Overview

The article underscores the critical importance of mastering assembly and fulfillment processes for achieving success in ecommerce. Efficient order processing, inventory management, and delivery strategies are essential components of this mastery. By detailing how effective inventory systems and streamlined operations can significantly enhance customer satisfaction, reduce costs, and maintain a competitive edge, the article illustrates the necessity of these practices in the rapidly evolving ecommerce landscape. Emphasizing reliability in these areas is not just beneficial; it is imperative for any business looking to thrive.

Introduction

The rapid growth of eCommerce has fundamentally transformed how businesses operate, rendering effective assembly and fulfillment more critical than ever. As consumers increasingly demand faster delivery and seamless shopping experiences, companies must refine their processes to remain competitive. This article explores essential strategies for mastering assembly and fulfillment, demonstrating how businesses can optimize their operations to enhance customer satisfaction while reducing costs.

What are the key challenges that hinder these processes? How can businesses overcome them to thrive in the ever-evolving eCommerce landscape? The answers lie in a commitment to excellence and continuous improvement.

Understand the Basics of Ecommerce Assembly and Fulfillment

The processes of assembly and fulfillment for ecommerce encompass the critical steps involved in preparing and supplying products to individuals who purchase online. The process of assembly and fulfillment for ecommerce entails the meticulous collection of various components or products, priming them for shipment, while fulfillment encompasses the entire processing cycle—from receiving the order to delivering it to the customer. Understanding these elements is essential for optimizing assembly and fulfillment for ecommerce operations.

