Overview

The article titled "10 Key Insights on Contract Pharmaceutical Packaging for Nutraceuticals" presents essential strategies and trends in pharmaceutical packaging tailored specifically for the nutraceutical sector. It underscores the significance of:

- Integrated solutions

- Sustainability

- Automation

- Regulatory compliance

These critical factors not only enhance operational efficiency but also foster consumer engagement and ensure adherence to industry standards. Ultimately, these insights position companies for success in an increasingly competitive market.

Introduction

The landscape of contract pharmaceutical packaging is rapidly evolving, driven by the increasing demand for efficiency, sustainability, and consumer-centric designs in the nutraceutical sector. As companies strive to meet regulatory standards and consumer preferences, understanding the key insights into this specialized packaging becomes essential.

What challenges and opportunities lie ahead for businesses navigating this complex terrain? How can they leverage innovative practices to enhance their market presence? This exploration not only highlights the pressing needs of the industry but also positions companies to adapt and thrive in a competitive market.

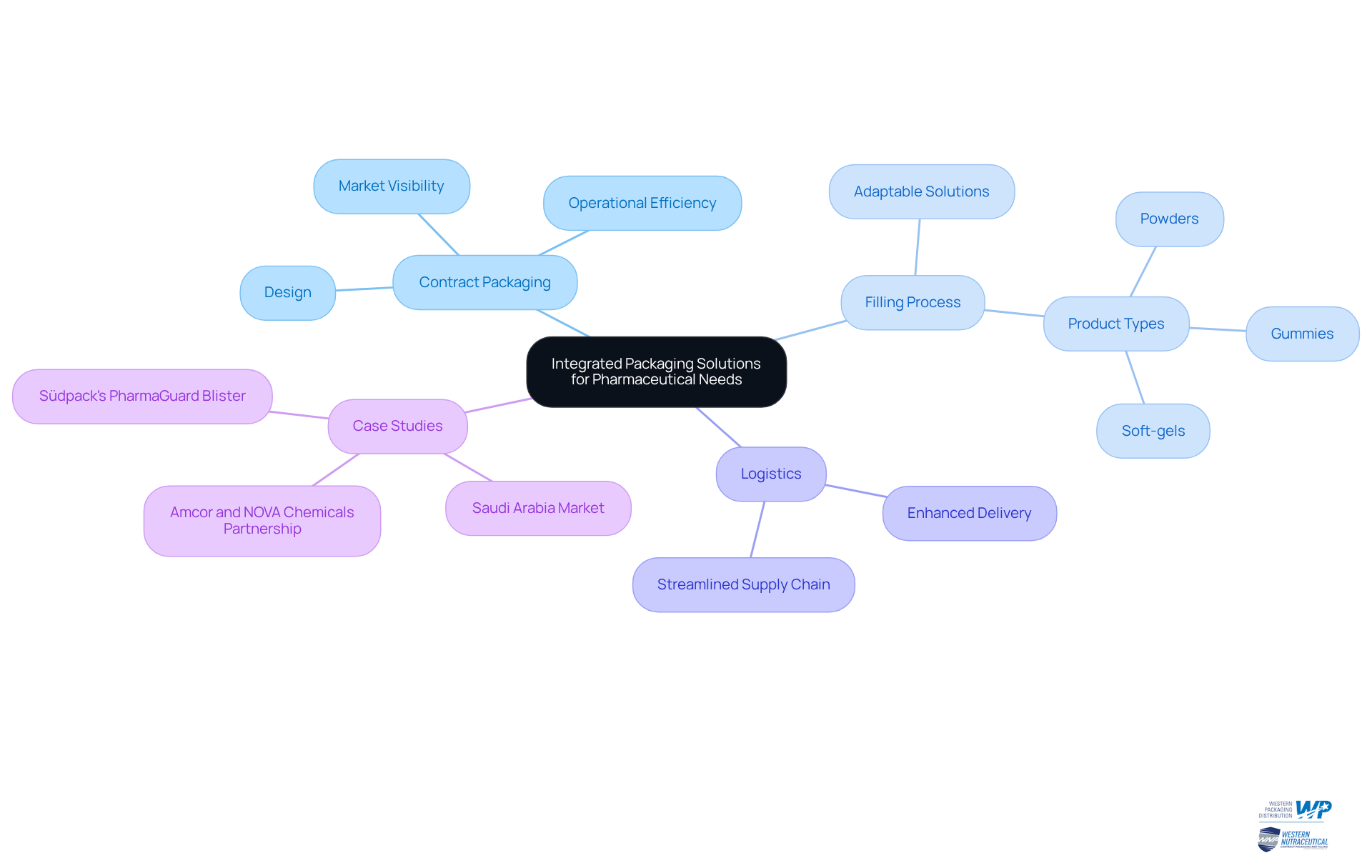

Western Packaging: Integrated Packaging Solutions for Pharmaceutical Needs

Western Packaging distinguishes itself in the pharmaceutical sector by delivering comprehensive solutions that include , seamlessly integrating design, filling, and logistics. Our filling process is designed to fit effortlessly into our holistic offerings, catering to your adaptable needs, from powders to gummies and soft-gels. This integrated approach streamlines the supply chain, significantly enhancing both product appeal and operational efficiency. By merging these essential services, Western Packaging empowers clients to concentrate on their core competencies while benefiting from a tailored process that meets the specific requirements of nutraceuticals.

