Overview

This article delineates nine significant benefits of employing assembly kits for efficient packaging, such as:

- Cost savings

- Time efficiency

- Customization

- Quality control

- Sustainability

These advantages arise from the capability of assembly kits to streamline operations, enhance product presentation, and improve supply chain management. As a result, organizations experience heightened efficiency and competitiveness in the market. By leveraging these benefits, businesses can position themselves for success in an increasingly demanding landscape.

Introduction

The packaging landscape is evolving rapidly, as businesses actively pursue innovative solutions aimed at enhancing efficiency and reducing costs. Assembly kits have emerged as a transformative strategy, presenting a multitude of benefits that streamline operations and elevate product presentation. However, how can companies effectively leverage these kits to not only meet market demands but also secure a competitive advantage? This article delves into the nine key advantages of utilizing assembly kits in packaging, unveiling insights that can revolutionize operational workflows and enhance brand appeal.

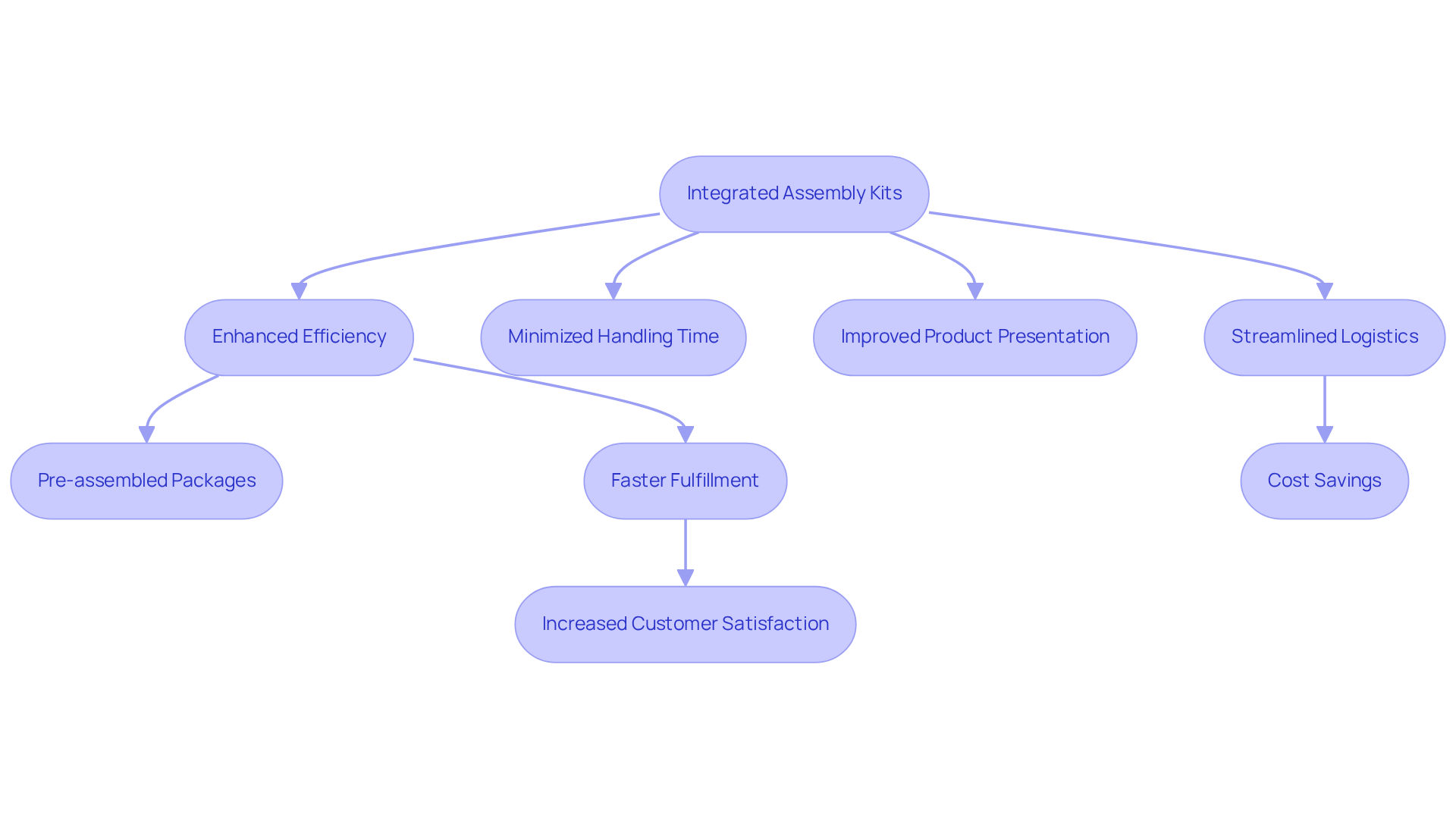

Western Packaging: Integrated Assembly Kits for Streamlined Packaging Solutions

Western Packaging delivers that significantly enhance the packaging process, complemented by our advanced filling services. Our filling process caters to a diverse range of products, from powders to gummies and soft-gels, ensuring that your packaging needs are met with precision. This includes personalized packaging solutions designed to elevate brand recognition and shelf appeal.

By merging various components into a single kit, businesses can minimize handling time and enhance overall efficiency. This strategy not only simplifies logistics but also improves product presentation, making items more appealing to consumers. The seamless integration of construction sets and filling services into the packaging process fosters a unified supply chain, ultimately benefiting both producers and distributors.

The effective implementation of assembly kits has streamlined operations. For instance, an assembly kit allows companies to pre-assemble packages, accelerating fulfillment and reducing errors. Such efficiency is vital in today's fast-paced market, where customer satisfaction is contingent upon timely delivery and product quality.

Furthermore, outsourcing logistics to third-party providers can enhance operational performance. These providers often negotiate better shipping rates, resulting in cost savings for companies. As industry leaders emphasize, utilizing construction sets not only enhances the fulfillment experience but also enables companies to focus on core activities, driving growth and innovation.

Looking ahead to 2025, the trend towards integrated construction sets is expected to continue, with companies increasingly recognizing their value in optimizing supply chain management. By embracing these solutions, companies can achieve greater flexibility and responsiveness to market demands, ensuring they maintain a competitive edge in an evolving landscape.