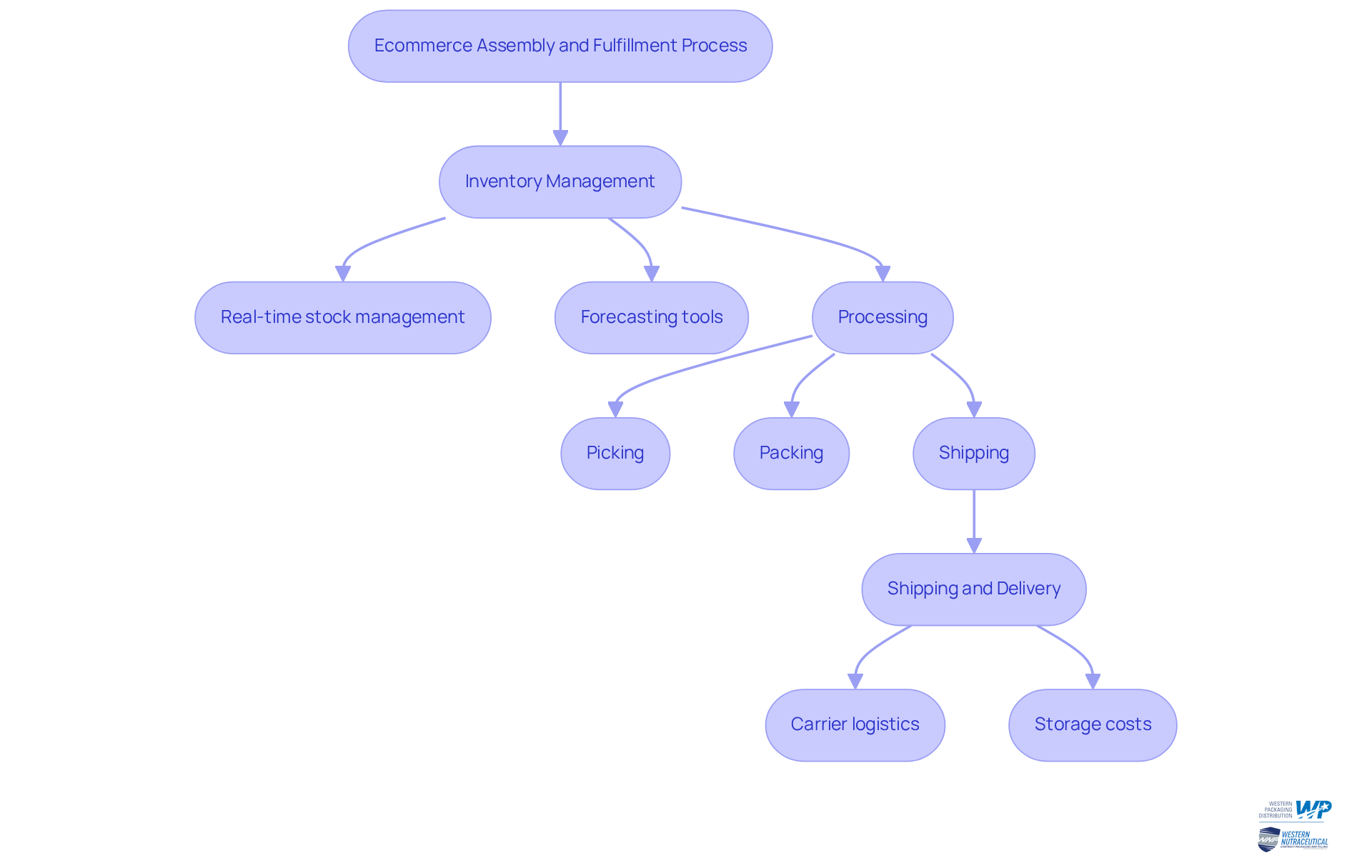

- Inventory Management: Effective inventory management is vital for ensuring product availability when orders are placed. In 2025, 67% of companies plan to adopt real-time stock management systems to enhance accuracy and meet increasing consumer demands. Furthermore, 73% of retailers report that utilizing forecasting tools improves stock precision, thereby reducing the likelihood of overstocking or stockouts. Companies employing automated inventory management systems can reduce stockouts by 30%, significantly enhancing operational efficiency.

- Processing: This stage encompasses all steps from receipt to shipment, including picking, packing, and shipping. Efficient order processing can yield a 30% improvement in order completion rates, minimizing delivery delays and boosting client satisfaction.

- Shipping and Delivery: The logistics of transporting products to clients involve various carriers and methods. Effective shipping strategies are essential, as storage costs—including warehousing—account for 20% of total stock expenses. Well-organized stock systems can decrease processing times by 23%, thereby improving delivery speed and client satisfaction.

With the projected to rise to 24.5% in 2025, and returns costing US retailers nearly $890 billion in 2024—representing 17% of total retail sales—businesses must prioritize efficient inventory management and delivery strategies. This focus will not only enhance client satisfaction but also reduce costs associated with returns. Taking action now to refine these processes is not just beneficial; it is essential for sustaining competitive advantage in the evolving eCommerce landscape.