Successful case studies highlight the substantial advantages of utilizing integrated wrapping solutions. Companies that adopt a unified approach often report reduced lead times and enhanced product delivery, critical factors in the fast-paced nutraceutical market. Notably, statistics reveal that integrated container solutions can yield a 20% increase in operational efficiency, underscoring the effectiveness of this strategy.

At the forefront of contract pharmaceutical packaging innovations, Western Packaging continually evolves its offerings to align with industry demands. Leaders in the field emphasize the importance of comprehensive wrapping strategies, with one stating that 'the combination of design and logistics not only enhances item safety but also boosts competitive edge in the industry.' This perspective reflects an increasing recognition of the necessity for cohesive presentation strategies in the nutraceutical sector, where consumer preferences are shifting towards more user-friendly and sustainable options.

By focusing on a cohesive model, Western Packaging adeptly navigates the complexities of contract pharmaceutical packaging while establishing itself as a preferred partner for enterprises aiming to enhance their service offerings and market visibility.

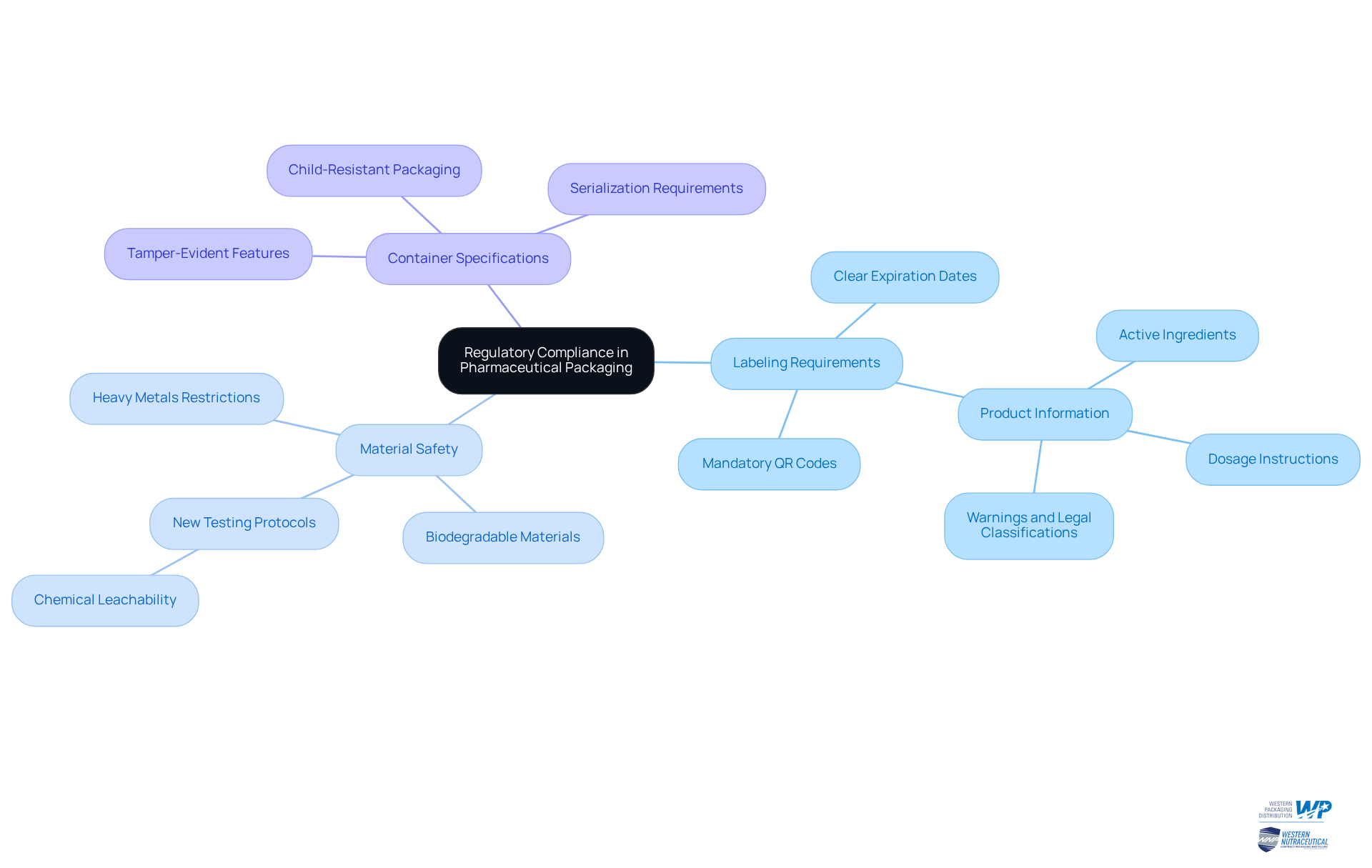

Regulatory Compliance: Navigating the Complexities of Pharmaceutical Packaging

Navigating the regulatory landscape is essential for any business in the pharmaceutical sector. Compliance with FDA regulations and other industry standards is not merely a requirement; it is a commitment to ensuring that products are safe and effective. At Western Packaging, we empower our clients to comprehend these complexities through expert advice on:

- Labeling requirements

- Material safety

- Container specifications that align with regulatory guidelines

This proactive approach significantly reduces the risk of or legal issues, reinforcing our dedication to reliability and quality in your packaging solutions.