Cost Savings: How Assembly Kits Reduce Packaging Expenses

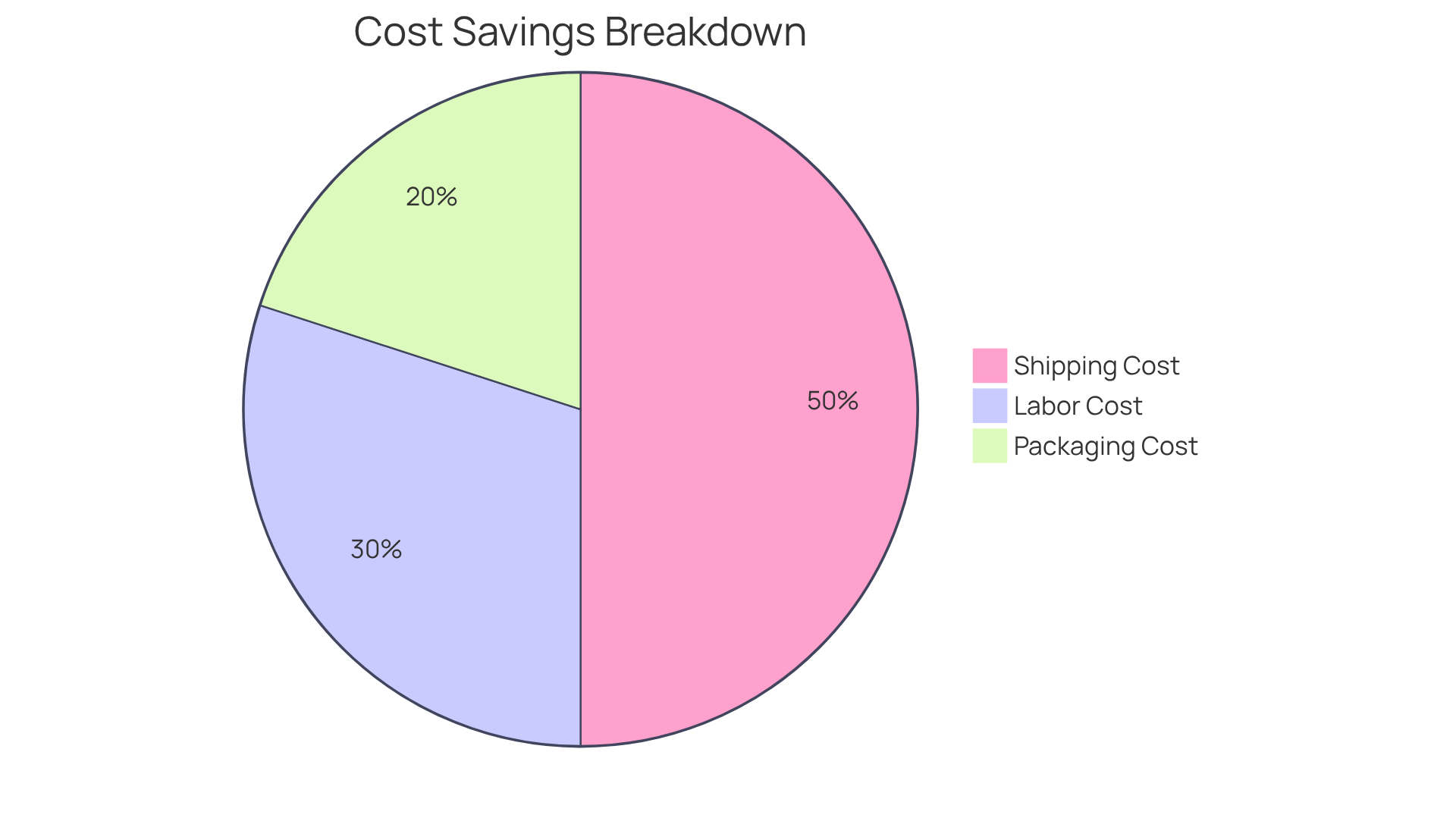

Assembly kits offer substantial cost savings by effectively minimizing both labor and material expenses. By pre-packaging components, companies can significantly reduce construction time and decrease the likelihood of errors that often lead to costly rework. For instance, kitting can lower labor costs associated with manual production, with firms reporting reductions in labor expenses by up to 30%.

Furthermore, consolidating shipments into sets not only simplifies logistics but also reduces shipping costs, as fewer packages are required to transport the same quantity of items. This operational efficiency leads to a more streamlined budget and enhanced profit margins, making packaging sets a strategic choice for companies aiming to .

Financial analysts have noted that the adoption of assembly kits can yield a 20% reduction in total packaging costs, underscoring the financial benefits of this methodology. Additionally, kitting supports corporate sustainability initiatives by minimizing the number of incoming boxes and the associated waste, thereby increasing its attractiveness for businesses seeking to improve their bottom line.

