Overview

The article elucidates the myriad benefits of blister packaging for nutraceutical manufacturers, underscoring its critical role in enhancing medication adherence, ensuring regulatory compliance, preserving product integrity, and promoting sustainability. These advantages are substantiated by data that highlights improved consumer trust, reduced waste, and increased brand visibility. Consequently, blister packaging emerges as a strategic choice for manufacturers aiming to optimize their operations and meet evolving market demands.

Introduction

The ascent of the nutraceutical industry underscores the essential role of effective packaging solutions, with blister packaging emerging as a transformative force. This innovative method not only enhances medication adherence and ensures regulatory compliance but also preserves product integrity, establishing itself as a crucial asset for manufacturers. Yet, in a landscape rich with options, what distinctly differentiates blister packaging? A thorough exploration of its diverse benefits reveals how it can:

- Streamline operations

- Elevate brand visibility

- Cultivate consumer trust in a market that demands both quality and sustainability

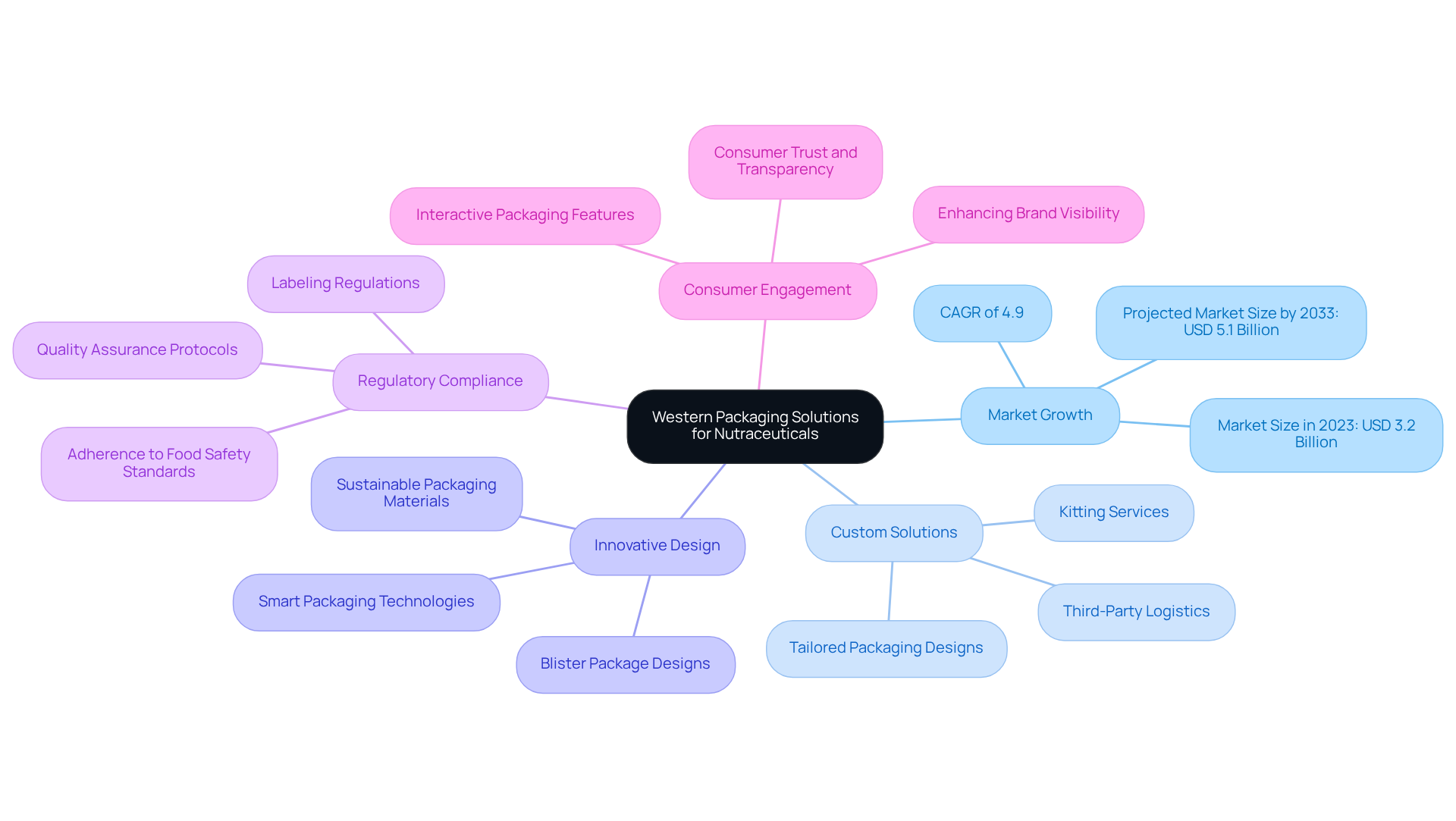

Western Packaging: Tailored Blister Packaging Solutions for Nutraceutical Manufacturers

Western Packaging excels in providing for nutraceutical manufacturers using blister package designs. The global nutraceutical packaging market is projected to grow at a CAGR of 4.9% from 2024 to 2033, underscoring the increasing demand for effective packaging.

