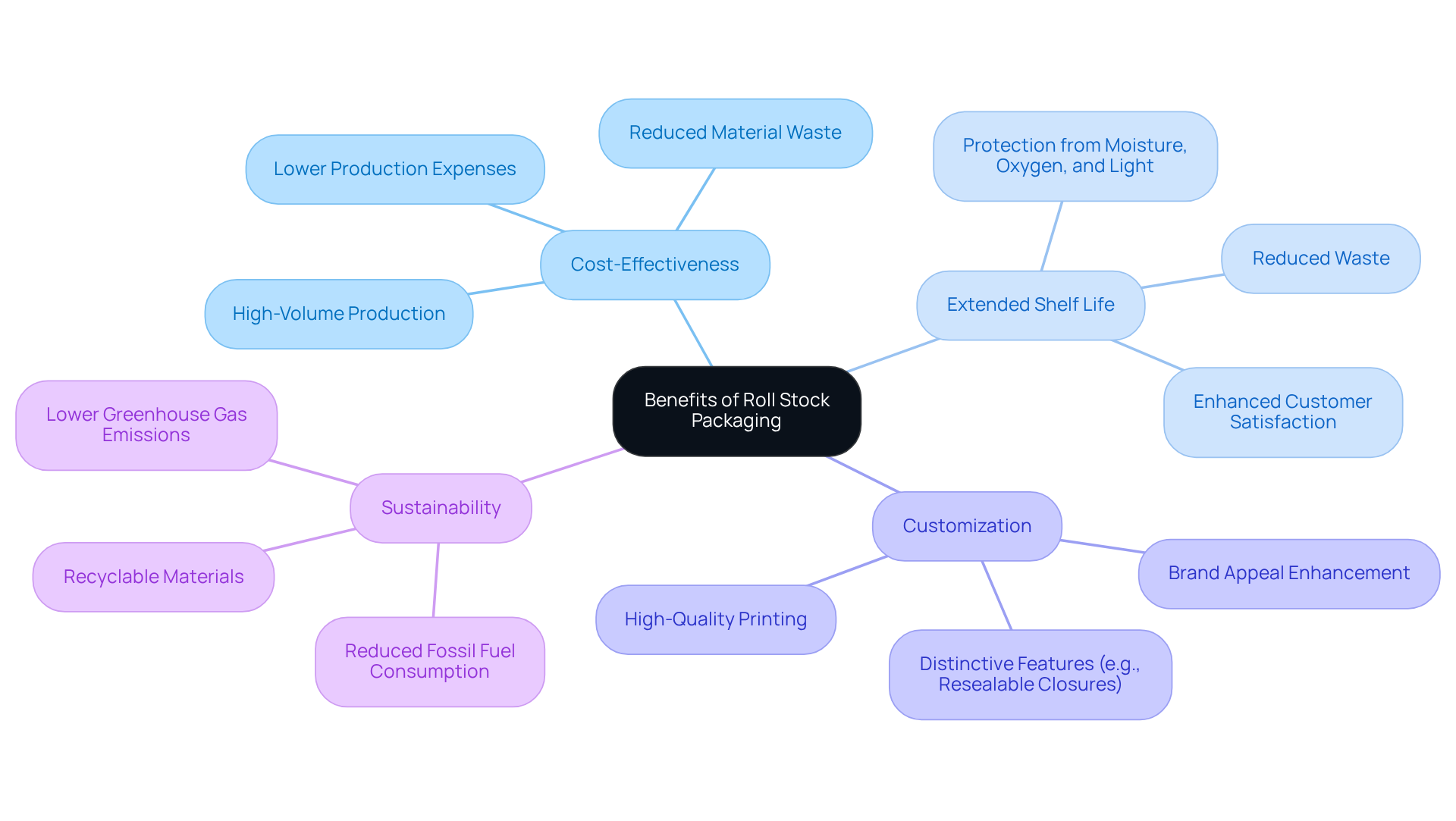

Highlight Benefits of Roll Stock Packaging for Nutraceutical Manufacturers

Roll stock packaging offers a multitude of advantages for nutraceutical manufacturers, including:

- Cost-Effectiveness: By employing a continuous format, manufacturers can significantly reduce material waste and production expenses. The manufacturing process of rollstock film utilizes continuous lengths of flexible material, facilitating high-volume production while minimizing waste. This efficiency is particularly beneficial for high-volume production runs, allowing brands to allocate resources more effectively and lower overall costs.

