Overview

This article outlines ten significant benefits of vertical form fill machines specifically tailored for nutraceuticals. These machines play a crucial role in enhancing efficiency, speed, cost savings, and customization within packaging processes. Automation is a key factor in this discussion, as it effectively reduces labor and errors, improves throughput, and allows for tailored solutions that precisely meet specific market demands. By leveraging these advantages, businesses can position themselves competitively within the nutraceutical sector.

Introduction

The packaging landscape for nutraceuticals is evolving rapidly, propelled by the pressing demands for efficiency, quality, and sustainability. Vertical form fill machines have emerged as a transformative solution, providing manufacturers with a versatile approach to packaging that not only enhances product appeal but also streamlines operations. What specific benefits do these advanced machines offer, and how can they revolutionize the nutraceutical industry? This article explores ten key advantages of vertical form fill machines, illustrating how they can elevate packaging processes and drive success in an increasingly competitive market.

Western Packaging: Tailored Vertical Form Fill Solutions for Enhanced Product Appeal

Western Packaging specializes in offering for vertical form fill that enhance the appeal of nutraceuticals. Our innovative container designs allow us to create visually striking options, such as large pouches for protein items and stick packs for nutraceuticals. These designs not only attract consumers but also effectively communicate your brand's values.

By merging functionality with creativity, we ensure that your products stand out on the shelf, driving sales and fostering brand loyalty. Rely on us to deliver custom flexible solutions that boost your brand recognition and meet your unique requirements.

Contact us today to discover how we can help enhance your product's market presence.

Increased Efficiency: Streamline Packaging Processes with Vertical Form Fill Machines

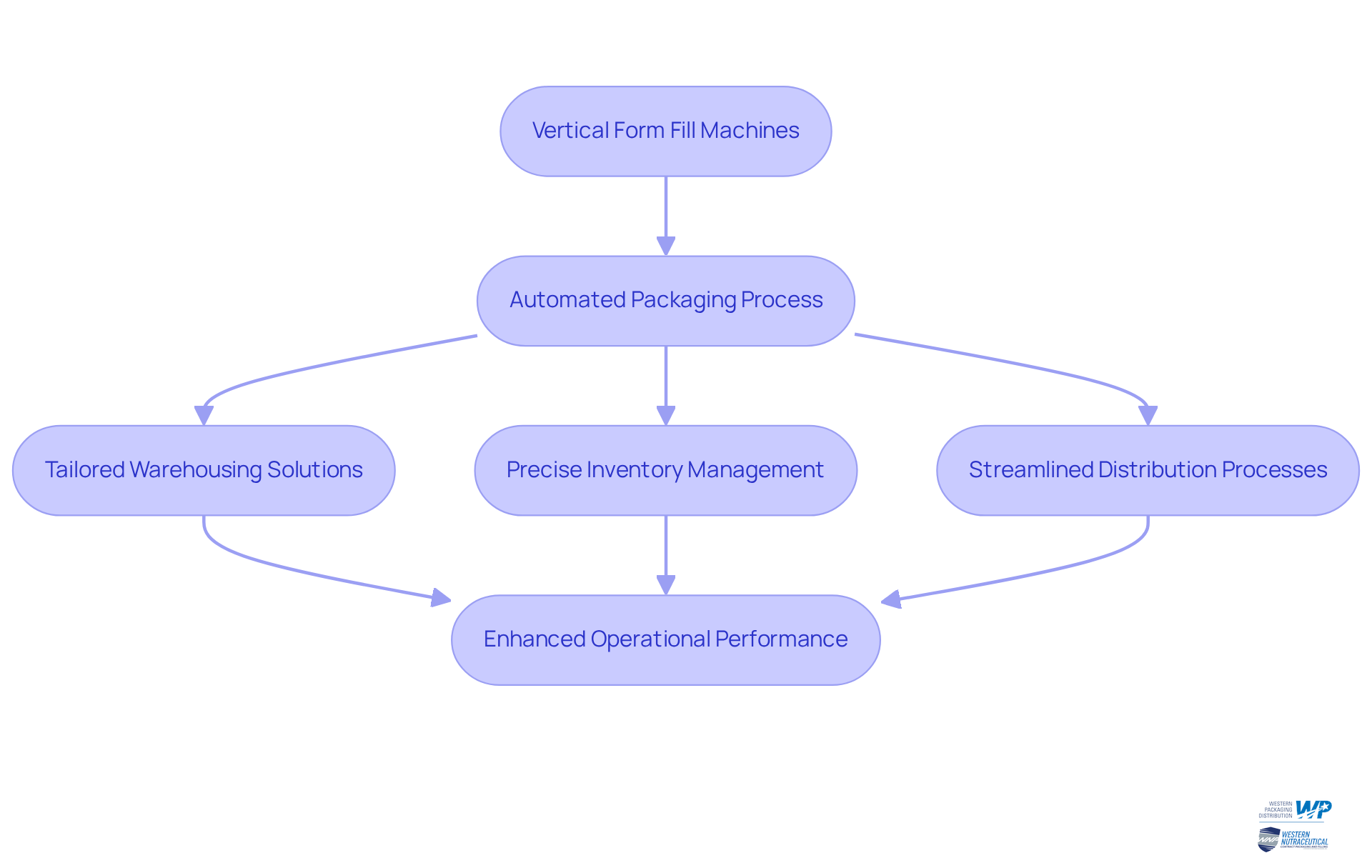

The use of vertical form fill packaging equipment significantly enhances operational efficiency by automating the packaging process. This automation not only reduces manual labor but also minimizes errors, allowing companies to package items with greater speed and precision.