By combining innovative design with comprehensive filling services—including kitting and third-party logistics—Western Packaging ensures that items comply with regulatory standards while effectively engaging consumers. This strategic approach not only enhances brand visibility but also maintains product integrity, positioning Western Packaging as a preferred partner in the nutraceutical sector.

Such customized services are essential for manufacturers aiming to optimize their packing processes and enhance distribution efficiency, ultimately bolstering their competitive advantage in a rapidly evolving market.

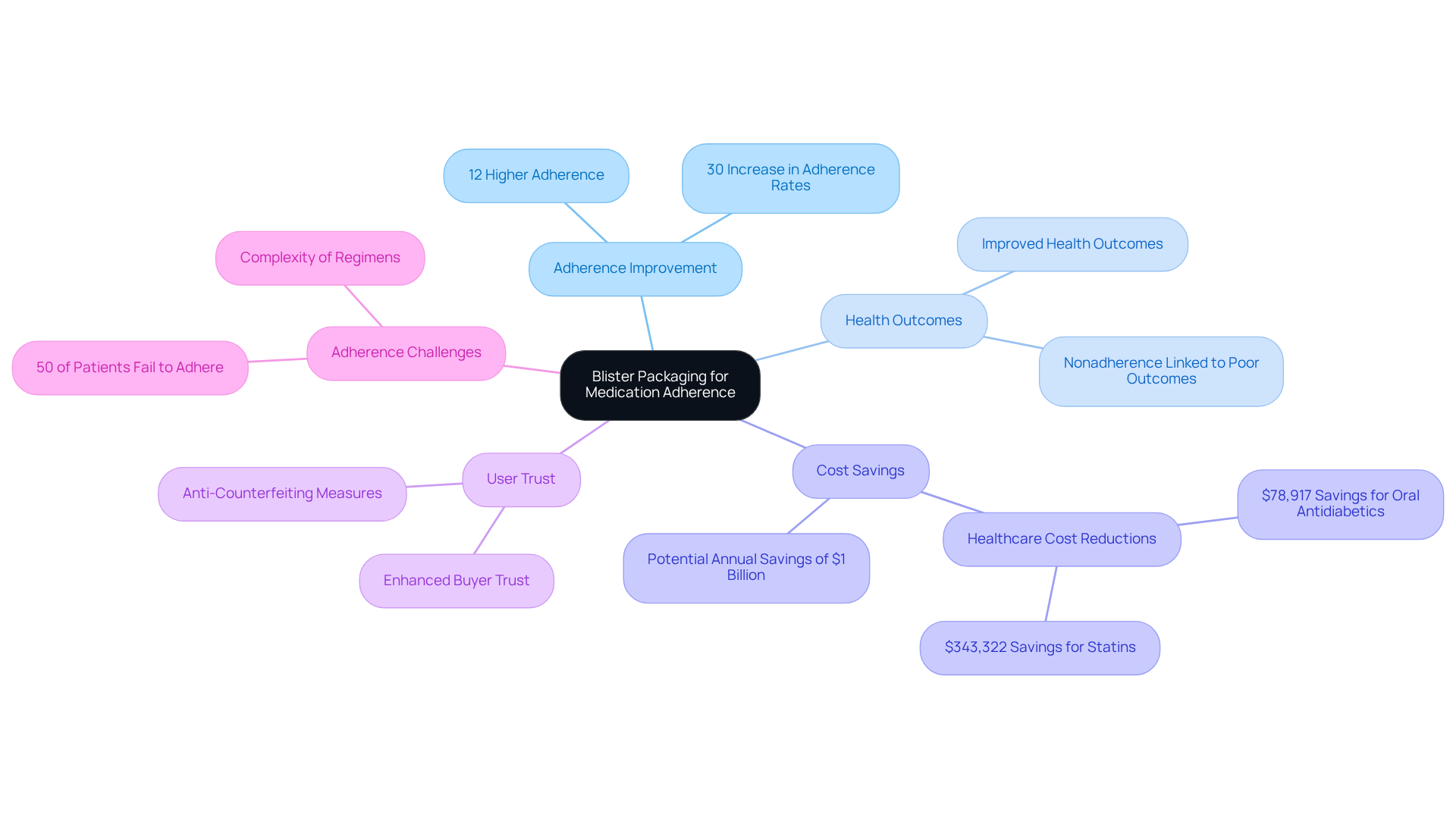

Enhance Medication Adherence with Blister Packaging

Blister packages are vital in enhancing medication adherence among consumers. They provide a systematic and organized method for dispensing doses, significantly reducing the likelihood of missed doses. Research indicates that patients utilizing medication packs have a 12% higher chance of adhering to their prescribed routines, leading to improved health outcomes. This is particularly crucial for nutraceuticals, where is necessary to achieve the desired health benefits.

Alarmingly, nearly 50% of patients fail to follow their medication instructions, underscoring the adherence challenges that specialized containers can effectively address. Additionally, the potential for healthcare cost reductions linked to improved adherence is noteworthy, with estimates suggesting substantial annual savings for health plans.