Explore Kitting and Assembly Processes for Efficient Fulfillment

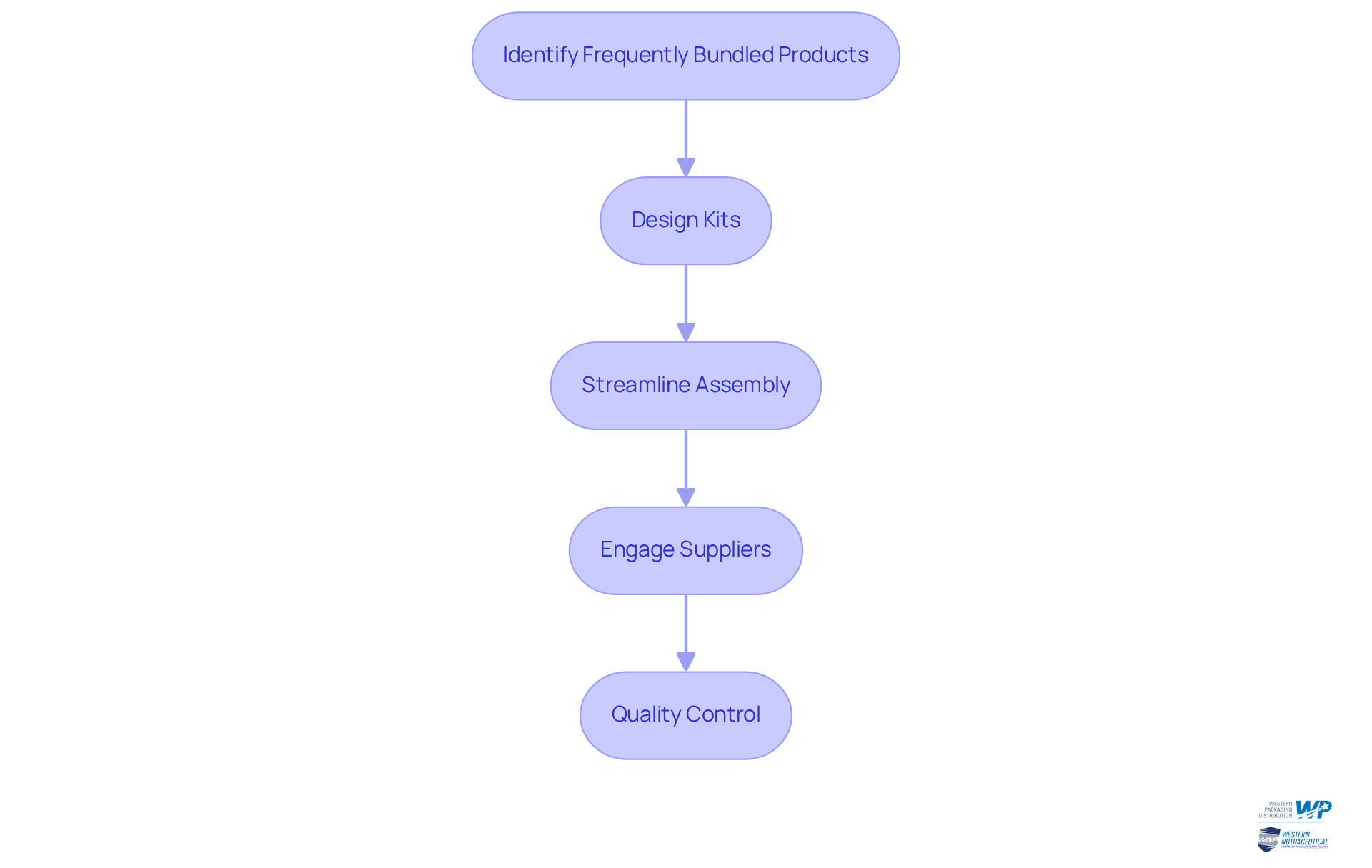

Kitting is the process of assembling related products together to create a single package or kit, which significantly improves assembly and fulfillment for ecommerce. To effectively implement kitting and assembly, consider the following steps:

- Identify Frequently Bundled Products: Analyze sales data to pinpoint products that are commonly purchased together. This insight aids in creating kits that align with consumer preferences.

- Design Kits: Develop attractive kits that provide value, such as combining complementary items or offering discounts for bundled purchases. This strategy can increase average order value and improve client satisfaction.

- : Optimize your warehouse layout to facilitate quick assembly of kits, ensuring that all components are easily accessible. Efficient organization reduces assembly time and minimizes errors.

- Engage Suppliers: Collaborate with suppliers to ensure the timely availability of kit components, which is essential for maintaining smooth operations and fulfilling client demand.

- Quality Control: Establish rigorous checks to confirm that all items in a kit are included and correctly packaged before shipping. This step is essential for upholding high standards and ensuring client satisfaction.

By leveraging kitting in the assembly and fulfillment for ecommerce, businesses can significantly reduce picking time, minimize errors, and enhance overall customer satisfaction, leading to improved operational efficiency. Additionally, kitting helps reduce the number of SKUs needed to stock, optimizing inventory management. Modern kitting software solutions can further streamline these processes, providing real-time tracking and enhancing overall productivity. As John Ponte notes, implementing kitting gives manufacturers a competitive edge through lower production costs and quicker assembly times.

