Overview

The article articulates the significant benefits of partnering with contract pharmaceutical companies. Such collaborations yield substantial cost savings, enhance quality control, and provide access to specialized expertise. By leveraging these partnerships, businesses can streamline operations, improve market responsiveness, and foster innovation. This strategic approach ultimately leads to greater operational efficiency and a competitive advantage within the pharmaceutical industry. Engaging with contract pharmaceutical companies is not merely a choice; it is a strategic imperative for those aiming to excel in this dynamic market.

Introduction

The pharmaceutical landscape is evolving at an unprecedented pace, with companies continually seeking innovative ways to enhance efficiency and profitability. Partnering with contract pharmaceutical companies presents a strategic avenue for businesses to unlock a multitude of benefits, ranging from significant cost savings to improved regulatory compliance.

However, amidst these advantages lies the challenge of navigating complex partnerships and ensuring quality control.

What are the key benefits that render these collaborations not just advantageous but essential for thriving in today’s competitive market? This exploration delves into the transformative power of contract pharma partnerships, revealing how they can propel businesses toward greater success.

Western Packaging: Integrated Packaging Solutions for Enhanced Efficiency

Western Packaging offers a comprehensive suite of that seamlessly combine design, filling, and third-party logistics (3PL) services. Our filling process is meticulously designed to accommodate a wide range of items, from powders to gummies and soft-gels, ensuring we meet the diverse needs of nutraceutical manufacturers. This holistic approach not only streamlines the supply chain but also significantly boosts appeal and operational efficiency.

By leveraging innovative packaging designs alongside our efficient filling services, businesses can ensure their products capture attention in competitive markets while optimizing distribution processes. This integration leads to shorter lead times and enhanced delivery performance, making it an appealing choice for businesses looking to elevate their packaging and logistics capabilities.

Research indicates that packaging serves as the first impression of a product, influencing purchasing decisions for 70% of consumers, underscoring its critical role in branding. Furthermore, organizations that adopt integrated packaging solutions often experience improved agility and responsiveness in their supply chains, allowing them to better meet customer demands and reduce operational costs.

This comprehensive strategy not only strengthens brand identity but also fosters a deeper connection with consumers through storytelling, as emphasized by Steve Jobs, ultimately driving business success. Additionally, our commitment to sustainability in packaging solutions is increasingly vital, aligning with consumer preferences for eco-friendly practices, further enhancing the attractiveness of integrated packaging.

Cost Savings: Reduce Operational Expenses with Contract Pharma Partnerships

Collaborating with contract pharma companies offers businesses significant cost reductions, especially when leveraging extensive 3PL services like those provided by Western Packaging. Outsourcing manufacturing and employing tailored logistics solutions enable companies to sidestep the substantial capital expenses tied to establishing and operating production facilities.

Contract manufacturers typically have established infrastructures that lower operational costs, allowing clients to focus their resources on core business activities. This strategic decision not only reduces labor costs but also enhances operational efficiency, ultimately improving the bottom line.