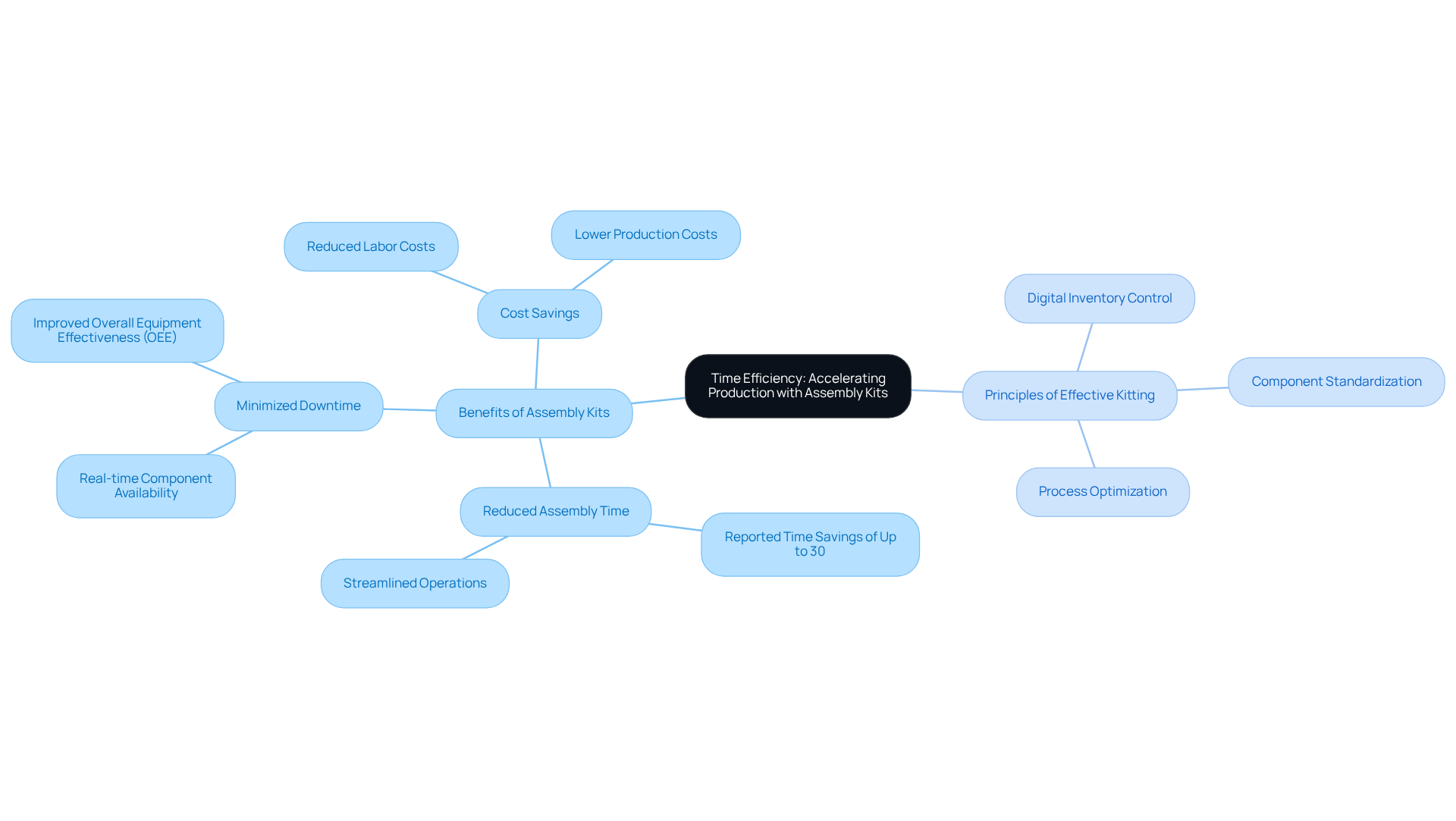

Time Efficiency: Accelerating Production with Assembly Kits

Using an assembly kit significantly accelerates production schedules by ensuring that all required components are pre-assembled and organized. This systematic approach enables workers to concentrate on the construction process, in searching for individual components. Consequently, downtime is minimized, and productivity is markedly enhanced, allowing businesses to respond swiftly to customer demands. This efficiency translates into a faster time-to-market for products, a critical advantage in today's competitive landscape.

For instance, manufacturers utilizing an assembly kit through kitting services have reported substantial reductions in assembly time, with some case studies indicating time savings of up to 30%. Industry leaders, including John Ponte, emphasize that implementing kitting not only streamlines operations but also cultivates a culture of continuous improvement, ultimately positioning companies for success in 2025 and beyond.

The three fundamental principles of effective kitting implementation are:

- Component standardization

- Digital inventory control

- Process optimization

These principles further enhance production efficiency. Additionally, implementing an assembly kit can lead to significant cost savings, making it an essential strategy for manufacturers aiming to improve their bottom line.

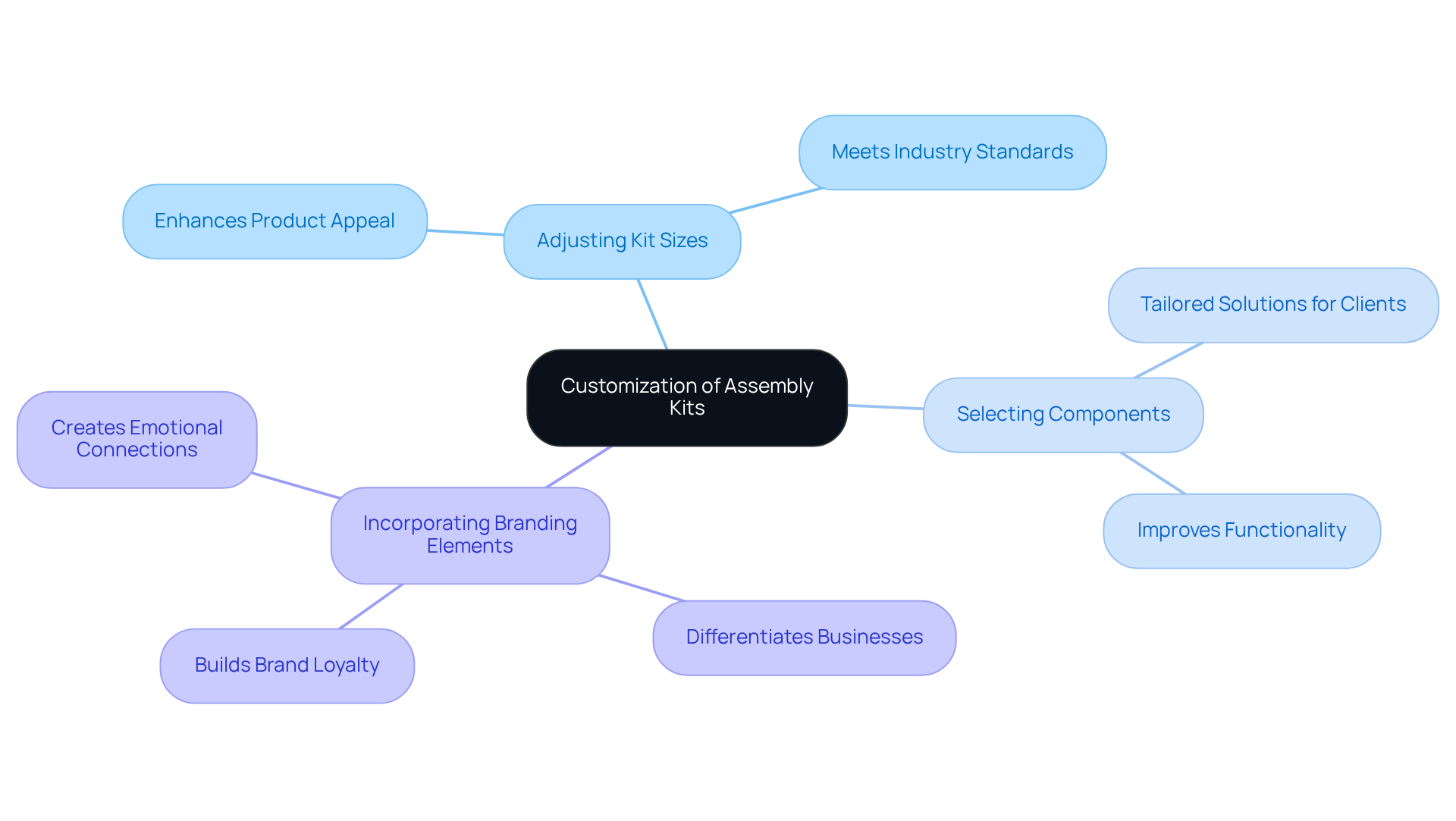

Customization: Tailoring Assembly Kits to Meet Unique Packaging Needs

Assembly kits can be meticulously customized to meet the unique needs of various industries and products. This customization may involve:

- Adjusting kit sizes

- Selecting specific components

- Incorporating distinctive branding elements

Such flexibility not only enhances product appeal but also empowers businesses to differentiate themselves in a competitive marketplace. Statistics indicate that 72% of buyers think that , highlighting the need for brands to invest in customized setups. As branding specialists observe, 'Emotionally resonant packaging cultivates brand loyalty,' suggesting that well-crafted packages can establish enduring connections with consumers.

