Overview

This article examines the substantial benefits of compliance packaging for nutraceutical manufacturers. It emphasizes how such packaging enhances medication adherence, ensures regulatory compliance, improves product safety, and boosts customer satisfaction.

Evidence supports these claims, demonstrating that compliance packaging can significantly increase adherence rates, reduce waste, and enhance brand loyalty. Ultimately, these advantages lead to better health outcomes and improved operational efficiency for manufacturers navigating a competitive market.

The case for compliance packaging is compelling, and its implementation is essential for those seeking to elevate their product offerings and customer satisfaction.

Introduction

The nutraceutical industry is undergoing a transformative shift, propelled by rising consumer health awareness and evolving regulatory demands. As manufacturers navigate this dynamic landscape, compliance packaging emerges as a critical solution that not only enhances product safety but also boosts consumer adherence and satisfaction.

With a plethora of options available, how can nutraceutical producers effectively leverage compliance packaging to maximize operational efficiency and meet consumer expectations? This article explores the multifaceted benefits of compliance packaging, highlighting its potential to:

- Elevate brand recognition

- Streamline supply chains

- Ultimately improve health outcomes for consumers

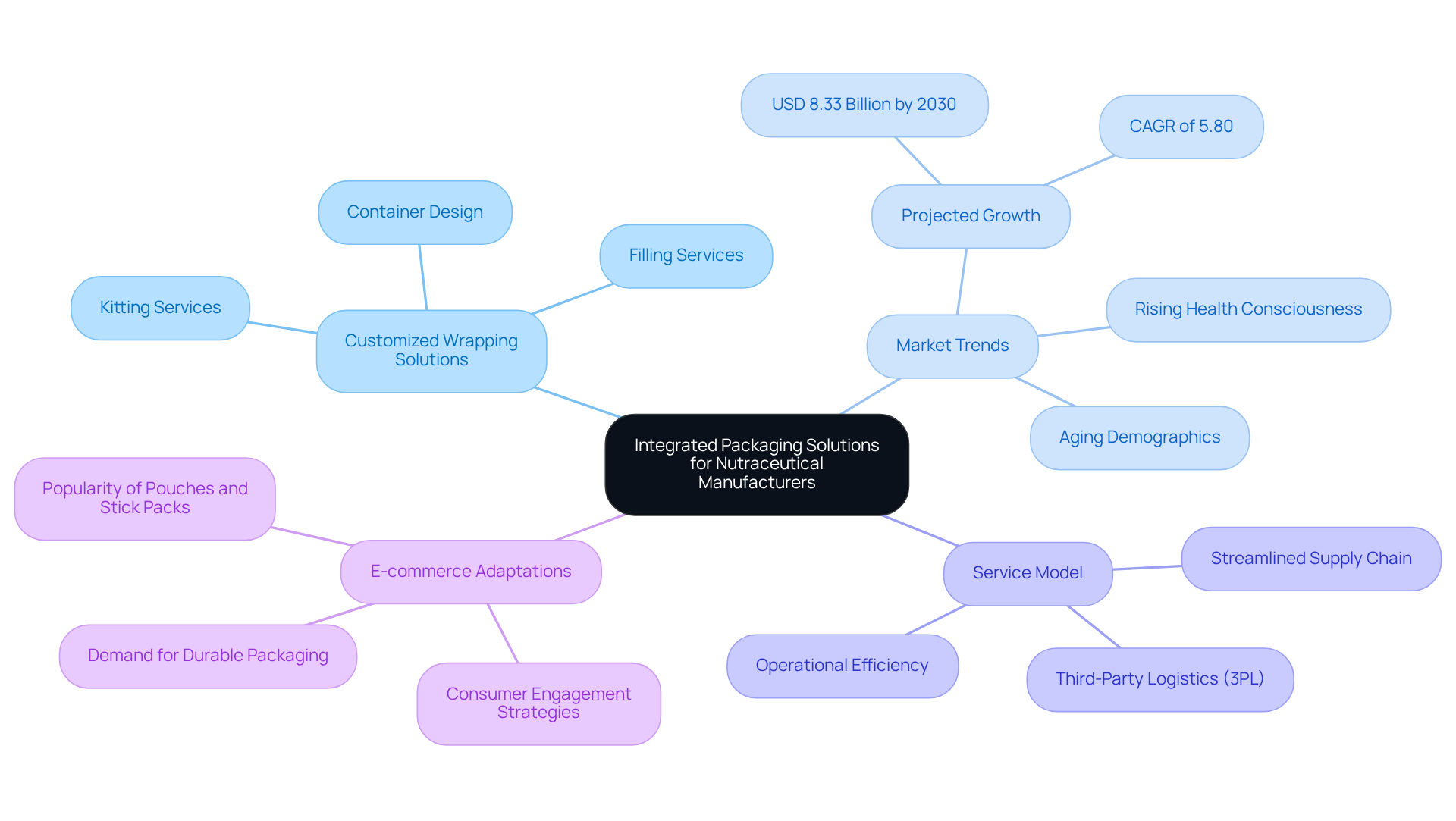

Western Packaging: Integrated Packaging Solutions for Nutraceutical Manufacturers

Western Packaging & Distribution excels in providing specifically designed for nutraceutical producers. Their integrated approach combines expert container design, filling services—including kitting—and robust third-party logistics (3PL), effectively streamlining the supply chain. This service model not only enhances product appeal but also ensures compliance packaging with stringent industry regulations, allowing manufacturers to concentrate on their core competencies while optimizing operational efficiency.

Recent trends indicate that the global nutraceutical container market is poised for significant growth, projected to reach USD 8.33 billion by 2030. This expansion is driven by a rising health consciousness and an aging demographic. Such growth underscores the importance of innovative solutions that meet evolving buyer needs. Industry leaders assert that integrated solutions can enhance supply chain efficiency, with studies revealing that companies implementing these strategies experience reduced lead times and improved product delivery.

The rise of e-commerce has necessitated containers that not only protect products during transport but also captivate consumers. As a result, adaptable and lightweight containers, such as pouches and stick packs, are gaining popularity, reflecting a shift towards convenience and sustainability. By capitalizing on these trends and leveraging our comprehensive 3PL services, Western Packaging positions itself as a preferred partner for nutraceutical manufacturers aiming to boost their market presence and operational effectiveness.