Choose the Right Fulfillment Partner for Your Business Needs

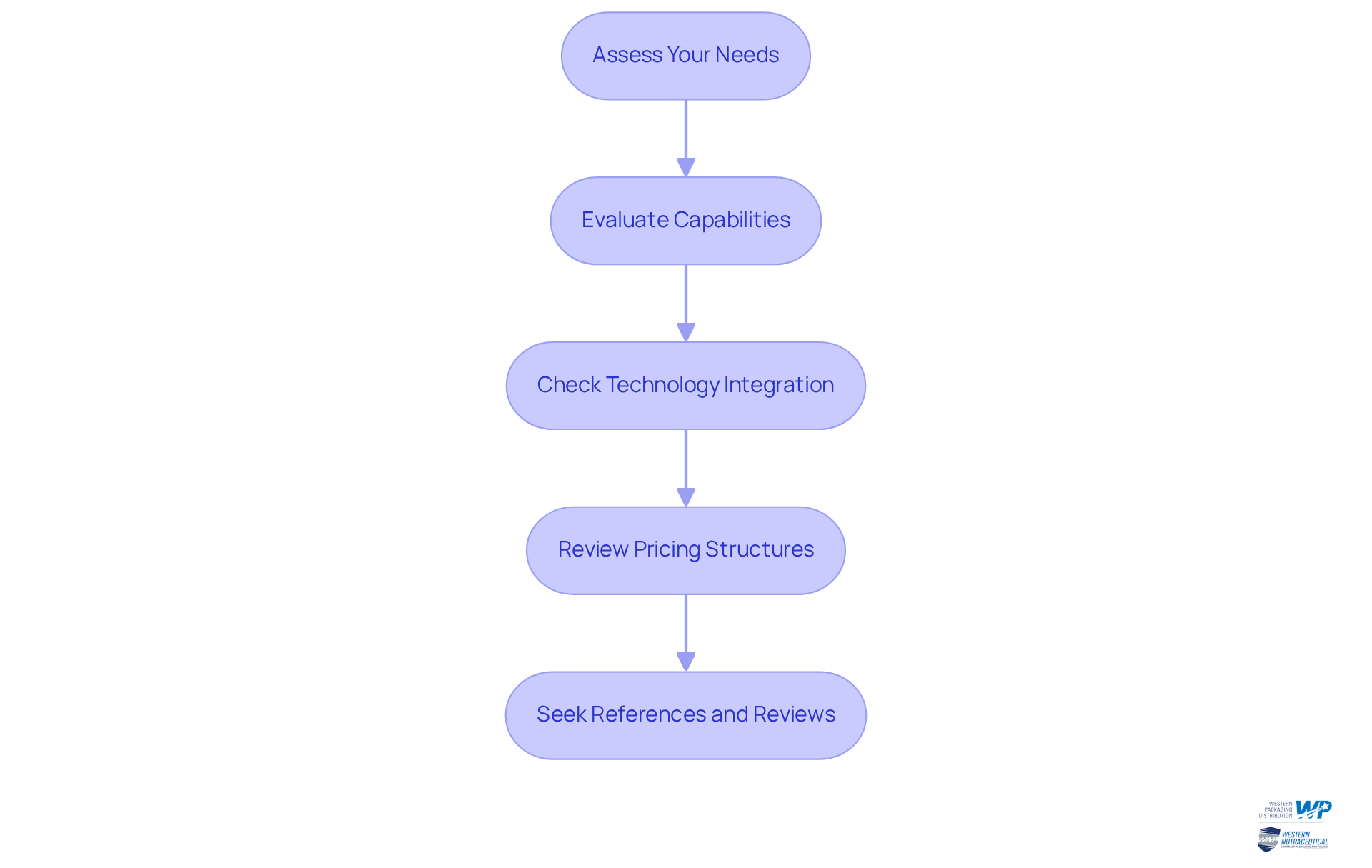

Choosing the right partner for assembly and fulfillment for ecommerce is crucial for optimizing your operations. To guide your decision-making process, consider the following essential factors:

- Assess Your Needs: Begin by clearly defining your specific requirements, including order volume, product types, and shipping destinations. Understanding these factors will enable you to identify partners that can effectively meet your demands.

- Evaluate Capabilities: Look for partners that offer services tailored to your needs, such as kitting, assembly, and comprehensive stock management. Western Packaging provides extensive 3PL services that encompass warehousing, logistics, and distribution, optimizing your operations and enhancing client satisfaction.

- Check Technology Integration: It is vital to ensure that the service provider can seamlessly integrate with your existing systems for order processing and inventory management. This capability is essential for maintaining and real-time data visibility, significantly reducing errors in storing, packing, and shipping.

- Review Pricing Structures: Gain a clear understanding of the cost implications associated with potential partners. This includes storage fees, shipping costs, and any additional charges for value-added services. Transparent pricing will help you avoid unexpected expenses and ensure alignment with your budget.

- Seek References and Reviews: Investigate potential partners by examining their reputation and reliability through customer testimonials and case studies. Successful assessments in the nutraceutical sector highlight the importance of selecting collaborators with established histories of meeting requirements.

By thoroughly evaluating these factors, you can select a partner that not only meets your operational needs but also excels in assembly and fulfillment for ecommerce, positioning your business for success in the competitive landscape.