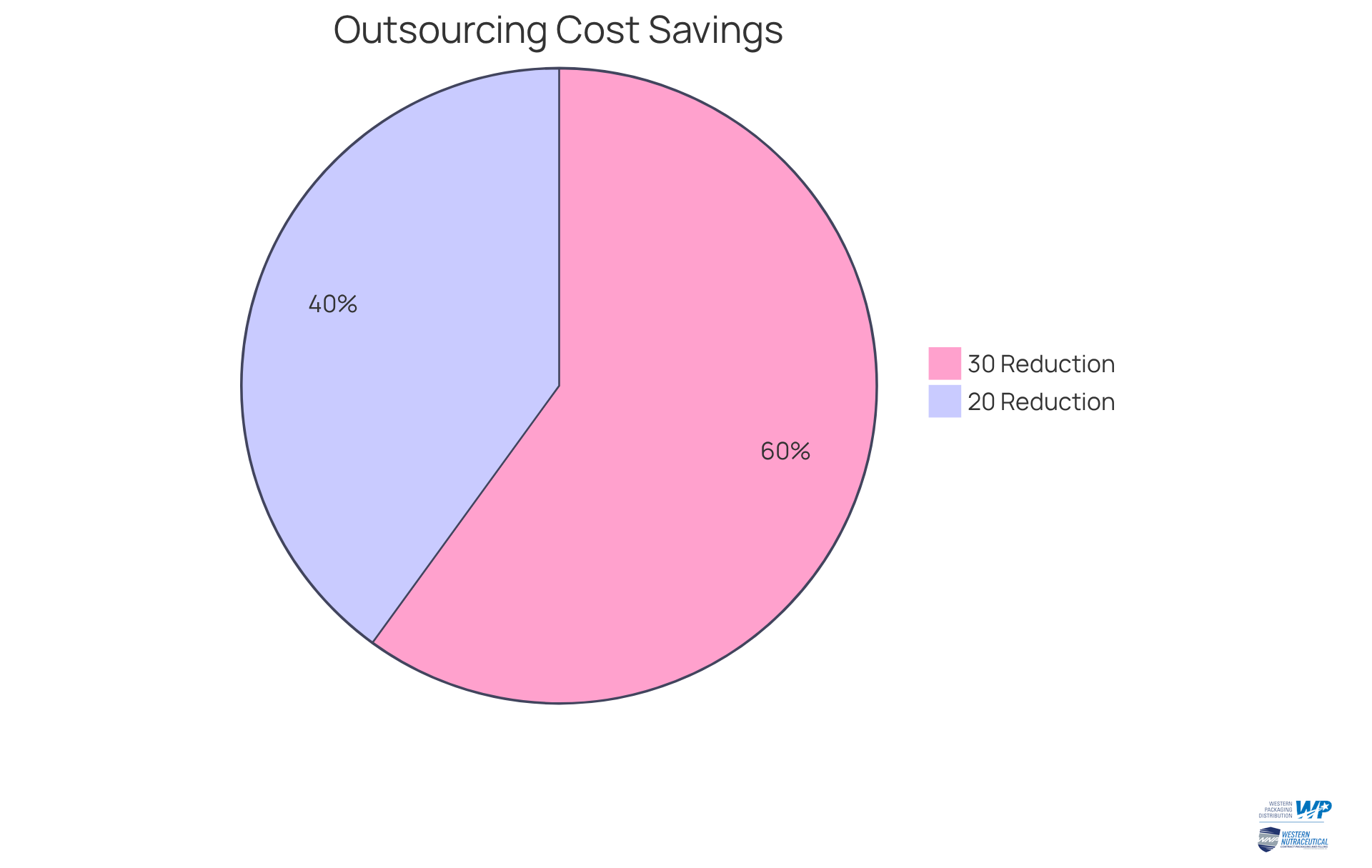

For example, businesses that have adopted outsourcing report operational cost reductions averaging between 20% and 30%, showcasing the tangible financial benefits of these partnerships. Moreover, financial analysts indicate that outsourcing manufacturing is increasingly perceived as a strategic enabler, empowering companies to swiftly adapt to market demands while upholding high-quality standards.

Noteworthy successes include a North American drug manufacturer that, after partnering with a contract producer and utilizing Western Packaging's 3PL services, achieved a remarkable turnaround in operational efficiency and cost management, resulting in substantial savings and improved product delivery timelines. This trend underscores the growing recognition of outsourcing as a in the industry.

Regulatory Compliance: Navigate Complex Regulations with Expert Support

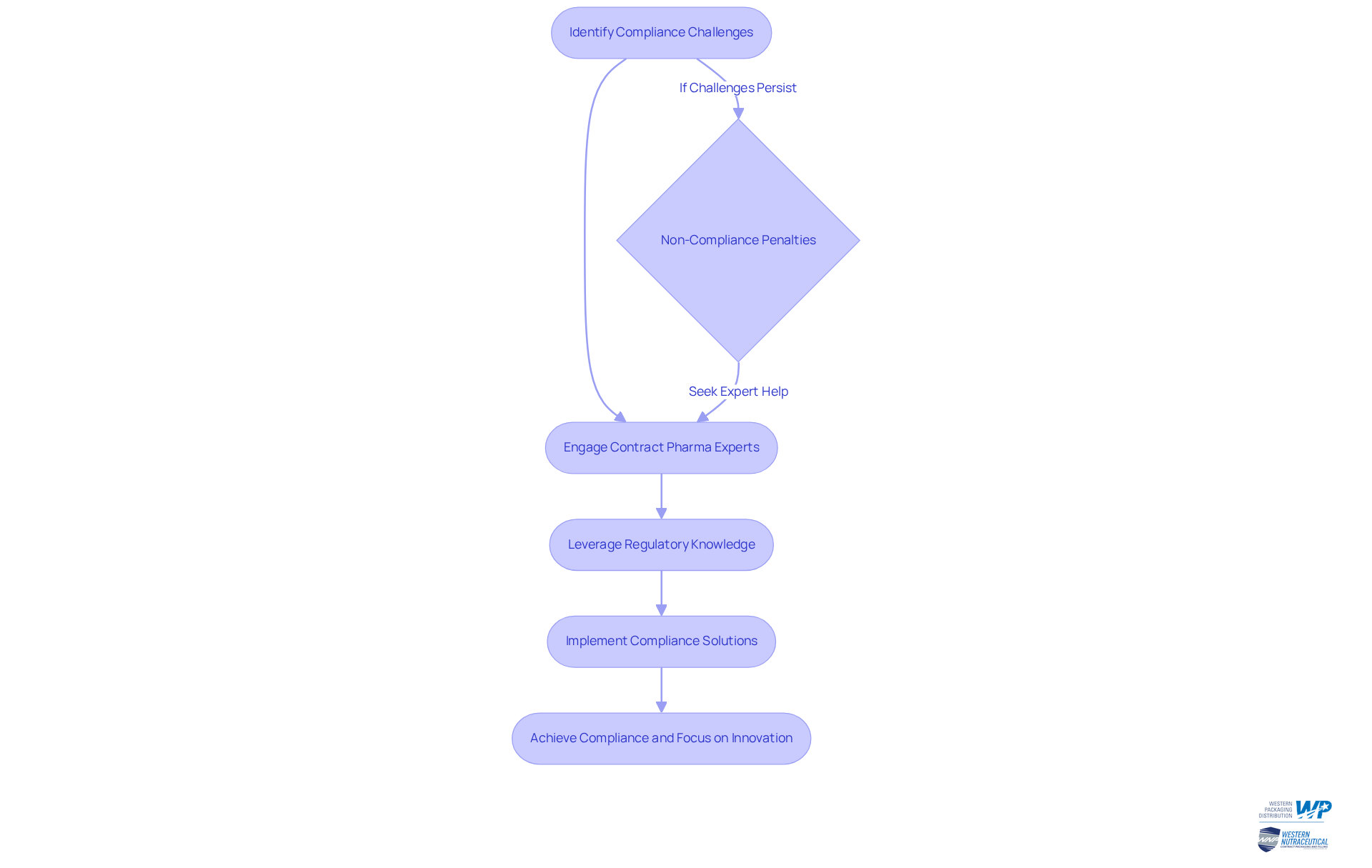

The pharmaceutical industry operates under stringent regulations, presenting significant compliance challenges for many companies. Contract pharma companies provide essential expertise in navigating these complex regulations, ensuring that products meet safety and efficacy standards. By leveraging their extensive knowledge of regulatory requirements, companies can significantly reduce the risk of non-compliance, which can incur severe penalties and costly recalls.