Manufacturers can leverage this advantage, positioning their products as not only effective but also user-friendly, thereby fostering buyer trust and satisfaction. As Eric P. Borrelli stated, 'sealed containers for medications, such as blister packages, are among the most widely acknowledged and confirmed methods for improving medication adherence.'

Furthermore, integrating robust anti-counterfeiting strategies in a blister package is essential for maintaining buyer confidence.

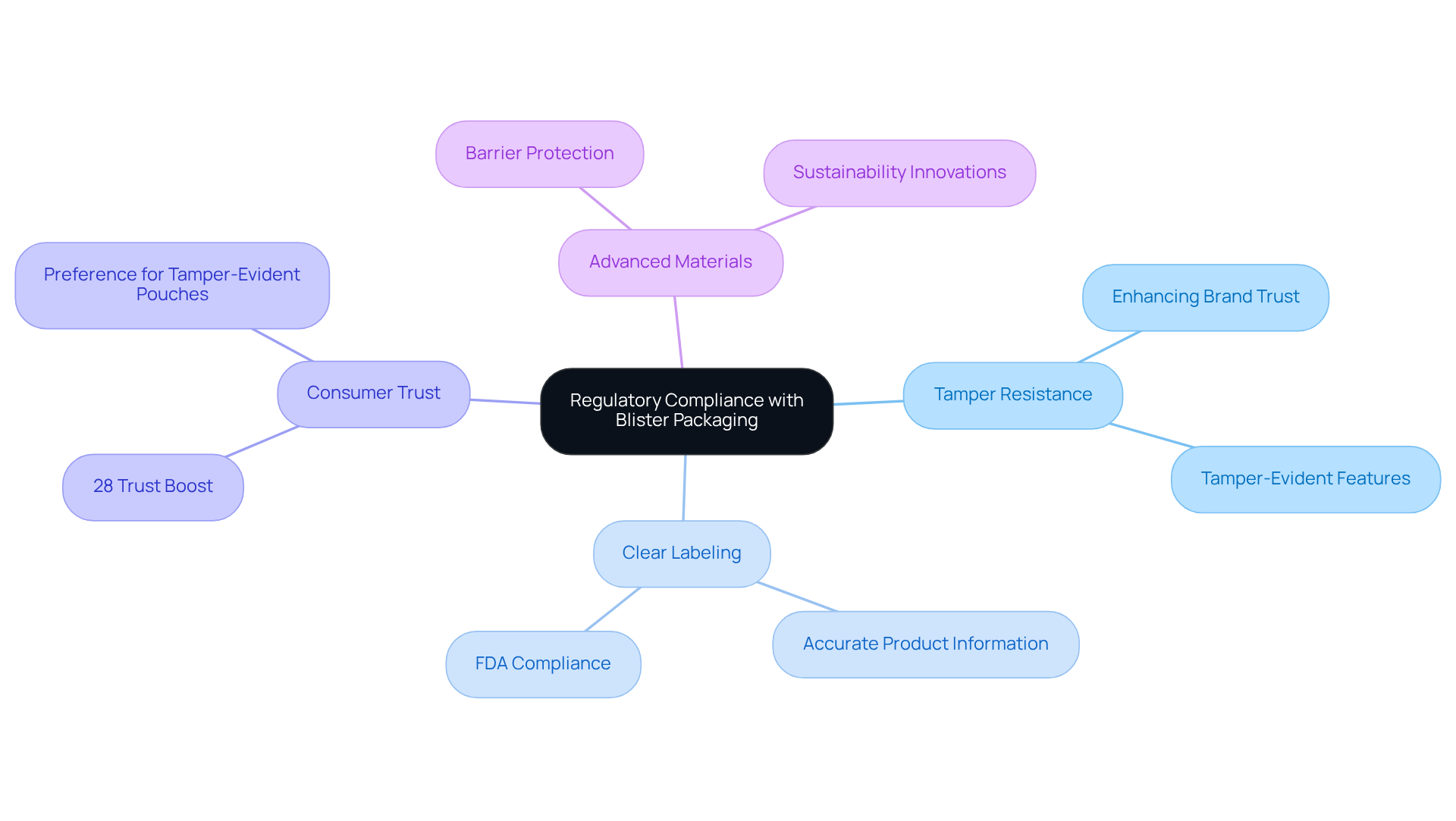

Meet Regulatory Compliance with Blister Packaging

Blister package solutions are crucial for nutraceutical manufacturers aiming to meet stringent regulatory compliance requirements. It ensures that products are tamper-resistant when packaged in a blister package, thereby safeguarding consumer safety and enhancing brand trust.

Clear and informative labeling plays a vital role in compliance, allowing manufacturers to effectively communicate essential product information. By employing protective wrapping, manufacturers demonstrate their commitment to quality and safety while addressing the growing public demand for reliable health products.

Notably, compliant nutraceutical containers can boost consumer trust by 28% compared to non-compliant alternatives, making compliance a critical factor in today's market. Furthermore, utilizing advanced barrier materials in capsule containers can help minimize product loss and extend shelf life, thereby supporting adherence to compliance and safety standards.

