Overview

This article examines the advantages and applications of bag-in-box packaging specifically for nutraceutical manufacturers. It underscores the packaging's critical role in enhancing product preservation and operational efficiency. By detailing how the design minimizes waste, prolongs shelf life, and addresses the increasing consumer demand for sustainable solutions, bag-in-box packaging emerges as a preferred choice within the health supplement industry. Such insights not only highlight the effectiveness of this packaging solution but also reinforce its significance in a competitive market.

Introduction

Bag in box packaging has emerged as a transformative solution in the nutraceutical industry, seamlessly combining practicality with sustainability. This innovative packaging method not only protects sensitive products but also enhances efficiency and reduces waste, making it an attractive option for manufacturers. As the demand for eco-friendly practices continues to grow, nutraceutical companies are presented with a unique opportunity: how can they leverage this packaging to meet consumer expectations while ensuring product integrity?

Define Bag-in-Box Packaging: An Overview

Bag in box packaging is an innovative solution that involves enclosing a flexible bag within a sturdy box, primarily designed for liquids, powders, gummies, soft-gels, and other sensitive items. This dual-layer system not only safeguards the contents from external elements but also enhances convenience during handling and transportation. The inner bag is crafted from materials that provide exceptional barrier properties, ensuring the product remains fresh and uncontaminated. The outer container adds extra structural strength, making it suitable for various applications, particularly in the health supplement industry.

Experts in the wrapping sector emphasize the numerous advantages of this design. For example, the built-in tap or valve feature allows for precise portion control, a critical aspect in commercial environments where efficiency is essential. This capability significantly reduces waste and enhances operational efficiency, making flexible container solutions a preferred choice for many health product manufacturers.

Western Packaging enhances this solution with its , seamlessly incorporating filling processes into the container system. This integration streamlines production and ensures that the containers are tailored to meet the specific needs of health products, further boosting product appeal and brand recognition. Additionally, our 3PL services optimize the supply chain by managing warehousing, inventory, and distribution, enabling manufacturers to concentrate on their core operations.

Recent advancements in box technology, such as the EasySplit design, have further improved recyclability, achieving over 90% recycling rates. This aligns with the growing demand for sustainable container solutions, particularly in the health supplement sector, where consumers increasingly favor environmentally friendly options.

The benefits of box-based containers extend beyond convenience and sustainability; they also play a vital role in product preservation. The design effectively shields sensitive ingredients from light and oxygen, both of which can degrade quality over time. This is especially crucial for nutraceuticals, where maintaining potency and efficacy is paramount.

Successful applications of flexible containers in nutraceutical production have demonstrated their efficiency. Companies have reported improved shelf life and decreased spoilage rates, contributing to overall operational efficiency. As the market for nutraceuticals continues to expand, the adoption of bag in box packaging solutions is poised to grow, driven by their ability to address the unique challenges of this industry.

