Overview

Assembly companies in the packaging industry represent specialized organizations that adeptly integrate various components into final products. They play a crucial role in optimizing production processes and maintaining stringent quality standards.

By discussing their essential functions—such as kitting and quality control—this article underscores their significance.

Furthermore, these companies have a profound impact on supply chain efficiency, a factor that is increasingly vital given the projected growth in the packaging market and the rising demand for sustainable solutions.

The expertise of assembly companies not only enhances operational reliability but also positions them as indispensable players in the evolving landscape of packaging and logistics.

Introduction

Assembly companies in the packaging industry serve as the backbone of efficient product delivery, seamlessly integrating various components into cohesive final products. As the demand for streamlined supply chain solutions escalates, these specialized firms not only enhance operational efficiency but also ensure adherence to quality and safety standards.

However, with rapid technological advancements and shifting consumer expectations, assembly companies must adapt to maintain their pivotal role in this evolving landscape. The ability to evolve is not just a necessity; it is a testament to their commitment to excellence and reliability in an ever-changing market.

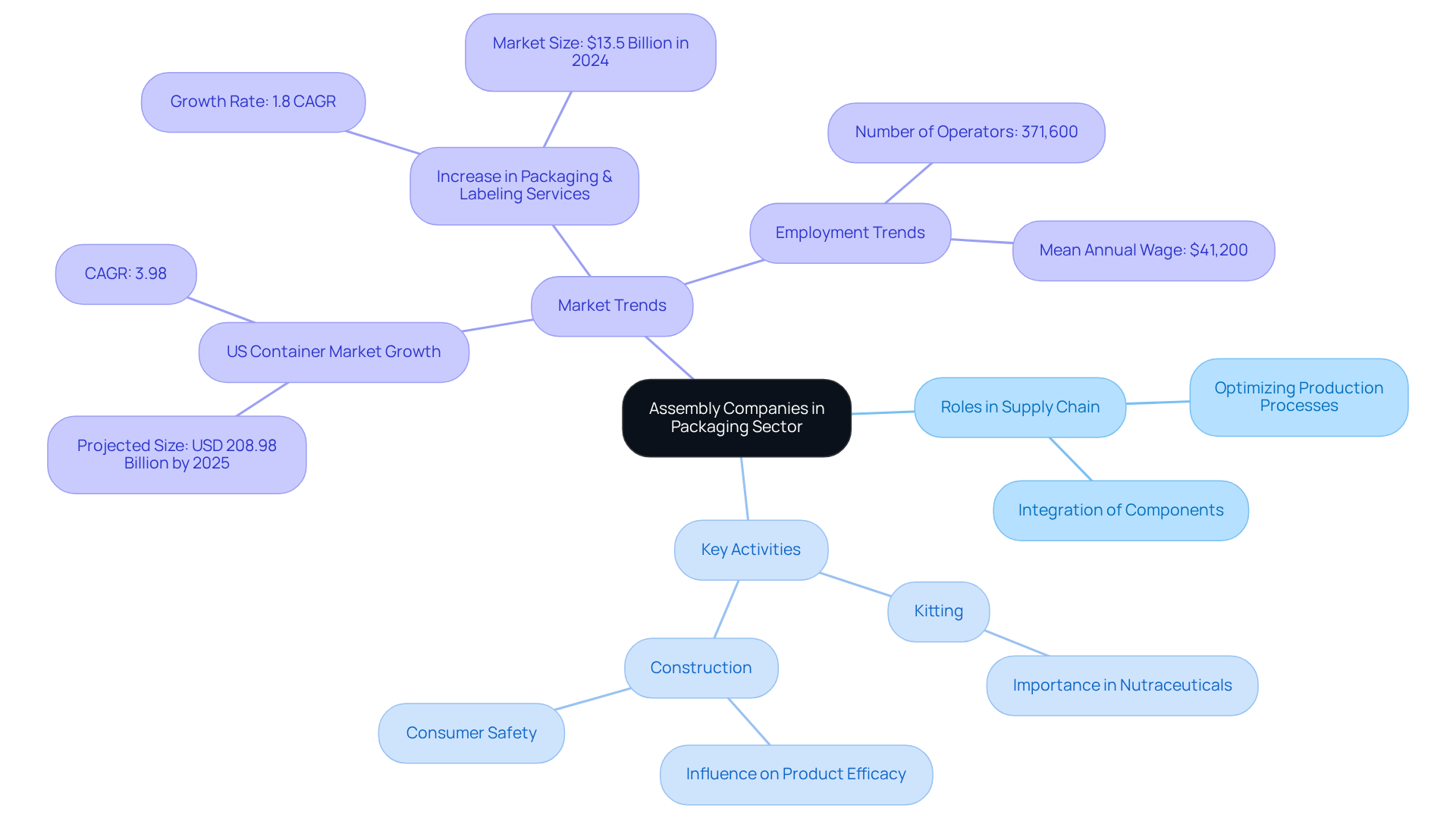

Defining Assembly Companies in the Packaging Sector