Improved Medication Adherence: Ensuring Compliance with Packaging Solutions

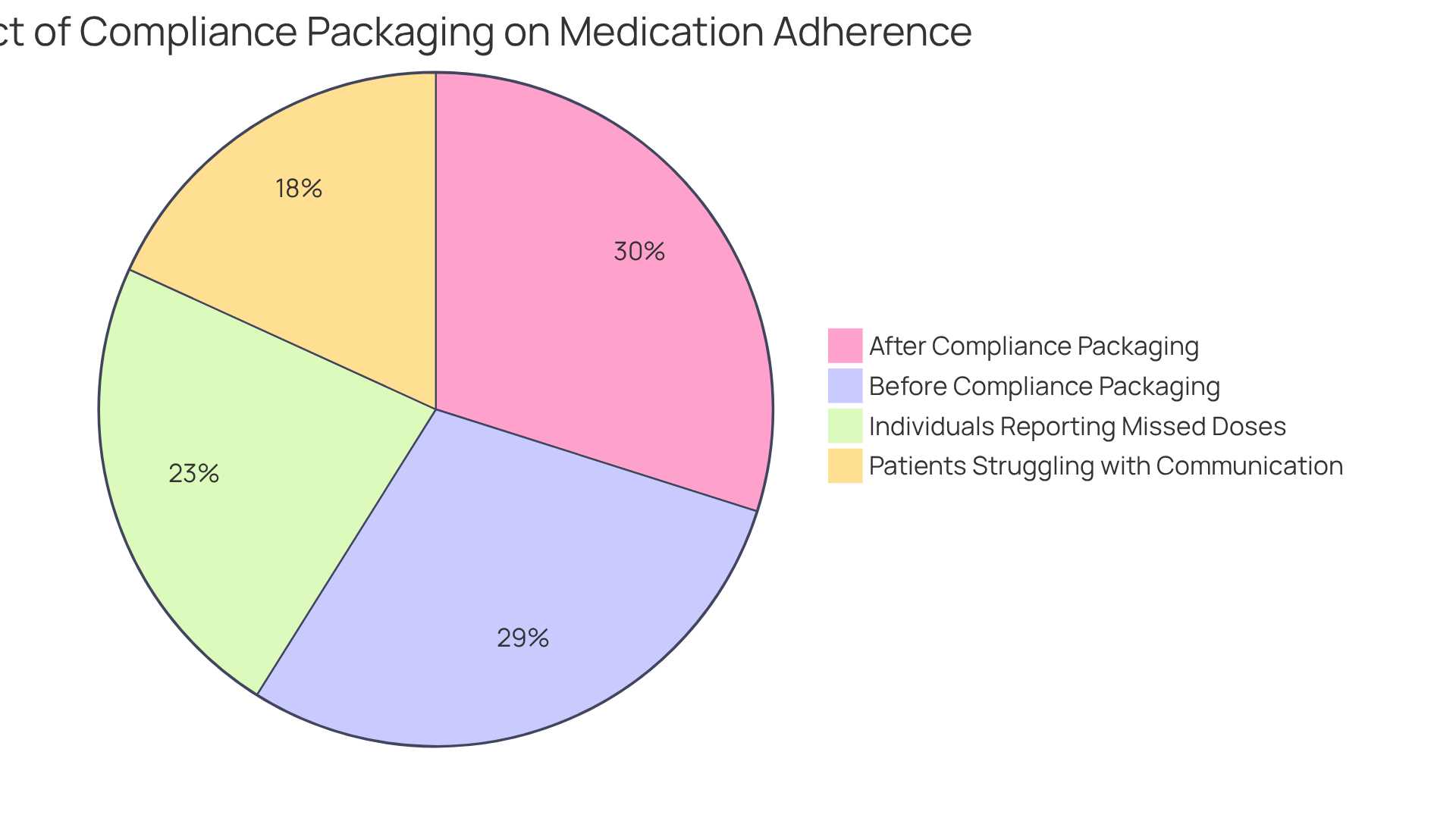

Compliance packaging, such as blister packs and multi-dose pouches, effectively organizes nutraceuticals in a user-friendly manner, facilitating adherence to dosing schedules. By clearly labeling the timing for each dose, these container solutions significantly reduce the risk of missed doses—an essential factor for nutraceuticals that require consistent intake to achieve optimal efficacy. Health experts recognize that these containers not only enhance patient adherence but also lead to improved health outcomes.

For example, studies indicate that blister wrapping can boost adherence rates from 79.8% to 82.2%, showcasing a tangible impact on consumer health. Furthermore, adherence containers address the prevalent issue of forgetfulness, with 63% of individuals taking five or more medications reporting missed doses. Additionally, 40-60% of patients struggle to accurately communicate their doctors' expectations shortly after receiving information, highlighting the communication gap that adherence solutions can help bridge.

By simplifying the medication plan, organized containers empower consumers to manage their health more effectively, ultimately resulting in better health outcomes and reduced healthcare costs. As Jason Z. Rose, CEO of AdhereHealth, states, 'By adopting more intuitive and more proactive medication management strategies, MA plans can avoid financial waste and improve their Star Ratings while actively helping members attain their long-term health goals.'

Manufacturers are encouraged to into their product lines to enhance adherence and improve health outcomes.