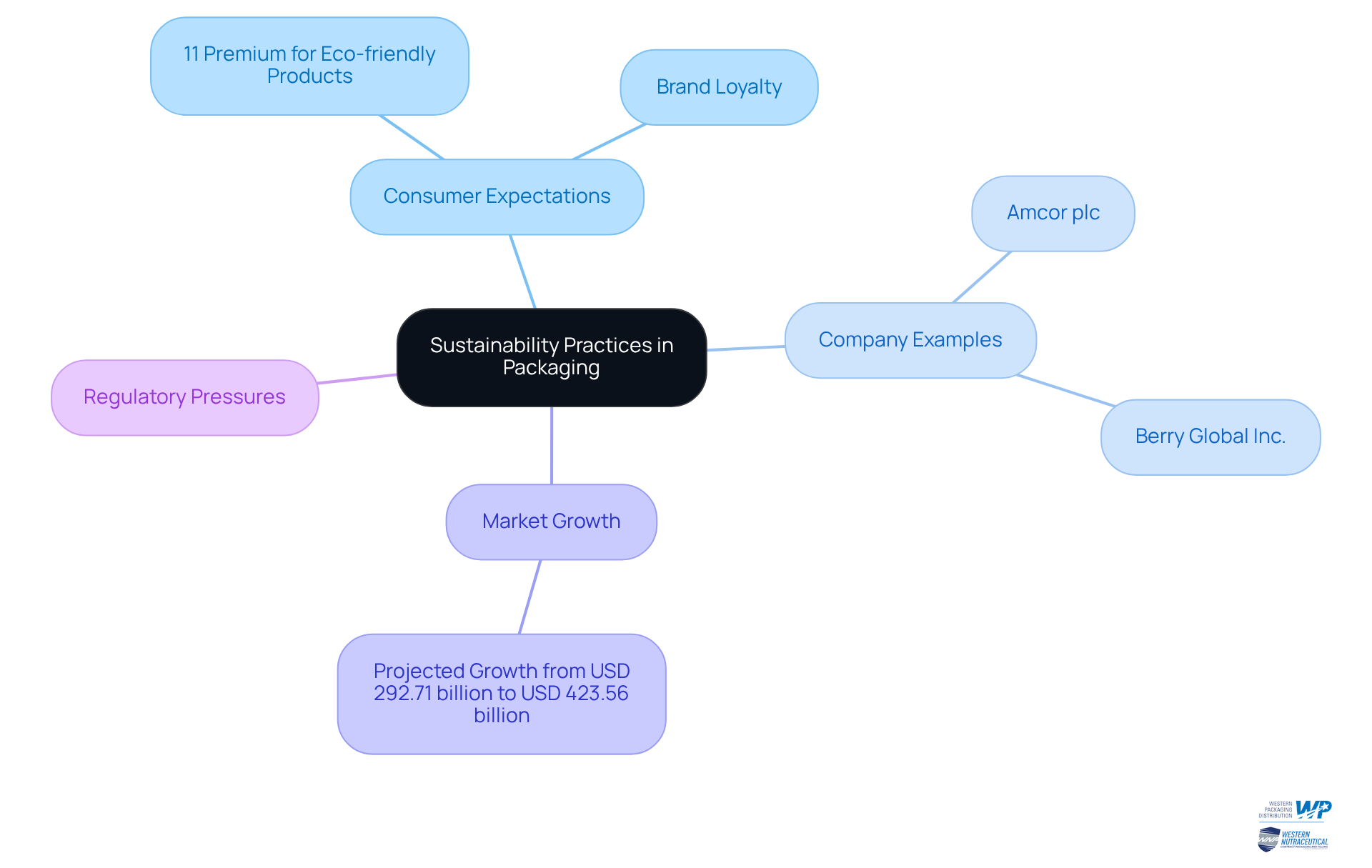

Sustainability Practices: Enhancing Environmental Responsibility in Packaging

Sustainability practices in the pharmaceutical industry have evolved from mere trends to essential components of business strategy. Western Packaging exemplifies this commitment by prioritizing and waste reduction throughout its packaging processes. By embracing sustainable practices, companies not only align with consumer expectations but also play a critical role in environmental conservation. This dedication to sustainability significantly enhances brand loyalty, particularly among environmentally conscious consumers who are increasingly attracted to products that reflect their values.

Notably, U.S. consumers are willing to pay an 11% premium for eco-friendly products, underscoring the financial incentive for brands to adopt sustainable practices. In the nutraceutical sector, where consumer preferences are shifting toward sustainable solutions, brands utilizing recyclable materials can distinguish themselves in a competitive market. Significant examples include firms like Amcor plc and Berry Global Inc., which have successfully integrated recyclable materials into their offerings, demonstrating that sustainability is not only beneficial for the environment but also a strategic advantage in appealing to a broader customer base.

Current trends reveal a growing focus on sustainable practices within the pharmaceutical sector, propelled by regulatory pressures and consumer demand for eco-friendly options. The sustainable container market is projected to expand from an estimated USD 292.71 billion in 2024 to USD 423.56 billion by 2029, reflecting a compound annual growth rate (CAGR) of 7.67%. As the industry progresses, the integration of sustainable materials will continue to shape the future of nutraceutical containers.

