Overview

The article highlights the significant benefits of contract pharmaceutical manufacturing for nutraceuticals, such as:

- Cost efficiency

- Scalability

- Regulatory compliance

- Access to specialized expertise

These factors collectively enhance operational efficiency and market competitiveness. Such advantages are vital, as they empower nutraceutical companies to concentrate on innovation and their core competencies. This focus enables them to effectively respond to evolving consumer demands while maintaining high-quality standards in a rapidly growing industry.

Introduction

The nutraceutical industry is witnessing remarkable growth, propelled by a significant increase in consumer demand for health supplements and personalized nutrition. As companies endeavor to sustain a competitive advantage, the benefits of contract pharmaceutical manufacturing become increasingly evident. This article delves into seven essential advantages of outsourcing production, encompassing:

- Cost efficiency

- Regulatory compliance

- Enhanced innovation potential

How can businesses capitalize on these opportunities to not only endure but excel in a swiftly changing market?

Western Packaging: Tailored Flexible Packaging Solutions for Enhanced Product Appeal

Western Packaging specializes in innovative that significantly enhance the visual appeal of health-related products. By leveraging creative designs and premium materials, brands can elevate their shelf presence, thereby attracting a broader consumer base. Customized packaging not only embodies the brand's identity but also effectively communicates its benefits, making it an essential element of marketing strategies within the health supplement sector.

Current trends indicate that:

- 68% of consumers express confidence in health-related products with attractive packaging, underscoring the necessity for brands to invest in impactful design.

- 72% of American shoppers believe that product presentation affects their purchasing decisions, highlighting the pivotal role of packaging in driving sales.

As the health supplement industry continues to grow, projected to reach USD 16.1 billion by 2035, the demand for versatile packaging solutions that blend aesthetics with functionality becomes increasingly critical. By prioritizing these aspects, Western Packaging empowers brands to not only distinguish themselves in a competitive market but also cultivate consumer loyalty and trust.

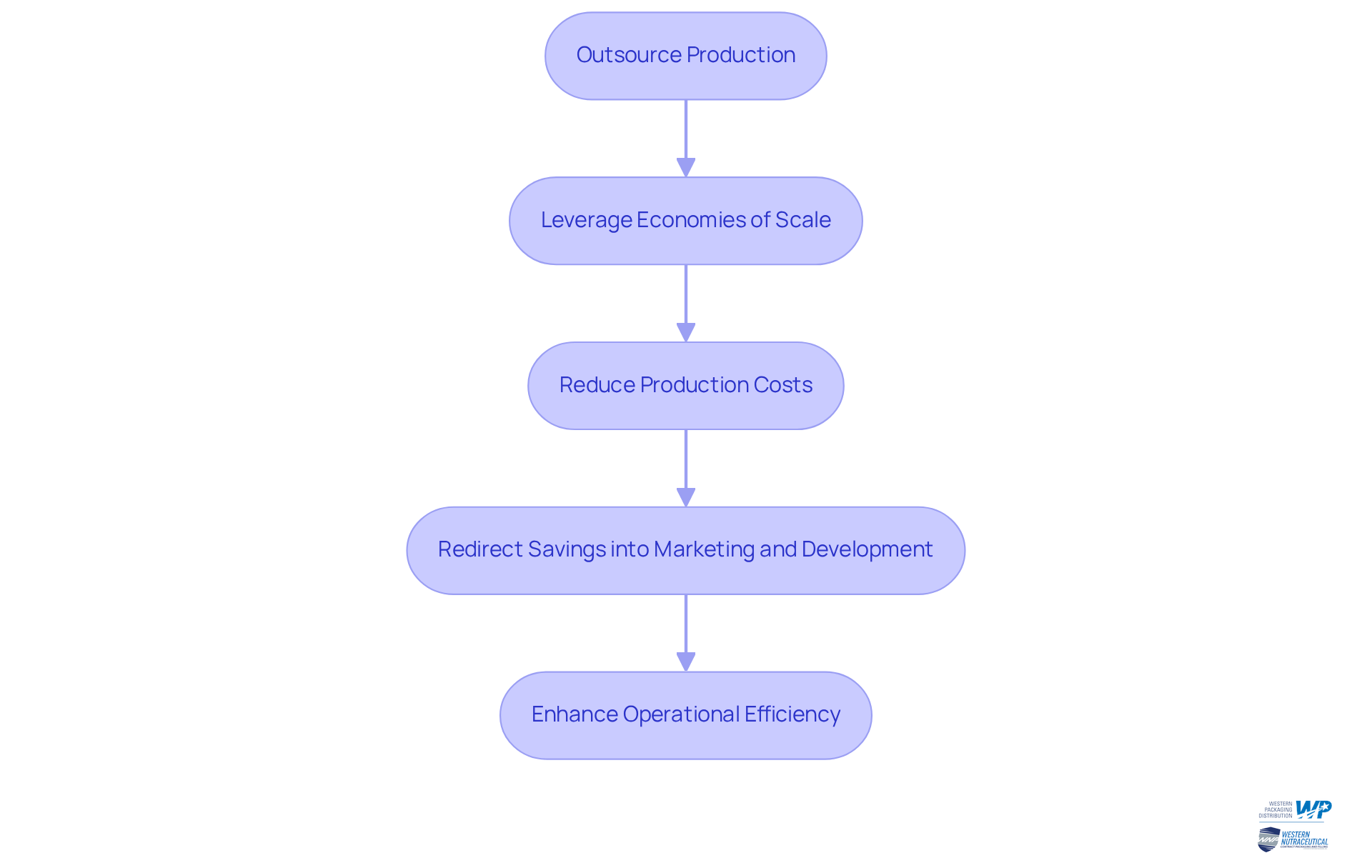

Cost Efficiency: Reduce Production Costs with Contract Manufacturing

Contract manufacturing offers nutraceutical firms a strategic pathway to significantly reduce production expenses by eliminating the need for substantial capital investments in facilities and equipment. By outsourcing production to specialized manufacturers, businesses can leverage economies of scale, which are vital in a market projected to reach USD 585.2 billion by 2035, growing from an estimated USD 187.6 billion in 2025 at a CAGR of 12.1%. This approach not only but also minimizes overhead expenses, enabling businesses to allocate resources more effectively.