To effectively implement , manufacturers should consider partnering with packaging specialists to ensure that their solutions align with both regulatory standards and consumer expectations.

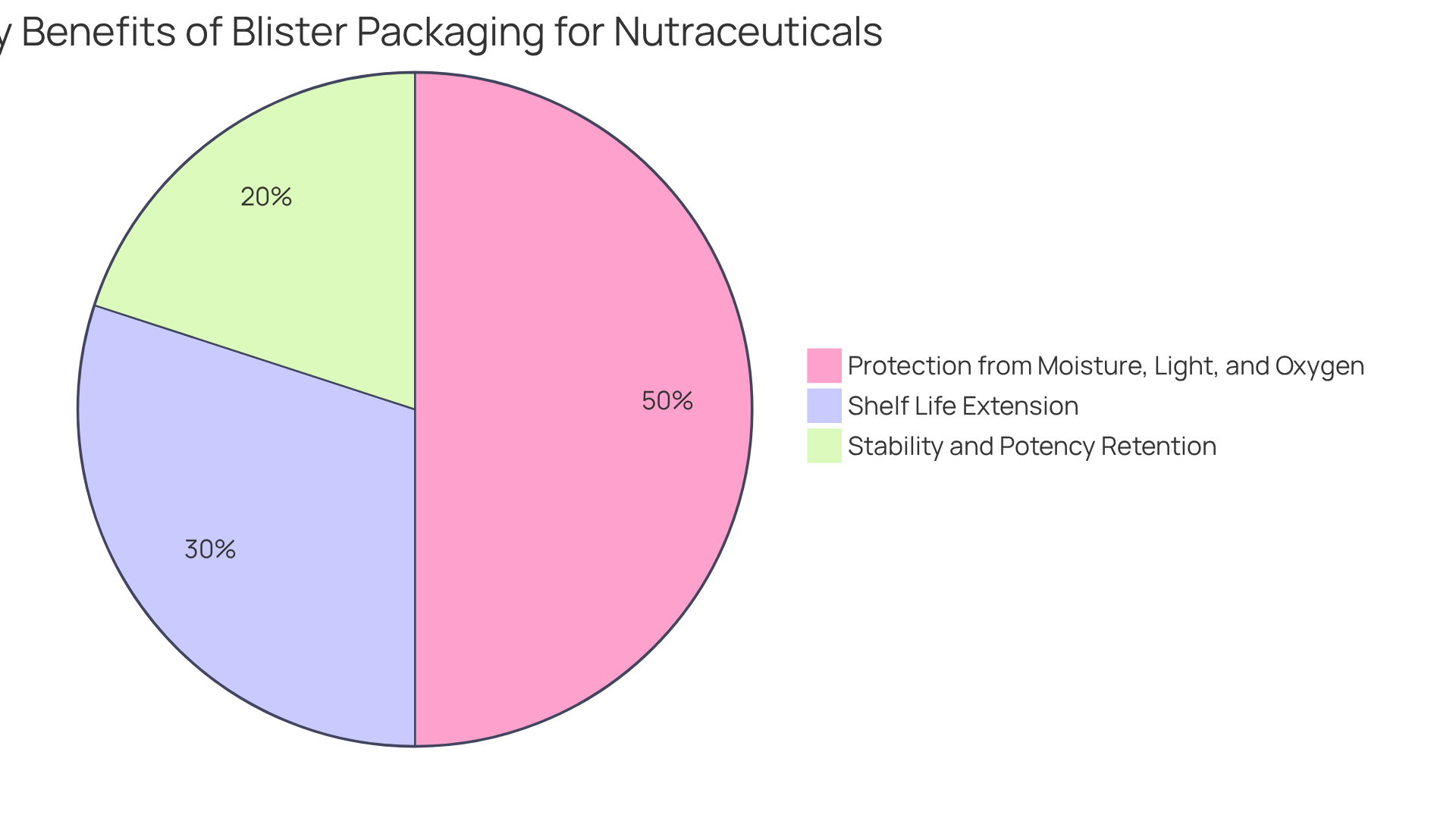

Ensure Product Integrity with Blister Packaging Solutions

Blister packages serve as a formidable barrier against moisture, light, and oxygen—critical elements that jeopardize the integrity of nutraceutical products. By enclosing each dose within a sealed environment, manufacturers can effectively maintain the potency and efficacy of their offerings throughout their shelf life. This preservation is particularly vital for sensitive ingredients, which are susceptible to degradation over time.

Research indicates that products stored in can retain their quality significantly longer than those in conventional wrappers, with sealed packs enhancing shelf life by as much as 30%. Nutraceuticals, including vitamins and herbal supplements, demonstrate improved stability and potency retention when stored in a blister package, underscoring their essential role for quality-focused manufacturers.

By leveraging customized adaptable wrappers from Western Packaging—such as large pouches for protein products and stick packs for nutraceuticals—brands can protect their offerings from environmental factors while also crafting appealing visual assets that elevate their shelf presence and brand recognition, ultimately fostering customer trust.