For instance, nutraceutical firms have effectively increased their product attractiveness by employing assembly kits that represent their brand identity and fulfill customer expectations. By aligning assembly kits with sector-specific requirements, companies can effectively distinguish themselves and enhance consumer involvement.

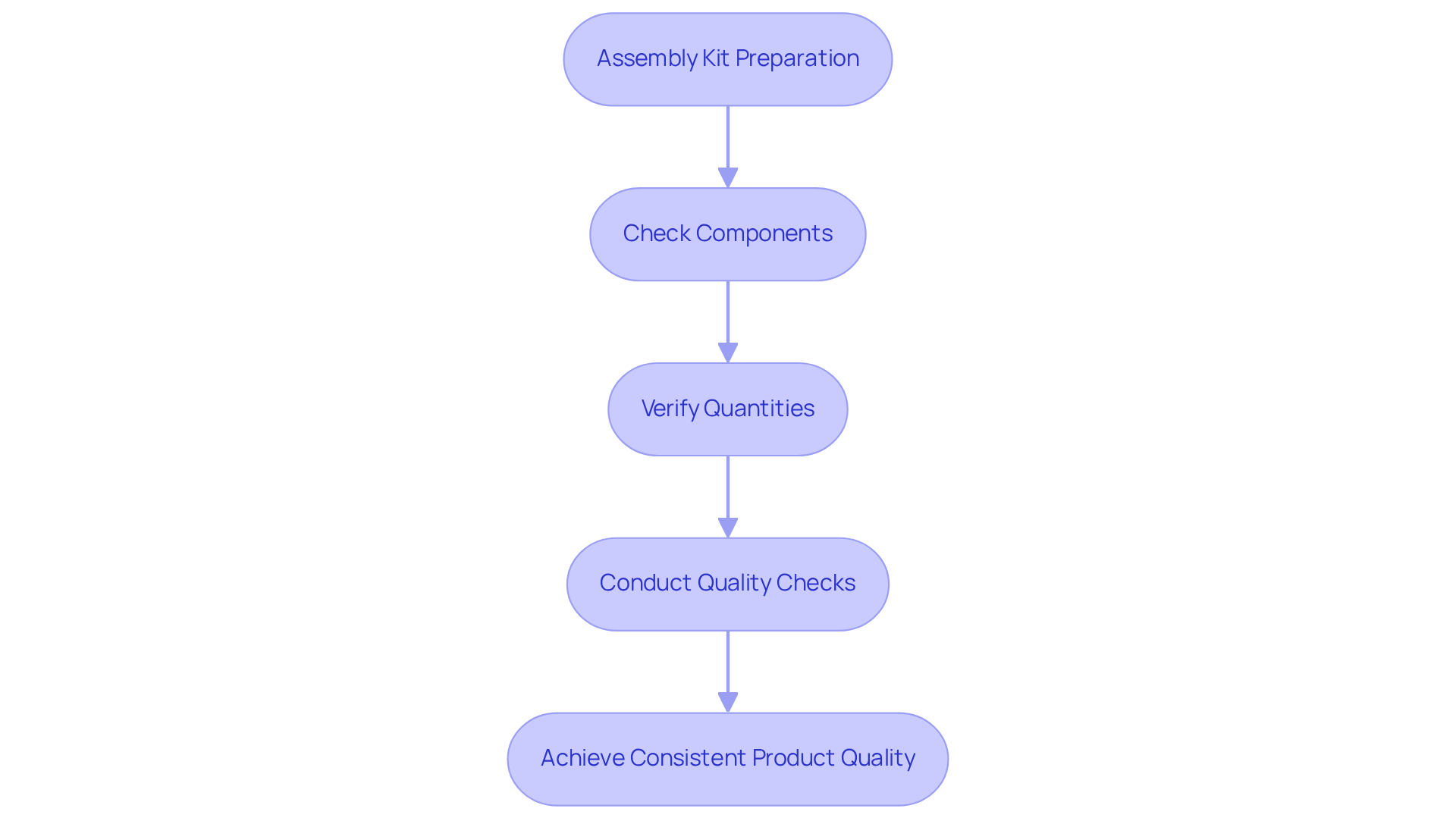

Quality Control: Ensuring Consistency with Assembly Kits

Assembly packages play a crucial role in [rigorous quality control](https://blog.westernpkg.com/10-benefits-of-contract-manufacturing-pharma-for-nutraceuticals) by guaranteeing that each package contains the correct components in the right quantities. This pre-assembly process significantly during production, resulting in a more consistent final product. By implementing quality checks at the kit level, companies can bolster their reputation for reliability and customer satisfaction—an essential factor in today’s competitive markets. Embracing these practices not only enhances operational efficiency but also positions businesses as leaders in quality assurance.