For instance, firms can redirect savings into marketing and product development, fostering innovation and driving growth. Industry leaders emphasize that efficient outsourcing can lead to substantial cost reductions while enhancing operational efficiency, allowing firms to focus on their core strengths.

As the demand for dietary supplements continues to rise, driven by an increased consumer focus on preventive healthcare and the growing need for personalized medicine, the financial flexibility gained through contract manufacturing becomes crucial for maintaining a competitive edge in the health product sector.

Larry Elder notes that outsourcing and the globalization of manufacturing empower firms to reduce expenses, benefiting consumers with more affordable goods and services, further underscoring the importance of this strategy.

Regulatory Compliance: Ensure Adherence to Industry Standards

Navigating the intricate landscape of regulatory compliance is paramount for nutraceutical manufacturers. In contract pharmaceutical manufacturing, companies typically possess robust systems designed to ensure adherence to Good Manufacturing Practices (GMP) and other industry standards. By partnering with manufacturers in contract pharmaceutical manufacturing, businesses can significantly diminish the risks linked to regulatory violations, thereby ensuring their offerings consistently meet safety and quality standards.

GMP plays a pivotal role in maintaining item integrity, as it helps prevent contamination and ensures accurate labeling and dosage—crucial elements for consumer safety and transparency. For instance, companies like Vitaquest have effectively incorporated GMP principles into their operations, leading to improvements in quality and reliability.

Furthermore, the advantages of GMP certification extend beyond mere compliance; it enhances brand credibility and market access, offering a competitive edge in the health supplement industry. Compliance officers observe that adherence to GMP is not just a regulatory requirement but a strategic necessity that safeguards brands and positions products as exemplars of quality in a competitive market. This commitment to quality is increasingly essential as consumer expectations evolve and regulatory scrutiny intensifies, making a cornerstone of successful supplement manufacturing. Additionally, it is vital to recognize that a single product recall can tarnish a business's hard-earned reputation, underscoring the importance of GMP compliance in preserving brand integrity.