By leveraging Western Packaging's comprehensive 3PL services, nutraceutical manufacturers can further amplify this efficiency. Our offerings include:

- Tailored warehousing solutions that guarantee optimal storage conditions

- Precise inventory management that mitigates stock discrepancies

- Streamlined distribution processes that shorten lead times

This seamless integration empowers businesses to meet escalating consumer demands without sacrificing quality, ultimately resulting in .

Versatile Applications: Package a Wide Range of Products with Vertical Form Fill Machines

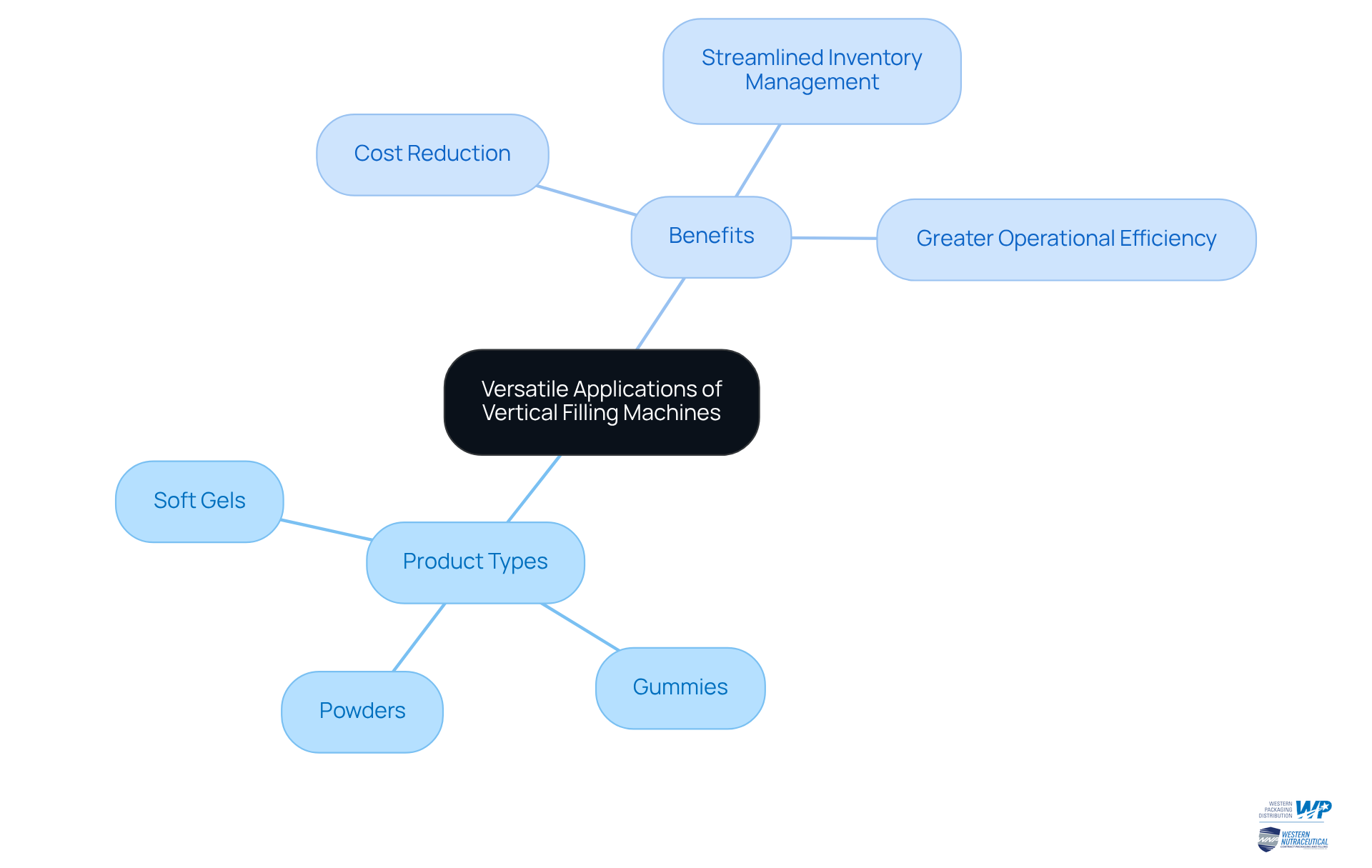

is expertly designed to handle a wide range of products, including powders, gummies, and soft gels. This remarkable versatility allows manufacturers to employ a single machine across multiple product lines, significantly reducing the need for specialized equipment. Such adaptability not only cuts costs but also streamlines inventory management and enhances production planning, ultimately leading to greater operational efficiency. By investing in reliable vertical filling solutions, businesses can optimize their processes and ensure consistent quality across their offerings.