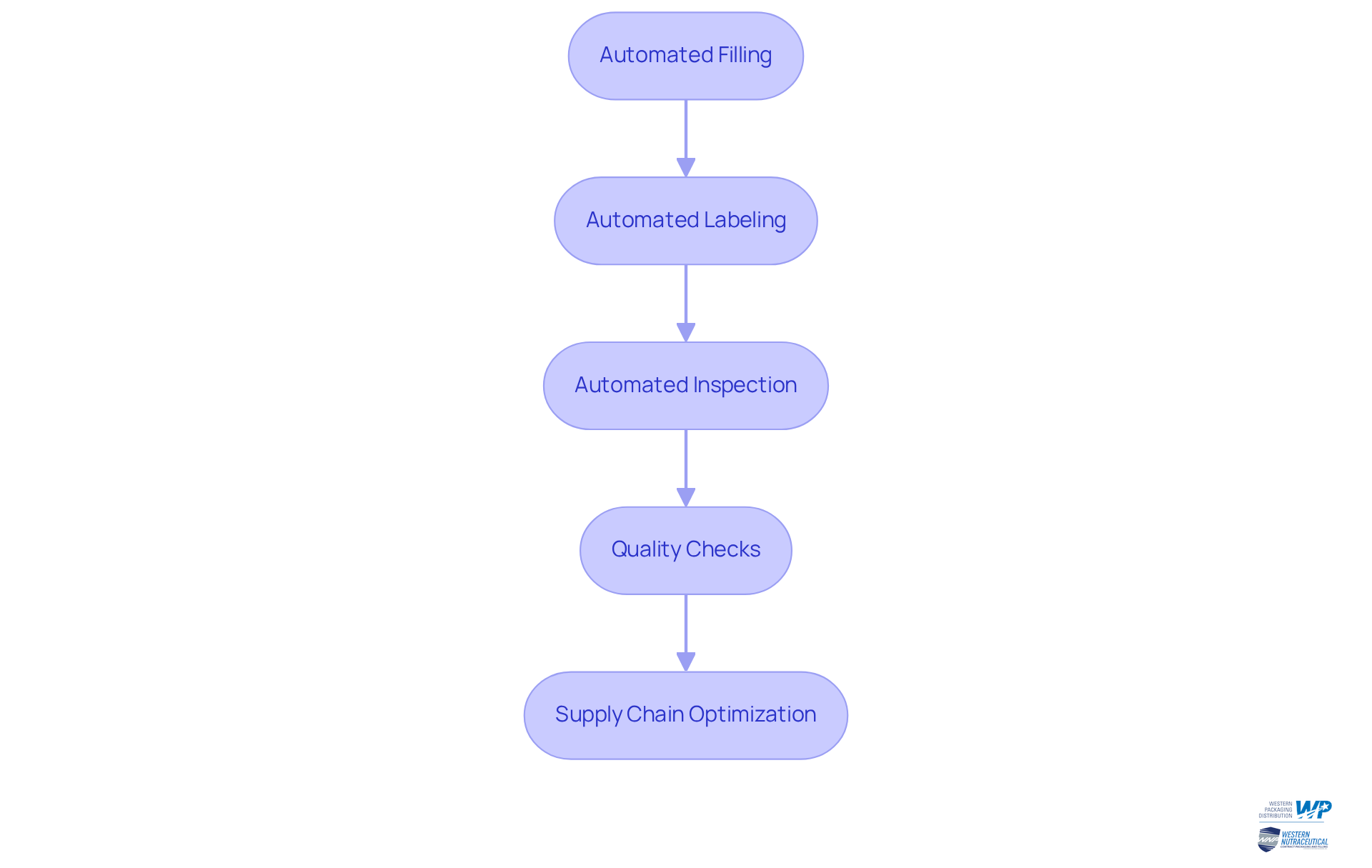

Automation in Packaging: Streamlining Processes for Greater Efficiency

The incorporation of automation in contract pharmaceutical packaging processes dramatically enhances both efficiency and accuracy. In contract pharmaceutical packaging, automated filling, labeling, and inspection systems minimize human error while significantly increasing production speed. For instance, automated systems can process thousands of units per hour, allowing companies to meet rising medication demands without compromising quality.

Western Packaging's filling process seamlessly integrates with these automated systems, providing extensive services that enhance production and deliver customized container solutions. This capability not only boosts operational efficiency but also enables businesses to adapt quickly to market fluctuations, thereby in contract pharmaceutical packaging.

Furthermore, automated systems include built-in quality checks, such as detecting missing components and ensuring compliance with regulatory standards, including the application of tamper-evident seals critical for FDA compliance. By optimizing supply chains with Western Packaging's 3PL services, companies can focus on core operations while enjoying the benefits of reduced labor costs and improved customer satisfaction through timely and precise deliveries.

Patient-Centric Design: Prioritizing User Experience in Pharmaceutical Packaging

Patient-centric design in pharmaceutical containers is critical for enhancing user experience and addressing the needs of the end user. Key considerations encompass:

- Ease of opening

- Clear labeling

- Accessibility for individuals with disabilities

Research indicates that 63% of customers view container design as equally important as the brand itself, underscoring the necessity for meticulous design. Western Packaging recognizes that efficient wrapping not only protects the product but also fosters positive interactions, ultimately leading to improved patient adherence and satisfaction. Innovations, such as recyclable, paper-based secondary containers, exemplify how companies can enhance usability while adhering to high-quality standards.

With the pharmaceutical container industry projected to expand at a from 2025 to 2034, emphasizing user experience becomes increasingly vital. Furthermore, with the self-injections market anticipated to reach USD 97.36 billion by 2031, the importance of user experience in this context cannot be overstated. By prioritizing user experience, businesses can create containers that resonate with consumers and support their health outcomes.

Outsourcing Trends: Leveraging External Expertise in Contract Packaging