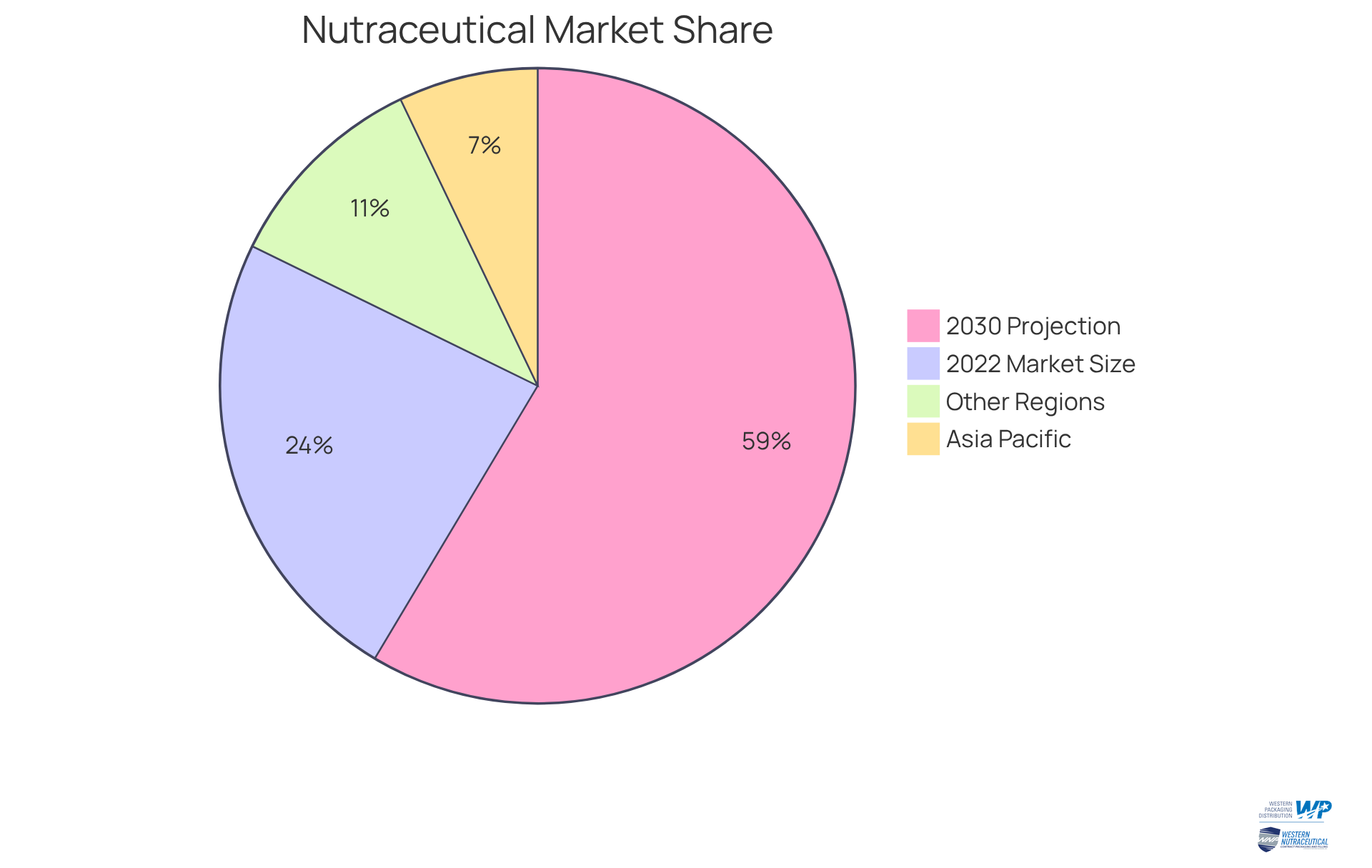

Scalability: Adapt Production Levels to Market Demand

Contract manufacturing offers significant scalability, allowing supplement companies to adjust production levels effectively in response to consumer demand. This adaptability is essential for brands striving to remain competitive amid rapidly changing trends, seasonal fluctuations, and unexpected demand surges. For example, the global nutraceutical contract manufacturing services sector was valued at approximately USD 133.34 billion in 2022 and is projected to grow to USD 329.84 billion by 2030, indicating a robust demand for flexible production capabilities. Notably, the Asia Pacific region represented over 40% of the market share in 2022, underscoring its importance in the global landscape.

Industry experts underscore the necessity of this flexibility. As one expert articulated, "A manager's role is to uncover an offering that is valuable, usable, and feasible," emphasizing the need for manufacturers to align production with consumer needs. Furthermore, Peter Drucker asserted that the goal of marketing is to know and understand the customer so well that the product or service fits him and sells itself, further highlighting the critical nature of adaptability in production.

Successful nutraceutical brands have effectively leveraged contract manufacturers to scale their operations. For instance, companies such as Herbalife and Glanbia have adjusted their production levels through contract pharmaceutical manufacturing to meet variable demand, ensuring they can capitalize on new trends without the burden of excess capacity. Other prominent firms in the industry, including Ashland and Biotrex Nutraceuticals, also implement strategic initiatives to align their production capabilities with market demands.

This strategic approach not only but also positions brands to respond swiftly to market dynamics, ultimately driving growth and customer satisfaction.

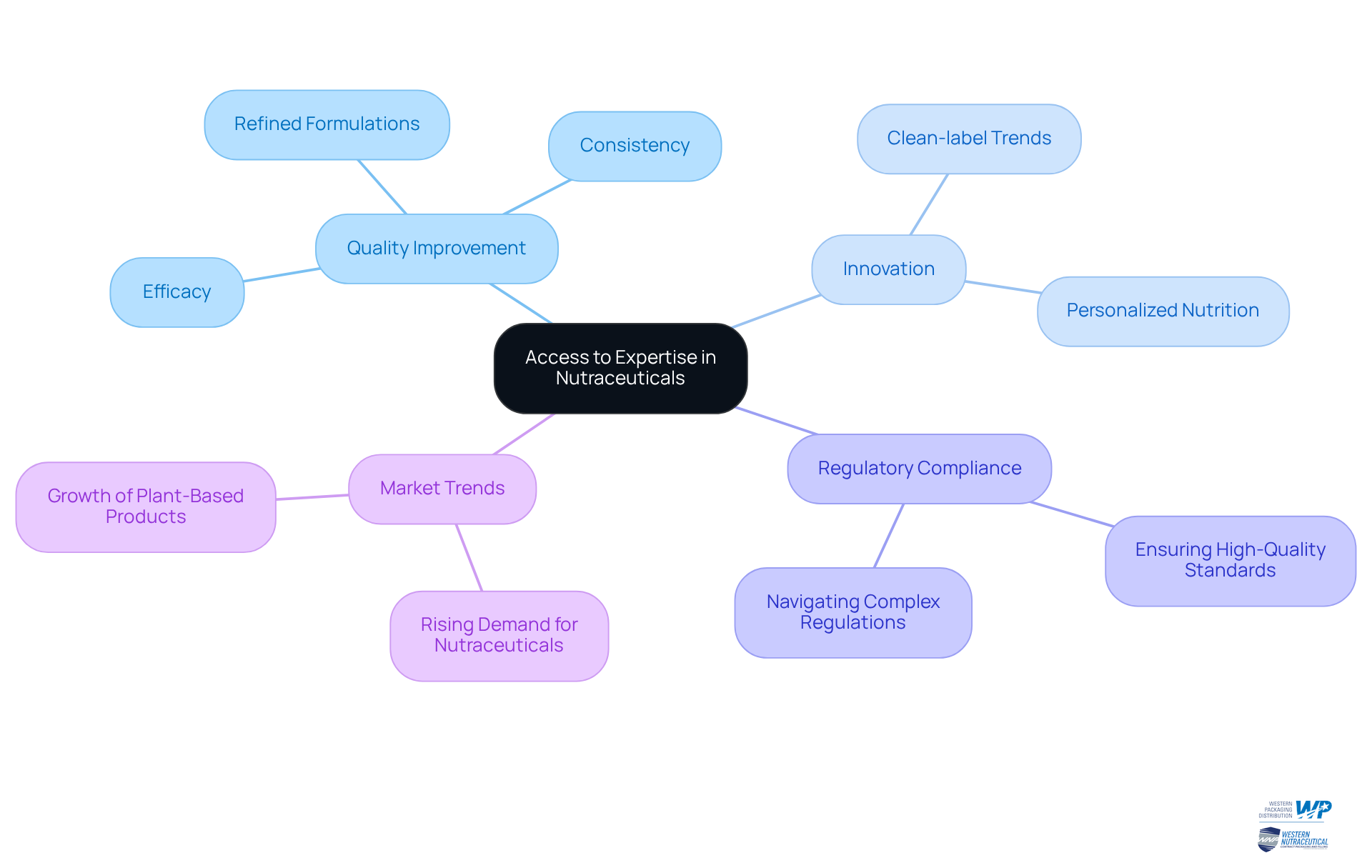

Access to Expertise: Leverage Specialized Knowledge for Quality Improvement

Contract manufacturers offer specialized expertise and advanced technologies that significantly enhance quality in the nutraceutical sector. By collaborating with these experts, companies can refine their formulations to meet consumer expectations and adhere to stringent regulatory standards. This partnership not only elevates quality but also , enabling brands to remain competitive in a rapidly evolving environment.