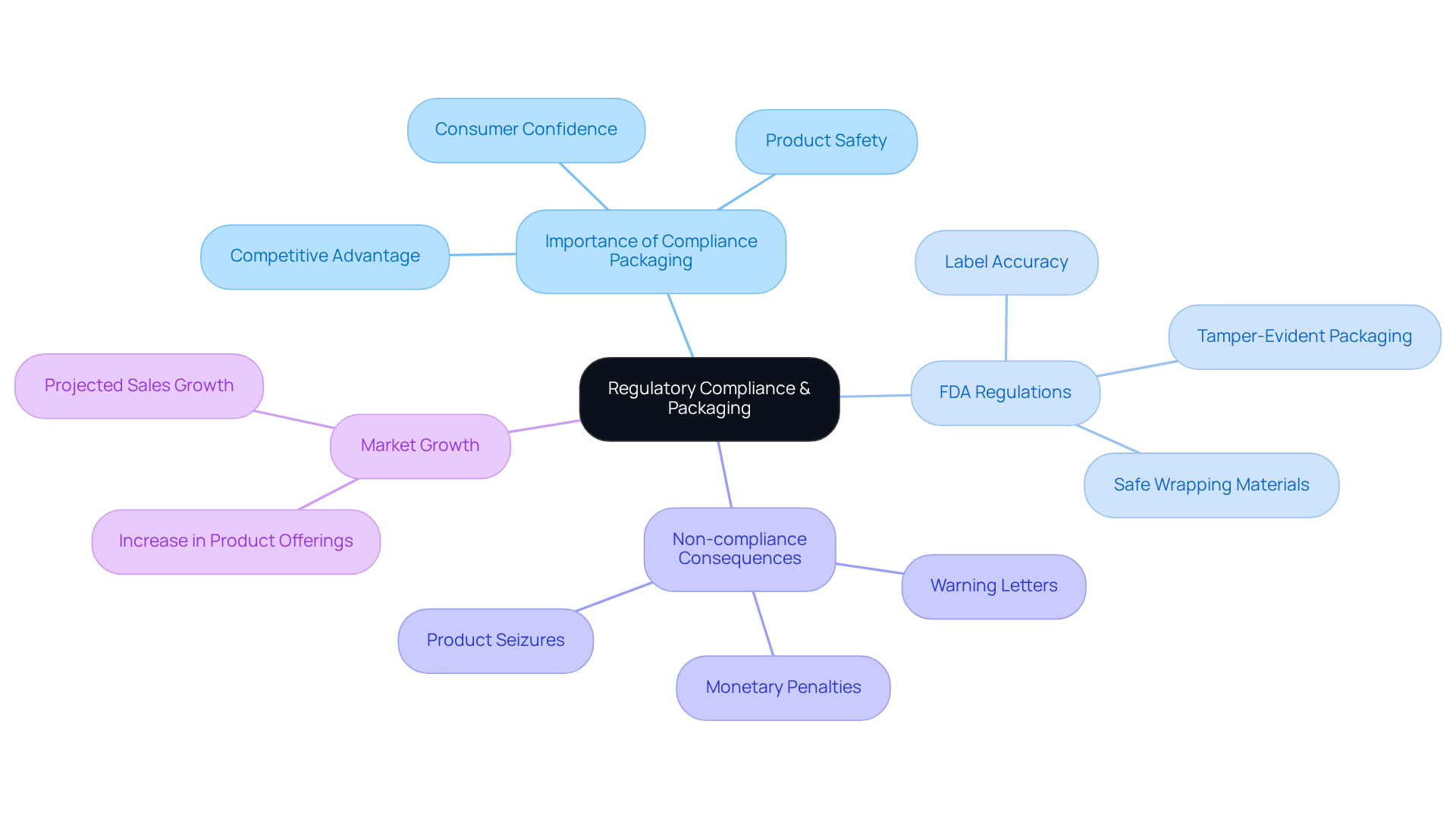

Regulatory Compliance: Meeting Industry Standards with Compliance Packaging

Compliance packaging is essential for nutraceutical producers to meet the stringent regulatory standards established by the FDA. This requirement encompasses ensuring that are safe, labels are accurate, and products are tamper-evident. By employing adherence container solutions, producers can optimize their processes to align with these regulations, significantly reducing the risk of non-compliance and the associated penalties.

For instance, in 2011, 73% of supplement producers examined by the FDA failed to comply with one or more regulations, underscoring the critical need for effective containment strategies. Moreover, the FDA possesses the authority to impose monetary penalties for non-compliance, which may include warning letters, fines, and product seizures.

As the dietary supplement market continues to grow, with sales projected to reach $166.58 billion by 2032, the importance of regulatory containers becomes increasingly evident. Expert opinions suggest that robust adherence strategies not only enhance product safety but also build consumer confidence, ultimately benefiting producers in a competitive landscape. By prioritizing compliance packaging, nutraceutical producers can safeguard their operations and ensure they meet the evolving standards set by regulatory authorities.