Outsourcing contract pharmaceutical packaging has emerged as a significant trend within the drug industry, enabling companies to access external expertise and resources. By collaborating with specialized providers like Western Packaging, businesses gain access to advanced technologies and industry insights that streamline their operations. This strategic partnership not only leads to substantial cost savings—often reducing overhead by 20-30% and eliminating staffing and machinery expenses—but also allows companies to concentrate on their core competencies, thereby enhancing overall business performance.

Industry leaders highlight that utilizing outside knowledge in contract pharmaceutical packaging can enhance efficiency and ensure adherence to regulatory standards. For instance, Cardinal Health observes that the sector of contract pharmaceutical packaging is undergoing significant expansion, fueled by rising outsourcing. Companies that have embraced this approach report faster turnaround times and higher quality control, supported by rigorous quality management processes that ensure compliance and high standards.

As the medicine container market continues to expand, with forecasts suggesting a reach of $50 billion by 2025 and a CAGR of 7% from 2025 to 2033, the advantages of outsourcing become more evident. This trend makes for producers aiming to enhance their operations.

Quality Control: Ensuring Product Integrity in Pharmaceutical Packaging

Quality control stands as a non-negotiable pillar of pharmaceutical packaging. Western Packaging employs stringent designed to ensure that each product adheres to the highest standards of safety and efficacy. This comprehensive approach encompasses:

- Meticulous inspections

- Rigorous testing of materials

- Strict compliance with industry regulations

By prioritizing quality control, companies not only protect their brand image but also instill consumer confidence in their products. In today's competitive market, reliability in packaging is essential—choose quality, choose trust.

Innovative Technologies: Transforming Pharmaceutical Packaging Solutions

The pharmaceutical container industry is experiencing a transformative shift, propelled by innovative technologies that are redefining traditional practices. Intelligent container solutions, which offer real-time information and enhanced item protection, are becoming essential for maintaining competitiveness. For instance, the increasing utilization of RFID tags to monitor medication conditions throughout the supply chain ensures both integrity and safety. Furthermore, tamper-evident seals and holographic labels act as effective anti-counterfeiting measures, thereby safeguarding consumer trust.