Assembly firms in the packaging industry represent specialized organizations dedicated to the integration of various components into a final product, ensuring readiness for distribution. These companies play a pivotal role in the supply chain, optimizing production processes that are essential for maintaining quality standards and operational efficiency. Activities such as kitting—where multiple items are packaged together—and construction, which involves merging different components into a cohesive unit, are particularly vital in sectors like nutraceuticals. In this context, precise construction not only influences product efficacy but also ensures consumer safety.

The increasing demand for efficient supply chain solutions amplifies the importance of assembly companies. For example, the US container market is projected to reach USD 208.98 billion by 2025, growing at a CAGR of 3.98%. This growth illustrates a rising dependence on integrated services that enhance product delivery and minimize lead times. Successful kitting initiatives in nutraceutical packaging demonstrate how organizations can streamline operations, allowing manufacturers to focus on core competencies while improving market responsiveness.

Statistics reveal that the role of manufacturing firms is becoming increasingly critical; the number of Packaging & Labeling Services enterprises in the US has risen by an average of 7.1% annually from 2020 to 2025, indicating a growing need for specialized production services. This trend highlights the importance of manufacturing firms in ensuring that products not only meet market demands but also adhere to stringent , ultimately fostering consumer confidence and brand loyalty. As noted by Mordor Intelligence, the United States sector for containers is rapidly evolving, driven by changing retail dynamics and technological innovations.