Boost Consumer Convenience with Blister Packaging

The blister package is meticulously crafted to prioritize user convenience, making it an essential choice for nutraceutical producers. Its intuitive, easy-to-open design facilitates swift access to doses, aligning seamlessly with the fast-paced lifestyles of modern consumers. Notably, around 85% of solid medications in European markets are housed in sealed units, underscoring the effectiveness of this storage method in enhancing user experience. The transparent quality of blister packages not only highlights the product but also empowers users to effectively , significantly enriching the overall user experience.

Furthermore, as the industry pivots towards sustainable materials, manufacturers are encouraged to explore eco-friendly alternatives that resonate with consumer preferences for responsible packaging. By emphasizing these elements of convenience and sustainability, nutraceutical manufacturers can broaden their customer base and foster enduring brand loyalty, as consumers value the thoughtful design that supports their health regimens.

For instance, companies like Amcor HealthCare lead the way with innovative, recyclable container solutions that enhance usability while addressing environmental challenges.

Achieve Cost-Effectiveness with Blister Packaging

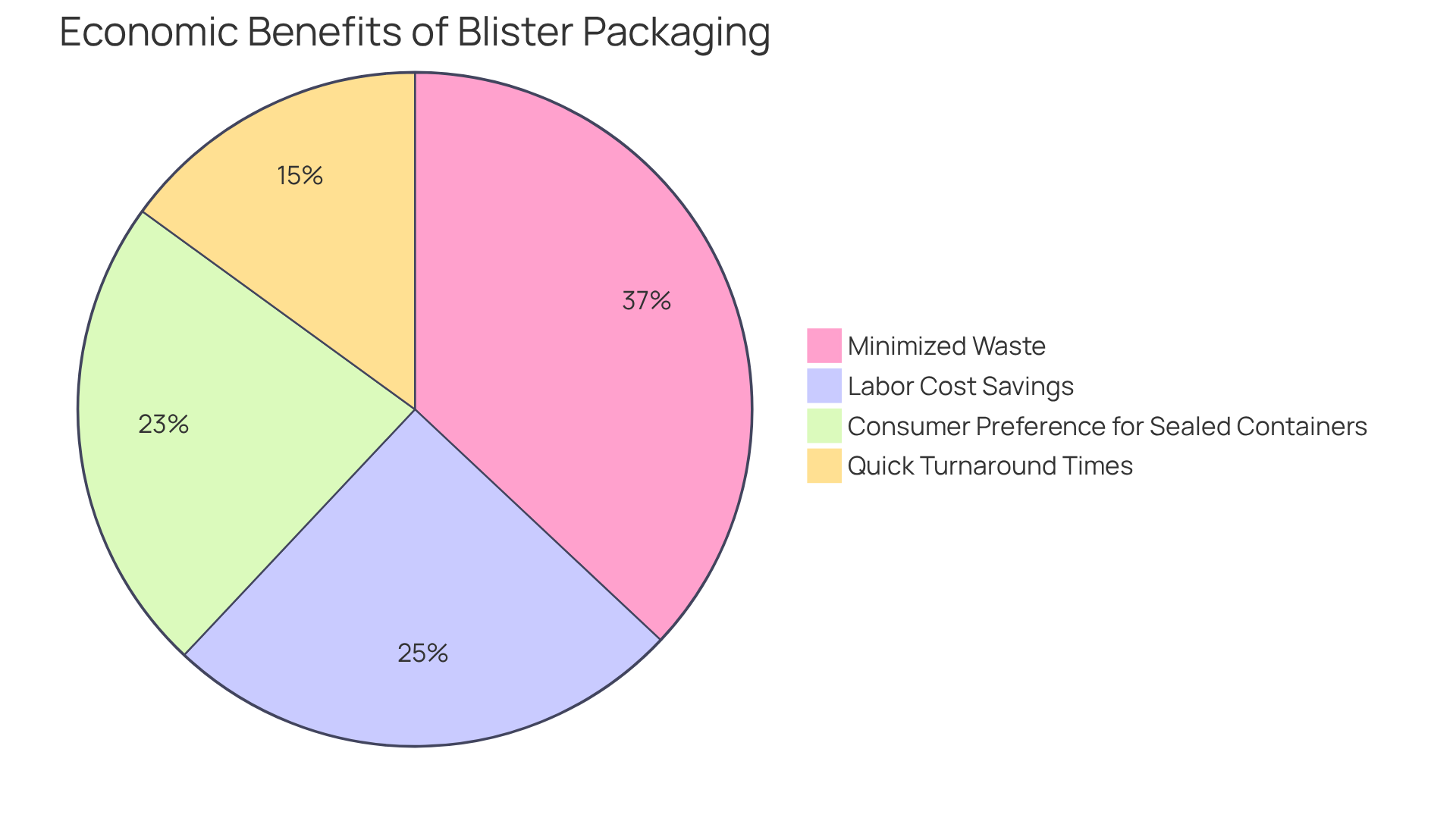

Blister package solutions offer a cost-effective option for nutraceutical manufacturers, significantly minimizing product waste and enhancing operational efficiency. By providing accurate dosing capabilities, this packaging method reduces the likelihood of overproduction and spoilage, resulting in substantial cost savings. Research indicates that optimizing pouch chamber layouts can decrease waste by approximately 37%. Furthermore, the efficient production techniques associated with bubble wrap lead to reduced labor expenses and quicker turnaround times, making it a financially prudent choice for companies aiming to improve their wrapping strategies.