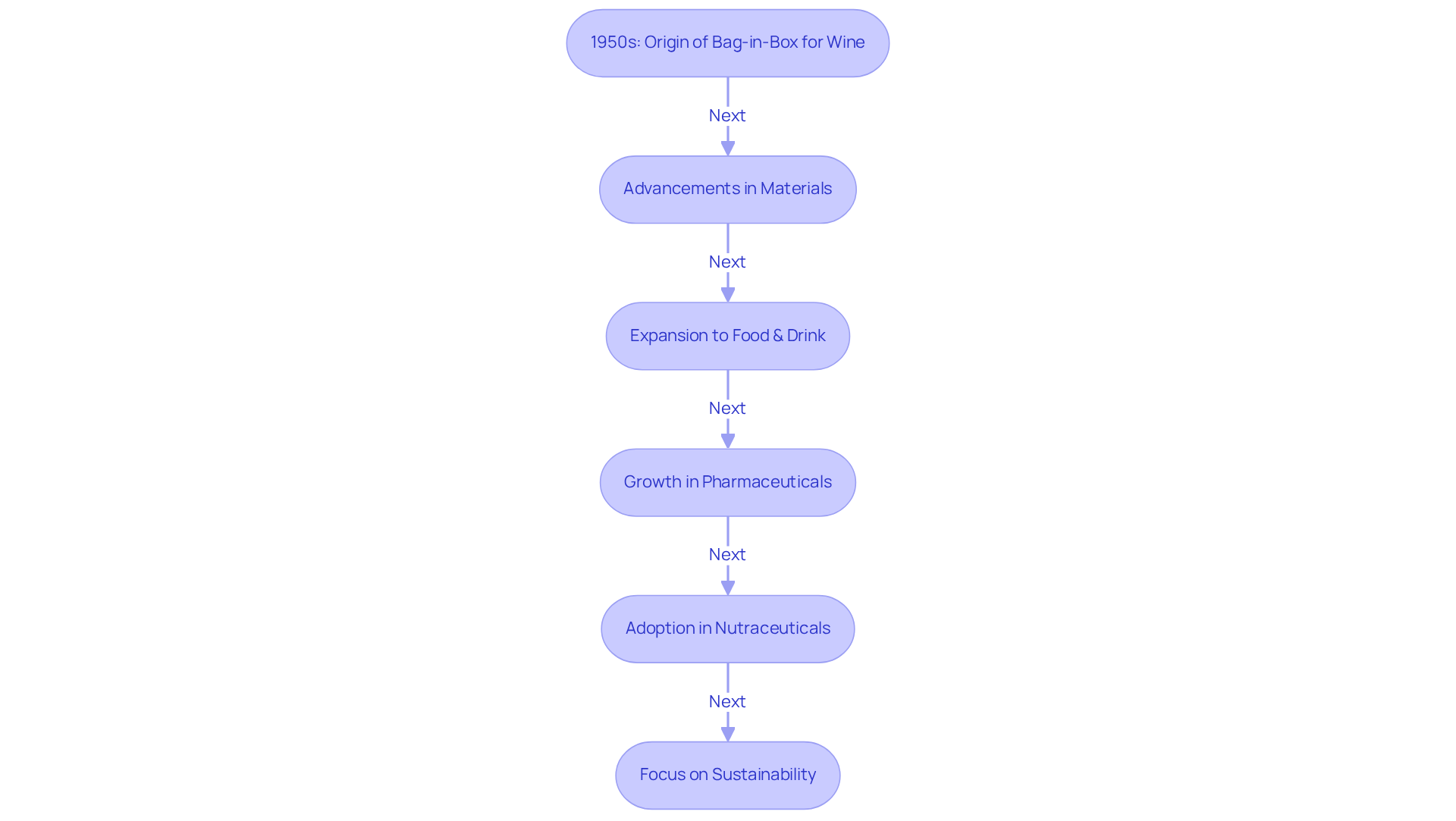

Trace the History and Evolution of Bag-in-Box Packaging

Bag in box packaging, which originated in the 1950s, was initially designed for wine. Their innovative structure not only preserved product quality but also enhanced convenience in storage and transportation. Over the decades, advancements in materials and production methods have facilitated the expansion of bag in box packaging systems across various industries, including food and drink, pharmaceuticals, and notably, nutraceuticals. This evolution is largely driven by an increasing demand for sustainable and efficient wrapping solutions.

In the nutraceutical sector, bag in box packaging has gained significant popularity due to its ability to prolong shelf life by minimizing oxygen exposure, thereby preserving item integrity. This design is especially beneficial for liquid nutraceuticals, as it allows for precise portion control and reduces waste. Case studies indicate that manufacturers adopting flexible packaging solutions have reported enhanced operational efficiency and improved product appeal. For example, companies utilizing this containment method have experienced substantial reductions in spoilage and wastage, aligning with the industry's movement towards sustainability.

Today, bag in box packaging solutions are recognized for their , making them a preferred choice among health product manufacturers who seek to optimize their container processes while meeting consumer demands for convenience and quality.