For instance, the dietary supplements sector, currently at the forefront of the industry, is witnessing a surge in demand for clean-label and plant-based offerings. This trend compels manufacturers to adopt advanced production methods. As a result, companies that leverage contract manufacturing expertise report substantial improvements in consistency and efficacy, ultimately cultivating greater consumer trust and satisfaction.

The increasing trend towards personalized nutrition further underscores the necessity for specialized knowledge, as brands strive to develop tailored solutions that resonate with health-conscious consumers. According to industry reports, the global nutraceutical contract manufacturing services sector is projected to reach USD 386.6 billion by 2033, reflecting a CAGR of 8.7% from 2025 to 2033. This growth underscores the rising dependence on contract manufacturers to address evolving consumer demands.

Furthermore, industry leaders stress that collaboration with contract manufacturers is crucial for navigating complex regulatory requirements, ensuring compliance, and upholding high-quality standards. Companies like NutraLab have effectively harnessed contract manufacturing to enhance their offerings, showcasing the tangible benefits of this strategic partnership.

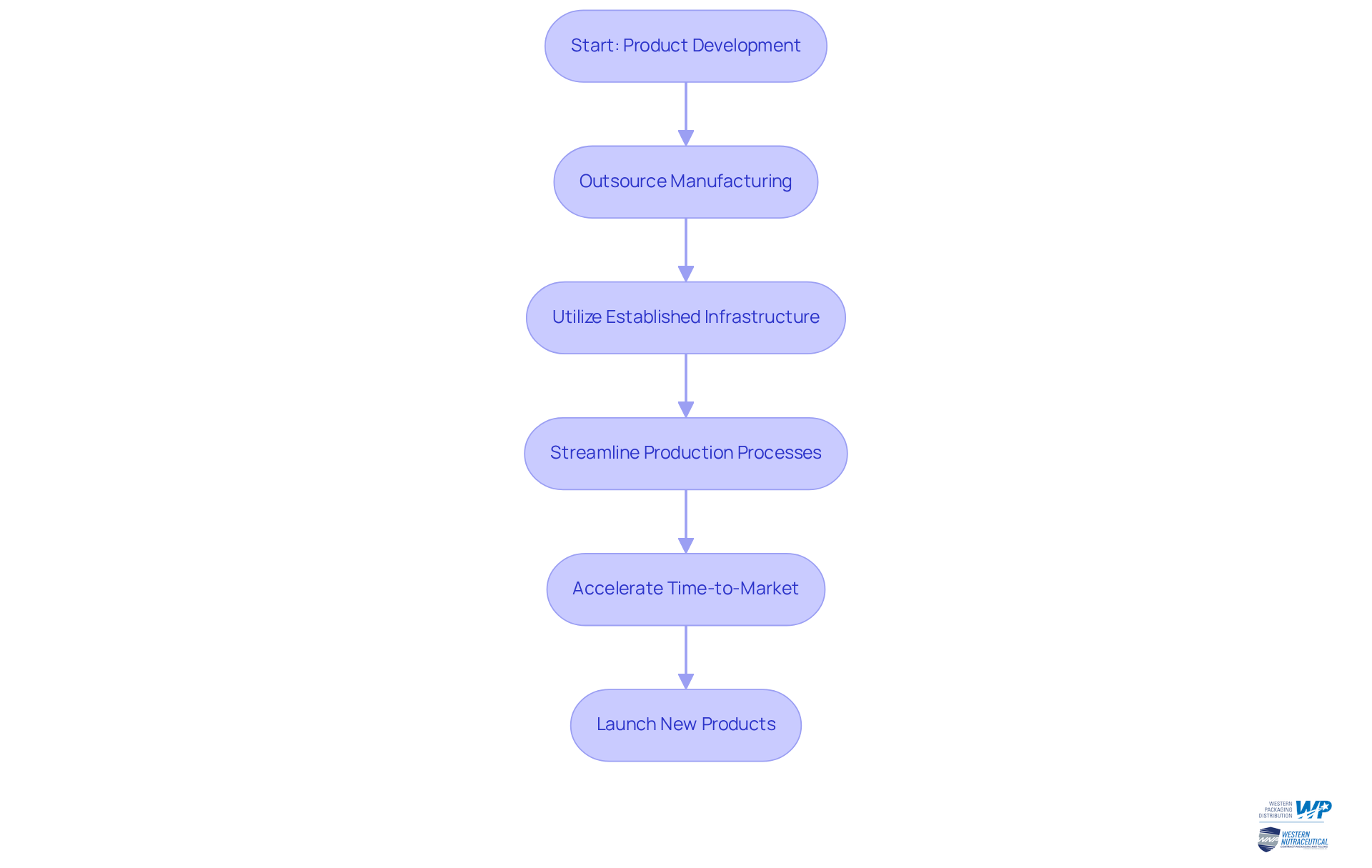

Speed to Market: Accelerate Product Launches with Contract Manufacturing

In today's fast-paced market, the ability to swiftly introduce offerings is essential for success. Contract pharmaceutical manufacturing plays a pivotal role in reducing time-to-market by streamlining production processes and utilizing established infrastructure. This efficiency empowers to launch new products at an accelerated pace, enabling them to capitalize on emerging trends and rapidly respond to consumer demands.

For instance, companies that have embraced outsourcing have reported significant improvements in their product launch timelines, with some enhancing their production capabilities to meet the rising demand for clean-label and plant-based products.

By leveraging the expertise and resources of contract pharmaceutical manufacturing, businesses can improve their market presence and secure a competitive edge in an increasingly dynamic industry. As the dietary supplement sector continues to evolve, the strategic use of contract pharmaceutical manufacturing will remain a key factor in driving innovation and growth.