- Extended Shelf Life: Flexible materials possess excellent barrier characteristics that protect products from moisture, oxygen, and light—key elements in maintaining the quality and effectiveness of nutraceuticals. Research indicates that roll stock packaging can extend the shelf life of products, which leads to reduced waste and enhanced customer satisfaction. This protection translates into , ultimately benefiting both manufacturers and consumers.

- Customization: The inherent flexibility of roll stock allows for high-quality printing and the integration of distinctive features such as resealable closures. These enhancements not only improve user experience but also elevate brand appeal, making products more attractive on the shelf. For example, leading food companies have adopted advanced netting solutions to address waste reduction and efficiency improvements in their wrapping processes.

- Sustainability: A significant number of roll stock materials are recyclable or sourced from sustainable origins, aligning with the increasing consumer demand for environmentally friendly alternatives. This commitment to sustainability not only fulfills regulatory requirements but also enhances brand reputation in a competitive market. Flexible wrapping solutions, such as roll stock packaging, can aid companies in their sustainability initiatives, resulting in reduced fossil fuel consumption, greenhouse gas emissions, and water usage compared to rigid containers.

By leveraging these advantages, nutraceutical producers can optimize their packaging processes, leading to improved operational efficiency and a stronger market presence.

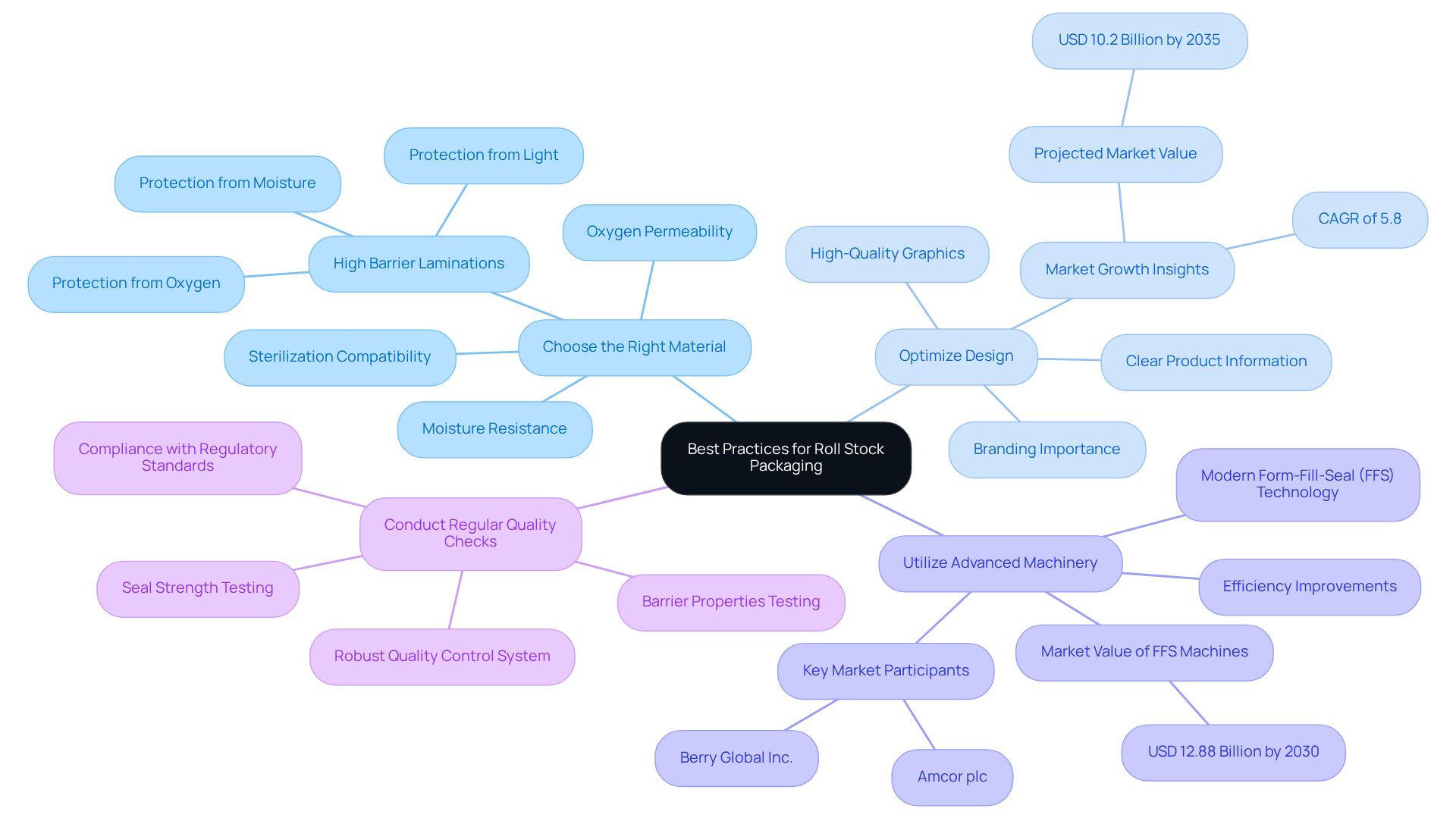

Implement Best Practices for Effective Roll Stock Packaging

Manufacturers must adhere to best practices that ensure quality and compliance to implement effective roll stock packaging.

- Choose the Right Material: Selecting flexible films with optimal barrier characteristics is essential for maintaining the integrity of nutraceutical items. Key considerations include moisture resistance, oxygen permeability, and compatibility with sterilization methods. High barrier laminations safeguard items from light, moisture, and oxygen, ensuring freshness and nutritional value.