Implement Effective Steps for Streamlined Assembly and Fulfillment

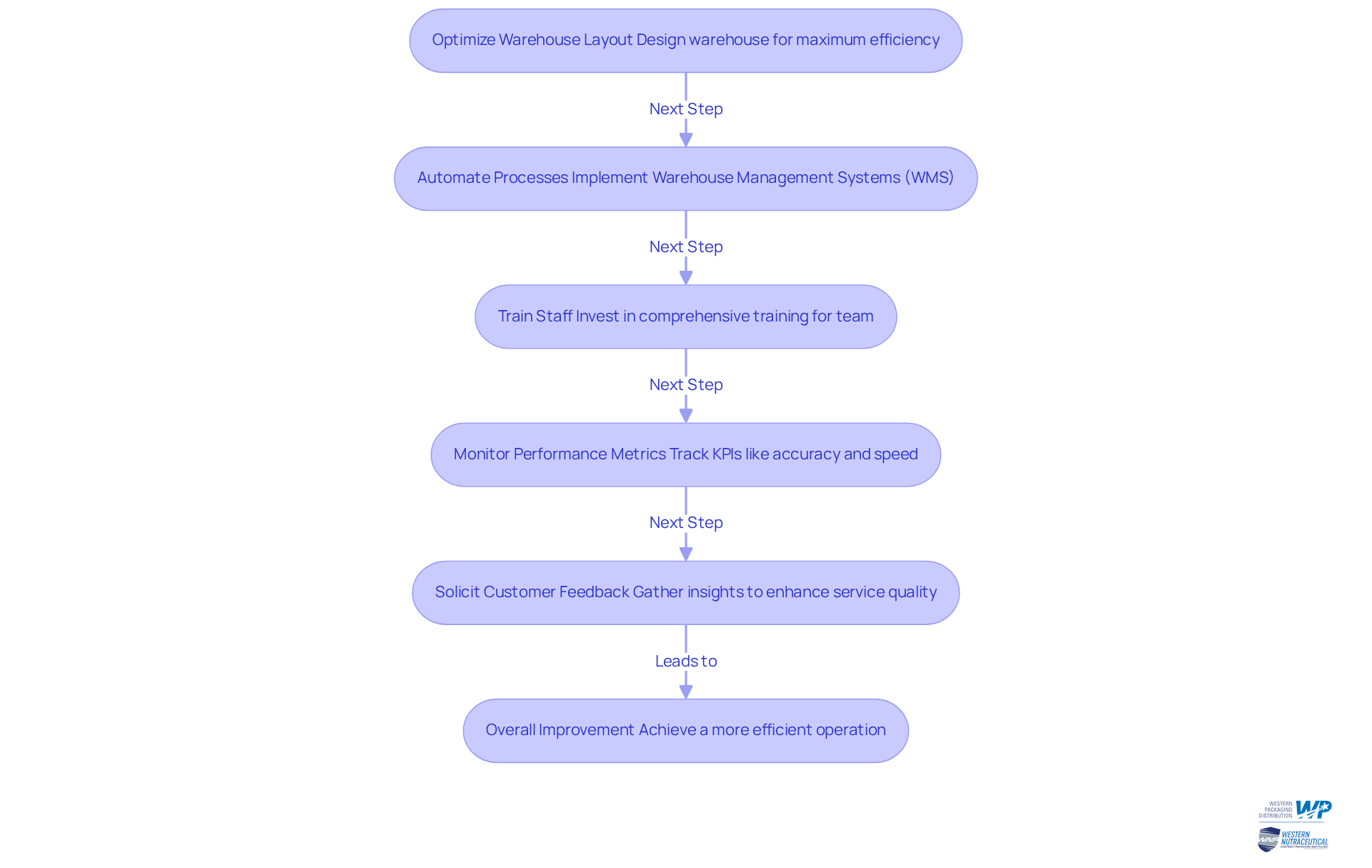

To enhance your assembly and fulfillment processes, consider implementing the following strategies:

- Optimize Warehouse Layout: Design your warehouse for maximum efficiency, ensuring that frequently picked items are easily accessible. This approach can significantly reduce picking times and improve overall productivity.

- Automate Processes: Leverage technological solutions like warehouse management systems (WMS) to streamline inventory monitoring and processing of requests. By 2025, it is anticipated that 90% of modern warehouses will utilize or adopt WMS, underscoring the industry's shift towards automation for enhanced accuracy and efficiency.

- Train Staff: Invest in comprehensive training for your team in assembly and delivery processes. Well-trained staff can minimize errors and enhance speed, contributing to a smoother operation.