As the bubble wrap market is projected to grow at a CAGR of 7.4% from 2024 to 2030, driven by increasing demand for eco-friendly packing solutions, producers are increasingly recognizing the economic benefits of adopting this innovative wrapping method. A report from the Flexible Packaging Association underscores that 83% of U.S. consumers prefer products with user-friendly features, with sealed containers ranking among the top choices for single-dose and portable items. This consumer preference highlights the within the nutraceutical sector, reinforcing the value of blister package as a strategic investment.

Promote Sustainability with Eco-Friendly Blister Packaging

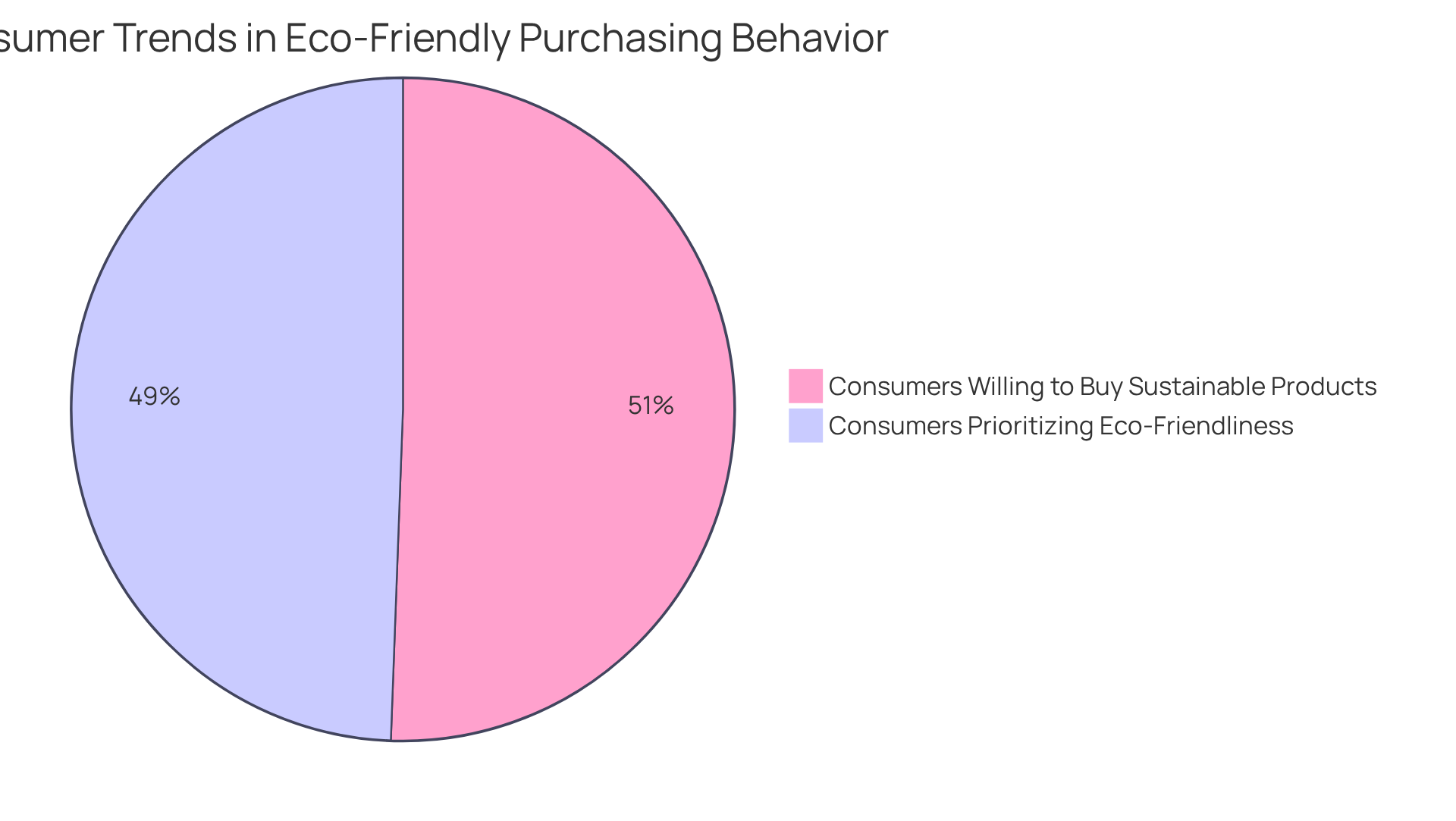

Eco-friendly blister package alternatives are increasingly accessible, enabling nutraceutical manufacturers to enhance sustainability in their product offerings. By utilizing recyclable materials and minimizing plastic waste, brands can effectively engage environmentally conscious consumers. This strategy not only strengthens brand reputation but also aligns with the growing demand for within the nutraceutical market.