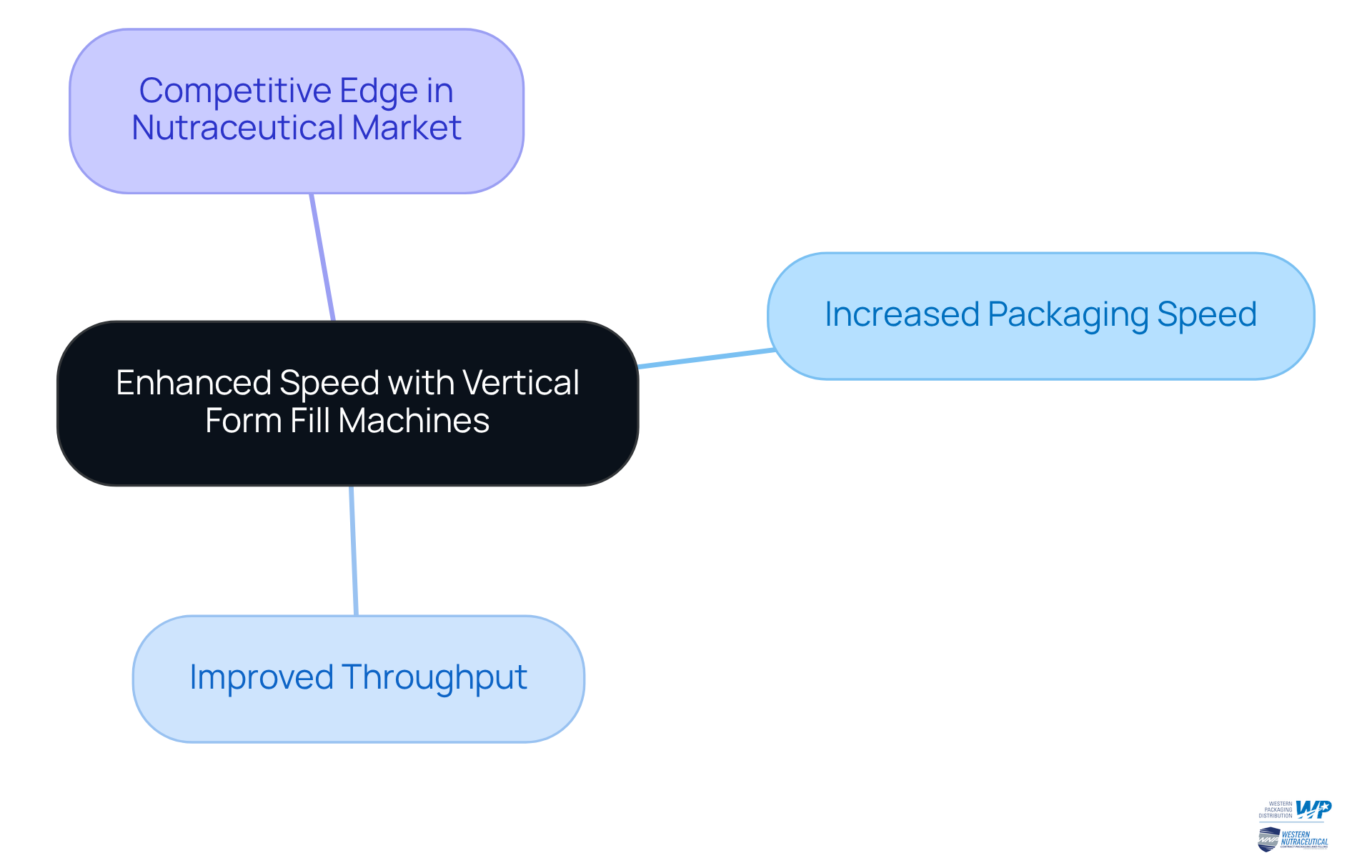

Enhanced Speed: Boost Packaging Throughput with Vertical Form Fill Machines

One of the most significant advantages of vertical packaging systems lies in their ability to enhance packaging speed. These sophisticated devices utilize a vertical form fill to operate at high velocities, markedly improving throughput and allowing businesses to meet larger orders within shorter timeframes. This capability proves especially advantageous in the rapidly evolving nutraceutical market, where can serve as a crucial competitive edge.