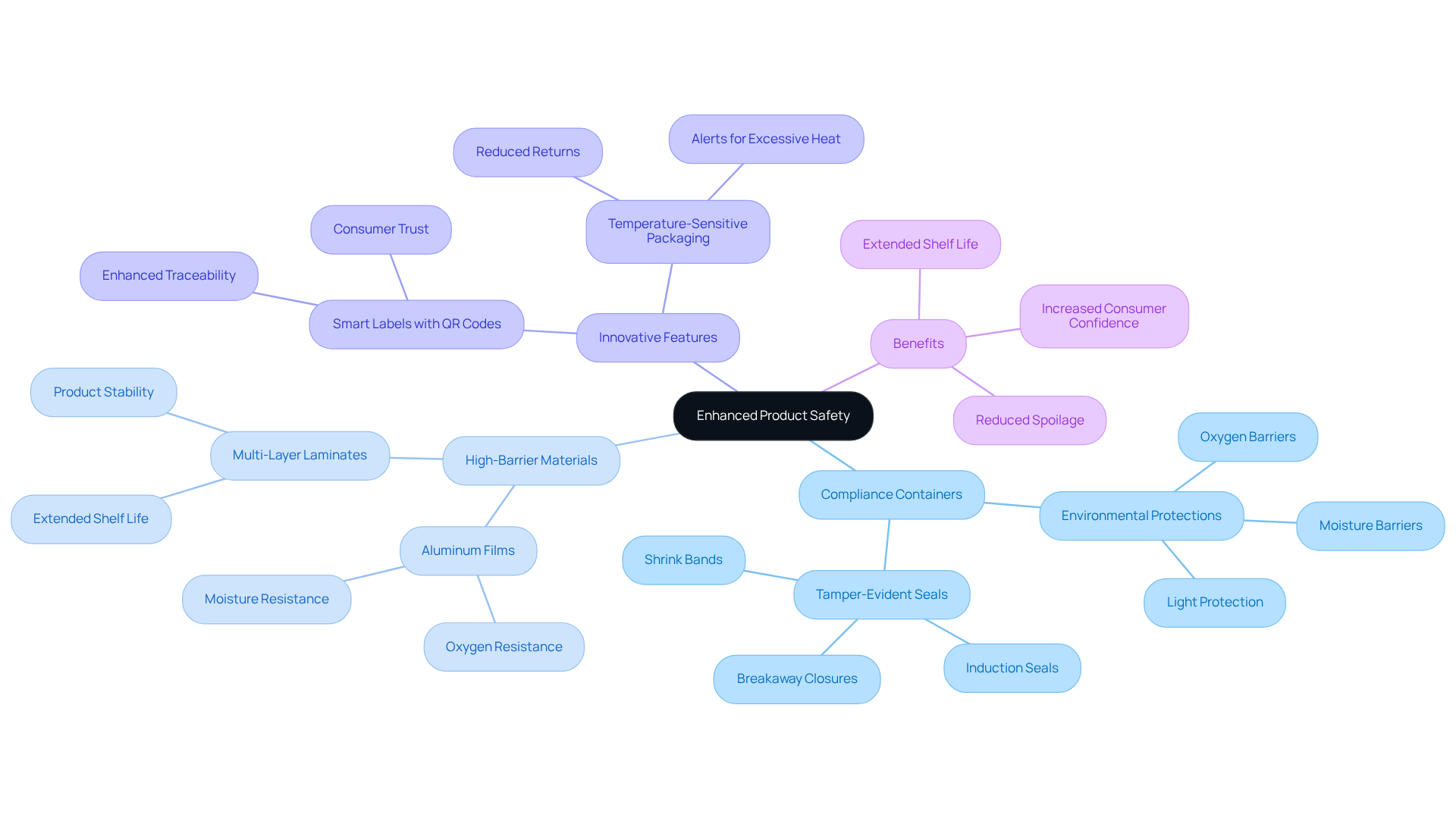

Enhanced Product Safety: Protecting Nutraceuticals with Compliance Packaging

Compliance containers fulfill a critical dual purpose: they not only organize doses but also shield nutraceuticals from detrimental environmental factors such as moisture, light, and air, which can jeopardize product quality. By utilizing high-barrier materials, producers can substantially enhance product safety. For example, advanced materials like aluminum-based films and multi-layer laminates offer exceptional moisture and oxygen barriers, crucial for maintaining the efficacy of sensitive ingredients. In fact, over 70% of pharmaceutical container producers prioritize high-quality barrier films to bolster drug stability and ensure compliance with regulations. Additionally, the integration of tamper-evident seals further strengthens this protection, guaranteeing that products remain secure and effective throughout their shelf life.

Recent advancements in compliance wrapping have introduced innovative features like smart labels with QR codes, which not only enhance traceability but also foster trust among consumers by offering transparency regarding product origins. Industry experts report that the implementation of QR codes on containers led to a 15% reduction in customer inquiries for a vitamin brand, underscoring the effectiveness of this innovation. Effective containment is paramount, directly influencing the efficacy and safety of nutraceuticals; thus, it plays a vital role in sustaining consumer trust and ensuring product integrity.

The benefits of high-barrier materials in nutraceutical containers are manifold: they extend shelf life, reduce spoilage, and enhance overall product stability. For instance, a probiotic producer observed a 30% decrease in product returns by employing temperature-sensitive containers, while another company achieved an 18-month extension in shelf life for fish oil supplements by using opaque, nitrogen-flushed bottles. These advancements underscore the indispensable role of , ultimately contributing to the success and reliability of nutraceutical products in a competitive market.

Convenience for Consumers: Streamlining Nutraceutical Use with Compliance Packaging

Compliance packaging revolutionizes the consumption of nutraceuticals by offering pre-measured doses that are easily accessible. This convenience particularly benefits busy individuals who struggle to . By employing intuitive and user-friendly product designs, manufacturers can significantly enhance the user experience, fostering greater satisfaction and brand loyalty.

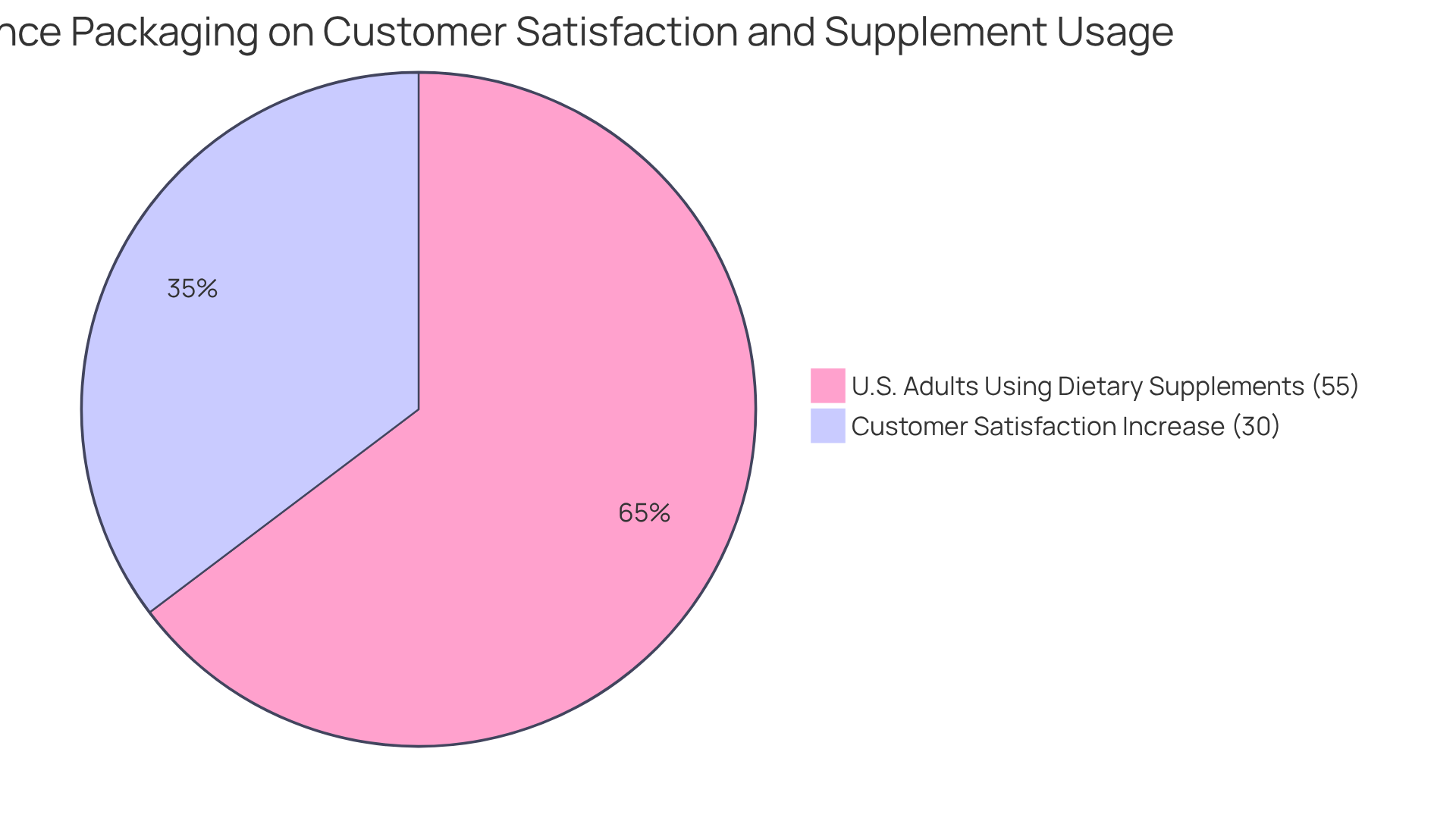

Statistics indicate that easy-to-use containers can yield a 30% boost in customer satisfaction, streamlining the daily process of taking supplements. For instance, blister packs and single-serve pouches not only ensure accurate dosing but also meet the growing demand for convenience among health-conscious individuals.