Notably, 85% of global shoppers have modified their purchasing behaviors to prioritize eco-friendliness, and 87% are willing to buy more sustainable products if they are readily available. Furthermore, sales of items with sustainability claims have surged by 34% compared to those without, underscoring the market potential for brands committed to responsible solutions.

Manufacturers embracing these eco-friendly initiatives can differentiate themselves in a competitive landscape, fostering customer loyalty and satisfying the expectations of a consumer base that prioritizes sustainability.

Utilize Versatile Blister Packaging for Diverse Nutraceutical Products

Blister packages stand out due to their remarkable adaptability, accommodating a diverse array of nutraceutical products such as tablets, capsules, gummies, and powders. This versatility enables manufacturers to implement a unified packaging solution across various product lines, significantly streamlining inventory management and reducing operational costs.

By leveraging blister containers, businesses can effectively cater to a wide range of consumer preferences and formats, thereby broadening their market presence.

Western Packaging's , which include large pouches for protein products and stick packs for nutraceuticals, enhance the shelf appeal of your offerings and bolster brand recognition.

Our innovative designs not only elevate visual appeal but also ensure a consistent brand identity, distinguishing your nutraceutical products in a competitive landscape.

Enhance Brand Visibility with Blister Packaging

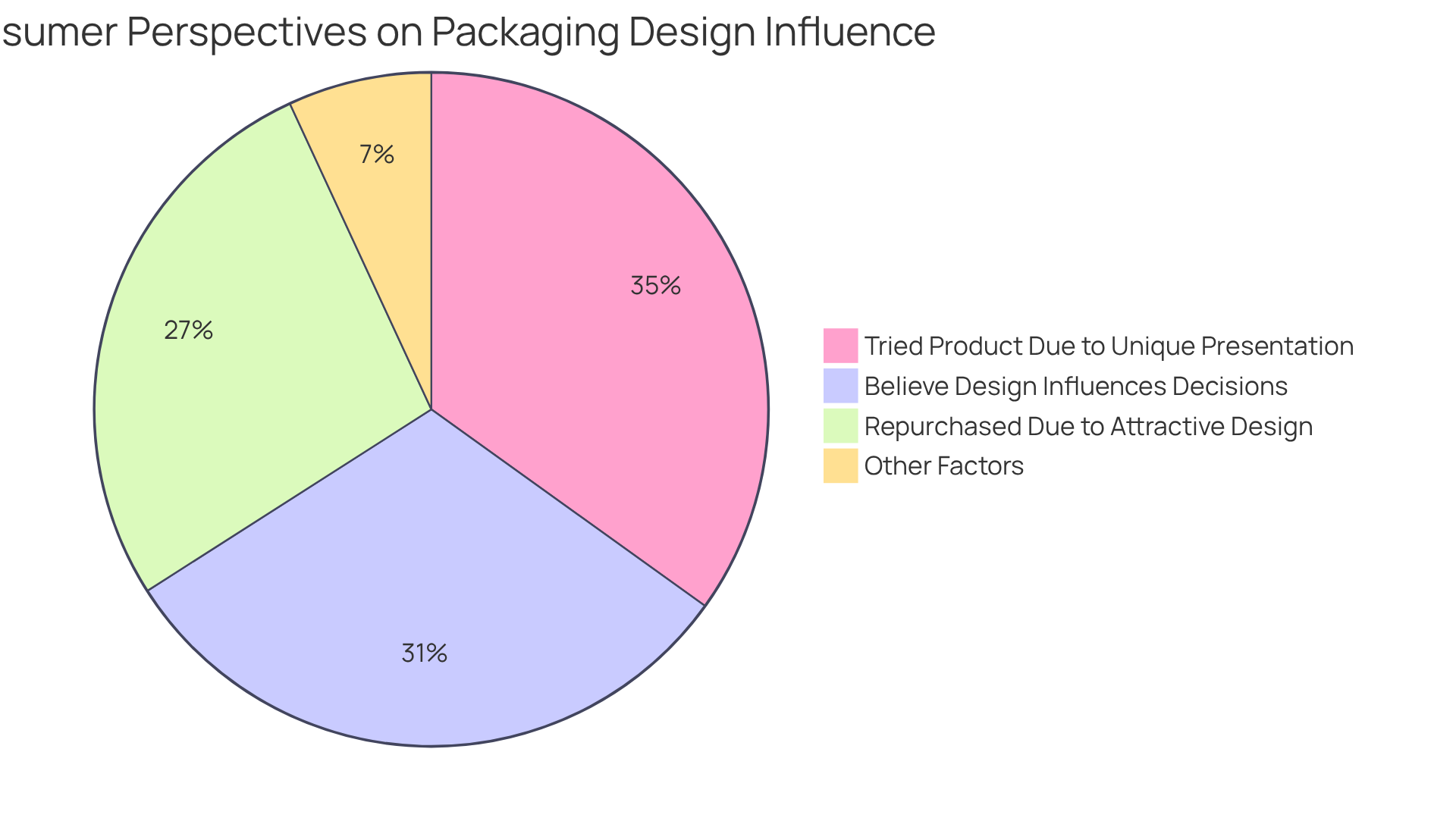

Blister packages represent a robust strategy for enhancing brand visibility within the nutraceutical sector. Customizable designs, vibrant colors, and clear labeling are critical elements that enable products to stand out on retail shelves. Research indicates that:

- 72% of American consumers believe design significantly influences their purchasing decisions.