Western Packaging stands at the forefront of these advancements, seamlessly integrating cutting-edge technologies into their offerings. This commitment not only enhances operational efficiency but also significantly boosts consumer engagement. Industry leaders emphasize that the ability to engage with consumers through containers presents a transformative opportunity. The incorporation of QR codes, for example, allows brands to provide direct access to product information, fostering transparency and trust.

In the nutraceutical sector, intelligent container solutions have a particularly profound impact. Customizable designs, such as easy-to-open blister packs, improve medication adherence, while interactive features facilitate real-time communication between brands and consumers. This level of involvement is crucial; research indicates that 94% of consumers are more likely to remain loyal to brands that prioritize .

As the market for intelligent containers continues to expand, with forecasts valuing it at $29.76 billion, companies that embrace these innovations will not only enhance item protection but also strengthen their industry presence and deepen consumer connections.

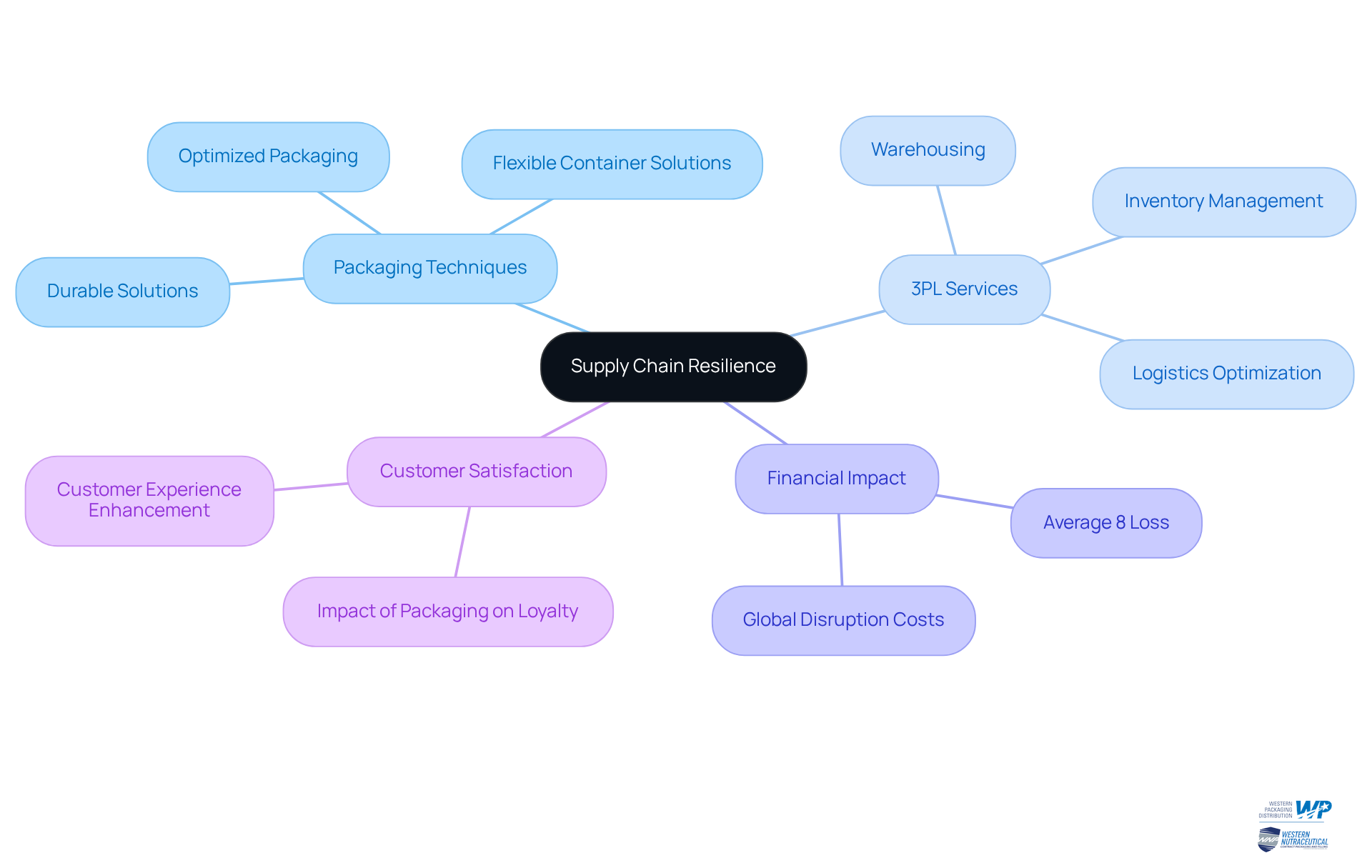

Supply Chain Resilience: Addressing Disruptions Through Effective Packaging

In today's unpredictable market, the resilience of supply chains is paramount for pharmaceutical companies. Efficient wrapping techniques in contract pharmaceutical packaging play a crucial role in minimizing disruptions, ensuring that items are safeguarded during transportation and storage.