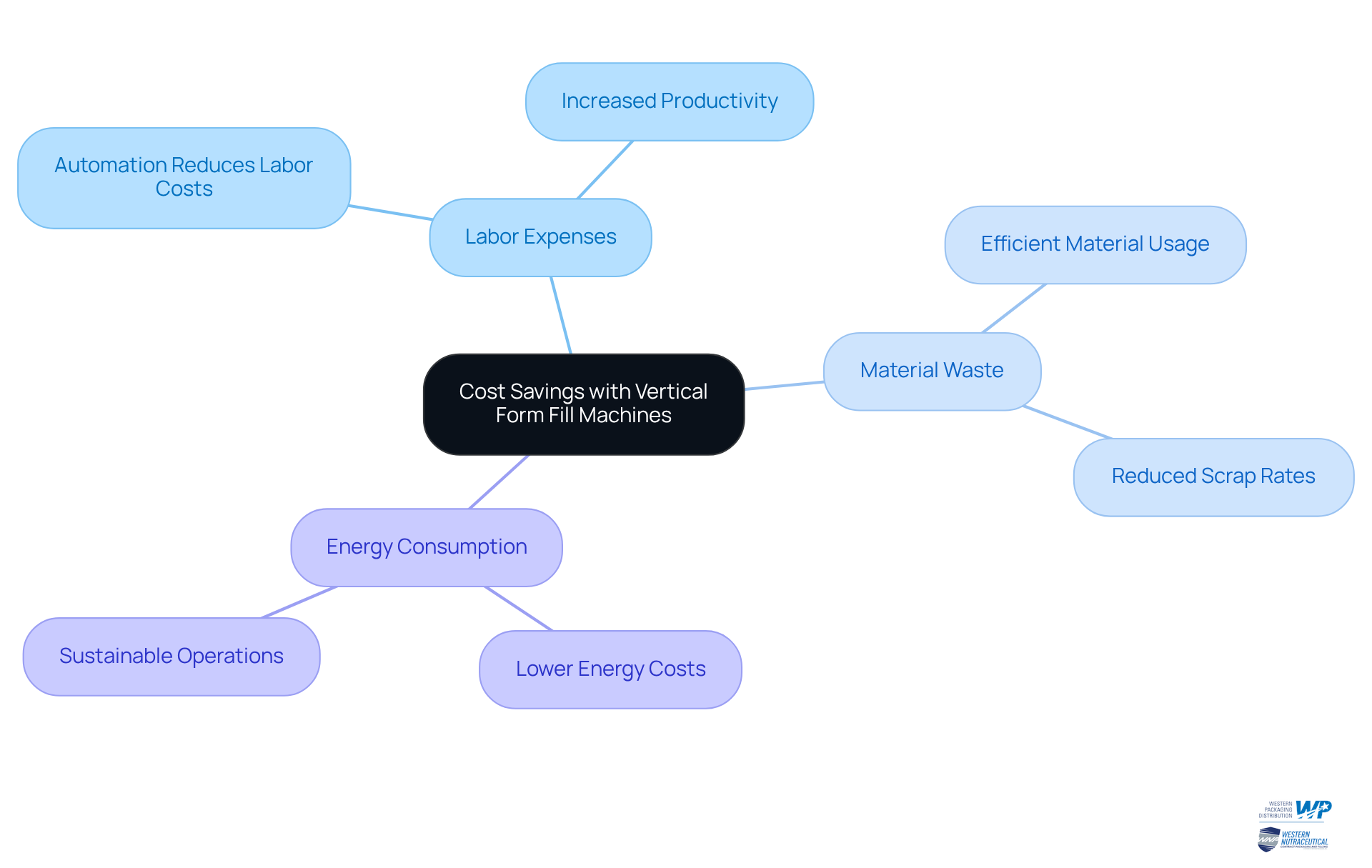

Cost Savings: Reduce Packaging Expenses with Vertical Form Fill Machines

Investing in vertical form fill equipment provides manufacturers with a pathway to significant cost savings. By automating the wrapping process, companies can effectively lower labor expenses while simultaneously decreasing material waste. Furthermore, the efficiency of these devices often results in reduced energy consumption, contributing to overall cost savings. This financial advantage is essential for businesses aiming to and sustain a competitive edge in the market by utilizing vertical form fill.