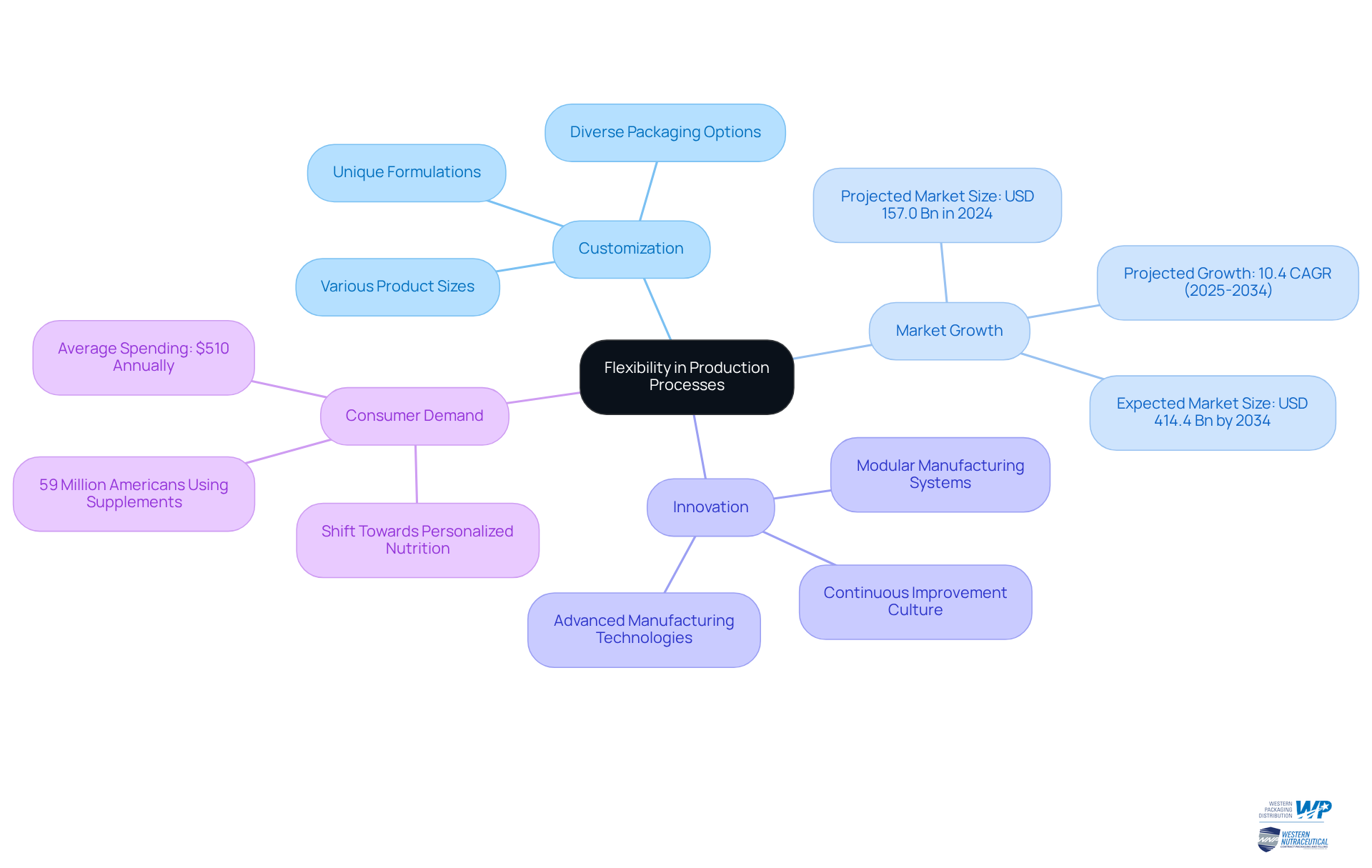

Flexibility: Customize Production Processes to Fit Business Needs

Contract pharmaceutical manufacturing offers essential flexibility to tailor production processes that meet specific business requirements. This adaptability empowers nutraceutical firms to create unique formulations, , and various product sizes that resonate with their target audience. As the nutraceutical sector continues to expand, with consumer preferences shifting towards personalized nutrition—evidenced by approximately 59 million Americans regularly using vitamins or supplements and spending an average of $510 annually—brands providing tailored solutions can significantly enhance their competitive advantage.

Industry leaders emphasize that adaptable production methods not only foster innovation but also enable organizations to respond swiftly to changing demand conditions. For instance, the implementation of modular manufacturing systems allows brands to efficiently adjust production volumes and formulations, ensuring alignment with consumer trends.

Furthermore, the market for contract pharmaceutical manufacturing services in the nutraceutical sector is projected to grow at a 10.4% CAGR during the forecast period from 2025 to 2034, underscoring the urgency for brands to embrace flexibility in their production processes. By doing so, health product firms can better address evolving consumer demands and strengthen their competitive stance.

As Ralph Marston aptly stated, 'Excellence is not a skill; it's an attitude,' highlighting that a commitment to excellence in flexibility can lead to enhanced responsiveness to changes.