For instance, the average global cost of a data breach reached $4.88 million in 2024, highlighting the financial repercussions of regulatory failures. Furthermore, 58% of healthcare organizations reported experiencing a third-party data breach in the past year, emphasizing the widespread risks associated with non-compliance. This support is particularly beneficial for smaller firms that may lack the resources to effectively .

Regulatory affairs professionals stress that ensuring compliance not only safeguards public health but also fosters trust among healthcare providers and patients. By collaborating with contract pharma companies, organizations can streamline their compliance processes, enabling them to focus on innovation and growth while adhering to necessary regulations.

Access to Expertise: Leverage Advanced Technology and Industry Knowledge

Contract pharma companies offer invaluable access to advanced technologies and specialized knowledge that can significantly enhance development and manufacturing processes. These firms typically invest in state-of-the-art equipment and innovative methodologies that may be beyond the reach of individual businesses. By partnering with contract pharma companies, companies can utilize this extensive knowledge base and technological expertise, leading to improved quality, accelerated development timelines, and a competitive edge in the marketplace.

For instance, a large pharmaceutical manufacturer faced challenges during the micronisation step of new inhalation drug candidates. By utilizing Britest tools, a cross-site team recognized key factors influencing the process, ultimately establishing a generic workflow that enhanced efficiency and quality. This case exemplifies how contract pharma companies can facilitate through their expertise.

Industry leaders emphasize the importance of leveraging such expertise. As one noted, "The best way to predict the future is to invent it together," highlighting the collaborative nature of successful partnerships. Contract pharma companies not only enhance development but also utilize advanced technologies to ensure that products meet strict quality standards. For instance, AstraZeneca's analytical scientists regained control over a test method, saving $10-50k for each out-of-specification result avoided, demonstrating the direct influence of advanced technology on quality.

In summary, collaborating with contract pharma companies allows enterprises to utilize advanced technology and sector expertise, enhancing quality and operational efficiency.

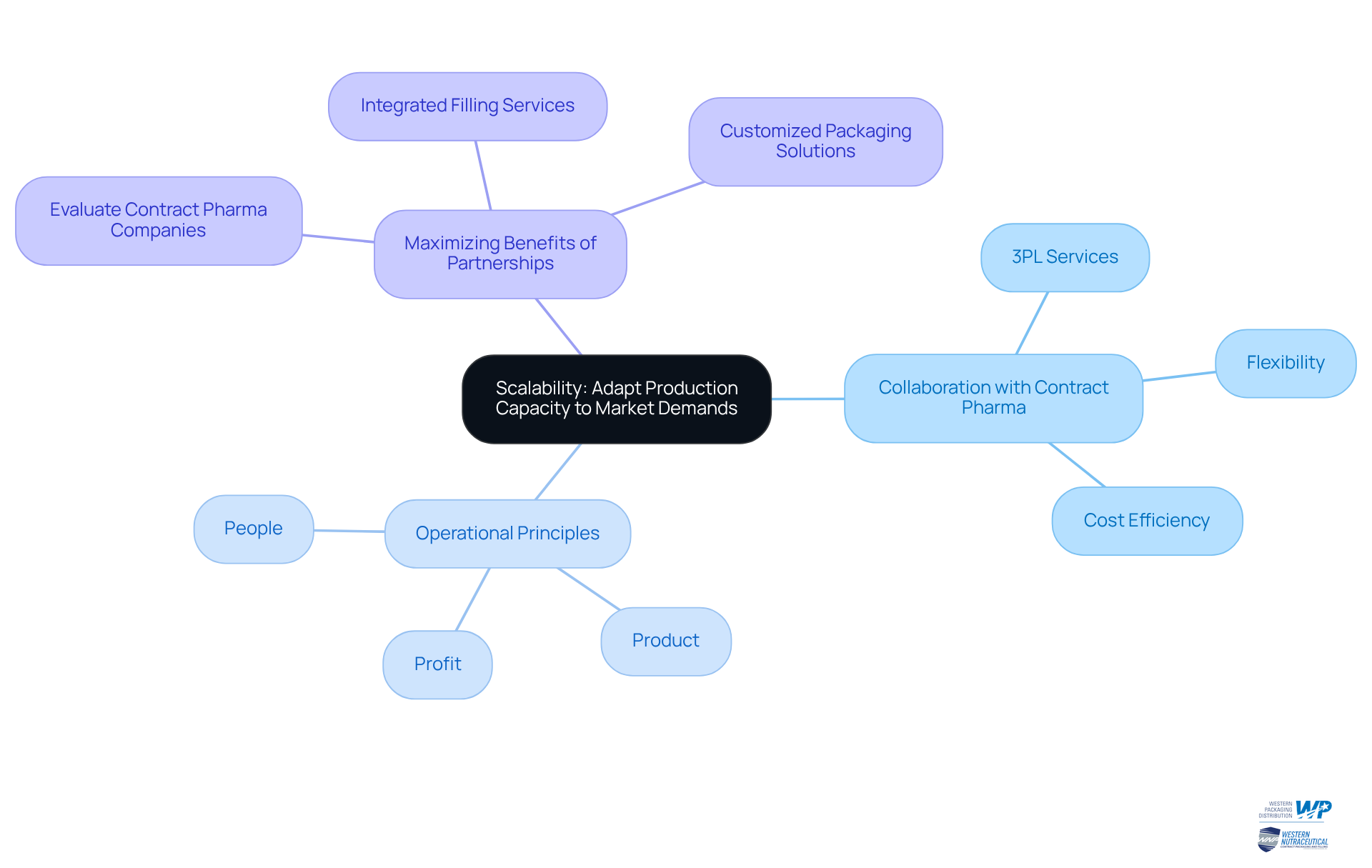

Scalability: Adapt Production Capacity to Market Demands

Collaborating with contract pharma companies offers a significant advantage in enhancing production capacity to meet evolving market demands. With Western Packaging's comprehensive 3PL services—tailored warehousing, inventory management, and logistics solutions—businesses can optimize their supply chain efficiency.