At Western Packaging, we focus on developing durable solutions in contract pharmaceutical packaging that not only protect products but also enhance operational efficiency. Our comprehensive 3PL services—including warehousing, inventory management, and logistics—are specifically tailored to optimize your supply chain.

By prioritizing resilience in design, businesses can navigate challenges more effectively, maintaining product availability and customer satisfaction. Companies that invest in optimized containers and integrated 3PL services for contract pharmaceutical packaging have reported significant improvements in their supply chain performance, which enables quicker transportation and faster processing of customer orders.

A recent survey indicated that global supply chain disruptions resulted in financial losses averaging approximately 8% of annual revenues, underscoring the stakes involved in effective management. As Gartner highlights, "83% of companies now prioritize customer-experience improvement in their digital business strategy for supply chains," emphasizing the essential role of product presentation in sustaining customer satisfaction.

To further strengthen resilience, companies should consider adopting that adapt to evolving market demands, ensuring they remain nimble and responsive in the face of disruptions.

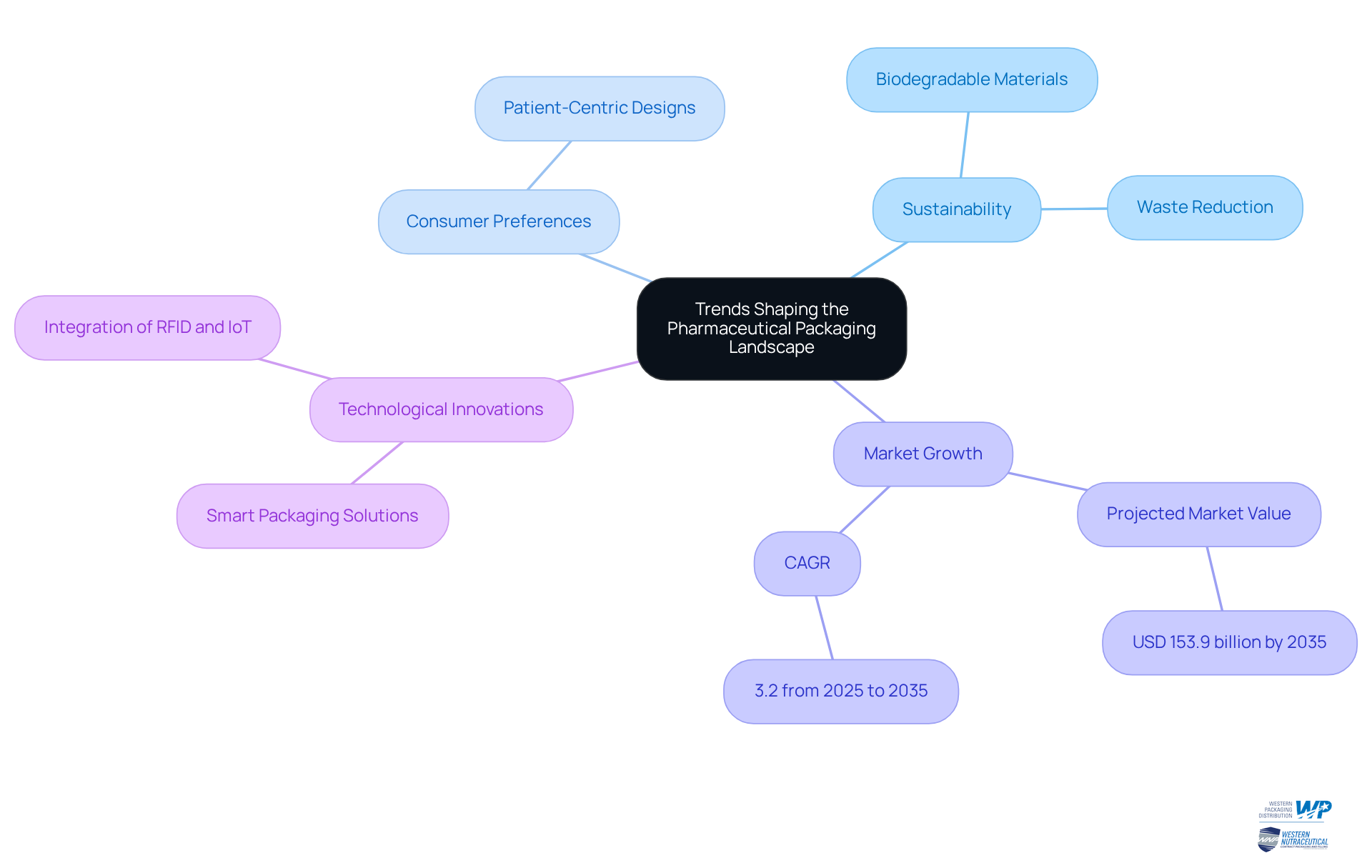

Future Insights: Trends Shaping the Pharmaceutical Packaging Landscape

The pharmaceutical container landscape is undergoing a significant transformation, driven by evolving consumer preferences, regulatory demands, and technological innovations. Notably, there is an increasing consumer demand for sustainable solutions, with a growing willingness to pay more for eco-friendly options. This shift prompts companies to explore and reduce waste, aligning with global sustainability goals. Statistics indicate that the pharmaceutical sector is expected to reach USD 153.9 billion by 2035, demonstrating a compound annual growth rate (CAGR) of 3.2% from 2025 to 2035, up from a value of USD 112.3 billion in 2025. Furthermore, the market recorded a historical CAGR of 2.5% from 2020 to 2024, illustrating a clear growth trend over time.

Industry analysts emphasize the importance of patient-centric designs, noting that containers must accommodate various demographics, including seniors who require easier-to-open mechanisms and larger fonts. Companies like Gerrsheimer AG are adapting to these preferences by enhancing their product range with user-friendly features, including expanded production capacity for accessible container solutions. Additionally, the integration of smart technologies, such as RFID tags and the MyDoses app, is becoming mainstream, enabling real-time tracking and improving medication adherence.

As the market evolves, companies that proactively adjust their product strategies to align with these trends will maintain a competitive advantage. The focus on sustainability, consumer preferences, and innovative technologies will define the future of pharmaceutical packaging, ensuring it meets the needs of both patients and regulatory standards.

Conclusion

The insights presented on contract pharmaceutical packaging for nutraceuticals underscore the critical role of integrated solutions in enhancing operational efficiency and meeting regulatory demands. By adopting a comprehensive approach that encompasses design, filling, and logistics, companies can streamline their processes and focus on core competencies, ultimately driving growth and improving product appeal.