- Optimize Design: Investing in high-quality graphics and branding on roll stock containers is crucial. The design should be visually appealing and functional, clearly conveying product information and benefits. This is particularly important as the is projected to expand significantly, with consumers increasingly recognizing containers as essential marketing tools. The market is expected to reach USD 10.2 billion by 2035, growing at a CAGR of 5.8%.

- Utilize Advanced Machinery: Employing modern form-fill-seal (FFS) machinery is vital for efficient roll stock packaging. The latest advancements in FFS technology enhance speed and accuracy, significantly reducing downtime and waste. The global market for FFS machines is anticipated to reach USD 12.88 billion by 2030, underscoring the importance of investing in state-of-the-art equipment. Key participants in this market include Amcor plc and Berry Global Inc., recognized for their innovative container solutions.

- Conduct Regular Quality Checks: Establishing a robust quality control system is essential for monitoring the integrity of materials. Regular testing for seal strength, barrier properties, and overall package performance ensures safety and compliance with regulatory standards. As the nutraceutical container market continues to grow, maintaining high-quality materials will be crucial for meeting consumer expectations and regulatory requirements. Compliance with these regulations is imperative for manufacturers to ensure product safety and transparency.

Ensure Regulatory Compliance and Quality Control in Packaging

To ensure regulatory compliance and maintain quality control in roll stock packaging, manufacturers should adopt the following strategies:

- Stay Informed on Regulations: Regularly review and update your knowledge of FDA regulations and guidelines concerning nutraceutical containers. This includes understanding labeling requirements, ingredient disclosures, and safety standards, as non-compliance can lead to significant penalties and a loss of consumer trust.