Whether launching a new product or addressing slower sales periods, manufacturers provide the needed to adjust operations accordingly. This capability empowers businesses to respond swiftly to market changes without incurring the financial burden of excess production capacity.

As Malcolm Forbes aptly noted, successful business operations hinge on three principles:

- People

- Product

- Profit

By concentrating on these principles, companies can bolster operational efficiency and focus on their core competencies, ultimately driving growth and enhancing customer satisfaction.

To maximize the benefits of such partnerships, businesses should evaluate potential contract pharma companies as manufacturers based on their flexibility and responsiveness to market demands, particularly those offering integrated filling services and customized packaging solutions like Western Packaging.

Speed to Market: Accelerate Product Launches with Contract Pharma

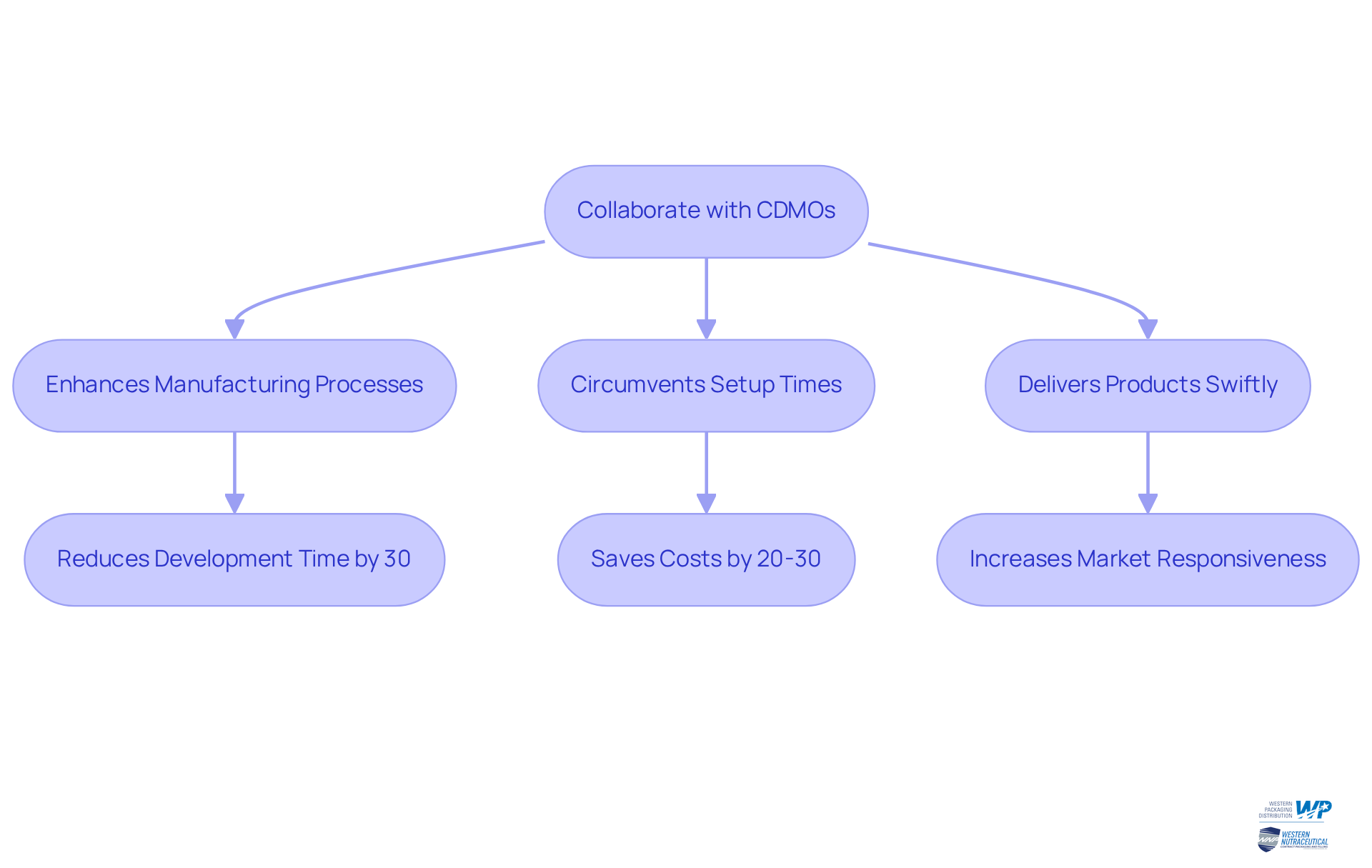

In the rapidly evolving medical landscape, achieving speed to market is paramount for success. Collaborating with contract pharma companies can significantly accelerate product launches by enhancing manufacturing processes and leveraging existing infrastructures. These strategic partnerships enable businesses to circumvent protracted setup times, allowing them to deliver products to consumers more swiftly. This agility not only enhances competitive positioning but also empowers organizations to seize emerging market opportunities effectively.

Industry leaders underscore the importance of these collaborations. For instance, a report indicates that pharmaceutical firms utilizing contract development and manufacturing organizations (CDMOs) can reduce their development time by as much as 30%. This reduction is crucial, particularly in a market where timely access to medications can greatly impact patient outcomes. Companies like Gilead Sciences have notably improved their distribution and delivery timelines through CDMO networks, ensuring quicker access to essential medicines.