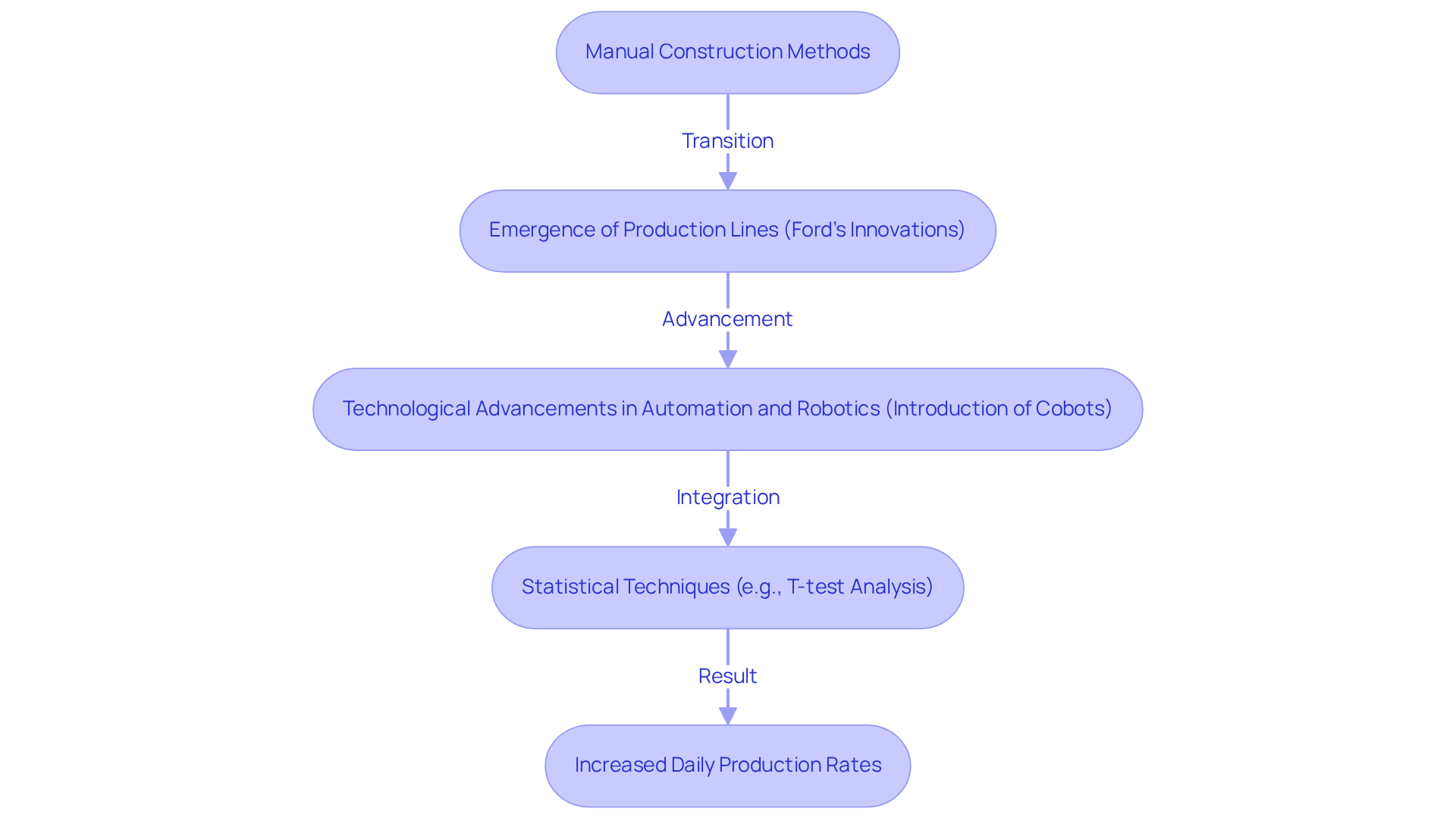

Historical Context and Evolution of Assembly Companies

The construction idea in the packaging sector has advanced considerably since its inception, transitioning from manual construction methods in early manufacturing. As industries expanded and consumer demands intensified, the necessity for more efficient production processes became increasingly evident. The emergence of production lines in the early 20th century marked a pivotal shift, enabling faster and more consistent manufacturing outputs. For instance, Ford's production line innovations reduced the manufacturing time for a motorcar from 12.5 hours to just 93 minutes, achieving an extraordinary 1,308% boost in productivity within a mere 18 months.

Over the decades, technological advancements, particularly in automation and robotics, have further transformed production practices. The integration of (cobots), projected to achieve ±0.02 mm repeatability by 2025, is expected to enhance precision and flexibility in manufacturing processes. Organizations employing T-test analysis in their manufacturing operations have reported up to a 12% improvement in product consistency and a 10% reduction in production time, underscoring the significance of statistical techniques in optimizing production operations.

Moreover, recent research indicates that the average daily production in manufacturing lines has increased from 293 units to 381 units, highlighting the efficiency improvements achieved through enhanced production methods. Today, assembly companies play a crucial role in the distribution sector by offering specialized services tailored to various market demands. Their ability to adapt to evolving technologies and consumer expectations positions assembly companies as integral players in enhancing manufacturing efficiency and driving innovation within the industry.