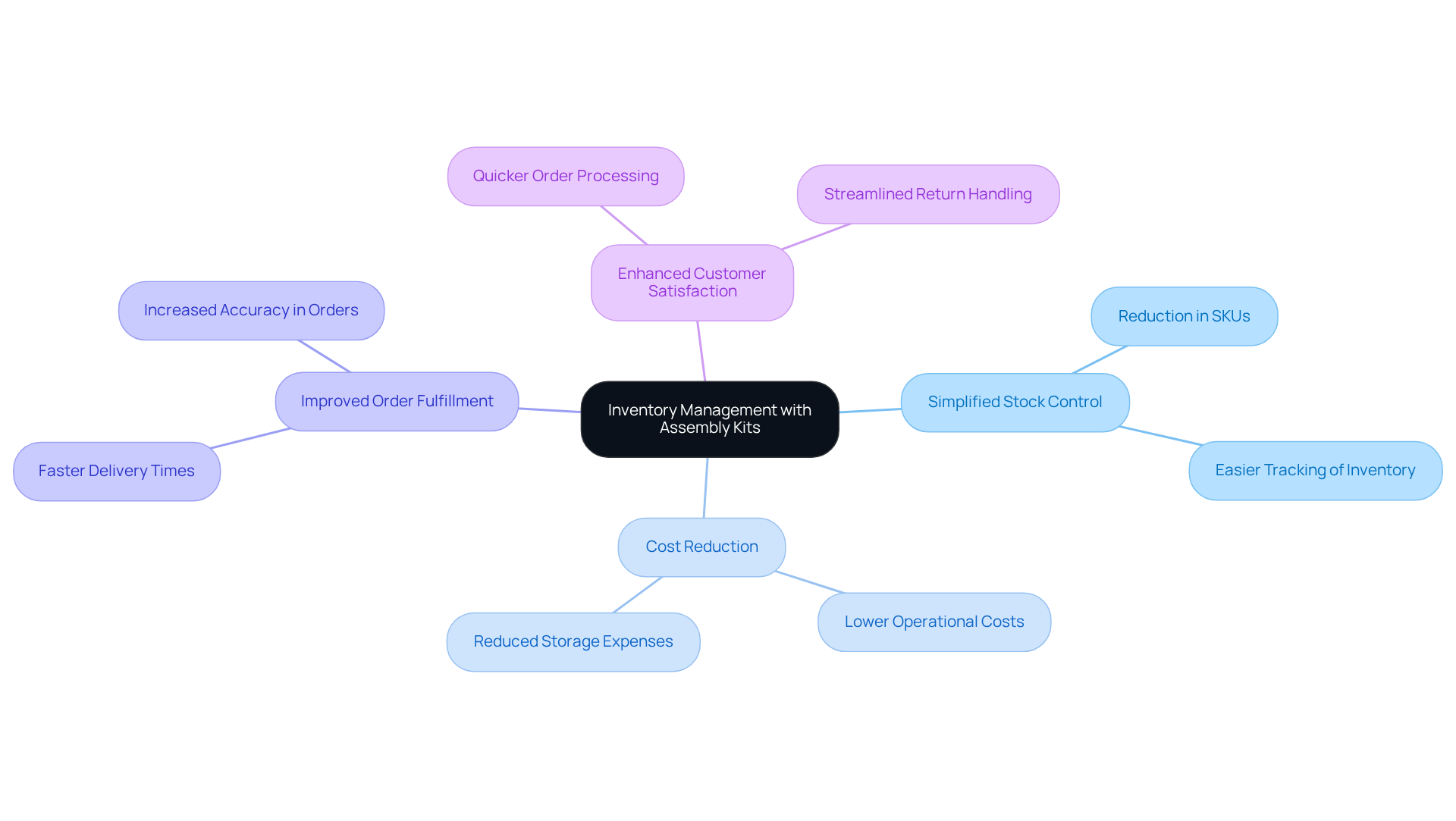

Inventory Management: Simplifying Stock Control with Assembly Kits

Assembly sets significantly enhance inventory management by consolidating multiple components into a single SKU, thereby simplifying stock control. This strategic approach associated with tracking individual items, leading to more accurate inventory counts. By minimizing the number of SKUs, companies can streamline their stock control processes, which not only lowers storage expenses but also improves order fulfillment precision. This efficiency is particularly advantageous for companies experiencing high product turnover rates.

In fact, businesses utilizing an assembly kit have reported a notable reduction in operational costs, as kitting and assembly services significantly lower these expenses. Moreover, client satisfaction has risen due to quicker and more dependable order processing. As noted by supply chain experts, "Fast delivery times lead to happier customers, as 88% of consumers are less likely to shop after a bad delivery experience."

Additionally, assembly kits streamline return handling by enabling prompt recognition and restocking of returned goods, thereby enhancing overall effectiveness and agility in today's competitive market.