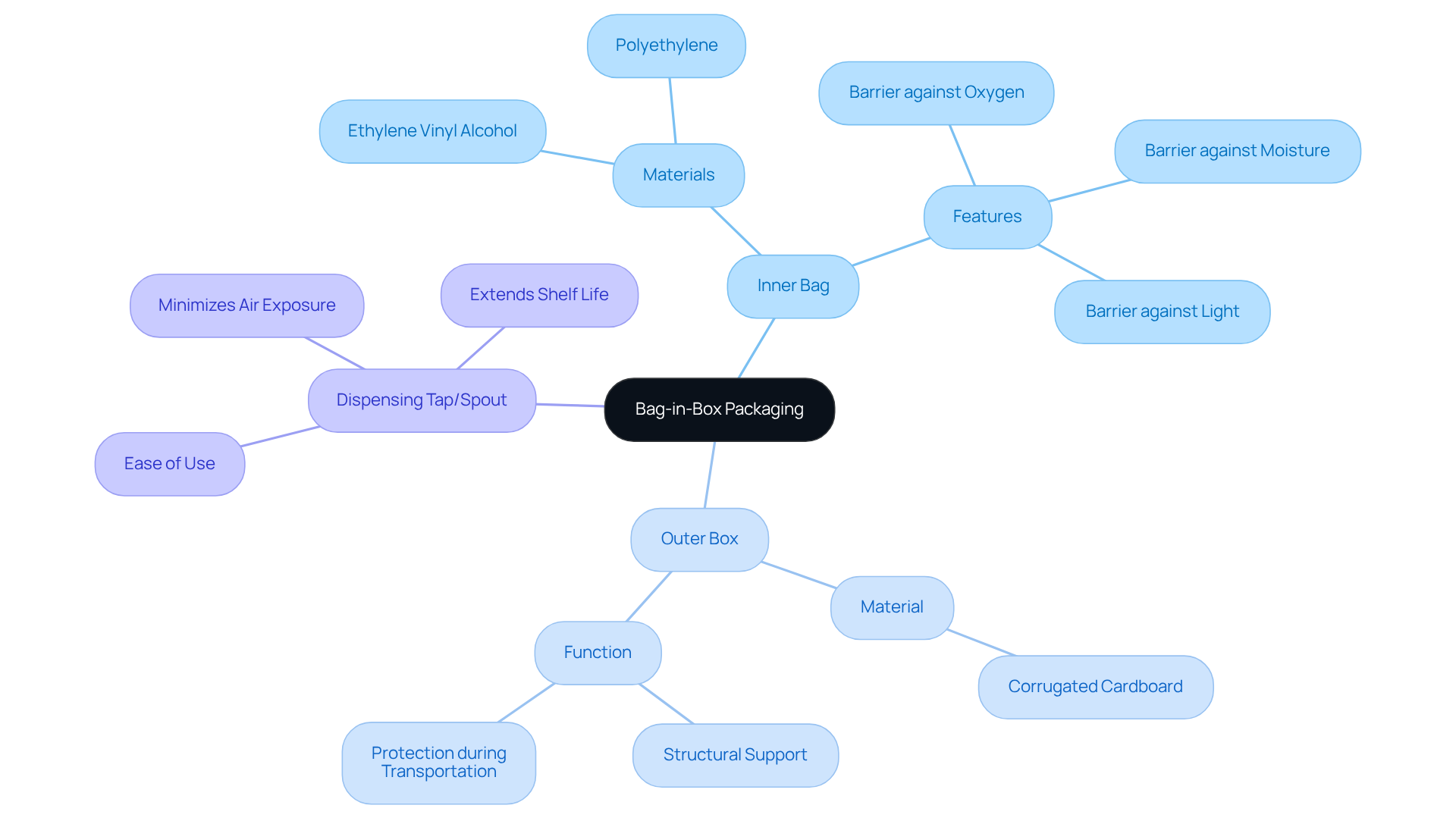

Identify Key Features and Components of Bag-in-Box Packaging

Bag in box packaging is made up of two fundamental components: the inner bag and the outer box. The inner bag is typically constructed from multi-layer films designed to provide excellent barrier characteristics against oxygen, moisture, and light—elements crucial for preserving the integrity of health-related items. These films often integrate materials such as polyethylene and ethylene vinyl alcohol, which enhance durability and shield sensitive contents from degradation. The outer box, generally made from corrugated cardboard, offers structural support and protects the inner bag during transportation.

Many box systems also feature a dispensing tap or spout, facilitating easy pouring while minimizing air exposure, which is vital for extending shelf life. This combination of protective features and user-friendly design positions bag in box packaging as an aiming to maintain quality and appeal. The integration of these elements not only enhances the functionality of the containers but also aligns with the growing demand for sustainable and efficient solutions in the health supplement sector.