Moreover, the growing reliance on CDMOs is driven by the expanding pipeline of biotech offerings and the increasing demand for personalized medicine. As highlighted by industry experts, outsourcing manufacturing not only reduces costs by approximately 20-30% but also enhances operational efficiency, allowing companies to concentrate on their core competencies. This strategic shift has proven beneficial for firms like Johnson & Johnson, which successfully , resulting in improved profit margins and reduced infrastructure costs.

Furthermore, the CDMO market is projected to expand at a compound annual growth rate of 7.4% from 2021 to 2028, underscoring the growing significance of these collaborations in the healthcare industry. Organizations employing CDMO strategies have demonstrated a 15% greater resilience during market fluctuations compared to those managing production internally, reinforcing the advantages of outsourcing.

In summary, collaborating with contract pharma companies is a strategic initiative that can lead to quicker launches, improved market responsiveness, and heightened overall efficiency in the pharmaceutical sector.

Risk Mitigation: Manage Supply Chain Disruptions with Strategic Partnerships

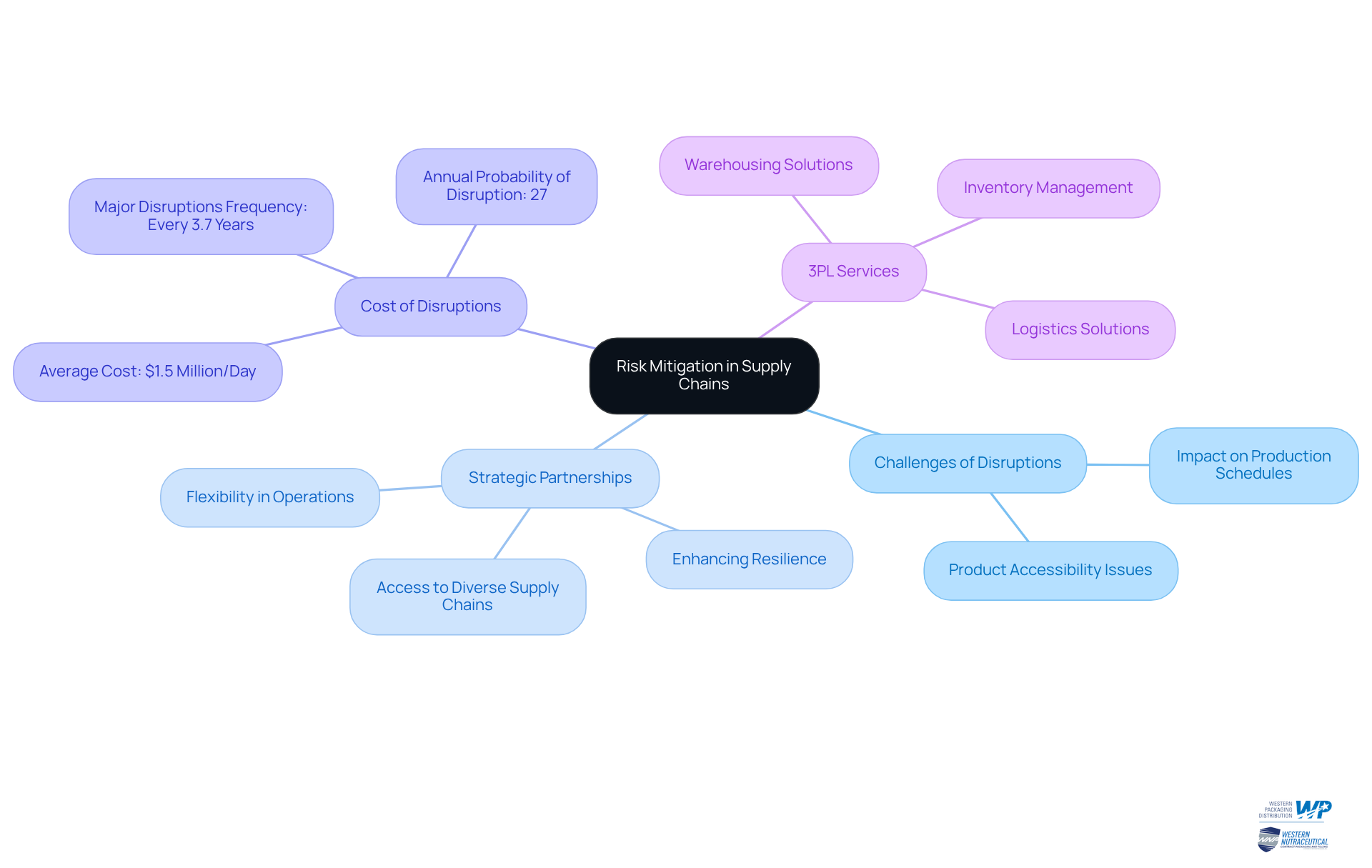

Supply chain disruptions pose significant challenges for drug manufacturers, impacting production schedules and product accessibility. To navigate these challenges effectively, it is essential to establish . Collaborations with contract pharma companies not only enhance resilience against disruptions but also provide access to diverse supply chains and established networks. This enables businesses to swiftly adapt to changes and mitigate the effects of unforeseen events. Implementing this strategic risk management approach is vital for ensuring operational continuity and consistent product availability.

Industry insights reveal that the average cost of a supply chain disruption is approximately $1.5 million per day, with major disruptions occurring roughly every 3.7 years and an annual probability of about 27%. Moreover, strategic partnerships enhance supply chain flexibility, foster innovation, and leverage shared strengths, ultimately leading to improved outcomes during crises.

By utilizing tailored 3PL services from Western Packaging, which include warehousing, inventory management, and logistics solutions, nutraceutical manufacturers can optimize their supply chain efficiency and fortify their defenses against potential disruptions.