- 81% have tried a new product solely because its presentation was unique.

This highlights the importance of an appealing display. By investing in visually compelling containers, nutraceutical manufacturers can effectively convey their brand message and capture consumer attention. This strategic approach not only drives sales but also , as consumers become more familiar with and trust the product.

Furthermore, the ability to customize protective packaging allows brands to differentiate themselves in a competitive landscape, reinforcing their identity and values. Notably, 63% of consumers have repurchased a product specifically due to its attractive design, underscoring the profound impact of thoughtful presentation on buying behavior.

Additionally, as consumers increasingly favor eco-friendly options over plastic, incorporating sustainable practices into the design of the blister package can enhance brand appeal and align with consumer preferences.

Leverage the Comprehensive Benefits of Blister Packaging

Blister packages offer a multitude of advantages for nutraceutical manufacturers, significantly enhancing medication adherence, ensuring regulatory compliance, and preserving product integrity. This container format not only offers buyer convenience but also promotes cost-effectiveness and sustainability, establishing itself as a versatile option that boosts brand visibility.

By leveraging these benefits, manufacturers can streamline their container processes, elevate customer satisfaction, and ultimately drive sales. With the from USD 3.4 billion in 2023 to USD 4.2 billion by 2028, the adoption of sealed containers emerges as a strategic initiative for manufacturers aiming to enhance their offerings and strengthen their market presence.

Notably, organizations that have embraced sealable containers have reported improved customer interaction and loyalty, with 83% of dietary supplement users expressing confidence in the dietary supplement industry. This statistic underscores the effectiveness of the blister package in addressing the evolving demands of health-conscious consumers, particularly through its capacity to safeguard products from moisture and contamination, thereby enhancing product integrity and extending shelf life.

Conclusion

Blister packaging emerges as a transformative solution for nutraceutical manufacturers, delivering a host of benefits that enhance product integrity, elevate consumer convenience, and ensure regulatory compliance. By adopting this innovative packaging approach, manufacturers can significantly improve medication adherence among consumers while positioning their products advantageously in a competitive marketplace. The strategic implementation of blister packages not only bolsters brand visibility but also fosters consumer trust, marking them as an essential choice within the nutraceutical sector.

This article underscores several key advantages of blister packaging, such as:

- Its effectiveness in enhancing medication adherence through organized dispensing.

- Its compliance with stringent regulatory standards.

- Its ability to preserve product quality against environmental factors.

- Its promotion of sustainability via eco-friendly materials.

- The cost-effectiveness of blister packaging, as it reduces waste and operational expenses, ultimately benefiting both manufacturers and consumers.

In the rapidly expanding nutraceutical market, embracing the comprehensive benefits of blister packaging is not merely a trend; it is a strategic necessity. Manufacturers are urged to leverage these advantages to enhance their offerings, drive customer satisfaction, and secure long-term brand loyalty. By prioritizing user-friendly, compliant, and sustainable packaging solutions, nutraceutical brands can effectively meet the evolving demands of health-conscious consumers, solidifying their position in a competitive landscape.

Frequently Asked Questions

What services does Western Packaging offer to nutraceutical manufacturers?

Western Packaging provides customized blister packaging solutions, combining innovative design with comprehensive filling services, including kitting and third-party logistics, to ensure regulatory compliance and enhance brand visibility.

What is the projected growth of the global nutraceutical packaging market?

The global nutraceutical packaging market is projected to grow at a CAGR of 4.9% from 2024 to 2033.

How does blister packaging enhance medication adherence?

Blister packaging provides a systematic and organized method for dispensing doses, significantly reducing the likelihood of missed doses. Research shows that patients using medication packs have a 12% higher chance of adhering to their prescribed routines.

What percentage of patients fail to follow their medication instructions?

Nearly 50% of patients fail to follow their medication instructions.

What are the benefits of medication adherence for manufacturers?

Improved medication adherence can lead to better health outcomes for consumers and potential healthcare cost reductions, allowing manufacturers to position their products as effective and user-friendly, fostering buyer trust and satisfaction.

Why is regulatory compliance important for nutraceutical manufacturers?

Regulatory compliance is crucial as it ensures that products are tamper-resistant, safeguarding consumer safety and enhancing brand trust. Compliant packaging can boost consumer trust by 28% compared to non-compliant alternatives.

What role does labeling play in regulatory compliance?

Clear and informative labeling is vital for compliance, allowing manufacturers to effectively communicate essential product information to consumers.

How can manufacturers ensure their packaging meets regulatory standards?

Manufacturers should consider partnering with packaging specialists to implement protective packaging solutions that align with regulatory standards and consumer expectations.