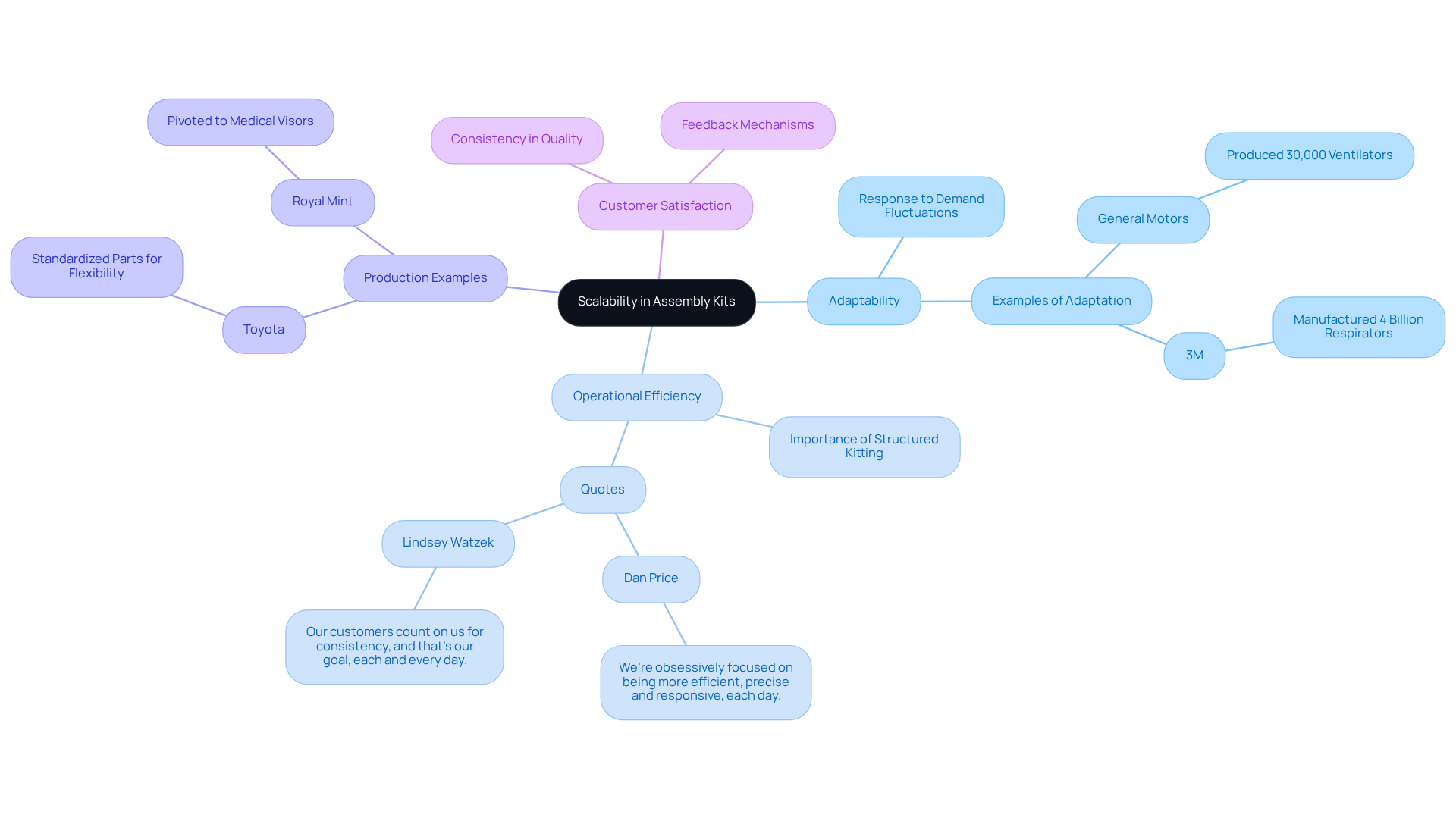

Scalability: Adapting Assembly Kits for Business Growth

The design of assembly kits allows for scalability, enabling businesses to adjust their production processes in response to fluctuating demand. As order volumes rise, companies can efficiently increase kit production without overhauling existing workflows. This adaptability is crucial for meeting customer needs promptly, especially in dynamic markets.

For instance, during the pandemic, firms such as General Motors shifted their production capabilities to create vital products, demonstrating the efficiency of adaptable manufacturing processes. Additionally, 3M manufactured more than four billion respirators in two years, further illustrating the scalability of production in response to demand.

Furthermore, businesses that implement structured kitting solutions often experience significant improvements in operational efficiency, allowing them to focus on growth rather than rectifying mistakes. As Dan Price, Shipping Manager, emphasizes, "We’re obsessively focused on being more efficient, precise and responsive, each day."

Statistics show that brands utilizing an assembly kit can enhance their production scalability, ultimately leading to better profit margins and client satisfaction. As Lindsey Watzek, Operations Lead, notes, consistency in delivering quality is paramount, and a well-structured kitting process supports this goal.

However, it is essential to remember that kitting should not be a source of stress; inefficient workflows often make it so. By aligning production sets with changing market demands and ensuring an informed single point of contact for effective collaboration, companies can guarantee they stay competitive and responsive to customer needs.

To enhance the advantages of construction sets, companies should frequently assess their existing for effectiveness.

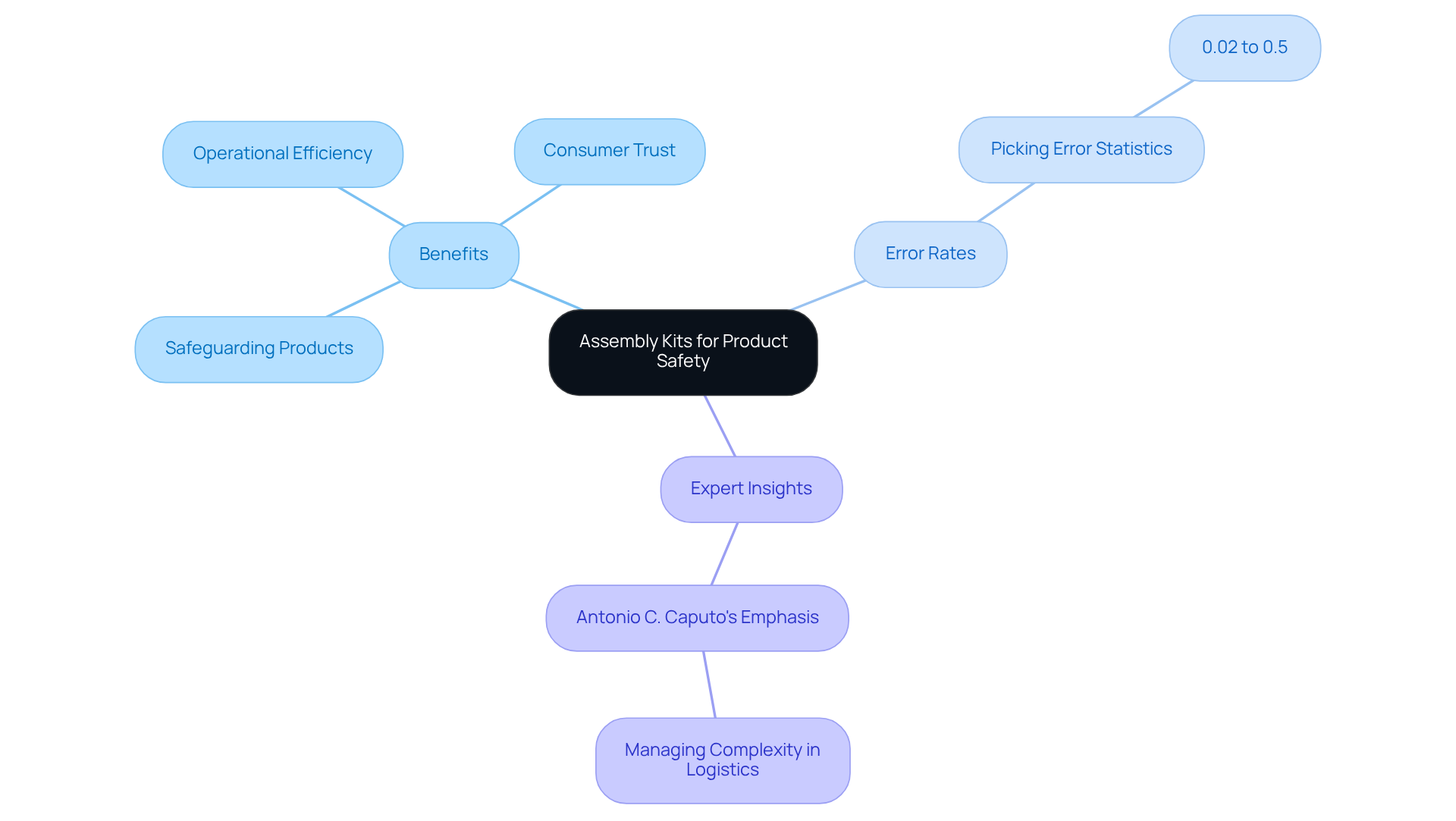

Safety: Protecting Products with Reliable Assembly Kits

Dependable assembly kits are essential for safeguarding products during transport and storage, as they securely package all components together. This cohesive strategy significantly reduces the risk of damage caused by shifting or missing components, which can lead to costly returns and customer dissatisfaction.