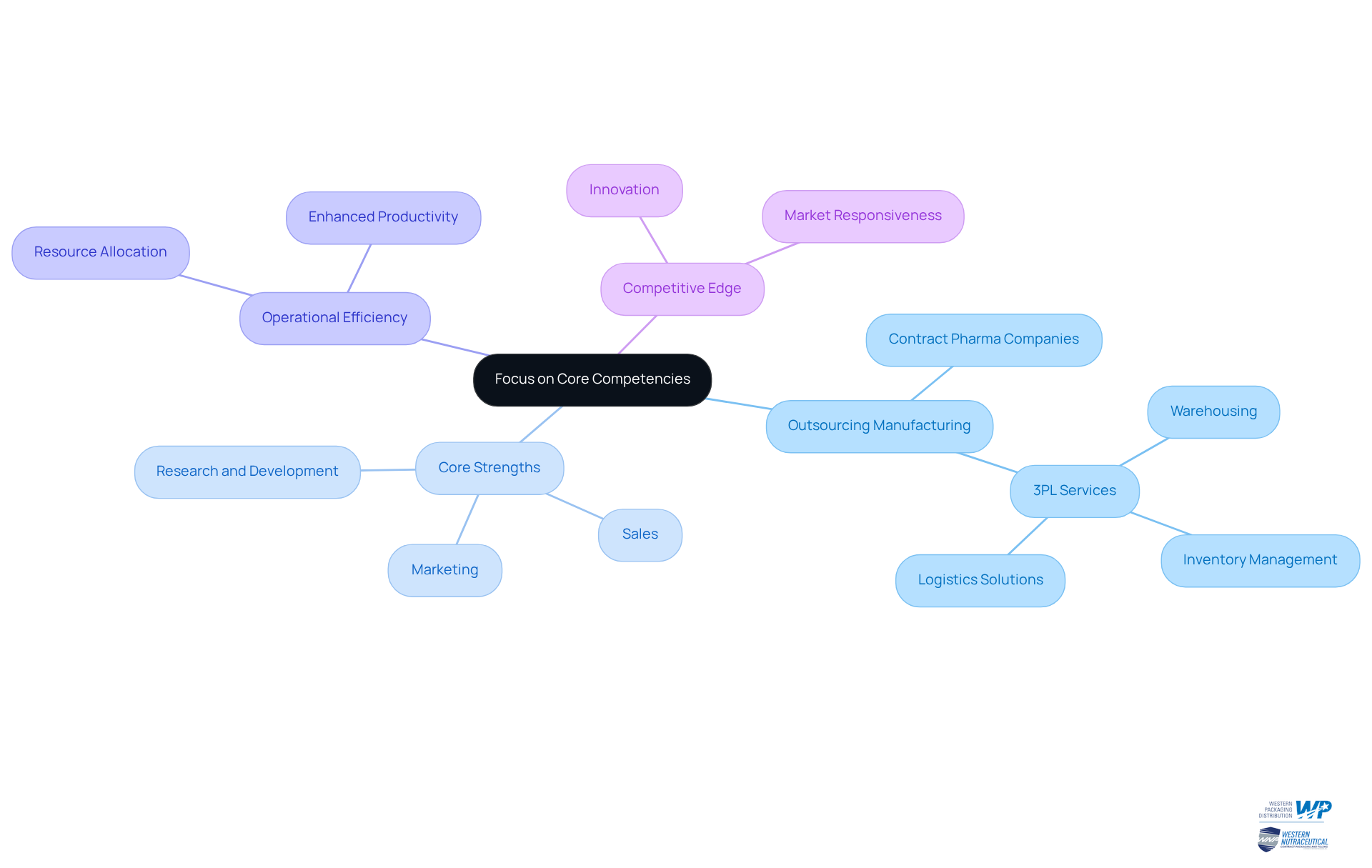

Focus on Core Competencies: Streamline Operations by Outsourcing Manufacturing

Outsourcing production to contract pharma companies empowers businesses to concentrate on their core strengths—research and development, marketing, and sales. By entrusting manufacturing responsibilities to specialized partners, organizations can optimize resource allocation and significantly enhance operational efficiency. This strategic focus not only fosters innovation and growth but also guarantees that products are manufactured to the .

Leveraging the expertise of manufacturers and the tailored 3PL services from Western Packaging—including warehousing, inventory management, and logistics solutions—drug firms can elevate their operations and respond more effectively to market demands.

Outsourcing transcends mere cost-saving; it is a strategic maneuver that enables businesses to boost productivity and maintain a competitive edge in an ever-evolving market.