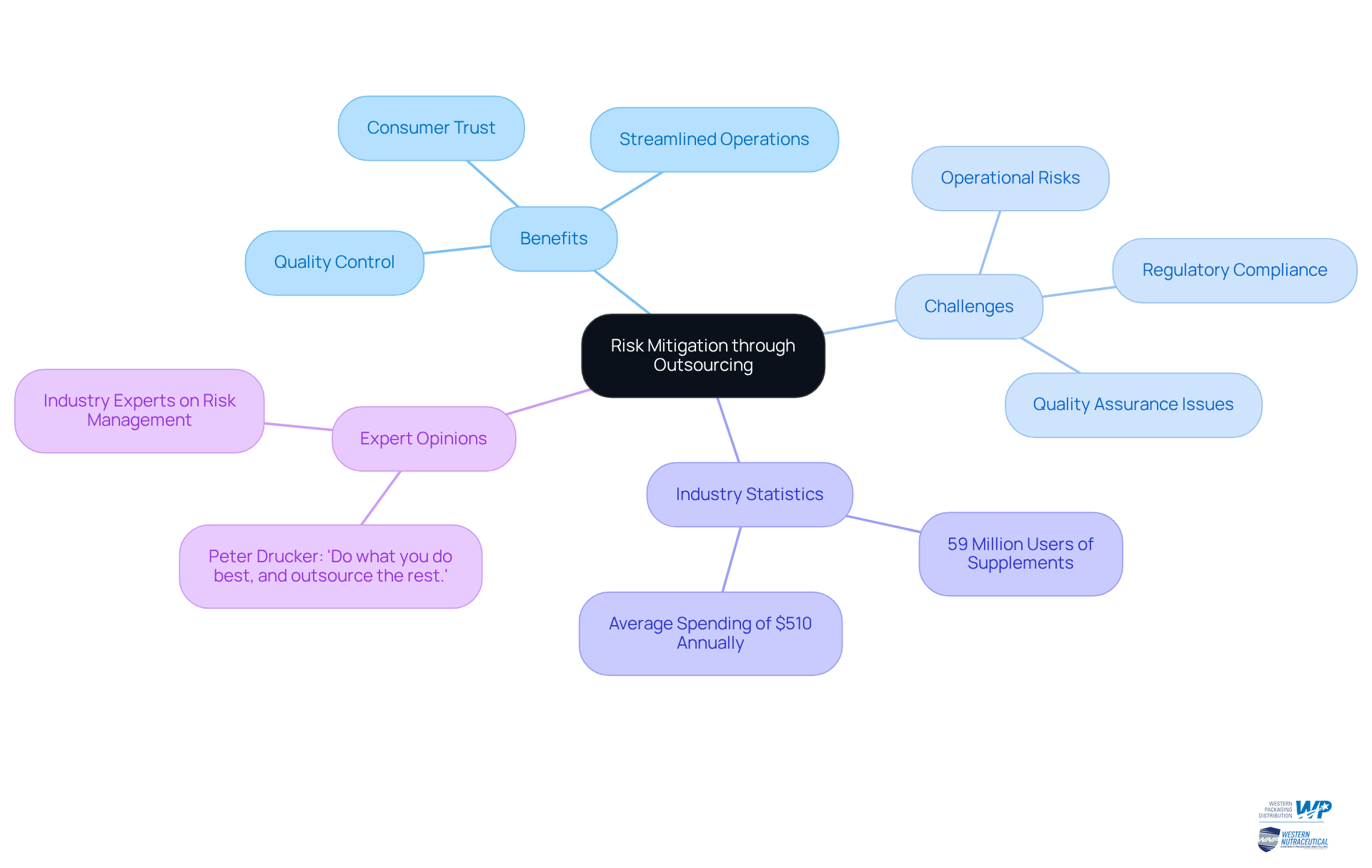

Risk Mitigation: Manage Operational Risks through Outsourcing

Outsourcing production to contract manufacturers offers businesses in the health supplement sector a strategic advantage in minimizing operational risks. By leveraging the expertise and established processes of these specialized manufacturers, brands can effectively mitigate risks associated with production delays, quality control challenges, and regulatory compliance. With approximately 59 million Americans regularly using vitamins or supplements, the critical need for in a competitive market is underscored. Maintaining high-quality standards is essential, as many supplement firms face substantial operational risks stemming from quality control issues.

Industry experts assert that outsourcing can streamline operations and enhance risk management. As Peter Drucker aptly noted, "Do what you do best, and outsource the rest." This proactive strategy not only safeguards the brand's reputation but also fosters consumer trust, which is vital in the health supplement sector.

Moreover, there are successful examples where dietary supplement firms have adeptly managed operational risks through outsourcing. For instance, a leading brand recently partnered with a GMP-certified manufacturer to bolster its production capabilities, resulting in a significant reduction in lead times and improved consistency of products. Such collaborations exemplify how outsourcing can convert operational challenges into growth and efficiency opportunities, ultimately benefiting both manufacturers and consumers alike.