As Suraj Gujar states, 'The trend towards user-friendly containers is not just about aesthetics; it’s about creating a seamless experience that encourages adherence to health regimens.' Moreover, with 55% of U.S. adults regularly using dietary supplements, the importance of convenient packaging becomes increasingly clear.

By focusing on compliance packaging and regulatory solutions, nutraceutical producers can effectively meet consumer demands while enhancing brand loyalty.

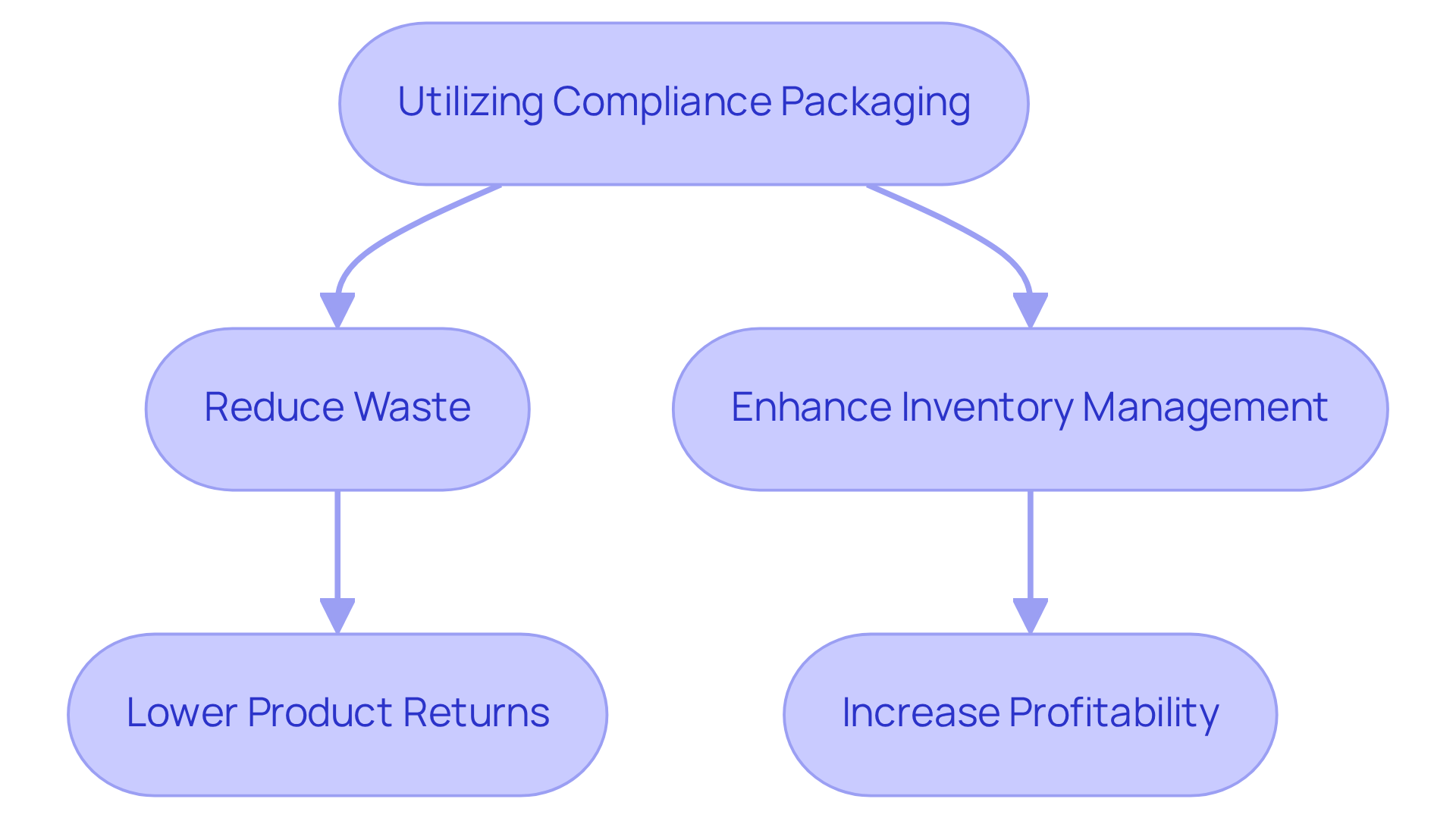

Cost-Effectiveness: Reducing Waste and Increasing Profitability with Compliance Packaging

By utilizing regulatory containers, producers significantly reduce waste associated with overproduction and mislabeling. Efficient wrapping solutions not only mitigate the risk of product returns but also enhance inventory management, ultimately driving profitability. Moreover, can lower labor costs and improve operational efficiency, establishing regulatory solutions as a financially sound choice for nutraceutical producers.

Brand Recognition: Elevating Nutraceuticals with Effective Compliance Packaging

Effective compliance packaging transcends mere functionality; it serves as a vital marketing resource for nutraceutical producers. By utilizing visually striking designs and clear labeling, brands can significantly enhance their product visibility on retail shelves.