Key arguments throughout the article emphasize the importance of sustainability, automation, and patient-centric design in the evolving pharmaceutical landscape. The shift towards eco-friendly materials and innovative packaging solutions not only aligns with consumer preferences but also positions companies to thrive in a competitive market. Furthermore, leveraging external expertise through outsourcing can lead to significant cost savings and improved quality control, reinforcing the necessity for strategic partnerships in this sector.

As the pharmaceutical packaging industry continues to evolve, businesses must remain agile and responsive to emerging trends. Embracing sustainability, prioritizing user experience, and implementing cutting-edge technologies will be paramount for success. Companies that proactively adapt their strategies in alignment with these trends will not only enhance their market presence but also contribute to a more sustainable and consumer-focused future in the nutraceutical sector.

Frequently Asked Questions

What services does Western Packaging provide in the pharmaceutical sector?

Western Packaging offers comprehensive solutions including contract pharmaceutical packaging, design, filling, and logistics, catering to various forms such as powders, gummies, and soft-gels.

How does Western Packaging's integrated approach benefit clients?

The integrated approach streamlines the supply chain, enhances product appeal, and improves operational efficiency, allowing clients to focus on their core competencies while receiving tailored packaging solutions.

What are the advantages of utilizing integrated wrapping solutions?

Companies using integrated wrapping solutions often experience reduced lead times and improved product delivery, with statistics indicating a potential 20% increase in operational efficiency.

How does Western Packaging ensure compliance with regulatory standards?

Western Packaging provides expert advice on labeling requirements, material safety, and container specifications to help clients navigate FDA regulations and other industry standards, reducing the risk of recalls or legal issues.

What sustainability practices does Western Packaging prioritize?

Western Packaging focuses on using recyclable materials and reducing waste in its packaging processes, aligning with consumer expectations and enhancing brand loyalty among environmentally conscious consumers.

What financial incentives exist for brands adopting sustainable practices?

U.S. consumers are willing to pay an 11% premium for eco-friendly products, making sustainability not only an ethical choice but also a strategic advantage in the market.

What is the projected growth of the sustainable container market?

The sustainable container market is expected to grow from approximately USD 292.71 billion in 2024 to USD 423.56 billion by 2029, reflecting a compound annual growth rate (CAGR) of 7.67%.

How does Western Packaging's approach to sustainability impact its clients?

By integrating sustainable practices, Western Packaging helps its clients distinguish themselves in a competitive market, appealing to consumers who prioritize eco-friendly options.