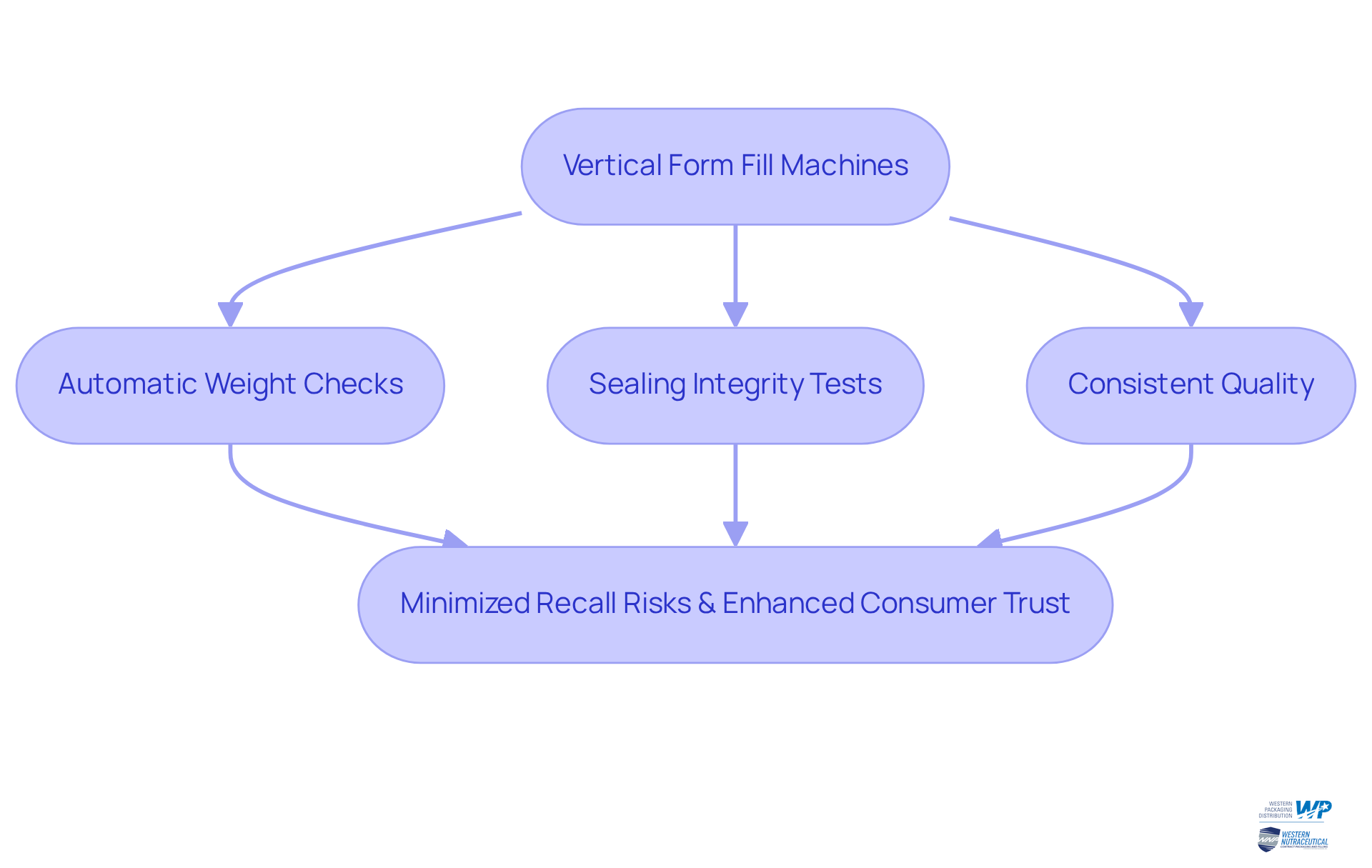

Improved Quality Control: Maintain High Standards with Vertical Form Fill Machines

Vertical form fill technology leverages advanced machines to ensure consistent quality in packaging. With features such as automatic weight checks and sealing integrity tests, these machines uphold that minimize the risk of recalls while boosting consumer confidence. This unwavering focus on quality holds particular significance in the nutraceutical sector, where product integrity is not just important—it is paramount. By investing in these sophisticated solutions, businesses can enhance their reliability and maintain the trust of their consumers.