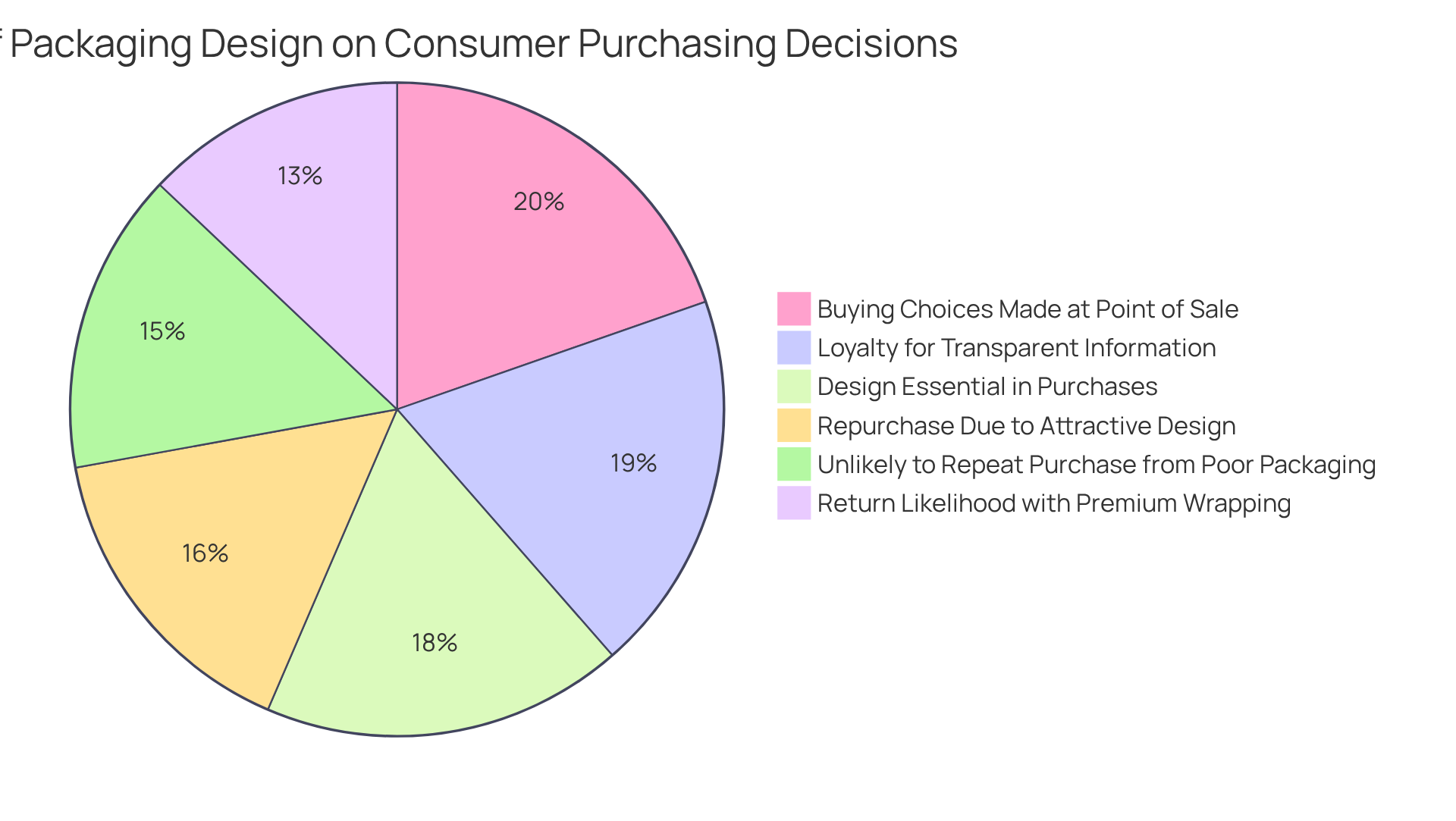

Studies reveal that:

- 72% of shoppers consider design essential in their purchasing decisions.

- 73% to 85% of buying choices are made at the point of sale.

This underscores the critical role aesthetics play in capturing consumer interest. Furthermore, clear labeling fosters trust, with 76% of individuals expressing loyalty to brands that provide transparent product information. Additionally, 60% of shoppers are unlikely to make a repeat purchase from an online seller if they receive a poorly wrapped item, highlighting the necessity of clarity and quality in packaging for customer retention.

This strategic focus on presentation not only boosts brand awareness but also cultivates customer loyalty, as consumers are more inclined to select items that are and easy to comprehend. In fact:

- 63% of shoppers have repurchased a product specifically due to its attractive design.

- 52% are more likely to return as customers to online retailers if their orders arrive in premium quality wrapping.

By prioritizing innovative container solutions and compliance packaging, including sustainable options that align with the growing consumer preference for eco-friendly materials, nutraceutical producers can create lasting impressions that drive sales and enhance brand loyalty.