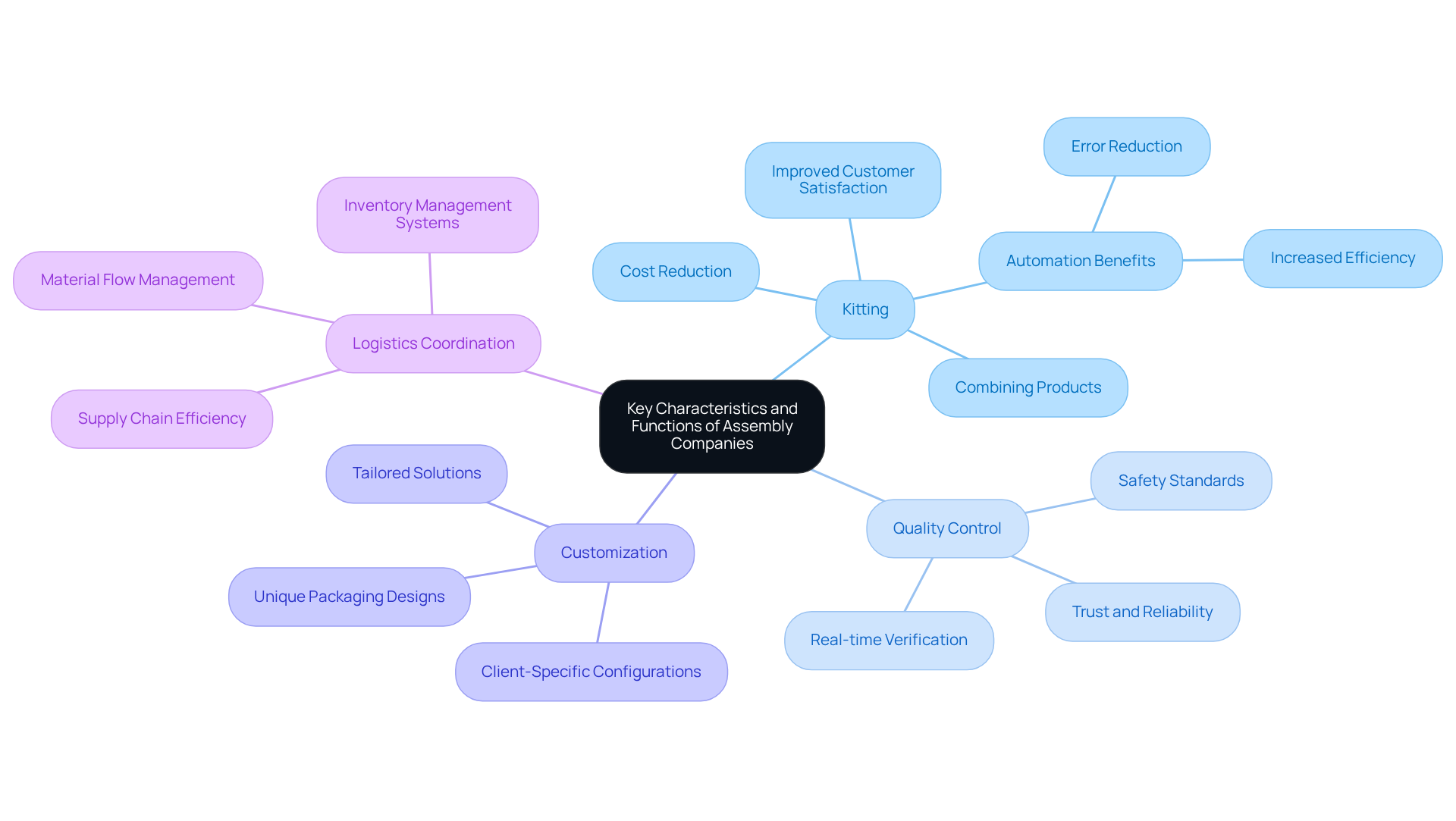

Key Characteristics and Functions of Assembly Companies

Assembly companies are recognized for their ability to enhance the packaging process through various essential functions, such as kitting, labeling, and quality control. These firms consistently employ specialized tools and skilled workers to ensure that items are assembled with precision and efficiency. Key functions include:

- Kitting: This involves combining multiple products into a single package for retail or distribution, enhancing convenience and presentation.

- Quality Control: Rigorous checks are implemented to guarantee that assembled items adhere to safety and quality standards, fostering trust and reliability.