- Implement Quality Assurance Protocols: Establish comprehensive quality assurance protocols that encompass testing for container integrity, product safety, and compliance with labeling regulations. Routine audits and inspections of both materials and processes are essential to uphold quality standards and mitigate risks associated with contamination. Notably, compliant nutraceutical containers can extend shelf life by 30% and increase consumer trust by 28% over non-compliant options, underscoring the importance of these protocols.

- Document Everything: Maintain thorough documentation of all wrapping processes, materials used, and quality control measures. This documentation is crucial for demonstrating compliance during inspections and audits, as well as for ensuring traceability throughout the supply chain.

- Train Staff Regularly: Ensure that all employees engaged in the wrapping process receive on the latest regulations and quality control practices. Ongoing education assists in upholding high standards and minimizing the risk of compliance issues, ultimately improving safety and consumer confidence. As Dr. Haven McCall emphasizes, "A critical step you should take is to implement a quality program that is compliant with FDA regulations and requirements."

By implementing these strategies, manufacturers can effectively navigate the complexities of roll stock packaging for nutraceuticals, ensuring safety, efficacy, and compliance with industry standards. Additionally, avoiding common pitfalls such as non-compliance leading to product recalls and fines will further enhance their operational success. The expected impact of these strategies includes improved consumer trust and reduced risk of compliance violations, which are critical for manufacturers in the nutraceutical sector.

Conclusion

The significance of roll stock packaging in the nutraceutical sector is paramount. This innovative packaging solution not only enhances production efficiency but also plays a vital role in sustaining product quality and appealing to consumer preferences. As the nutraceutical market continues to expand, the strategic implementation of roll stock packaging emerges as a key factor for brands aiming to thrive in a competitive landscape.

Throughout this article, the numerous benefits of roll stock packaging have been underscored, including:

- Cost-effectiveness

- Extended shelf life

- Customization

- Sustainability

By adopting best practices—such as selecting the right materials, optimizing design, utilizing advanced machinery, and ensuring rigorous quality control—manufacturers can significantly enhance their operational efficiency and market presence. Furthermore, staying informed about regulatory compliance and maintaining high-quality standards are essential to foster consumer trust and safeguard brand integrity.

Ultimately, embracing effective roll stock packaging strategies not only addresses immediate operational needs but also positions nutraceutical brands for long-term success. As consumer demand for health-focused products rises, manufacturers are encouraged to prioritize innovative packaging solutions that meet regulatory standards and resonate with environmentally conscious consumers. The time to act is now; investing in roll stock packaging is an investment in the future of nutraceuticals.

Frequently Asked Questions

What is roll stock packaging?

Roll stock packaging refers to a continuous length of film or material that is fed into a machine to create pouches or bags, commonly used in the nutraceutical sector.

Why is roll stock packaging important in the nutraceutical industry?

It is important because it provides efficient, high-speed wrapping solutions for products like dietary supplements and health foods, which are in high demand.

What is the projected growth of the nutraceutical container market?

The global nutraceutical container market is projected to grow at a compound annual growth rate of 5.6% from 2025 to 2030, reaching approximately USD 6.95 billion by 2030.

How does roll stock packaging enhance production efficiency?

It facilitates rapid wrapping rates, allowing brands to meet the increasing consumer demand for nutraceutical products efficiently.

What customization options does roll stock packaging offer?

Roll stock packaging provides significant customization options in design and functionality, enabling brands to differentiate themselves in a competitive market.

Why is visual appeal important in roll stock packaging?

Visual appeal is critical in attracting consumers, as product presentation can significantly influence purchasing decisions in the nutraceutical industry.

How does roll stock packaging maintain product freshness and integrity?

The design of roll stock packaging includes superior barrier properties that help maintain the freshness and efficacy of dietary supplements throughout their intended shelf life.

What role does packaging play in compliance and consumer safety?

Effective packaging ensures compliance with industry regulations and addresses consumer concerns regarding product quality and safety, which is particularly important for nutraceuticals with sensitive ingredients.