Kitting has been shown to enhance operational efficiency by simplifying component retrieval, with picking error rates reported between 0.02% and 0.5% in industrial warehouses. This reduction in errors decreases and ensures that the correct components are readily accessible.

By investing in high-quality assembly kits, companies not only bolster product integrity but also foster consumer trust. As logistics experts emphasize, effective management of complexity in production is vital for improving performance and maintaining quality.

Antonio C. Caputo highlights that errors in logistic processes pose a significant industrial challenge, underscoring the necessity of managing complexity. Integrating assembly components into logistics processes can lead to improved order accuracy and increased customer satisfaction, ultimately reinforcing brand loyalty.

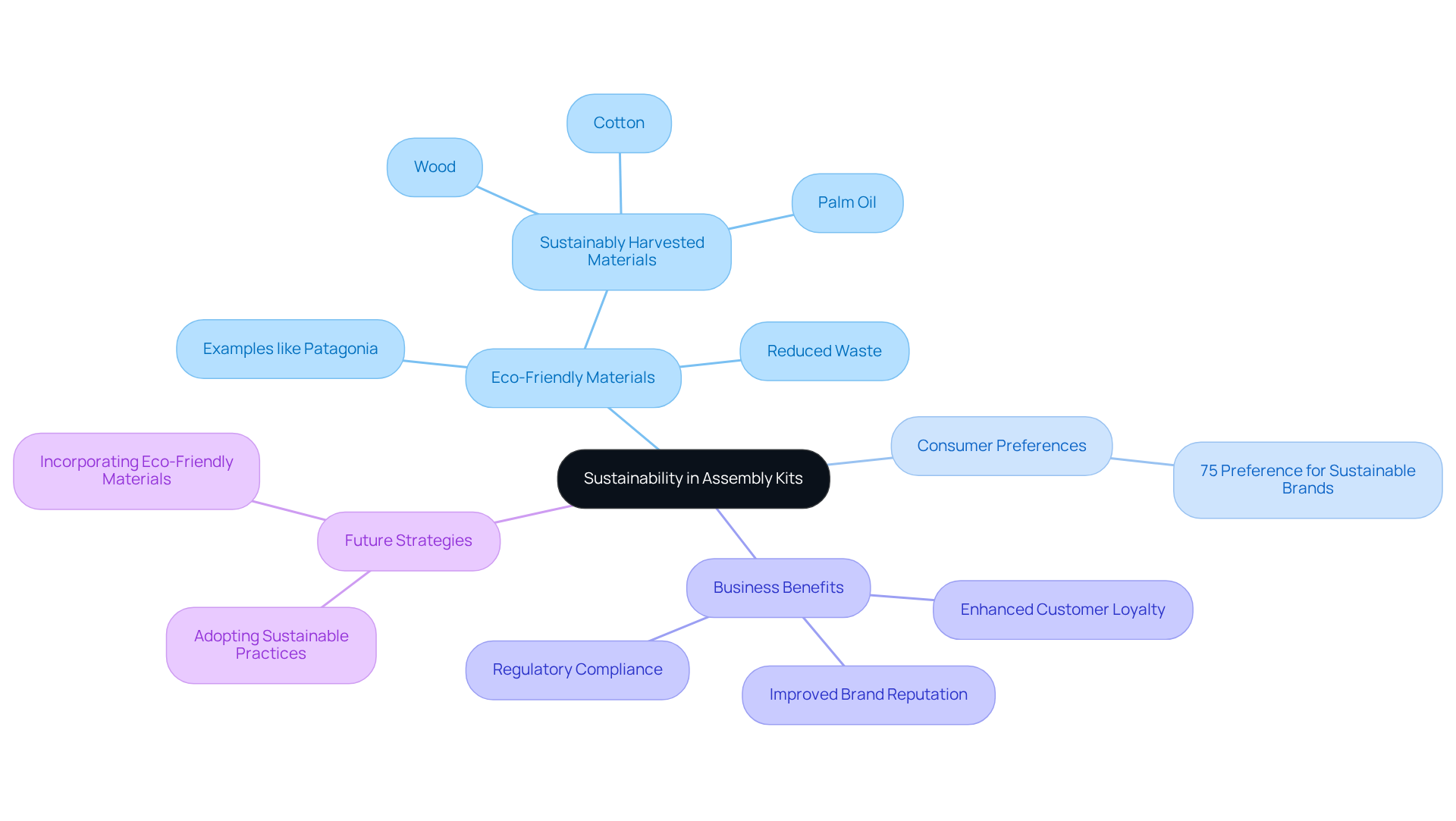

Sustainability: Eco-Friendly Practices with Assembly Kits

An assembly kit can be created with a strong emphasis on sustainability, utilizing eco-friendly materials that significantly minimize waste. By merging various elements into one package, companies not only reduce the quantity of packaging material used but also contribute to a smaller environmental impact. This strategic approach resonates with the growing number of environmentally conscious consumers; studies indicate that 75% of consumers prefer .

Furthermore, sustainably harvesting raw materials like wood, cotton, or palm oil prevents deforestation, showcasing the tangible benefits of eco-friendly materials. Companies employing sustainable construction packages have reported enhanced customer loyalty and involvement. For instance, Patagonia's dedication to sustainability illustrates how eco-friendly methods can lead to business success.

Additionally, adopting eco-friendly practices enhances brand reputation in a marketplace increasingly driven by ethical considerations. Companies that fail to address their environmental impact may face greater regulatory and reputational risks.

As we progress into 2025, the incorporation of sustainable materials in assembly kits for construction is not merely a trend but an essential strategy for brands seeking to thrive in a competitive environment. Producers are urged to begin incorporating environmentally friendly materials into their assembly kits now to remain competitive.