- Customization: Tailored solutions are provided to meet specific client requirements, such as unique packaging designs or configuration options, ensuring satisfaction.

- Logistics Coordination: The management of material and finished product flow is optimized to enhance supply chain efficiency, contributing to overall operational success.

These characteristics empower assembly companies to provide comprehensive solutions that significantly improve for their clients.

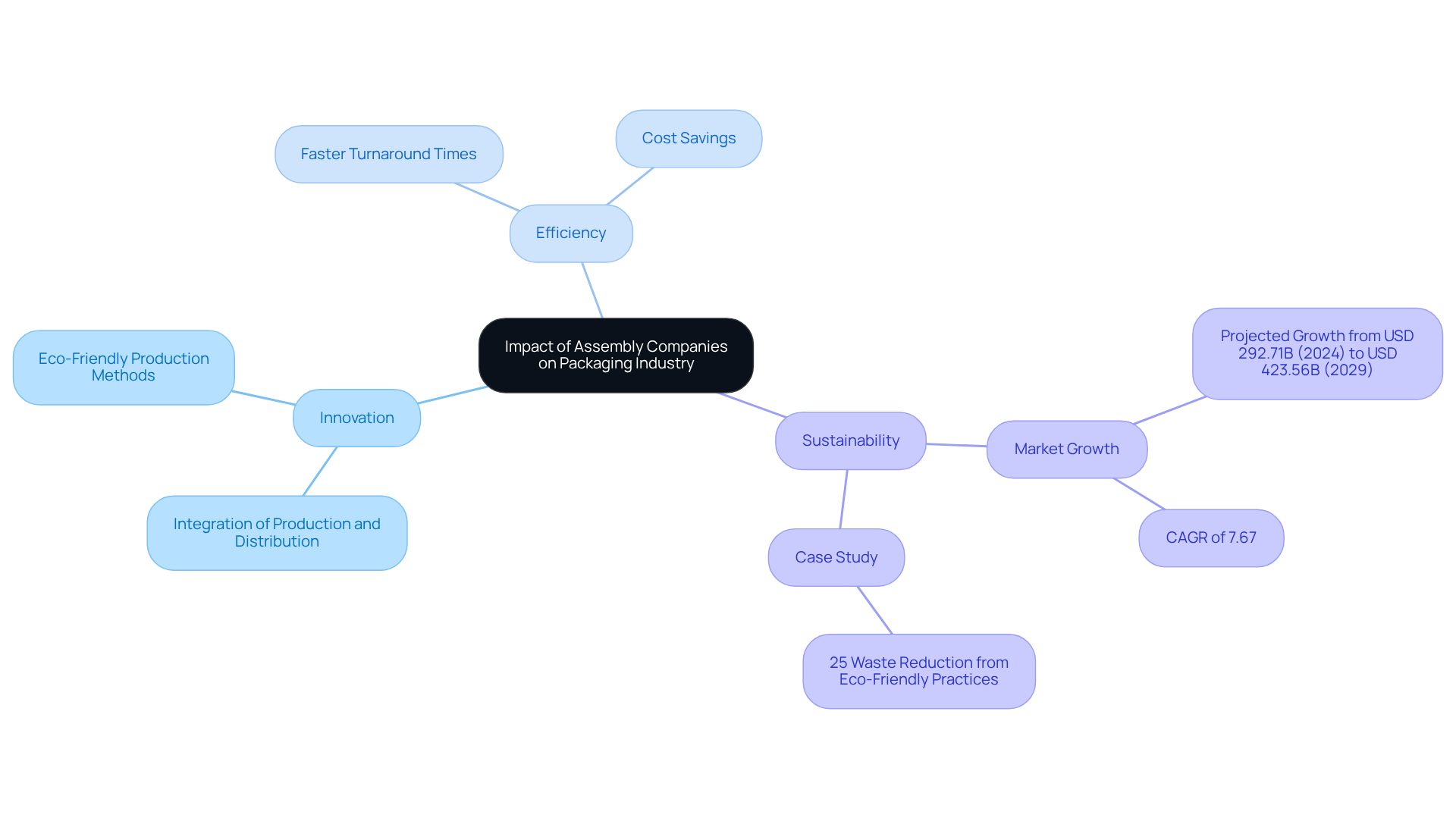

Impact of Assembly Companies on Packaging Industry Dynamics

Assembly companies play a pivotal role in shaping the containerization sector by driving innovation and enhancing efficiency. Their capacity to integrate production processes with distribution options results in significantly faster turnaround times and cost savings, essential in today's competitive landscape. Notably, the sustainable wrapping market is projected to expand from an estimated USD 292.71 billion in 2024 to USD 423.56 billion by 2029, underscoring the industry's growth and innovative spirit.

As consumer preferences increasingly favor convenience and sustainability, manufacturers are proactively adapting by providing environmentally friendly wrapping solutions and construction techniques that minimize waste. This shift not only elevates their importance but also positions them as , setting benchmarks for quality and efficiency.

A compelling case study, 'Major Businesses Adapting to Sustainable Wrapping,' revealed that the adoption of eco-friendly production methods led to a 25% reduction in waste, illustrating the significant impact these enterprises can have on overall wrapping efficiency. By embracing innovation and sustainability, assembly companies are not only responding to current market demands, but they are also laying the groundwork for future advancements in the packaging industry.

Conclusion

Assembly companies are indispensable components within the packaging industry, ensuring that products are efficiently assembled and primed for distribution. By integrating various components into cohesive units, these firms enhance the overall supply chain, enabling manufacturers to uphold high-quality standards while optimizing production processes. The significance of assembly companies is underscored by their adaptability to evolving market demands and technological advancements, reinforcing their position as essential players in the packaging landscape.

This article has explored key insights regarding the historical evolution of assembly companies, the defining characteristics of their operations, and their substantial impact on industry dynamics. The transition from manual methods to advanced automation reflects a commitment to improving efficiency and responsiveness. The functions of kitting, quality control, customization, and logistics coordination highlight the comprehensive solutions that assembly firms provide, ultimately fostering consumer trust and satisfaction. Furthermore, the growing emphasis on sustainability and innovation within the packaging sector illustrates how assembly companies are not only meeting current demands but also shaping future industry trends.