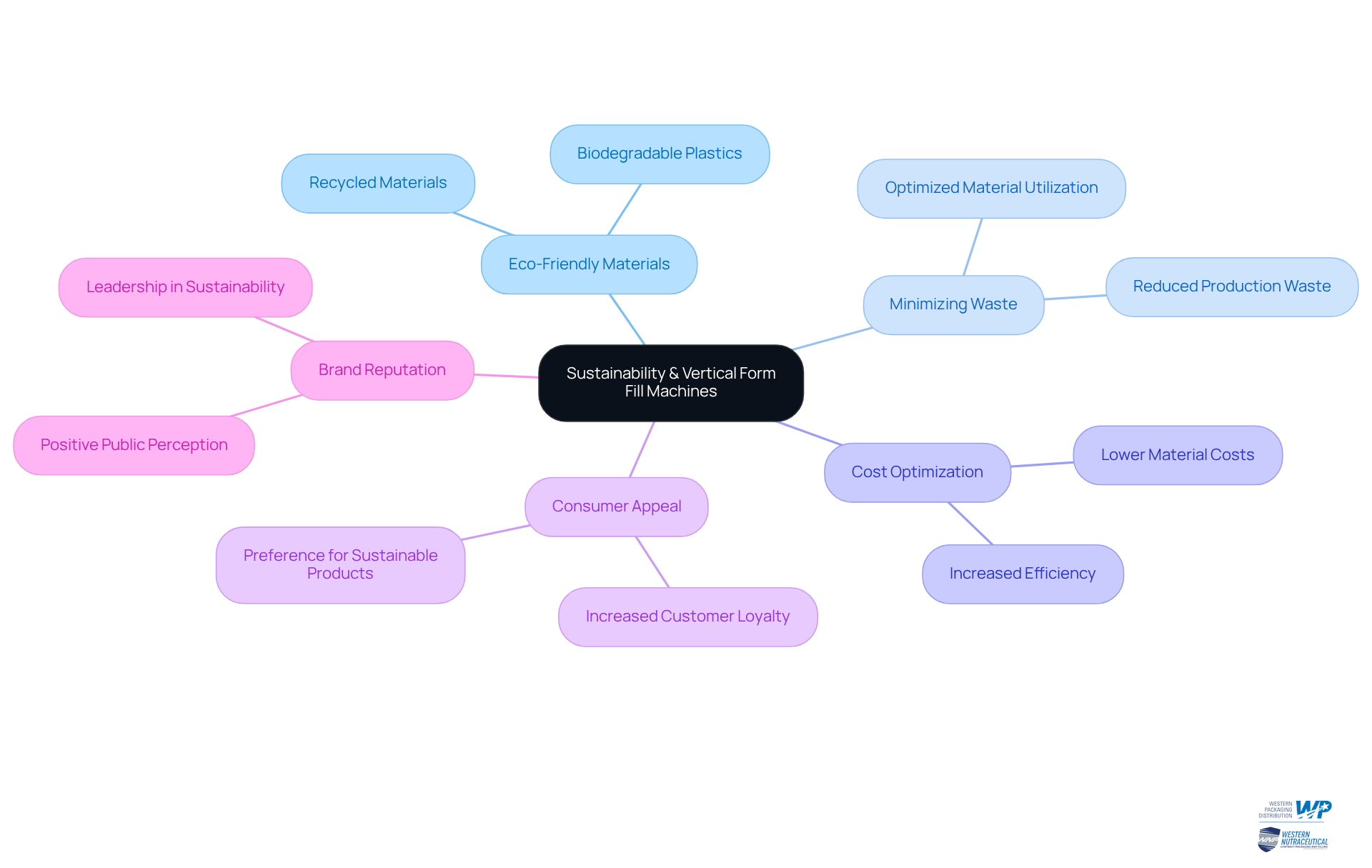

Sustainability: Promote Eco-Friendly Practices with Vertical Form Fill Machines

Vertical form fill technology plays a pivotal role in advancing by employing eco-friendly materials and minimizing waste. These devices are meticulously designed to optimize material utilization, resulting in reduced costs and diminished environmental impact. By embracing sustainable packaging methods, businesses can not only appeal to environmentally conscious consumers but also significantly enhance their brand reputation. This strategic shift not only demonstrates a commitment to sustainability but also positions companies as leaders in responsible practices within the industry.

Technological Innovation: Leverage Advanced Features of Vertical Form Fill Machines

Modern vertical form fill machines come with advanced features such as touch-screen interfaces, programmable settings, and real-time monitoring capabilities. These innovations significantly enhance usability and provide greater flexibility in container operations.

By leveraging these technologies in conjunction with Western Packaging's integrated filling services for powders, gummies, and soft-gels, businesses can streamline their production processes and enhance supply chain efficiency. This synergy empowers nutraceutical producers to respond more adeptly to market shifts while offering that enhance product appeal.

Embrace the future of packaging—partner with us for reliable, cutting-edge solutions that drive your success.