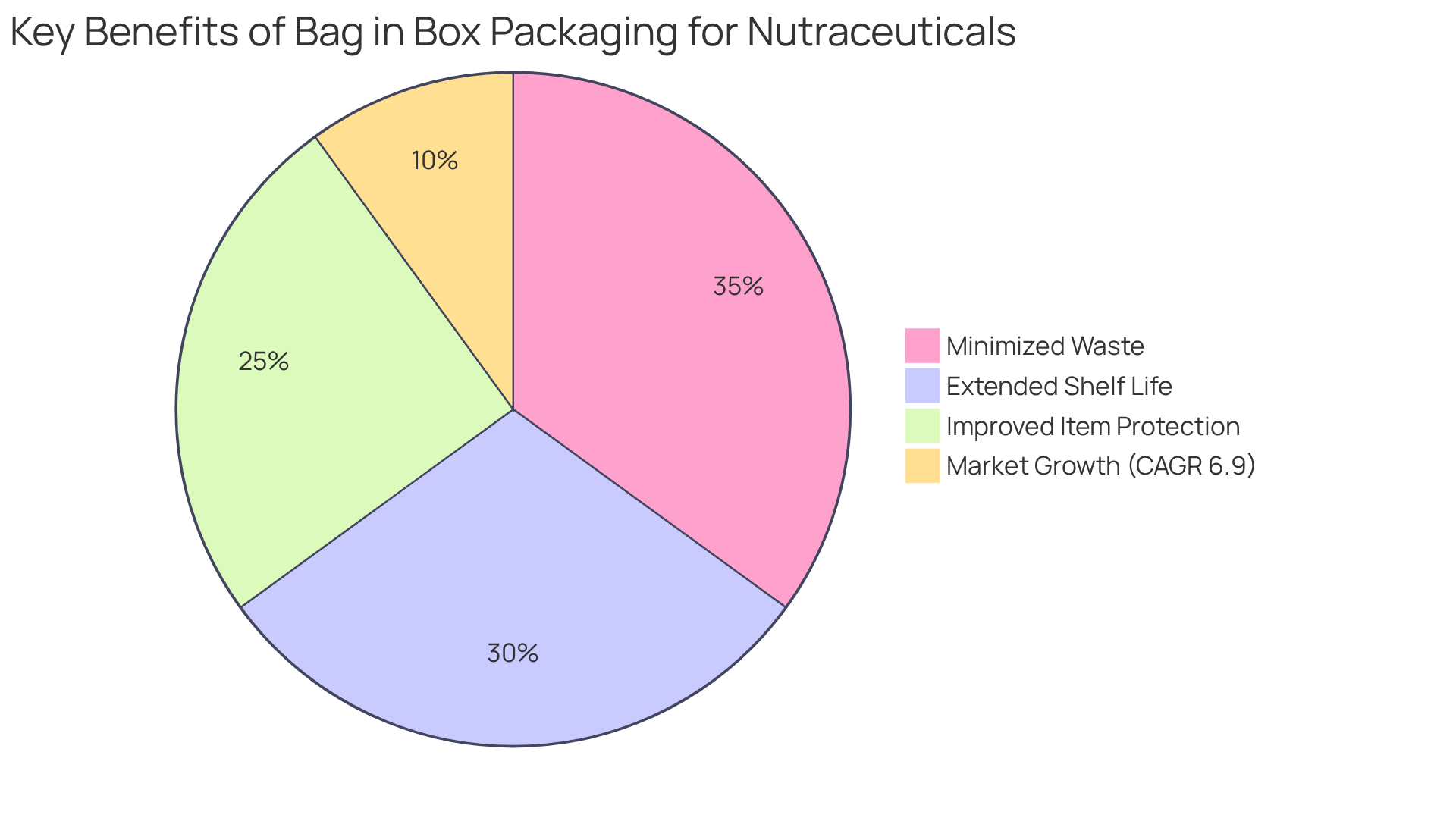

Explore Benefits and Applications for Nutraceutical Manufacturers

Bag in box packaging presents a multitude of advantages for nutraceutical producers, including:

- Extended shelf life

- Minimized waste

- Improved item protection

The airtight seal of the inner bag effectively prevents contamination and oxidation, thereby preserving the potency of dietary supplements over time. Furthermore, these containers allow for up to 99% evacuation of contents, significantly reducing waste. Their lightweight design contributes to lower shipping costs and a diminished environmental footprint. This solution is particularly beneficial for , such as powders and liquid supplements, enabling manufacturers to distribute their offerings efficiently while appealing to eco-conscious consumers.