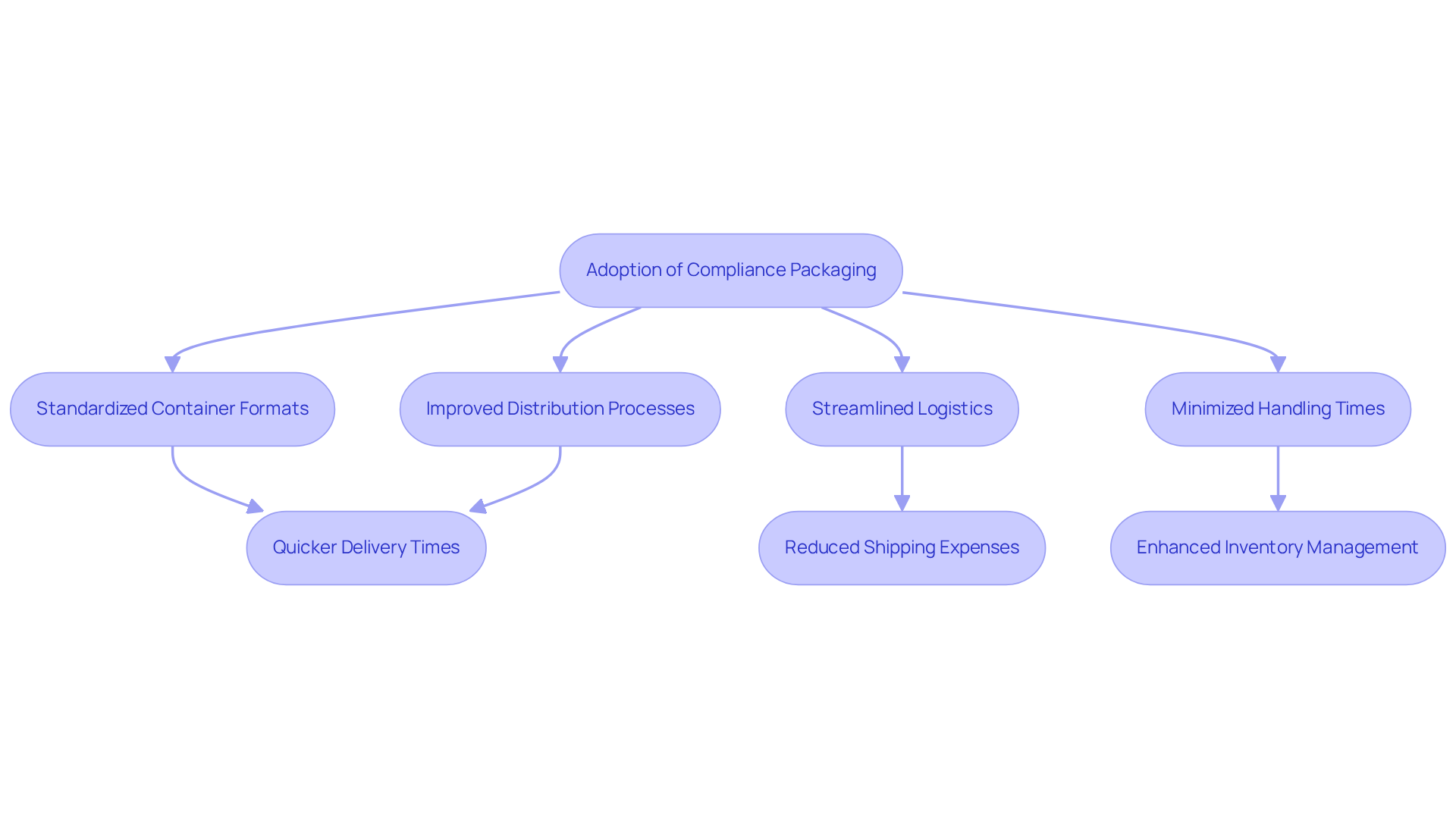

Supply Chain Efficiency: Optimizing Operations with Compliance Packaging

Compliance containers play a pivotal role in enhancing supply chain efficiency by streamlining logistics and minimizing handling times. By adopting standardized container formats, manufacturers can significantly improve their distribution processes, resulting in quicker delivery times and reduced shipping expenses. This approach not only simplifies logistics but also enhances inventory management through clear labeling and organization, facilitating easier stocking and selling for retailers.

Logistics experts highlight the significance of presentation in operational efficiency. A prominent quote from a logistics specialist emphasizes that 'standardized containers can result in significant decreases in logistics expenses, as they facilitate more effective use of space and resources during transport.' This sentiment resonates throughout the sector, where compliance packaging is recognized for its ability to alleviate challenges in the supply chain.

Looking ahead to 2025, the focus on compliance packaging solutions is expected to strengthen, as firms strive to further enhance logistics operations. Western Packaging's offers customized flexible solutions that accommodate a variety of products, from powders to gummies. Their comprehensive 3PL services improve supply chain management by providing warehousing, inventory management, and distribution solutions tailored to the specific needs of nutraceutical producers.

The impact of standardized containers on logistics expenses cannot be overstated; they accelerate operational speed and lead to substantial cost savings. By reducing handling times and enhancing overall efficiency, compliance packaging solutions empower nutraceutical producers to thrive in a competitive market. To remain resilient in a challenging environment, producers should assess their existing wrapping strategies and explore opportunities for standardization, ensuring they are well-prepared for the evolving landscape of supply chain risks.