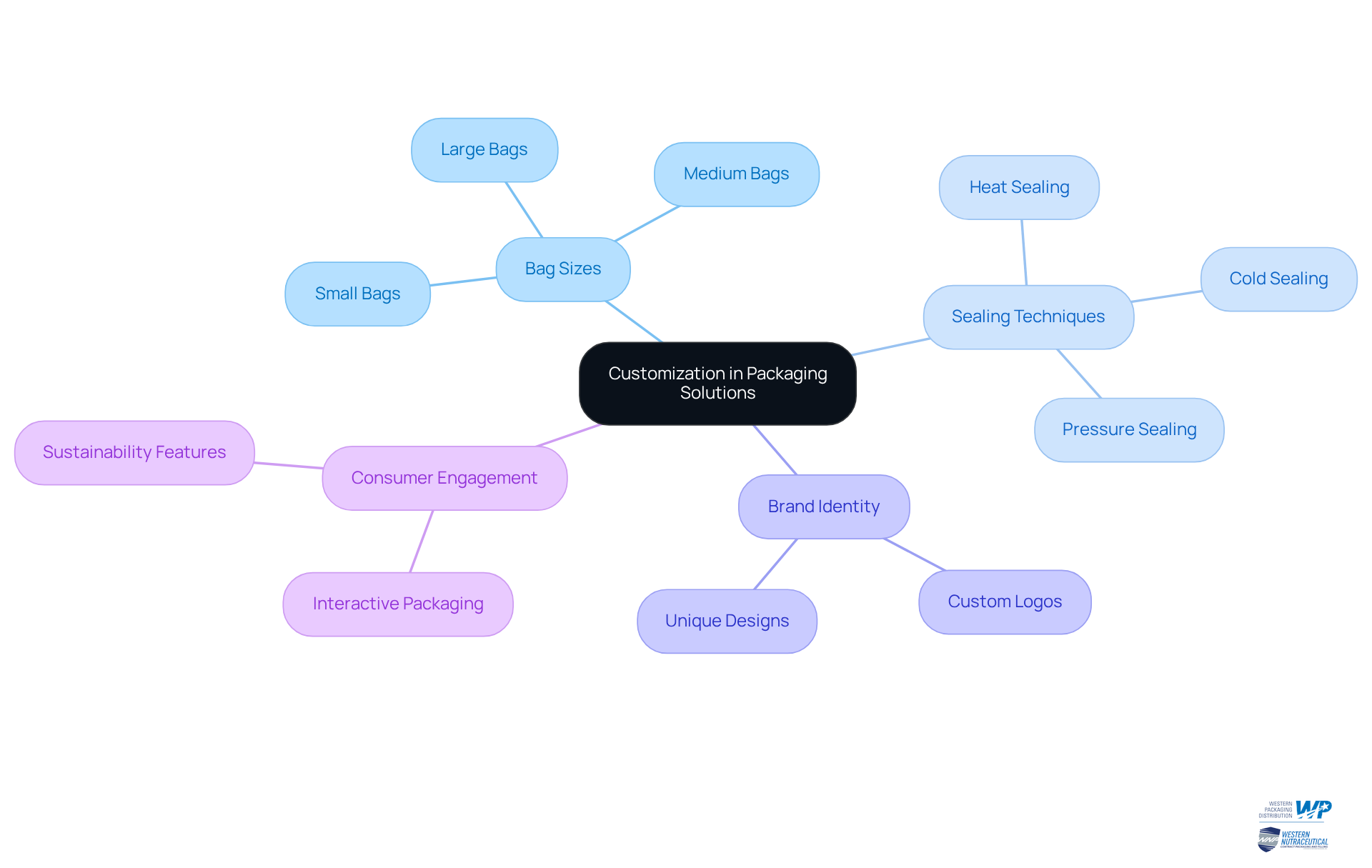

Customization: Tailor Packaging Solutions with Vertical Form Fill Machines

Vertical form fill devices provide a wealth of , empowering producers to tailor containers to meet specific product requirements and consumer preferences. From various bag sizes to unique sealing techniques, these devices enable businesses to create packaging that reflects their brand identity and resonates with their target audience. This degree of customization not only enhances market presence but also significantly boosts consumer engagement, making it a strategic advantage in today's competitive landscape.