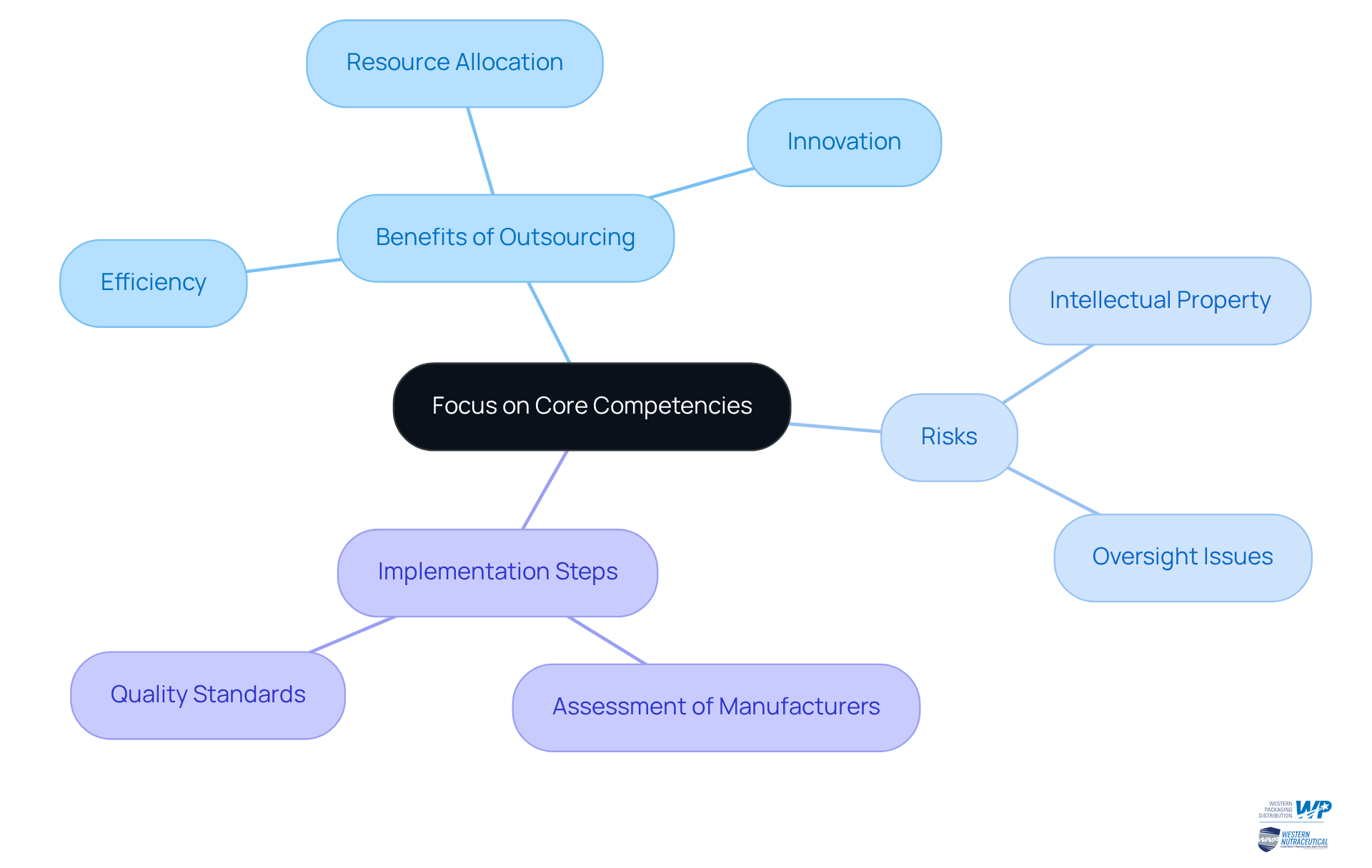

Focus on Core Competencies: Enhance Business Efficiency by Outsourcing

By outsourcing manufacturing procedures, health supplement firms can focus on their core competencies, such as development and marketing. This strategic approach enables businesses to allocate resources more effectively, enhancing overall efficiency and driving innovation.

With the projected to reach USD 182.47 billion in 2024 and anticipated to grow at a CAGR of 8.7% through 2033—driven by the rising demand for personalized nutrition and clean-label products—companies can significantly strengthen their competitive positioning and better serve their clients.

Business leaders underscore the importance of this focus; as Kevin E. Kruse states, "Just be really good at one thing. The best, actually. And let others handle what you’re not good at." Additionally, Gita Gopinath advises, "Focus on what you’re really good at and get help for everything else," emphasizing the value of specialization.

However, organizations must also consider potential risks associated with outsourcing, such as intellectual property concerns and diminished oversight of production processes.

To initiate the outsourcing process effectively, supplement firms should conduct a thorough assessment of potential contract manufacturers, ensuring alignment with their quality standards and business objectives.