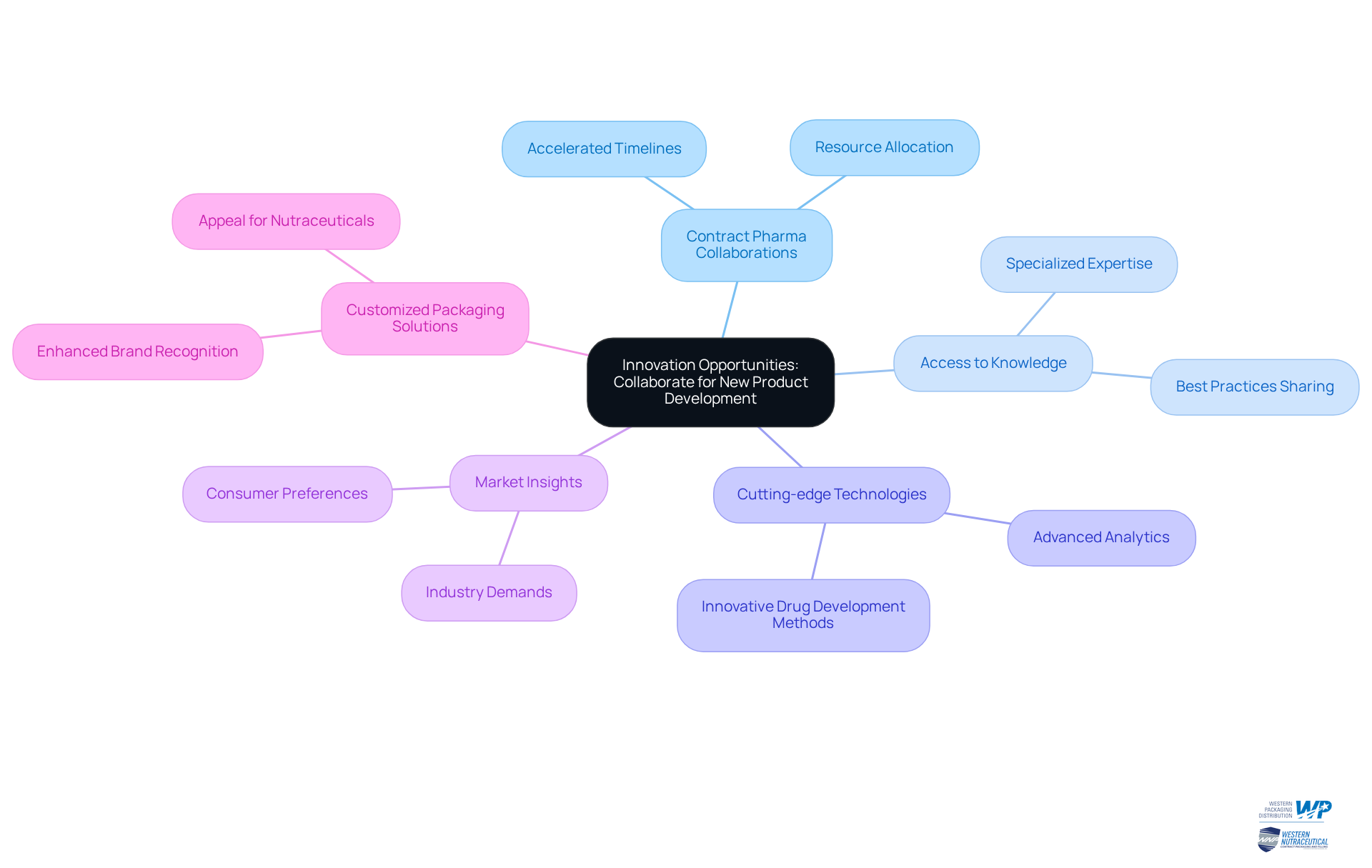

Innovation Opportunities: Collaborate for New Product Development

Collaborating with contract pharma companies unlocks significant opportunities for innovation and the development of new offerings. These partnerships grant access to specialized knowledge, cutting-edge technologies, and invaluable market insights, all crucial for creating new products. By harnessing the strengths of their contract partners, businesses can craft innovative solutions tailored to the evolving needs and preferences of consumers. This not only enhances service offerings but also strengthens market presence, enabling companies to effectively respond to industry demands.

At Western Packaging, our focus lies in customized flexible packaging solutions, including large pouches for protein items and stick packs for nutraceuticals, designed to enhance appeal and brand recognition. Our expertise in innovative packaging design ensures that your products stand out on the shelf, making a lasting impression on consumers. Successful collaborations within contract pharma companies exemplify this dynamic approach. For instance, organizations engaged in strategic partnerships have reported accelerated timelines for product development and improved resource allocation. Such collaborations often facilitate the sharing of best practices and risk mitigation, ultimately cultivating a culture of innovation that propels the industry forward. As the healthcare sector continues to evolve, embracing these collaborative opportunities will be essential for organizations striving to remain competitive and adaptable to market shifts.