In light of these insights, it is evident that assembly companies drive efficiency and innovation within the packaging industry. As consumer preferences shift towards sustainable practices and convenience, the role of these firms will continue to evolve, presenting opportunities for further advancements. Stakeholders in the packaging sector are encouraged to recognize the critical contributions of assembly companies and consider strategic partnerships that leverage their expertise to navigate the complexities of modern production and distribution challenges.

Frequently Asked Questions

What are assembly companies in the packaging sector?

Assembly companies in the packaging sector are specialized organizations that integrate various components into a final product, ensuring it is ready for distribution.

What role do assembly companies play in the supply chain?

They optimize production processes essential for maintaining quality standards and operational efficiency, which is crucial for effective supply chain solutions.

What activities are commonly performed by assembly companies?

Common activities include kitting, where multiple items are packaged together, and construction, which involves merging different components into a cohesive unit.

Why is precise construction important in sectors like nutraceuticals?

Precise construction influences product efficacy and ensures consumer safety, making it vital in sectors such as nutraceuticals.

What is the projected growth of the US container market by 2025?

The US container market is projected to reach USD 208.98 billion by 2025, growing at a CAGR of 3.98%.

How do successful kitting initiatives benefit manufacturers?

Successful kitting initiatives streamline operations, allowing manufacturers to focus on core competencies while improving market responsiveness.

What trend is observed in the number of Packaging & Labeling Services enterprises in the US?

The number of Packaging & Labeling Services enterprises in the US has risen by an average of 7.1% annually from 2020 to 2025, indicating a growing need for specialized production services.

What impact do manufacturing firms have on product quality and consumer confidence?

Manufacturing firms ensure that products meet market demands and adhere to stringent quality and safety regulations, fostering consumer confidence and brand loyalty.

What factors are driving changes in the United States container sector?

The sector is rapidly evolving due to changing retail dynamics and technological innovations.