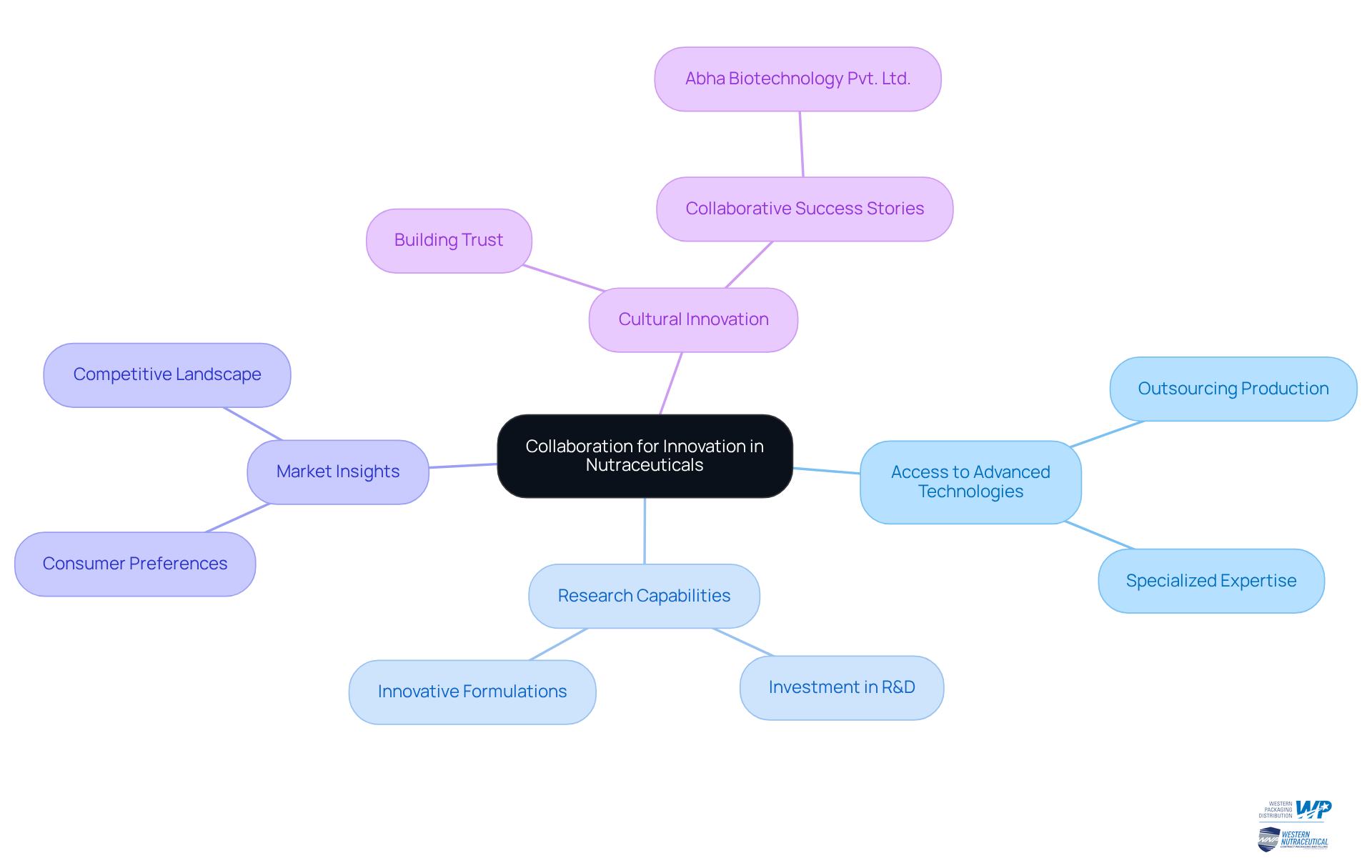

Innovation Potential: Collaborate for New Product Development Opportunities

Collaboration with contract pharmaceutical manufacturing significantly enhances innovation in the nutraceuticals sector. These partnerships provide access to advanced technologies, extensive research capabilities, and valuable market insights, enabling nutraceutical firms to develop innovative offerings that align with shifting consumer preferences. By cultivating a culture of innovation, brands can effectively distinguish themselves in a competitive landscape, driving long-term growth and success.

Industry leaders underscore the critical role of collaboration in this endeavor. For example, outsourcing production allows companies to concentrate on their core competencies while harnessing the specialized expertise of contract pharmaceutical manufacturing. This synergy not only optimizes operations but also of innovative offerings tailored to specific consumer needs.

Successful collaborations illustrate this trend. Companies like Abha Biotechnology Pvt. Ltd. have positioned themselves as leading suppliers of contract manufacturing services, producing high-quality formulations that meet the rising demand for personalized nutrition. As noted by Abha Biotechnology, "Our state-of-the-art facility is creating high-quality formulations, such as plant protein, pre-workout energy, and joint care items." Such partnerships enable nutraceutical brands to expand their product ranges and enhance their market presence, ultimately benefiting both consumers and brand owners alike.

The global market for contract pharmaceutical manufacturing services in nutraceuticals was valued at USD 133.34 billion in 2022 and is projected to grow at a CAGR of 12.04% from 2023 to 2030. This growth highlights the increasing significance of collaboration in the nutraceuticals industry. As the market continues to evolve, the integration of collaboration and innovation will be essential for companies striving to excel in this dynamic environment.

Conclusion

The advantages of contract pharmaceutical manufacturing for nutraceuticals are multifaceted and crucial for businesses aiming to thrive in a competitive market. By outsourcing production, companies can enhance their operational efficiency while focusing on core competencies such as product development and marketing. This strategic approach not only allows for cost savings but also improves regulatory compliance and provides the flexibility to adapt to market demands, ultimately fostering innovation and growth.

Key insights from the article highlight the importance of:

- Tailored flexible packaging

- Cost efficiency

- Regulatory adherence

- Access to specialized expertise

Each of these elements plays a vital role in shaping a brand's success in the nutraceutical sector. As the industry continues to evolve, the ability to scale production, mitigate risks, and accelerate time-to-market becomes increasingly significant for companies looking to meet consumer expectations and capitalize on emerging trends.

In conclusion, embracing contract pharmaceutical manufacturing is not merely a tactical decision; it is a strategic imperative for nutraceutical firms aiming to secure a competitive edge. As the market for dietary supplements expands, companies must leverage these benefits to innovate, improve quality, and ultimately deliver products that resonate with health-conscious consumers. By prioritizing collaboration and flexibility in production processes, businesses can navigate the complexities of the industry and position themselves for long-term success.

Frequently Asked Questions

What does Western Packaging specialize in?

Western Packaging specializes in innovative flexible packaging solutions that enhance the visual appeal of health-related products.

How does tailored packaging benefit health-related brands?

Tailored packaging elevates shelf presence, attracts a broader consumer base, embodies the brand's identity, and effectively communicates product benefits, making it essential for marketing strategies in the health supplement sector.

What percentage of consumers trust health-related products with attractive packaging?

68% of consumers express confidence in health-related products with attractive packaging.

How does product presentation influence purchasing decisions among American shoppers?

72% of American shoppers believe that product presentation affects their purchasing decisions, highlighting the importance of packaging in driving sales.

What is the projected growth of the health supplement industry by 2035?

The health supplement industry is projected to reach USD 16.1 billion by 2035.

How can contract manufacturing help nutraceutical firms reduce production costs?

Contract manufacturing allows firms to eliminate substantial capital investments in facilities and equipment, leverage economies of scale, lower labor costs, and minimize overhead expenses, enabling better resource allocation.

What market growth is projected for the nutraceutical industry by 2035?

The nutraceutical market is projected to grow from an estimated USD 187.6 billion in 2025 to USD 585.2 billion by 2035, at a CAGR of 12.1%.

What role does regulatory compliance play in nutraceutical manufacturing?

Regulatory compliance ensures adherence to Good Manufacturing Practices (GMP) and other industry standards, minimizing risks linked to regulatory violations and ensuring safety and quality of products.

Why is GMP important for nutraceutical manufacturers?

GMP helps maintain item integrity, prevents contamination, ensures accurate labeling and dosage, enhances brand credibility, and provides a competitive edge in the health supplement industry.

What are the consequences of failing to comply with GMP?

Non-compliance with GMP can lead to regulatory violations, product recalls, and damage to a business's reputation, making compliance essential for preserving brand integrity.