Enhanced Quality Control: Ensure Product Integrity with Expert Oversight

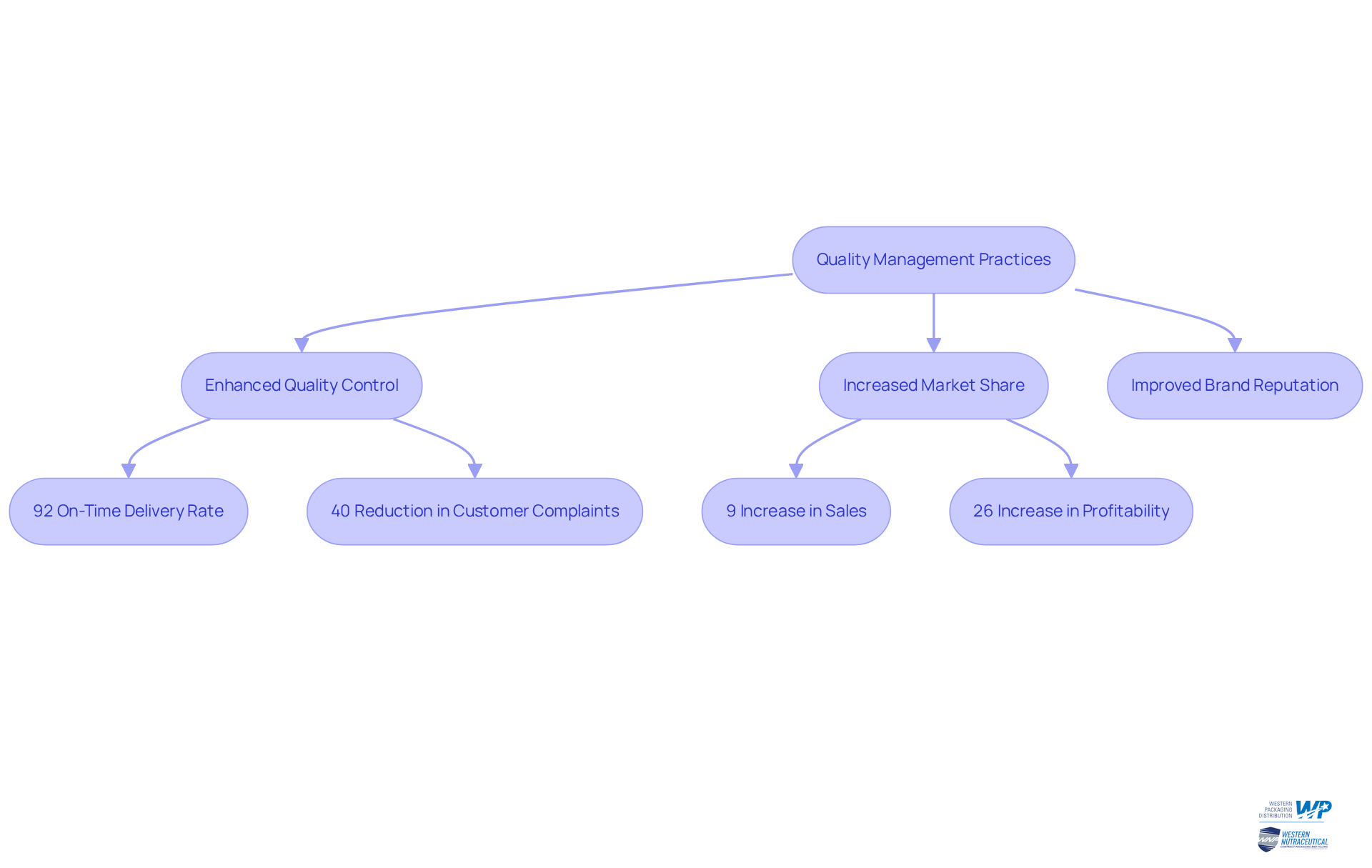

In the pharmaceutical industry, maintaining high-quality standards is paramount. Collaborating with contract pharma companies can significantly bolster quality control measures. These organizations typically establish robust quality management systems (QMS) and employ skilled staff dedicated to preserving item integrity. By leveraging their specialized expertise, businesses can ensure that their offerings adhere to the highest safety and efficacy standards, thereby minimizing the risk of quality-related issues. This approach not only but also fosters long-term relationships with clients.

As noted by quality assurance experts, 'Quality is not an act, it is a habit,' underscoring the necessity of consistent quality practices. Companies that prioritize quality management are more likely to experience increased market share and improved brand reputation, reinforcing the critical role of effective QMS in maintaining product integrity.

For instance, organizations with mature quality management systems achieve an average on-time delivery rate of 92%, compared to just 74% for those without, showcasing the tangible benefits of partnering with contract manufacturers committed to quality excellence. Furthermore, companies investing in quality management practices report a 40% reduction in customer complaints and an average increase of 9% in sales and 26% in profitability, highlighting the financial advantages of prioritizing quality.

Conclusion

Partnering with contract pharmaceutical companies presents a wealth of strategic advantages that can significantly enhance operational efficiency, reduce costs, and drive innovation. By outsourcing manufacturing and leveraging specialized expertise, businesses can concentrate on their core competencies while adeptly navigating complex regulatory landscapes and responding swiftly to market demands.

The article underscores key benefits such as:

- Cost savings through reduced operational expenses

- Improved regulatory compliance

- Access to advanced technologies

- Scalability in production

- Accelerated speed to market

Each of these factors plays a pivotal role in fostering a more resilient and competitive pharmaceutical landscape, enabling companies to adapt to changes and effectively seize new opportunities.

Ultimately, embracing partnerships with contract pharma companies transcends mere tactical decision-making; it emerges as a vital strategy for long-term success in the pharmaceutical industry. Organizations are strongly encouraged to explore these collaborations, as they not only streamline operations but also pave the way for innovative solutions that meet evolving consumer needs. By investing in these strategic alliances, businesses can position themselves at the forefront of the industry, ensuring sustainability and growth in an ever-changing market.

Frequently Asked Questions

What integrated packaging solutions does Western Packaging offer?

Western Packaging offers a comprehensive suite of integrated packaging solutions that combine design, filling, and third-party logistics (3PL) services, accommodating a wide range of items from powders to gummies and soft-gels.

How do integrated packaging solutions benefit businesses?

These solutions streamline the supply chain, enhance operational efficiency, reduce lead times, and improve delivery performance, helping businesses capture attention in competitive markets.

What role does packaging play in consumer purchasing decisions?

Packaging serves as the first impression of a product and influences purchasing decisions for 70% of consumers, highlighting its importance in branding.

How can integrated packaging solutions impact supply chain agility?

Organizations that adopt integrated packaging solutions often experience improved agility and responsiveness in their supply chains, enabling them to better meet customer demands and reduce operational costs.

What is the significance of sustainability in packaging solutions?

A commitment to sustainability in packaging aligns with consumer preferences for eco-friendly practices, enhancing the attractiveness of integrated packaging solutions.

What are the cost benefits of collaborating with contract pharma companies?

Collaborating with contract pharma companies can lead to significant cost reductions, allowing businesses to avoid substantial capital expenses associated with establishing and operating production facilities.

How much can businesses save by outsourcing manufacturing?

Businesses that adopt outsourcing report operational cost reductions averaging between 20% and 30%, showcasing the financial benefits of these partnerships.

What are the compliance challenges in the pharmaceutical industry?

The pharmaceutical industry faces stringent regulations, and companies often struggle with compliance, which can lead to severe penalties and costly recalls.

How do contract pharma companies assist with regulatory compliance?

Contract pharma companies provide essential expertise in navigating complex regulations, helping companies ensure their products meet safety and efficacy standards and reducing the risk of non-compliance.

Why is ensuring compliance important for businesses?

Ensuring compliance safeguards public health, fosters trust among healthcare providers and patients, and allows organizations to focus on innovation and growth while adhering to necessary regulations.