Customer Satisfaction: Boosting Loyalty with Compliance Packaging Solutions

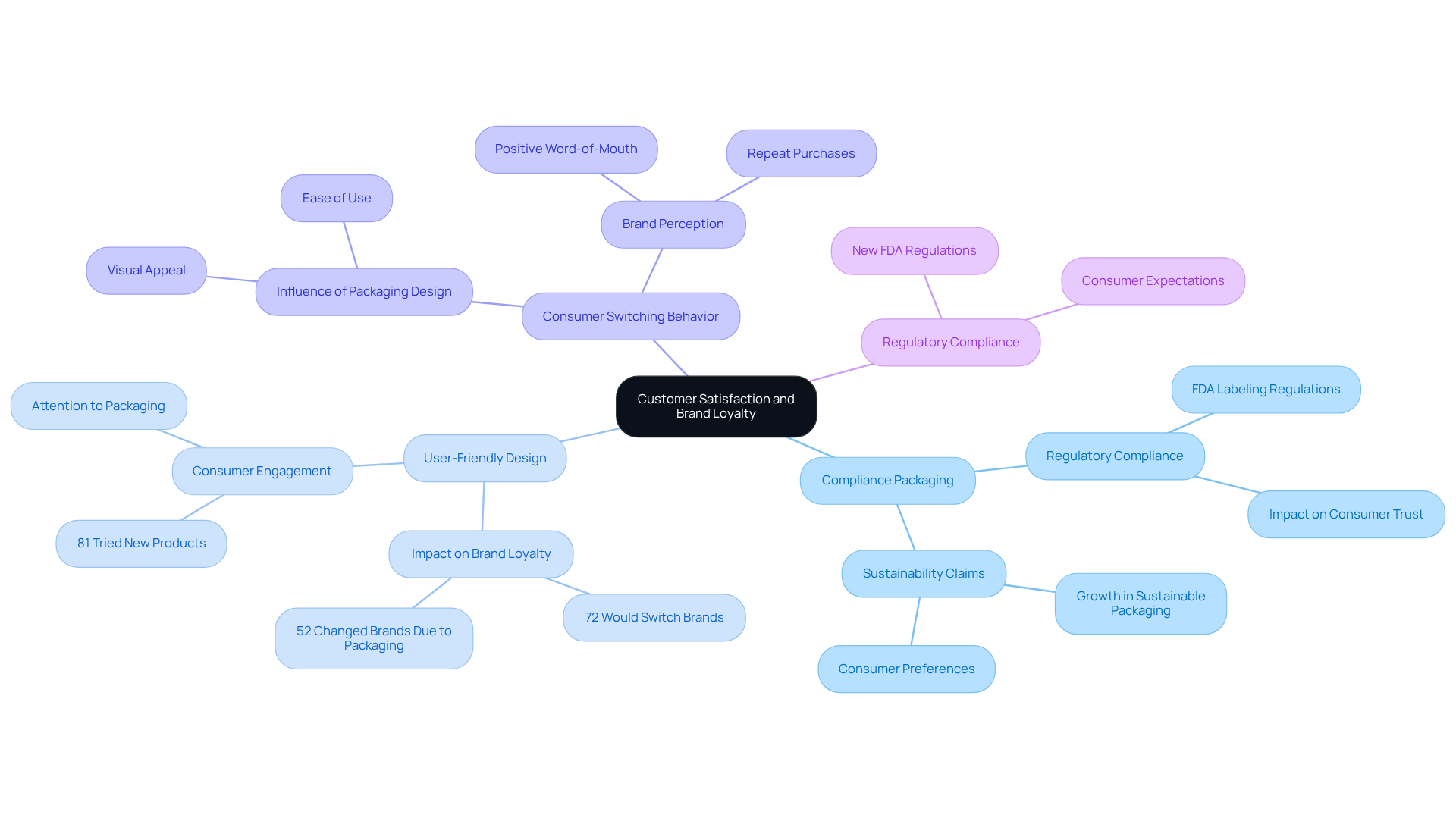

Compliance containers are pivotal in enhancing customer satisfaction and fostering brand loyalty among nutraceutical manufacturers. When buyers encounter containers that are straightforward and simple to utilize, their likelihood of remaining increases significantly. Indeed, 72% of shoppers would switch brands for products that offer more user-friendly containers, underscoring the importance of convenience in purchasing decisions. This loyalty not only leads to repeat purchases but also generates positive word-of-mouth, with 52% of customers having changed brands due to presentation, further strengthening the brand's reputation in a competitive market.

Moreover, efficient regulatory wrapping can directly influence buyer behavior. A study revealed that 81% of consumers have tried a new product simply because its design captured their attention. This illustrates the potential for nutraceutical brands to attract new customers through innovative and user-friendly designs. As the FDA's new labeling regulations take effect on February 25, 2025, brands that prioritize compliance will not only meet regulatory requirements but also enhance their appeal to consumers who increasingly value convenience and clarity in product information. According to Moira Stein, "Effective and innovative secondary wrapping can enhance shelf impact, create unique and memorable user experiences, elevate brand perception, and add value."

In conclusion, by investing in compliance packaging solutions that prioritize user experience, nutraceutical producers can significantly boost customer satisfaction, leading to increased brand loyalty and a stronger market presence. To ensure compliance with the new FDA regulations while enhancing user experience, manufacturers should regularly evaluate their design concepts.

Improved Health Outcomes: The Positive Impact of Compliance Packaging on Nutraceuticals

Compliance containers are essential for enhancing health outcomes by promoting adherence to nutraceutical routines. Research indicates that effective adherence systems yield an average adherence rate of 71%, compared to just 63% with traditional methods. This notable improvement significantly mitigates the risk of health complications linked to non-adherence, a critical concern given that nearly half of patients with chronic conditions face challenges with medication adherence. For example, studies demonstrate that elevated adherence rates are associated with a 51% reduction in the likelihood of hospitalization due to exacerbations in chronic diseases such as COPD.

Moreover, adherence containers not only assist individuals in consuming their nutraceuticals as directed but also bolster the reputation of providers as purveyors of effective health solutions. Healthcare professionals assert that adherence to nutraceuticals can lead to enhanced health outcomes, with one expert stating that compliance packaging can effectively support better medication adherence for high-risk patients. This scenario creates a win-win situation: foster brand loyalty and trust, ultimately benefiting both consumers and manufacturers within the nutraceutical market.

Conclusion

The significance of compliance packaging in the nutraceutical industry is paramount. By integrating user-friendly designs and adhering to regulatory standards, manufacturers can effectively enhance product safety, improve medication adherence, and streamline operations. This multifaceted approach not only meets consumer demands but also aligns with industry regulations, ultimately leading to greater operational efficiency and customer satisfaction.

Key insights from the article reveal that compliance packaging serves as a crucial tool for nutraceutical manufacturers. It bolsters medication adherence by organizing doses, ensures regulatory compliance to avoid penalties, and enhances product safety through advanced materials. Additionally, the convenience offered by these packaging solutions fosters customer loyalty and satisfaction, while also providing cost-effective benefits that reduce waste and improve profitability.

As the nutraceutical market continues to evolve, the imperative for innovative compliance packaging solutions becomes increasingly clear. Manufacturers are encouraged to prioritize these strategies not just for regulatory adherence but also to cultivate a strong market presence. Embracing compliance packaging can lead to improved health outcomes for consumers, ultimately reinforcing the importance of these solutions in driving both brand loyalty and business success.

Frequently Asked Questions

What services does Western Packaging & Distribution offer to nutraceutical manufacturers?

Western Packaging & Distribution provides customized wrapping solutions, expert container design, filling services including kitting, and robust third-party logistics (3PL) to streamline the supply chain for nutraceutical producers.

Why is compliance packaging important for nutraceutical manufacturers?

Compliance packaging is essential for meeting stringent FDA regulatory standards, ensuring that wrapping materials are safe, labels are accurate, and products are tamper-evident, thus reducing the risk of non-compliance and associated penalties.

How does compliance packaging improve medication adherence?

Compliance packaging, such as blister packs and multi-dose pouches, organizes nutraceuticals in a user-friendly manner, clearly labeling dosing schedules to reduce missed doses and enhance patient adherence, leading to improved health outcomes.

What market trends are affecting the nutraceutical container market?

The global nutraceutical container market is projected to reach USD 8.33 billion by 2030, driven by rising health consciousness and an aging demographic, highlighting the need for innovative solutions that meet evolving buyer needs.

What types of containers are becoming more popular in the nutraceutical industry?

Adaptable and lightweight containers, such as pouches and stick packs, are gaining popularity due to their convenience and sustainability, especially in the context of the rise of e-commerce.

What impact do adherence containers have on consumer health?

Adherence containers can significantly boost adherence rates, with studies showing increases from 79.8% to 82.2%, and help bridge communication gaps regarding medication expectations between patients and healthcare providers.

What are the consequences of non-compliance with FDA regulations for nutraceutical producers?

Non-compliance can lead to monetary penalties imposed by the FDA, including warning letters, fines, and product seizures, making it crucial for producers to prioritize compliance packaging.

How can manufacturers enhance their market presence and operational effectiveness?

By integrating compliance and adherence packaging into their product lines and leveraging comprehensive 3PL services, manufacturers can improve health outcomes and boost their market presence.