- Monitor Performance Metrics: Regularly track key performance indicators (KPIs) such as request accuracy, processing speed, and client satisfaction. Monitoring these metrics is crucial for identifying areas for improvement and ensuring operational excellence.

- Solicit Customer Feedback: Actively gather insights from customers regarding their satisfaction experience. This feedback is invaluable for making necessary adjustments and .

Automating assembly processes in e-commerce can lead to significant benefits, including a 99% reduction in operational errors and a 50% increase in storage capacity. Case studies demonstrate that warehouses utilizing automation technologies, such as autonomous mobile robots (AMRs) and AI-powered systems, experience improved efficiency and quicker order processing. For instance, the case study on "AI, Analytics, and Forecasting" illustrates how AI and predictive analytics enhance operational efficiency by forecasting demand and planning labor deployment.

As industry expert Dave Waters notes, "Artificial Intelligence will be rampant in the digital supply chain," underscoring the critical role of automation in modern logistics. Additionally, Martin Christopher emphasizes that "the real competition is between supply chains, not companies," highlighting the importance of optimizing your supply chain through automation. By implementing these steps, you can create a more efficient and effective assembly and fulfillment for ecommerce operation that meets the evolving demands of your business.

Conclusion

Mastering assembly and fulfillment processes is crucial for achieving success in the competitive realm of ecommerce. By understanding the intricacies of these operations, businesses can enhance their efficiency, improve customer satisfaction, and ultimately drive growth. The significance of effective inventory management, streamlined processing, and strategic shipping cannot be overstated, as these elements play a vital role in shaping the overall customer experience.

The article emphasizes several key strategies that can be employed to optimize assembly and fulfillment:

- Implementing kitting

- Selecting the right fulfillment partner

- Automation and performance monitoring

Each step is designed to create a more efficient operation. Automation and performance monitoring are highlighted as essential components that can lead to significant improvements in accuracy and speed, while also reducing costs associated with returns and delays. Moreover, the importance of training staff and soliciting customer feedback is underscored, ensuring that businesses remain responsive to evolving market demands.

In a rapidly changing ecommerce landscape, the ability to adapt and refine assembly and fulfillment processes is not just advantageous; it is essential for long-term sustainability and competitive advantage. By prioritizing these strategies, businesses can position themselves for success, meeting the needs of their customers while navigating the complexities of modern logistics. Embracing these practices will not only enhance operational efficiency but also foster lasting relationships with customers, ultimately driving brand loyalty and growth in the years to come.

Frequently Asked Questions

What is ecommerce assembly and fulfillment?

Ecommerce assembly and fulfillment involve the processes of preparing and supplying products for online purchases, including the collection of components, order processing, and delivery to customers.

Why is inventory management important in ecommerce?

Effective inventory management ensures product availability when orders are placed, helping to meet consumer demands and reducing the likelihood of overstocking or stockouts.

What percentage of companies plan to adopt real-time stock management systems by 2025?

By 2025, 67% of companies plan to adopt real-time stock management systems to enhance accuracy.

How do forecasting tools impact inventory management?

73% of retailers report that utilizing forecasting tools improves stock precision, which helps in reducing overstocking or stockouts.

What are the benefits of automated inventory management systems?

Companies using automated inventory management systems can reduce stockouts by 30%, significantly enhancing operational efficiency.

What does the processing stage in ecommerce entail?

The processing stage includes all steps from receipt of the order to shipment, such as picking, packing, and shipping.

How can efficient order processing affect order completion rates?

Efficient order processing can yield a 30% improvement in order completion rates, minimizing delivery delays and boosting client satisfaction.

What are the key considerations for shipping and delivery in ecommerce?

Effective shipping strategies are essential, as storage costs account for 20% of total stock expenses, and well-organized stock systems can decrease processing times by 23%.

What is the projected average return rate for ecommerce purchases by 2025?

The average return rate for ecommerce purchases is projected to rise to 24.5% by 2025.

How much did returns cost US retailers in 2024?

Returns cost US retailers nearly $890 billion in 2024, representing 17% of total retail sales.

Why should businesses prioritize efficient inventory management and delivery strategies?

Prioritizing these strategies enhances client satisfaction and reduces costs associated with returns, which is essential for maintaining a competitive advantage in the evolving ecommerce landscape.