As the demand for sustainable container solutions continues to rise, bag in box packaging options emerge as an attractive choice for health supplement brands looking to enhance their market presence and align with consumer preferences for environmentally friendly practices. Notably, various nutraceutical brands have adopted bag in box packaging solutions to substantially reduce waste, underscoring the practical benefits of this innovative container method.

The bag in box packaging market is projected to grow at a CAGR of 6.9% from 2024 to 2030, reflecting a robust trend towards this sustainable packaging option.

Conclusion

Bag in box packaging stands out as a pivotal innovation for nutraceutical manufacturers, seamlessly combining functionality with sustainability. This dual-layer system not only protects sensitive products but also enhances operational efficiency, making it an optimal choice for the health supplement industry. Its design maintains product integrity while minimizing waste, positioning it as a frontrunner in modern packaging solutions.

Key insights throughout this article have highlighted the historical evolution of bag in box packaging, tracing its origins in the wine industry to its widespread application in nutraceuticals. The advantages of this packaging method—extended shelf life, reduced spoilage, and user-friendly dispensing features—underscore its significance in meeting the demands of both manufacturers and environmentally conscious consumers. Furthermore, the integration of advanced materials and designs reflects a commitment to sustainability that resonates with today’s market trends.

As the nutraceutical sector continues to expand, embracing bag in box packaging emerges as a strategic move for manufacturers aiming to enhance product appeal while aligning with consumer preferences for eco-friendly practices. The projected growth of this packaging method reinforces its importance in the industry, encouraging manufacturers to consider innovative solutions that not only protect their products but also contribute positively to the environment. Adopting bag in box packaging could very well be the key to thriving in a competitive market, ensuring that nutraceutical brands remain relevant and appealing to a discerning audience.

Frequently Asked Questions

What is bag-in-box packaging?

Bag-in-box packaging is a system that encloses a flexible bag within a sturdy box, designed primarily for liquids, powders, gummies, soft-gels, and other sensitive items. This dual-layer system protects the contents and enhances convenience during handling and transportation.

What are the benefits of bag-in-box packaging?

The benefits include exceptional barrier properties that keep products fresh and uncontaminated, precise portion control through built-in taps or valves, reduced waste, enhanced operational efficiency, and improved product preservation by shielding sensitive ingredients from light and oxygen.

How does bag-in-box packaging enhance operational efficiency?

The built-in tap or valve feature allows for precise portion control, which is crucial in commercial environments. This capability reduces waste and increases efficiency, making it a preferred choice for health product manufacturers.

What role does Western Packaging play in bag-in-box solutions?

Western Packaging offers integrated filling services that streamline production and ensure containers meet the specific needs of health products. They also provide 3PL services to optimize the supply chain, managing warehousing, inventory, and distribution.

How does the EasySplit design improve sustainability in bag-in-box packaging?

The EasySplit design enhances recyclability, achieving over 90% recycling rates, which aligns with the growing demand for sustainable container solutions, especially in the health supplement sector.

Why is bag-in-box packaging important for product preservation?

Bag-in-box packaging effectively shields sensitive ingredients from light and oxygen, which can degrade quality over time. This is particularly important for nutraceuticals, where maintaining potency and efficacy is essential.

What have companies experienced using flexible containers in nutraceutical production?

Companies have reported improved shelf life and decreased spoilage rates, contributing to overall operational efficiency, indicating a successful application of flexible containers in the nutraceutical industry.

Is the adoption of bag-in-box packaging expected to grow?

Yes, as the market for nutraceuticals continues to expand, the adoption of bag-in-box packaging solutions is poised to grow due to their ability to address the unique challenges of the industry.