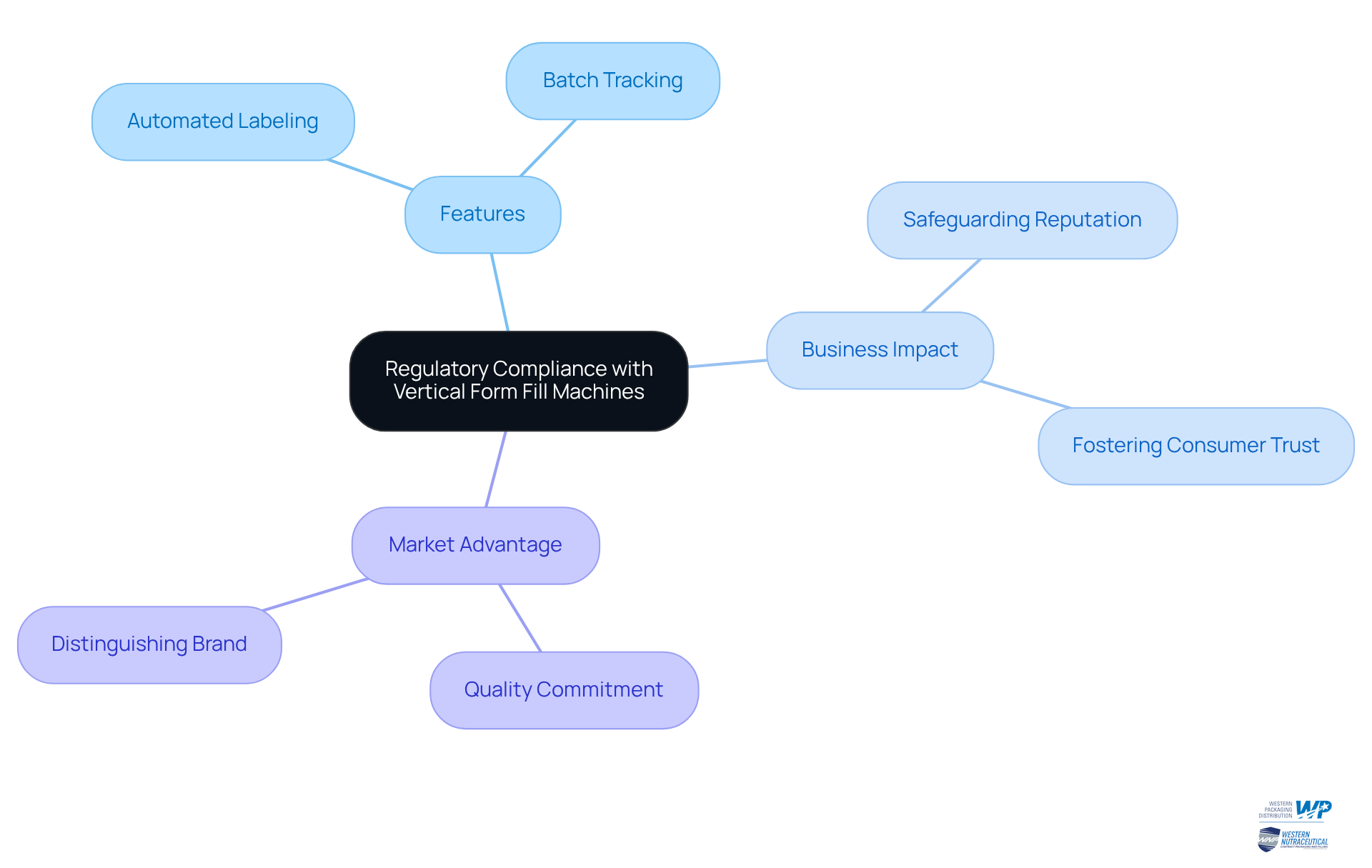

Regulatory Compliance: Ensure Adherence with Vertical Form Fill Machines

For manufacturers aiming to meet stringent industry regulations regarding packaging and labeling, vertical form fill machines are essential. With features such as and batch tracking, these machines ensure that products comply with legal standards, significantly reducing the risk of non-compliance. By prioritizing adherence to regulations, businesses not only safeguard their reputation but also foster consumer trust in their offerings. Investing in reliable packaging solutions is not just a choice; it is a commitment to quality and compliance that can distinguish a brand in a competitive market.

Conclusion

The advantages of vertical form fill machines in the nutraceutical sector are profound, providing manufacturers with a pathway to enhanced efficiency, cost savings, and improved product quality. By automating the packaging process, these machines streamline operations and offer the flexibility required to adapt to the diverse range of products within the industry. Their capability to maintain high standards of quality control and promote sustainability further solidifies their essential role in modern packaging solutions.

Key insights throughout this article emphasize how vertical form fill machines contribute to:

- Faster packaging speeds

- Reduced labor costs

- Effective compliance with industry regulations

The customization options available allow brands to create packaging that resonates with consumers, enhancing market presence and fostering brand loyalty. Moreover, the technological innovations integrated into these machines empower manufacturers to respond swiftly to market demands while ensuring consistent quality.

In a competitive landscape where efficiency and sustainability are paramount, investing in vertical form fill machines transcends mere operational decision-making; it represents a strategic advantage. Embracing these advanced packaging solutions can propel businesses forward, enabling them to meet consumer expectations and thrive in the ever-evolving nutraceutical market. The time to explore the benefits of vertical form fill technology is now, as it presents a unique opportunity to enhance product appeal and operational performance.

Frequently Asked Questions

What does Western Packaging specialize in?

Western Packaging specializes in offering customized solutions for vertical form fill packaging that enhance the appeal of nutraceutical products.

What types of container designs does Western Packaging offer?

Western Packaging offers innovative container designs, including large pouches for protein items and stick packs for nutraceuticals, aimed at attracting consumers and effectively communicating brand values.

How does Western Packaging ensure products stand out on the shelf?

By merging functionality with creativity in their packaging designs, Western Packaging ensures that products stand out, driving sales and fostering brand loyalty.

What are the benefits of using vertical form fill machines?

Vertical form fill machines enhance operational efficiency by automating the packaging process, reducing manual labor, minimizing errors, and allowing for greater speed and precision in packaging.

How can Western Packaging's 3PL services amplify efficiency for nutraceutical manufacturers?

Western Packaging's 3PL services include tailored warehousing solutions, precise inventory management, and streamlined distribution processes, which collectively help businesses meet consumer demands without sacrificing quality.

What types of products can be packaged using vertical form fill machines?

Vertical filling equipment can handle a wide range of products, including powders, gummies, and soft gels, allowing manufacturers to use a single machine across multiple product lines.

What are the advantages of using a single machine for multiple product lines?

Using a single machine for multiple product lines reduces the need for specialized equipment, cuts costs, streamlines inventory management, and enhances production planning, leading to greater operational efficiency.