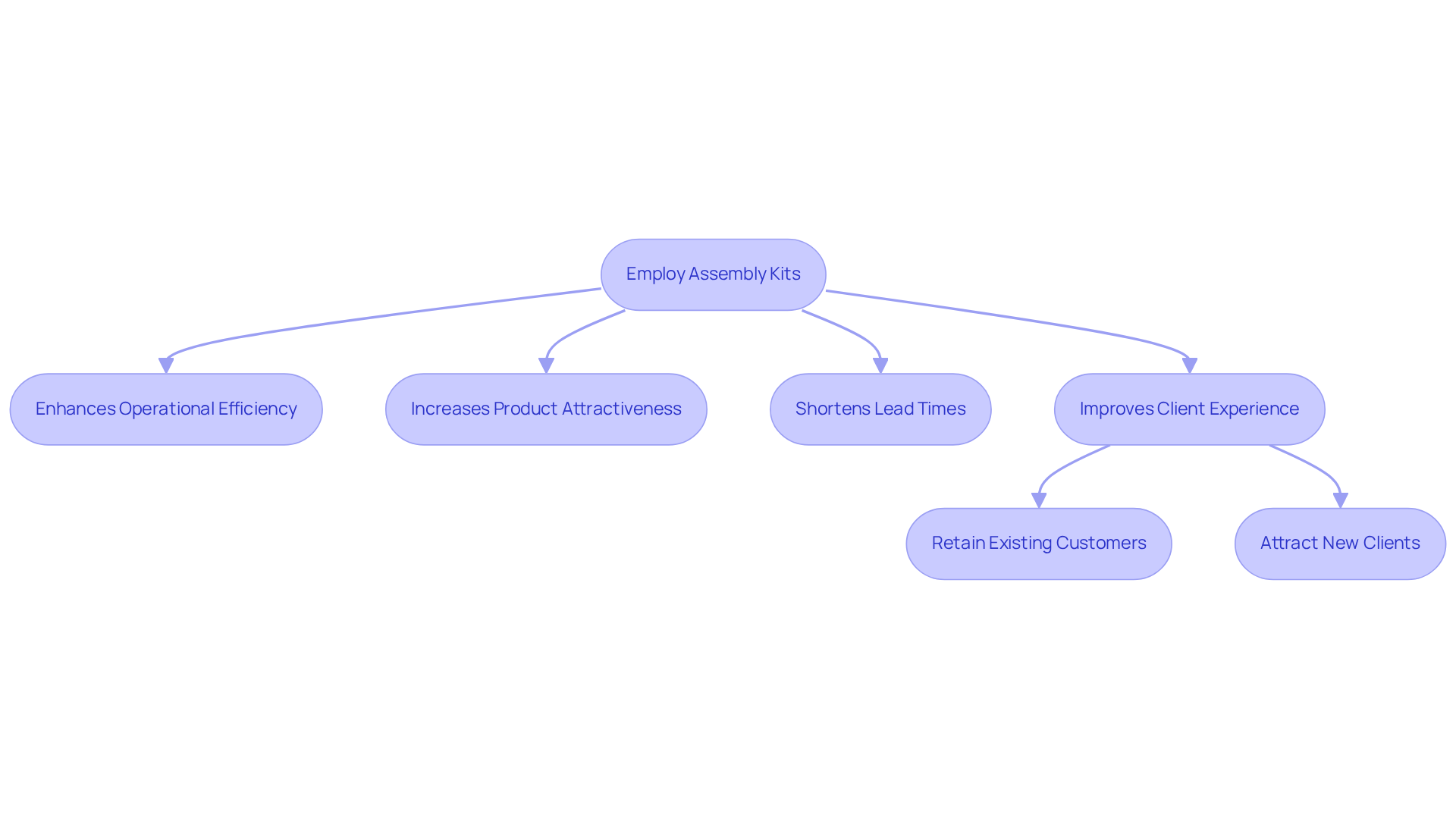

Competitive Advantage: Gaining Market Edge with Assembly Kits

Employing construction sets provides companies with a significant advantage by greatly enhancing operational efficiency and increasing product attractiveness. Firms utilizing construction kits can swiftly adapt to market demands, effectively shortening lead times and improving the client experience.

For instance, the introduction of a robotic kit construction system has achieved an average cycle time of 17-20 seconds per container, demonstrating improved precision and productivity. This not only aids in retaining existing customers but also attracts new clientele, positioning the business advantageously within a competitive landscape.

As market analyst Scott Frappier observes, "Efficient and effective distribution operations hinge on fully harnessing the available capabilities of your software and leveraging them to their fullest potential."

By leveraging an assembly kit, companies can optimize their processes and enhance their overall market presence, ensuring they remain ahead of the competition.

Conclusion

Utilizing assembly kits in packaging represents a transformative strategy for businesses aiming to enhance both efficiency and effectiveness. By integrating various components into cohesive kits, companies can streamline operations, reduce costs, and improve product presentation, ultimately leading to heightened customer satisfaction and brand loyalty.

This article highlights several pivotal benefits of assembly kits. These include:

- Significant cost savings through reduced labor and material expenses

- Time efficiency by accelerating production schedules

- Improved inventory management

- Customization options that empower businesses to tailor their packaging solutions to specific market needs

- Rigorous quality control measures that ensure consistency and reliability

- Scalability that enables companies to adapt to changing demands

- Eco-friendly practices that align with the growing consumer preference for sustainability

As the packaging landscape evolves, embracing assembly kits is not merely a strategic advantage; it is a necessity for businesses aiming to thrive in a competitive environment. By prioritizing these innovative solutions, companies can enhance operational performance, foster customer loyalty, and position themselves as leaders in their respective industries. The future of packaging lies in the effective implementation of assembly kits, paving the way for greater efficiency, sustainability, and success.

Frequently Asked Questions

What are integrated assembly kits and how do they benefit packaging solutions?

Integrated assembly kits are construction sets that enhance the packaging process by merging various components into a single kit, minimizing handling time, improving efficiency, and simplifying logistics. They also enhance product presentation, making items more appealing to consumers.

What types of products can Western Packaging's filling services accommodate?

Western Packaging's filling services cater to a diverse range of products, including powders, gummies, and soft-gels.

How do assembly kits streamline operations in packaging?

Assembly kits allow companies to pre-assemble packages, which accelerates fulfillment, reduces errors, and enhances overall operational efficiency, crucial for timely delivery and maintaining product quality.

What cost savings can companies expect from using assembly kits?

Companies can achieve significant cost savings by reducing labor and material expenses, with reports indicating labor cost reductions of up to 30%. Additionally, consolidating shipments into sets simplifies logistics and reduces shipping costs.

How do assembly kits contribute to corporate sustainability?

Assembly kits support sustainability initiatives by minimizing the number of incoming boxes and associated waste, making them an attractive option for businesses aiming to improve their environmental impact.

What time efficiency advantages do assembly kits offer?

Assembly kits accelerate production schedules by ensuring all required components are pre-assembled and organized, minimizing downtime and enhancing productivity, which allows for a faster time-to-market for products.

What are the fundamental principles of effective kitting implementation?

The three fundamental principles of effective kitting implementation are component standardization, digital inventory control, and process optimization.

What is the expected trend for integrated construction sets by 2025?

The trend towards integrated construction sets is expected to continue, with companies increasingly recognizing their value in optimizing supply chain management, enhancing flexibility, and responsiveness to market demands.